Professional Documents

Culture Documents

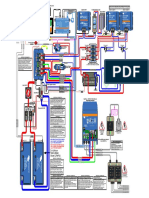

NEOTERIC ELEVATOR - 630KG-MRL-1.0ms-3-3-3-2022020953

NEOTERIC ELEVATOR - 630KG-MRL-1.0ms-3-3-3-2022020953

Uploaded by

yadira correaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NEOTERIC ELEVATOR - 630KG-MRL-1.0ms-3-3-3-2022020953

NEOTERIC ELEVATOR - 630KG-MRL-1.0ms-3-3-3-2022020953

Uploaded by

yadira correaCopyright:

Available Formats

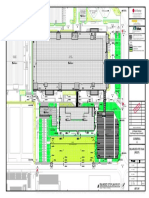

2022020953 BY CLIENT

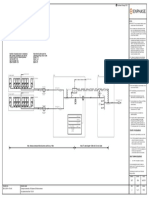

1.Main Power 220V, 3-Phase ,60Hz ,Max

tolerance allowed ±7%. Light Power ±110V.The

clients have the duty to suply the power wiring to

the main power box of elevator company.

2.Close hoistway should be set exhaust

hole(commonly on the top or the buttom of

hoistway),and the area should not less than 1% of

the hoistway area. The exhaust hole should be

set guard.

Hook:20KN(By Client) Elevator Specifications 3.The pitset should be waterprove,and floor

surface in the pit should be flattened.

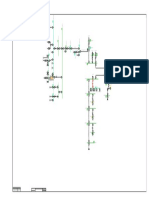

Function passenger lift

120 4.Before installation,all of the floor structure

B-B Loading(kg) 630 opening should be set safety rail which is not less

500

500

550

than 1.2m and ensure enough strength.

Speed(m/s) 1.0 5.When there is accessible way for human in

pitset,the CWT buffer should be installed on solid

100 Traction Ratio 2:1(D320-5-Ø8-12) pillar or ask for installing the CWT safety gear to

manufacturer.

Traction Machine MCK100

6.The machine room shall be constructed in

4.2 firepoof and dustpoof material;the floor of which

Motor(kw) can wishstand an evenly distributed load of 600kg

Overhead Height≥3500

Rated Electric Current(A) 16 per squre meter.(support point for machine bed

not included).

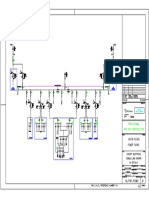

Door Operation center opening 7.If the shaft wall is bricky, there shall be concrete

beams at the postions of guide rail brackets and a

A B Landing Door Size(mm) 900(W) x 2100(H) linted above each landing door cutout. The height

270 805 875

of the beam and lintel shall be no less than

Shaft Size(mm) 1950(W) x 1750(D) 300mm.

8.When the distance between adjacent landing

Cabin Size(mm) 1100(W) x 1400(D) x 2350(H) doors is more than 11m, a safety door shall be

3p-220V±7%V 60 HZ provided in between.(by client).Please confirm it

Shaft Light Inst. (By Client)nx7000

∅320 Main Power Supply with our company.

485 485

110V±7% V 60 HZ

2150

320

Light Power Supply

160

9. The allowable building tolerances of shaft

HD=1750

dimensions in sectional veiws are : 0~+25mm if

245

∅320 ∅320

Total Height=11500 shaft height<30m,0~+35mm if 30m Height

60m,0~+50mm if 60m Height 90m.

660

finished floor Travel Height=6500

Overhead Height=3500 10. This technical ruquirement is an integral part

of the well diagram of the elevator room.

Shaft Anchor n x 1500

Cut Out Fireman Switch 11. Please indicate the layout of ring beam and

HW=1950

Controller 180x80(For Ground Floor)

Door hole Height= 2150

Clear Door Height= 2100

A B 165

the height of each floor when you confirm the

HOISTWAY PLAN Cut Out For Hall Button drawing, and return one copy after you sign the

opinion.

Travel Height=6500

480x100(For All Floors)

1800

A B

1200

270 805 875

finished floor

2150

Clear Door Width= 900 Stress bearing table(KN)

62

Door hole width=1050

62 CWT DBG=800

∅320

Door Hole Drawing(other floors) R1 300 R2 250 R3 200

485 485

finished floor R4 R5 R6

320

CD=1400

160

HD=1750

R7 R8

245

∅320 ∅320

Project Name:

Pit Depth ≥ 1500

200~220

Design

660

CW=1100

100 Elevator Type Layer station number

80

60

3/3/3

30

Check

2F(OH) 3500 Capacity 630kg The stop signal

85

Persons 8 Cabin size(W*D)

Former Outline Drawing No.

OP=900 1F 3500 Speed 1.0m/s Cabin height

500

500

450 ROP=1050 450 Drag the way VVVF Opening size(W*H)

62 CAR DBG=1250

HW=1950

62

PBF 3000 Power Opening type

Current Landing door number

Outline Drawing N0. A B

A-A HOISTWAY PLAN

Sign

levator layout drawing NEOTERIC ELEVATOR

Pit Depth ≥ 1500

Floor Mark Designer Approver

2022020953

Date

Floor Distance/(mm) Auditor Date

You might also like

- Al924a GB 019221900 1123 23062014Document1 pageAl924a GB 019221900 1123 23062014mahaNo ratings yet

- Ship Roll: StabilityDocument6 pagesShip Roll: StabilityDanial KhanNo ratings yet

- Section 8 Designing The Input Supply: Figure 8-1. Rectification SchemesDocument6 pagesSection 8 Designing The Input Supply: Figure 8-1. Rectification Schemescmvb123No ratings yet

- MPPTDocument5 pagesMPPTMahir Asif ShadmanNo ratings yet

- Eht Design Summary SampleDocument1 pageEht Design Summary SampleHolly SmithNo ratings yet

- 3,4 CoreDocument3 pages3,4 CoreNgô Trí DũngNo ratings yet

- Slides 10Document33 pagesSlides 10aaroncete14No ratings yet

- Agcx Deuge Valve 2-2.5-3Document7 pagesAgcx Deuge Valve 2-2.5-3sreeramNo ratings yet

- 7 Surname, Given Name, Middle Name, Course Code & Title, Experiment No. and TitleDocument5 pages7 Surname, Given Name, Middle Name, Course Code & Title, Experiment No. and TitleKenneth SanguyoNo ratings yet

- Lecture 2: Load Allocation Across A Feeder: ECE 5984: Power Distribution System AnalysisDocument18 pagesLecture 2: Load Allocation Across A Feeder: ECE 5984: Power Distribution System Analysisante mitarNo ratings yet

- Note 3 Neo DiagramaDocument10 pagesNote 3 Neo DiagramaMundo PcellNo ratings yet

- Aerator Base: Section B - B Detail of Centre Partition WallDocument1 pageAerator Base: Section B - B Detail of Centre Partition Wallbuddhika SiriwardhanaNo ratings yet

- Cable and Wire Way Sizing CalculationDocument2 pagesCable and Wire Way Sizing Calculationพงศ์ชนก ศรีสถาวรNo ratings yet

- Project Information Company InformationDocument2 pagesProject Information Company InformationHasrudin UsmanNo ratings yet

- 2100-E-20002 2 AprobDocument1 page2100-E-20002 2 AprobEnrique Rodriguez VillalobosNo ratings yet

- Yauli TiclioDocument1 pageYauli TiclioJhon James Rojas CarhuamacaNo ratings yet

- One-Line Diagram - OLV1 (Edit Mode) : Page 1 10:51:55 Jan 25, 2021 Project File: SLDDocument1 pageOne-Line Diagram - OLV1 (Edit Mode) : Page 1 10:51:55 Jan 25, 2021 Project File: SLDTommy NewtonNo ratings yet

- Electrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECODocument2 pagesElectrical Power Generator - Agregati - Electrolux Macedonia - ELITE - IVECOIgor MatijevićNo ratings yet

- Typical Enphase SLD 3ph ResiDocument1 pageTypical Enphase SLD 3ph Resielectromec technologyNo ratings yet

- Union Flacq Power Plant: SEE HV Options SEE HV OptionsDocument1 pageUnion Flacq Power Plant: SEE HV Options SEE HV OptionsjavNo ratings yet

- Cable TrenchDocument1 pageCable Trenchsema.waaheenNo ratings yet

- Abfw 15-1552 - SID - DED - 01-02-OLFDocument1 pageAbfw 15-1552 - SID - DED - 01-02-OLFyonie prasetyoNo ratings yet

- Single Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Document1 pageSingle Line Diagram Gardu Induk Indarung V: 158 5R1 5TB1 5J1 5W1 5W/5U1 5K1 5Z2 5Z1Silver SoulNo ratings yet

- Load Flow Du Reseau Sud A L'horizon 2025Document1 pageLoad Flow Du Reseau Sud A L'horizon 2025kevinkiangebeiNo ratings yet

- 2019-SLD As at Mar 19Document1 page2019-SLD As at Mar 19Chamil EdirimuniNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- M100Document1 pageM100Ahmed YaseenNo ratings yet

- Projeto Eletrico - Ubs - Ronfoldo-Folha A0Document1 pageProjeto Eletrico - Ubs - Ronfoldo-Folha A0Andre LelesNo ratings yet

- LPS Juice Factory - Design.Document2 pagesLPS Juice Factory - Design.Bilal KhalidNo ratings yet

- As-Built General ARC - 11Document1 pageAs-Built General ARC - 11Dong ToanNo ratings yet

- Facility Layout FINAL-Layout1Document1 pageFacility Layout FINAL-Layout1Daniel EvansNo ratings yet

- Philips A17r8mpw-001 Ba17p5f0103 2 PsuDocument5 pagesPhilips A17r8mpw-001 Ba17p5f0103 2 Psujose luis montillaNo ratings yet

- RA626422004P0A1Document1 pageRA626422004P0A1yassir zyadahNo ratings yet

- 3kva 48Vdc Solar Home Inverter Spec 2013 2kw PanelDocument2 pages3kva 48Vdc Solar Home Inverter Spec 2013 2kw PanelnagendrabnpNo ratings yet

- The Interaction Between Any Two Charges Is Completely Unaffected by The Presence of OthersDocument9 pagesThe Interaction Between Any Two Charges Is Completely Unaffected by The Presence of Otherssuma mumuNo ratings yet

- General Notes For: Edgedrain OutletDocument4 pagesGeneral Notes For: Edgedrain OutletIbrahimNo ratings yet

- En Skydeck Wall ChartDocument3 pagesEn Skydeck Wall ChartPaplu PaulNo ratings yet

- FT HSR 2d Hanyoung NuxDocument1 pageFT HSR 2d Hanyoung NuxJP Vásquez HidalgoNo ratings yet

- Multilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersDocument5 pagesMultilevel Six-Phase Machine Drive System Composed of Three-Level and Two-Level InvertersPhelipe LealNo ratings yet

- Terreo LuzDocument1 pageTerreo Luzpp cerejoNo ratings yet

- Us Van Drawing Vebus Bms Multiplus 3kw DMC 400ah LDocument1 pageUs Van Drawing Vebus Bms Multiplus 3kw DMC 400ah LLudovic TualNo ratings yet

- SPA - NTU-CD-GE-ES-101 ELEC Schematic (N.12.09)Document4 pagesSPA - NTU-CD-GE-ES-101 ELEC Schematic (N.12.09)Nam Ho NgocNo ratings yet

- cc2202 13 Pergola1660741306520Document1 pagecc2202 13 Pergola1660741306520Ramees MalikNo ratings yet

- National Plant Matrix-2022-V04Document5 pagesNational Plant Matrix-2022-V04LeonNo ratings yet

- Final Drawing Les (1) - Page 1Document1 pageFinal Drawing Les (1) - Page 1Motlatjo RakgothoNo ratings yet

- Friction Loss Chart - MDPEDocument2 pagesFriction Loss Chart - MDPEManoj NairNo ratings yet

- Motor StartingDocument1 pageMotor StartingMoazam AliNo ratings yet

- NRL Network Study 23 - 12 - 22 ModelDocument1 pageNRL Network Study 23 - 12 - 22 Modelsameed bhaiNo ratings yet

- Layout PLANDocument1 pageLayout PLANMostafa MostafizNo ratings yet

- 3 - CO2169 标准图纸 DT1 2022-6-1Document3 pages3 - CO2169 标准图纸 DT1 2022-6-1kolwin .chindwinNo ratings yet

- C32with EMCP3Document4 pagesC32with EMCP3أبو أنس المسلمNo ratings yet

- 6starmhbasement-001 (Sheet 1 of 6)Document1 page6starmhbasement-001 (Sheet 1 of 6)Jacob FryeNo ratings yet

- Lecture 11 SlidesDocument15 pagesLecture 11 SlidesDanishNo ratings yet

- Manual de Instruccion 5kvaDocument1 pageManual de Instruccion 5kvaJuanca PiaNo ratings yet

- ETE MurosDocument1 pageETE MurosLuanaGuimarãesNo ratings yet

- Plano Lobby (Sistema de Audio) : C. A. P. C. E. EDocument1 pagePlano Lobby (Sistema de Audio) : C. A. P. C. E. EArturoMontNo ratings yet

- Solid State - Sample MaterialDocument41 pagesSolid State - Sample MaterialMukund BachankarNo ratings yet

- Is The Electrostatic Field Conservative?: Q R Q RDocument16 pagesIs The Electrostatic Field Conservative?: Q R Q Rsuma mumuNo ratings yet

- Openfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelDocument15 pagesOpenfoam Simulation of The Flow in The Hoelleforsen Draft Tube ModelAghajaniNo ratings yet

- Conceptual, FEED, Detailed Eng - Phases (An Overview)Document7 pagesConceptual, FEED, Detailed Eng - Phases (An Overview)nazeer_mohdNo ratings yet

- Quiz 01, MTH-501Document9 pagesQuiz 01, MTH-501Shining_900% (1)

- Prof. Philip Kotler SlideDocument30 pagesProf. Philip Kotler SlideKhant Zaw ThantNo ratings yet

- The Role of Goverment in Ecotourism DevelopementDocument10 pagesThe Role of Goverment in Ecotourism DevelopementYunita MariaNo ratings yet

- How To Read A Dji Terra Quality ReportDocument10 pagesHow To Read A Dji Terra Quality ReportRazvan Julian PetrescuNo ratings yet

- Activity Sheets: Quarter 3 - MELC 2Document9 pagesActivity Sheets: Quarter 3 - MELC 2Alexa HullezaNo ratings yet

- Comparative and Superlative AdjectivesDocument5 pagesComparative and Superlative AdjectivesYoussef BrsNo ratings yet

- Calculation of Potential Flow Around An Elliptic Cylinder Using Boundary Element MethodDocument15 pagesCalculation of Potential Flow Around An Elliptic Cylinder Using Boundary Element MethodDoğancan UzunNo ratings yet

- Genetic Mutation LAB SHEET REVISEDDocument2 pagesGenetic Mutation LAB SHEET REVISEDyusufoyololaNo ratings yet

- Canada Oilfield EquipmentDocument8 pagesCanada Oilfield Equipmenteduardo.torresNo ratings yet

- HZ 01Cpr: Material Safety Data SheetDocument6 pagesHZ 01Cpr: Material Safety Data SheetFakhreddine BousninaNo ratings yet

- Android - Activity and Intent FinishedDocument30 pagesAndroid - Activity and Intent FinishedsaraNo ratings yet

- Colah Github Io Posts 2015 08 Understanding LSTMsDocument16 pagesColah Github Io Posts 2015 08 Understanding LSTMsMithun PantNo ratings yet

- Retail Assignment RenzJanuaryDocument3 pagesRetail Assignment RenzJanuaryHoneyPotGameing d (HoneyPotGaming)No ratings yet

- HP LaserJet Managed MFP E72425-E72430 - CPMDDocument526 pagesHP LaserJet Managed MFP E72425-E72430 - CPMDDaniel GarciaNo ratings yet

- Resume - Soumya Prasad SenguptaDocument2 pagesResume - Soumya Prasad Senguptagcgary87No ratings yet

- Light MeterDocument12 pagesLight MeterAmar Nath PrasadNo ratings yet

- Floating Boat Library-Mini Project-1Document37 pagesFloating Boat Library-Mini Project-1parmayadav56789No ratings yet

- Aide Memoire On UtilitiesDocument11 pagesAide Memoire On UtilitiesFaress RabiNo ratings yet

- ARM Instruction SetDocument3 pagesARM Instruction SetnhungdieubatchotNo ratings yet

- Statement of Claim Form PDFDocument3 pagesStatement of Claim Form PDFWalla MahmoudNo ratings yet

- CookiesDocument130 pagesCookiesNinjamuppetNo ratings yet

- Bovaird Loeffler 2016Document13 pagesBovaird Loeffler 2016coolchannel26No ratings yet

- Task Force ProposalDocument8 pagesTask Force ProposalForkLogNo ratings yet

- Caserm/D: Publication Ordering InformationDocument326 pagesCaserm/D: Publication Ordering InformationjohnNo ratings yet

- Revision On Unit 1,2 First Secondry (Hello)Document11 pagesRevision On Unit 1,2 First Secondry (Hello)Vivian GendyNo ratings yet

- Ecm 9Document1 pageEcm 9Misa GamezNo ratings yet

- Shellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFDocument16 pagesShellscriptingbook-Sample - Steves Bourne-Bash Scripting Tutorial PDFAnonymous Wu14iV9dqNo ratings yet

- A Total Productive Maintenance (TPM) Approach To Improve Overall Equipment EfficiencyDocument4 pagesA Total Productive Maintenance (TPM) Approach To Improve Overall Equipment EfficiencyIJMERNo ratings yet

- Case Study 148 169Document22 pagesCase Study 148 169Vonn GuintoNo ratings yet