Professional Documents

Culture Documents

Temporary Structure Erection Work Risk Assessments

Temporary Structure Erection Work Risk Assessments

Uploaded by

hussein aliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Temporary Structure Erection Work Risk Assessments

Temporary Structure Erection Work Risk Assessments

Uploaded by

hussein aliCopyright:

Available Formats

https://www.instagram.com/reel/CgPR45GgymJ/?

igshid=YmMyMTA2M2Y= @

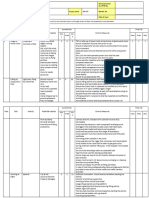

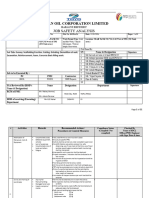

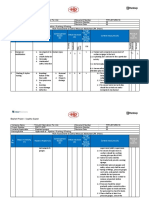

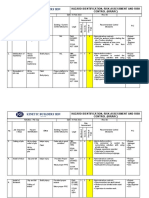

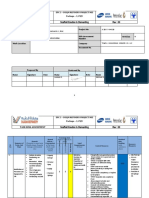

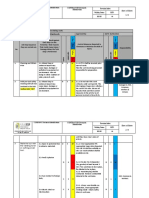

Ref. No.: GPL F HS 02 Date: 10/20/2020

Rev.No.: 00 Page no. 01 of 01 GPL/HIRA/03

Hazard Identification & Risk Assessment Format

Activity: Temporary structure erection work

Risk

Risk Assessment Assessment

Non-Significant (NS)

existing Control additional

Ref. Of WI/ SOP :-

Legal Yes/No

Significant (S) /

Measures Control

Measures

Sr. No. Activity z Risk ( Probable Outcome) Additional Control Measure Opportunities & Action Remark

Probability(P)

Probability(P)

Severity(S)

Severity(S)

Risk Level

Risk Level

(H/M/L) :

(H/M/L) :

Existing Control

1. Individual ID cards will be

checked at entrance gate by

security and daily tool box

1. Trained workers to be deployed after induction training will be conducted

1. Deployment of 1. Personal Injury 2. Conduct induction training for

Mobilization of manpower untrained/inexperienced persons 2. Personal Injury training, screening & medical checkup etc. ID cards

1 Internal will be provided to workers. P2 S2 M S new workers P2 S2 L Nil

2. Lack of awarensess about

construction hazards 2. Informing hazard to associated personnel and

safe work methodology to crew members

1. Obtain work permit before

starting work

2. Provide colour code on all

1. Cut, laceration 1. Use cut resistant handgloves crane & lifting tools & tackles

1. Sharp edge

2. Backpain, sprain, 2. Conduct training on manual & mechanical after inspection

2. Improper material handling injury material handling

3. Vehicle without reverse horn or 3. Ensure valid documents of

helper 3. Hit by vehicle 3. Ensure functioning of reverse horn and vehicle & crane

4. Hit by vehcile, availability of helper

4. Unauthorized/ incompetent

driver major injury, property 4. Check valid driver license of driver

2 Material unloading Internal damage 5. Ensure use of shoulder pads while material P3 S2 M S P2 S2

5. Material shifting without 5. Shoulder pain shifting manually

M Nil

shoulder pads

6. Load failure, hit by 6. Ensure third party inspection of crane & lifting

6. Defective crane/lifting tools crane tools and tackles

&tackles

7. Swinging material while lifting 7. Injury, propert 7. Use two guide ropes to control swinging of

damage material

by crane

8. Improper material stacking 8. Fall of material, 8. All materials to be stacked properly away from

injury the access

1. Unsafe working platform Internal 1. Falling from height, 1. Provide safe platform or scaffold 1. Obtain work permit before

2. Damaged ladder injury 2. Inspect ladder before use. starting work

3. Provide lifeline for anchoring safety harness

3. Absence of anchorage point 2. Falling from height, 4. Ensure use of cotton hand gloves while handling sharp

2. Conduct TBT Nil

while working at height injury materials. 3. Conduct height work training

4. Handling sharp edge 3. Falling from height, 5. Conduct training on manual material handling. 4. Ensure use of PPE's like

5. Improper material handling injury 6. Ensure use of rubber hand gloves while handling with Helmet, safety shoes, reflective

6. Contact with cement 4. Cut, laceration cement jacket

7. Working at height without 5. Backpain, starin 7. Ensure full body harness while working at height

8. Provide body earthing for temporary structure. Nil

safety harness 6. Skin irritation 9. All power cables to be overrouted at appropriate at height.

8. Absence of body earthing for 7. Falling from height, Provide insulation of non conducting material wherever

3 Fixing of MS structure temporary structure injury power cable passing on metal part P2 S2 M S P1 S2 L

9. Poor power cable management 8. Electrocution 10. Use standard male female connector for power cable Yes

10. Unsafe electrical joints 9. Electrocution joints. Multiple joints should not be allowed.

10. Electrocution Nil

Nil

1. Ensure hot work permit

2. Ensure competent welder &

1. Fire, burn, property gas cutting operator

damage 3. Ensure supervision.

1. Defective welding machine 4. Ensure availability of fire

2. Gas cutting set without flash 2. Fire, burn, 1. Pre inspection to be done for welding machine

property damage 2. Provide flash back arrestor for DA & oxygen near torch & extinguisher & fire watcher

back arrestor near gas cylinder 5. Conduct training on hot work

3. Gas cylinders without valve 3. Damage of safety

valve, major injury

3. Provide valve protection cap for DA & oxygenc cylinder safety, electrical safety & power

protection cap 4. Cylinders to be sured by chain tools safety

4. Damage of safety 5. All power cables to be properly over routed

4. Unsecured gas cylinders 6. Ensure PPE's like Helmet,

valve, major injury 6. Remove combustible & flammable materials from hot work

5. Poor power cable management Internal 5. Trip, fall, area. P3 S3 H S safety shoes, welding face shield, P2 S3 M Nil

6. Poor housekeeping 7. Ensure inspection of power tools. Ensure appropriate guard leather apron, leather hand

7. Defective power tools electrocution

6. Fire for rotating part gloves

8. Flying particles from chopsaw 8. Ensure use of safety goggle while operating grinding

machine/grinding machine 7. Cut, laceration, machine or chopsaw machine

major injury 9. Ensure adequate illumination (Min. 50 Lux)

9. Poor illumination 8. Eye injury

4 Fabrication work

9. Trip, fall

1. Ensure male nurse will be

available. 2. Ensure ambulance

will be available. 3. Ensure

1. Ensure ample drinking water to all employees and workers. awareness training will be

2.

Ensure cool drinking water by providing hassan cloth around conducted

Working in hot whether Internal Heat Stroke, heat water tank. 3. P2 S2 M NS P1 S2 L Nil

stress Ensure availability of ORS powder in emergency.

4. Rest room will be provided to

workers.

Cut injury, Skin 1. conduct TBT housekeeping &

Inflammation / Health 1.Segreate scrap separate like plastic, paper, metal waste mangement before work

5 Housekeeping & disposal of Snake bite, contact with sharp Internal N P3 S3 NS 2. provided all required PPE's like P1 S3

scrap/waste part, dust, mix all type of scrap risk, personnal injury, 2. used dust bin for all scrap. 3. follow 5S work H L Nil

property damage, system mask, cut resistance gloves,

enivornmental issue goggle on handling & collecting

of scrap

1. Conduct training for all regarding emergency

6 General (In case of emergency) 1. Confusion Internal 1. Personal Injury plan. Y P2 S2 M S * Conduct Mock drill as per plan P1 S2 L Nil

2. Aware all about assembly point.

RISK Calculation / Evaluatio

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 L L M M

P2 : Remote P2 L M M H

P3 : Possible P3 M M H H

P4 : Probable P4 M H H H

A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

Severity (s)

B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible

C : Risk to be controlled as far as reasonably practicable

S2 : Minor

D : Risk is controlled as far as reasonably practicable .

S3 : Sever

-- : Acceptable risk

S4 : Extreme

LEGAL : If activity come under legal implecation (significant) than additional control measures is to be taken and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

PREPARED BY KEC PROJECT MANAGER PMC SAFETY MANAGER

PMC PROJECT MANAGER GPL SAFETY MANAGER GPL PROJECT MANAGER

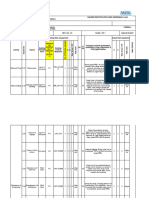

GODREJ PROPERTIES LIMITED

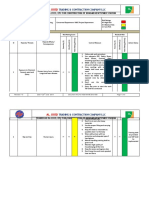

Ref. No.: GPL F HS 02 Date: 10/20/2020

Rev.No.: 00 Page no. 01 of 01 GPL/HIRA/03

Hazard Identification & Risk Assessment Format

Activity: Temporary structure erection work

Risk

Risk Assessment Assessment

Non-Significant (NS)

existing Control additional

Ref. Of WI/ SOP :-

Legal Yes/No

Significant (S) /

Measures Control

Measures

Sr. No. Activity Hazard Issues (Internal/External) Risk ( Probable Outcome) Existing Control Additional Control Measure Opportunities & Action Remark

Probability(P)

Probability(P)

Severity(S)

Severity(S)

Risk Level

Risk Level

(H/M/L) :

(H/M/L) :

1. Individual ID cards will be

checked at entrance gate by

security and daily tool box

1. Trained workers to be deployed after induction training will be conducted

1. Deployment of 1. Personal Injury 2. Conduct induction training for

Mobilization of manpower untrained/inexperienced persons 2. Personal Injury training, screening & medical checkup etc. ID cards

1 Internal will be provided to workers. P2 S2 M S new workers P2 S2 L Nil

2. Lack of awarensess about

construction hazards 2. Informing hazard to associated personnel and

safe work methodology to crew members

1. Obtain work permit before

starting work

2. Provide colour code on all

1. Cut, laceration 1. Use cut resistant handgloves crane & lifting tools & tackles

1. Sharp edge

2. Backpain, sprain, 2. Conduct training on manual & mechanical after inspection

2. Improper material handling injury material handling

3. Vehicle without reverse horn or 3. Ensure valid documents of

helper 3. Hit by vehicle 3. Ensure functioning of reverse horn and vehicle & crane

4. Hit by vehcile, availability of helper

4. Unauthorized/ incompetent

driver major injury, property 4. Check valid driver license of driver

2 Material unloading Internal damage 5. Ensure use of shoulder pads while material P3 S2 M S P2 S2

5. Material shifting without 5. Shoulder pain shifting manually

M Nil

shoulder pads

6. Load failure, hit by 6. Ensure third party inspection of crane & lifting

6. Defective crane/lifting tools crane tools and tackles

&tackles

7. Swinging material while lifting 7. Injury, propert 7. Use two guide ropes to control swinging of

damage material

by crane

8. Improper material stacking 8. Fall of material, 8. All materials to be stacked properly away from

injury the access

1. Unsafe working platform Internal 1. Falling from height, 1. Provide safe platform or scaffold 1. Obtain work permit before

2. Damaged ladder injury 2. Inspect ladder before use. starting work

3. Provide lifeline for anchoring safety harness

3. Absence of anchorage point 2. Falling from height, 4. Ensure use of cotton hand gloves while handling sharp

2. Conduct TBT Nil

while working at height injury materials. 3. Conduct height work training

4. Handling sharp edge 3. Falling from height, 5. Conduct training on manual material handling. 4. Ensure use of PPE's like

5. Improper material handling injury 6. Ensure use of rubber hand gloves while handling with Helmet, safety shoes, reflective

6. Contact with cement 4. Cut, laceration cement jacket

7. Working at height without 5. Backpain, starin 7. Ensure full body harness while working at height

8. Provide body earthing for temporary structure. Nil

safety harness 6. Skin irritation 9. All power cables to be overrouted at appropriate at height.

8. Absence of body earthing for 7. Falling from height, Provide insulation of non conducting material wherever

3 Fixing of MS structure temporary structure injury power cable passing on metal part P2 S2 M S P1 S2 L

9. Poor power cable management 8. Electrocution 10. Use standard male female connector for power cable Yes

10. Unsafe electrical joints 9. Electrocution joints. Multiple joints should not be allowed.

10. Electrocution Nil

Nil

1. Ensure hot work permit

2. Ensure competent welder &

1. Fire, burn, property gas cutting operator

damage 3. Ensure supervision.

1. Defective welding machine 4. Ensure availability of fire

2. Gas cutting set without flash 2. Fire, burn, 1. Pre inspection to be done for welding machine

property damage 2. Provide flash back arrestor for DA & oxygen near torch & extinguisher & fire watcher

back arrestor near gas cylinder 5. Conduct training on hot work

3. Gas cylinders without valve 3. Damage of safety

valve, major injury

3. Provide valve protection cap for DA & oxygenc cylinder safety, electrical safety & power

protection cap 4. Cylinders to be sured by chain tools safety

4. Damage of safety 5. All power cables to be properly over routed

4. Unsecured gas cylinders 6. Ensure PPE's like Helmet,

valve, major injury 6. Remove combustible & flammable materials from hot work

5. Poor power cable management Internal 5. Trip, fall, area. P3 S3 H S safety shoes, welding face shield, P2 S3 M Nil

6. Poor housekeeping 7. Ensure inspection of power tools. Ensure appropriate guard leather apron, leather hand

7. Defective power tools electrocution

6. Fire for rotating part gloves

8. Flying particles from chopsaw 8. Ensure use of safety goggle while operating grinding

machine/grinding machine 7. Cut, laceration, machine or chopsaw machine

major injury 9. Ensure adequate illumination (Min. 50 Lux)

9. Poor illumination 8. Eye injury

4 Fabrication work

9. Trip, fall

1. Ensure male nurse will be

available. 2. Ensure ambulance

will be available. 3. Ensure

1. Ensure ample drinking water to all employees and workers. awareness training will be

2.

Ensure cool drinking water by providing hassan cloth around conducted

Working in hot whether Internal Heat Stroke, heat water tank. 3. P2 S2 M NS P1 S2 L Nil

stress Ensure availability of ORS powder in emergency.

4. Rest room will be provided to

workers.

Cut injury, Skin 1. conduct TBT housekeeping &

Inflammation / Health 1.Segreate scrap separate like plastic, paper, metal waste mangement before work

5 Housekeeping & disposal of Snake bite, contact with sharp Internal N P3 S3 NS 2. provided all required PPE's like P1 S3

scrap/waste part, dust, mix all type of scrap risk, personnal injury, 2. used dust bin for all scrap. 3. follow 5S work H L Nil

property damage, system mask, cut resistance gloves,

enivornmental issue goggle on handling & collecting

of scrap

1. Conduct training for all regarding emergency

6 General (In case of emergency) 1. Confusion Internal 1. Personal Injury plan. Y P2 S2 M S * Conduct Mock drill as per plan P1 S2 L Nil

2. Aware all about assembly point.

RISK Calculation / Evaluatio

Probability (P) P/S S1 S2 S3 S4

P1: Improbable P1 L L M M

P2 : Remote P2 L M M H

P3 : Possible P3 M M H H

P4 : Probable P4 M H H H

A : Hazards must be avoided (or the level of risk reduced significantly and reliable by controls)

Severity (s)

B : Hazards should be avoided (or the level of risk reduced significantly and reliable by controls)

S1 : Negligible

C : Risk to be controlled as far as reasonably practicable

S2 : Minor

D : Risk is controlled as far as reasonably practicable .

S3 : Sever

-- : Acceptable risk

S4 : Extreme

LEGAL : If activity come under legal implecation (significant) than additional control measures is to be taken and has to be reviewed periodically.

S : Significant

NS : Non - Significant.

PREPARED BY KEC PROJECT MANAGER PMC SAFETY MANAGER

PMC PROJECT MANAGER GPL SAFETY MANAGER GPL PROJECT MANAGER

You might also like

- AS2870 Footing SystemsDocument7 pagesAS2870 Footing SystemsEver Piñon-Simonsson83% (6)

- HIRA Revised Drain WorkDocument11 pagesHIRA Revised Drain WorkNagadevan GovindanNo ratings yet

- HIRA - Godrej GCR Project - PHE System-Water Supply WorkDocument11 pagesHIRA - Godrej GCR Project - PHE System-Water Supply WorkRajput AmitNo ratings yet

- Monorail Crane Calculation NoteDocument3 pagesMonorail Crane Calculation Noteeljammal100% (1)

- Line Sizing (SI) Gas PhaseDocument10 pagesLine Sizing (SI) Gas PhaseRian Intan SaputraNo ratings yet

- Fire Shaft - HiraDocument177 pagesFire Shaft - HiraVENKATESAN MNo ratings yet

- Excavation Risk AssessmentsDocument7 pagesExcavation Risk Assessmentshussein aliNo ratings yet

- HIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Document5 pagesHIRA - Installation & Use of PIM For Elevator Assembly in Shaft - Rev 0Shaik MajeedNo ratings yet

- Barricading Work Risk AssessmentsDocument1 pageBarricading Work Risk AssessmentsHSE1 SHAMNETNo ratings yet

- Risk Assessment Fire Hydrant Installation Testing CommissioningDocument11 pagesRisk Assessment Fire Hydrant Installation Testing CommissioningTorre 11 Departamento 1808No ratings yet

- RA - EIA HousekeepingDocument1 pageRA - EIA HousekeepingعمروNo ratings yet

- HIRA Reference Bearing & StopprtDocument51 pagesHIRA Reference Bearing & StopprtPlanning C7100% (1)

- Baseline Risk AssessmentDocument15 pagesBaseline Risk AssessmentPhanankosi Dube100% (1)

- Pile Test (Maintained Load Test - MLT)Document4 pagesPile Test (Maintained Load Test - MLT)Shures Kumar SubramaniyamNo ratings yet

- 2.8c Risk Assessment - 001 Site Survey of Land Rev. July 2019Document7 pages2.8c Risk Assessment - 001 Site Survey of Land Rev. July 2019sadafnoor997No ratings yet

- SL No Activity Personnel Involved Hazard Risk Control Measures Responsible Residual RiskDocument4 pagesSL No Activity Personnel Involved Hazard Risk Control Measures Responsible Residual Riskshaikh abdul100% (1)

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- GroutingDocument1 pageGroutingraphael damanik100% (1)

- Concrete ChippingDocument3 pagesConcrete ChippingAbhijit ParasharNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- 22.# Hiradec Dosing PumpDocument7 pages22.# Hiradec Dosing PumpPankaj PandeyNo ratings yet

- Hira Gaurd HouseDocument14 pagesHira Gaurd HouseNagadevan GovindanNo ratings yet

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- 18 - RA Roadworks Risk AssessmentDocument1 page18 - RA Roadworks Risk Assessmentkumar100% (1)

- Risk Assessment of ShutteringDocument4 pagesRisk Assessment of ShutteringMAB AliNo ratings yet

- Hira - RCC Road ActivityDocument3 pagesHira - RCC Road Activitytariq1987100% (2)

- 2.8c Risk AssessmentDocument40 pages2.8c Risk AssessmentSn AhsanNo ratings yet

- HIRA - StoresDocument3 pagesHIRA - StoresMMRDACA07 SAFETY100% (1)

- OHS-PR-09-03-F07 JOB SAFE PROCEDURE (20) OPGW Cable Installation and SplicingDocument12 pagesOHS-PR-09-03-F07 JOB SAFE PROCEDURE (20) OPGW Cable Installation and Splicingmohammed tofiqNo ratings yet

- Installation of Electrical Earthing System REV 2Document15 pagesInstallation of Electrical Earthing System REV 2amal100% (1)

- JSA Excavation Chipping Work 03Document11 pagesJSA Excavation Chipping Work 03nrphsebarauniNo ratings yet

- RA Flushing &Hydro-TestingDocument8 pagesRA Flushing &Hydro-Testingalla malikNo ratings yet

- HIRADC - Pile CapDocument4 pagesHIRADC - Pile CapKalai ArasanNo ratings yet

- Focus Audit Temp WorksDocument2 pagesFocus Audit Temp WorksArunKumar GanesanNo ratings yet

- Hydro Static Test: Risk AssessmentDocument10 pagesHydro Static Test: Risk Assessmentmohammed a hseNo ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- Heat Stress Management PlanDocument4 pagesHeat Stress Management Planthennarasu100% (1)

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- 4.HIRA Excavation OnlyDocument6 pages4.HIRA Excavation OnlyMD Abdullah100% (1)

- Panels Erection at Station: Ehs Risk AssessmentDocument4 pagesPanels Erection at Station: Ehs Risk AssessmentRohit SinghNo ratings yet

- 005 Civil Works PDFDocument5 pages005 Civil Works PDFghada gattouch100% (1)

- Civil EHS Risk Assessment - 1. ExcavationDocument2 pagesCivil EHS Risk Assessment - 1. Excavationshamshu123No ratings yet

- Ra (en) كهرباء أرضيDocument15 pagesRa (en) كهرباء أرضيMd abdul Irfan100% (1)

- Hira - IbsplDocument7 pagesHira - IbsplAbdul Raheem100% (1)

- Scaffold Erection & Dismantling Rev: 00: Task Risk AssessmentDocument9 pagesScaffold Erection & Dismantling Rev: 00: Task Risk Assessmentibrahim100% (1)

- 011 Duct Lifter SWMSDocument2 pages011 Duct Lifter SWMSJ JohnsonNo ratings yet

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- 2-Geotechnical InvestigationDocument5 pages2-Geotechnical InvestigationAmeerHamzaWarraichNo ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- SWMS - ConcreteDocument10 pagesSWMS - ConcreteMuhammadNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- Brick Laying Risk Assessment (SWMS)Document8 pagesBrick Laying Risk Assessment (SWMS)lenindraNo ratings yet

- OHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEDocument21 pagesOHS-PR-09-03-F02 RISK ASSESSMENT For INSTALLATION OF WALL MOUNTED JIB CRANEmohammed tofiqNo ratings yet

- JSA Building WorksDocument9 pagesJSA Building WorksMon Trang Nguyễn100% (1)

- RA For Stone Work Rev0Document5 pagesRA For Stone Work Rev0yahiya0% (1)

- Risk Assessment For Structural Cabling System Testing and CommissioningDocument5 pagesRisk Assessment For Structural Cabling System Testing and CommissioningInfas YahyaNo ratings yet

- Guidelines of - Sign Board & Site FencingDocument2 pagesGuidelines of - Sign Board & Site FencingGeorge GeorgianNo ratings yet

- Risk Assessment For Production and ErectionDocument14 pagesRisk Assessment For Production and ErectionFurqan FarrukhNo ratings yet

- 3.2 HIRA Register - BlankDocument3 pages3.2 HIRA Register - Blankshobha shelarNo ratings yet

- Tower Crane Height Extension & Support Fixing Risk AssessmentDocument2 pagesTower Crane Height Extension & Support Fixing Risk AssessmentMontadhar HaithamNo ratings yet

- 06 - Method Statement - Rev.2Document2 pages06 - Method Statement - Rev.2hussein aliNo ratings yet

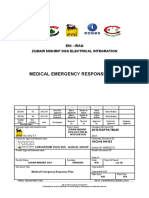

- ZMDEI - ABG - Drill ReportDocument5 pagesZMDEI - ABG - Drill Reporthussein aliNo ratings yet

- Mom-Eni-Cxu-0113 2023-04-26Document3 pagesMom-Eni-Cxu-0113 2023-04-26hussein aliNo ratings yet

- Probems of Legal Translation3.1.2023Document19 pagesProbems of Legal Translation3.1.2023hussein aliNo ratings yet

- Please Do Not Merge Cells, Please Do Not Change Cells' FormatDocument32 pagesPlease Do Not Merge Cells, Please Do Not Change Cells' Formathussein aliNo ratings yet

- Please Do Not Merge Cells, Please Do Not Change Cells' FormatDocument46 pagesPlease Do Not Merge Cells, Please Do Not Change Cells' Formathussein aliNo ratings yet

- Please Do Not Merge Cells, Please Do Not Change Cells' FormatDocument28 pagesPlease Do Not Merge Cells, Please Do Not Change Cells' Formathussein aliNo ratings yet

- Ihab PreDocument25 pagesIhab Prehussein aliNo ratings yet

- Please Do Not Merge Cells, Please Do Not Change Cells' FormatDocument28 pagesPlease Do Not Merge Cells, Please Do Not Change Cells' Formathussein aliNo ratings yet

- Atr TozziDocument64 pagesAtr Tozzihussein aliNo ratings yet

- Effects of Subtitle Speed On Proportional Reading TimeDocument19 pagesEffects of Subtitle Speed On Proportional Reading Timehussein aliNo ratings yet

- Atr Abg CoDocument28 pagesAtr Abg Cohussein aliNo ratings yet

- Please Do Not Merge Cells, Please Do Not Change Cells' FormatDocument28 pagesPlease Do Not Merge Cells, Please Do Not Change Cells' Formathussein aliNo ratings yet

- Health and Safety Solutions Accident Investigation FormDocument2 pagesHealth and Safety Solutions Accident Investigation Formhussein aliNo ratings yet

- Zubair Mishrif SS Medical EmergencyDocument19 pagesZubair Mishrif SS Medical Emergencyhussein aliNo ratings yet

- Shakespeare and Intellectual Castration in The AraDocument9 pagesShakespeare and Intellectual Castration in The Arahussein aliNo ratings yet

- The Aspect of Political Oppression in Ahmad Dawood's Short StoriesDocument11 pagesThe Aspect of Political Oppression in Ahmad Dawood's Short Storieshussein aliNo ratings yet

- The Influence of Defamiliarization On Literary WorDocument2 pagesThe Influence of Defamiliarization On Literary Worhussein aliNo ratings yet

- 02.project HSSE Induction Attendance Sheet - ZM DGS Expansion ProjectDocument2 pages02.project HSSE Induction Attendance Sheet - ZM DGS Expansion Projecthussein aliNo ratings yet

- DeathDocument8 pagesDeathhussein aliNo ratings yet

- 3340 10626 1 PBDocument6 pages3340 10626 1 PBhussein aliNo ratings yet

- Halas Batchelor Animation 2005Document8 pagesHalas Batchelor Animation 2005hussein aliNo ratings yet

- Study of Anthony Pym S Theory On DifferentDocument96 pagesStudy of Anthony Pym S Theory On Differenthussein aliNo ratings yet

- Review International Receptionof Emily DickinsonDocument4 pagesReview International Receptionof Emily Dickinsonhussein aliNo ratings yet

- Zme 0046 Abg Con MTS 0001Document17 pagesZme 0046 Abg Con MTS 0001hussein aliNo ratings yet

- CS 251010DFPCTB435 Exde00 40Document1 pageCS 251010DFPCTB435 Exde00 40hussein aliNo ratings yet

- Labor Camp - Erection & Operation Risk AssessmentsDocument2 pagesLabor Camp - Erection & Operation Risk Assessmentshussein aliNo ratings yet

- Hot Work 2022riskDocument14 pagesHot Work 2022riskhussein aliNo ratings yet

- 251010DFMSTB454 Exde02 13Document13 pages251010DFMSTB454 Exde02 13hussein aliNo ratings yet

- 251010DFMSTB430 Exde01 15Document15 pages251010DFMSTB430 Exde01 15hussein aliNo ratings yet

- ABAP On HANA Course Material Consuming Stored Procedure Module 8BDocument8 pagesABAP On HANA Course Material Consuming Stored Procedure Module 8Btopankajsharma0% (1)

- Robert Half Singapore IT Resume SampleDocument2 pagesRobert Half Singapore IT Resume SampleJR EnriquezNo ratings yet

- Time Line of Quantum ComputationDocument13 pagesTime Line of Quantum ComputationRourav BasakNo ratings yet

- Troubleshooting The RF Ampl...Document2 pagesTroubleshooting The RF Ampl...ebl21100% (1)

- Copper OxideDocument2,227 pagesCopper OxideArshad ShaikhNo ratings yet

- LeafletsDocument2 pagesLeafletsAmir FarajiNo ratings yet

- Manual Book Perkins APP 66Document2 pagesManual Book Perkins APP 66ardyanmustsuccessNo ratings yet

- EagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG ProjectDocument2 pagesEagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG Projectsudhindra_tiwariNo ratings yet

- 23) E-00-0800 - General Test Methods For Cold Impact Behavior On Automotive PlasoDocument5 pages23) E-00-0800 - General Test Methods For Cold Impact Behavior On Automotive PlasoShyam MehtaNo ratings yet

- CVDocument3 pagesCVSyed ShahbazNo ratings yet

- Kobelco Mark IV: Return To ContentsDocument20 pagesKobelco Mark IV: Return To ContentsVictor Hugo Mezquita100% (2)

- 英展电子秤说明书Document32 pages英展电子秤说明书FrankNo ratings yet

- Manual Multimetro MetermanDocument2 pagesManual Multimetro MetermanMarco CortésNo ratings yet

- Lead Mechanical EngineerDocument5 pagesLead Mechanical EngineervcharlesNo ratings yet

- A Full Wave RectifierDocument14 pagesA Full Wave RectifierVarun Jain50% (6)

- Earthquake Load Sharing Between Timber Framed and Masonry WallsDocument9 pagesEarthquake Load Sharing Between Timber Framed and Masonry WallsjeccoNo ratings yet

- EEE G613 Advanced DSP - Lab Experiment 2: CientDocument2 pagesEEE G613 Advanced DSP - Lab Experiment 2: CientAYUSH KUMAR CHOWDHURYNo ratings yet

- 10967A ENU CompanionDocument154 pages10967A ENU Companionyusoffb01No ratings yet

- Alix Partners Industry ReportDocument8 pagesAlix Partners Industry ReportsreecegNo ratings yet

- Question Bank H 1Document3 pagesQuestion Bank H 1Trupti bagalNo ratings yet

- Caja de Cambio Caracteristicas T318 PDFDocument2 pagesCaja de Cambio Caracteristicas T318 PDFLenny Virgo100% (1)

- 42CrMo DatasheetDocument2 pages42CrMo DatasheetAhmad AlshahrourNo ratings yet

- PMAY G - Model 9Document12 pagesPMAY G - Model 9DanielNo ratings yet

- 406MHz Sarsat Beacon Tester BrochureDocument2 pages406MHz Sarsat Beacon Tester Brochuretangocanh80No ratings yet

- Goulds Pumps: Aquaboost™ IiDocument4 pagesGoulds Pumps: Aquaboost™ IiAnonymous 7xHNgoKE6eNo ratings yet

- Pitman BP40 Spec Sheet-R5Document5 pagesPitman BP40 Spec Sheet-R5helpdesk0No ratings yet

- Mathematical Theory of Viscous FluidsDocument23 pagesMathematical Theory of Viscous Fluidscth_yaoNo ratings yet