Professional Documents

Culture Documents

Unalloyed Steels e 0219

Unalloyed Steels e 0219

Uploaded by

iuliaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unalloyed Steels e 0219

Unalloyed Steels e 0219

Uploaded by

iuliaCopyright:

Available Formats

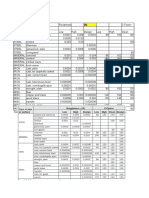

Unalloyed steels

DIN Short EN GB USA F J Chemical analysis in weight per cent Upper and lower range

Stooss material specification specification

specification no. according Type UNS C Si Mn P S Cr Ni Mo V Al Nb Other

to DIN

Unalloyed hardened steels

1.1121 Ck 10 C10E 040 A 10 SAE 1010 C10E S 10 min. 0.07 0.15 0.40

CK 10 max. 0.10 0.40 0.60 0.025 0.015 0.10 0.50

DIN 17210

1.1141 Ck 15 C15E SAE 1015 C15E S 15 min. 0.12 0.15 0.40 0.020

CK 15 max. 0.17 0.35 0.60 0.035 0.035

DIN 17210 / EN 10084

1.0038 Rst37-2 S235JRG2 EN 40B A252(1) S235JRG2 S 10 min. 0.12

ST 37-2 max. 0.17 0.50 1.60 0.050 0.050 0.30 0.30 0.080 Cu max. 0.40 N max. 0.0070

DIN 17100 / EN 10025

Unalloyed steels for hardening and tempering

1.1151 Ck 22 C22E 070M20 SAE 1023 XC25 S 22 C min. 0.18 0.15 0.40 0.020

Ck 22 max. 0.23 0.30 0.60 0.035 0.030 0.30 0.050

DIN 17201 / EN 10083-1 / General machine construction / DIN 17243 - C22.8

1.1181 Ck 35 C35E 080M38 SAE 1035 XC25 S 35 C min. 0.33 0.15 0.50

CK 35 max. 0.39 0.35 0.80 0.025 0.030 0.40 0.40 0.100

DIN 17204 / EN 10083-1 / General machine construction

1.1191 Ck 45 C45E 080M46 SAE 1045 XC45 S 45 C min. 0.44 0.15 0.50 0.010

CK 45 M1 max. 0.49 0.35 0.80 0.020 0.025

DIN 17200 / EN 10083-1 / General machine construction

1.1221 Ck 60 C60E 070M60 SAE 1064 XC65 S 60 MC min. 0.57 0.15 0.60

CK 60 max. 0.65 0.35 0.90 0.035 0.030

DIN 17201 / EN 10083-1 / General machine construction

1.1231 Ck 67 2C567 060A67 SAE 1070 XC68 S 70 CM min. 0.65 0.15 0.60

CK 67 max. 0.72 0.35 0.90 0.035 0.035

DIN 17222 / Spring steel, parts for rail vehicles

1.0570 St 52-3 S355J2G3 EN50D SAE 1025 S355J2G3 SM 50 A min. 0.17 0.30 1.40 0.020 0.03

ST 52-3 max. 0.20 0.55 1.60 0.025 0.015 0.30 1.00 0.080 0.20 0.05 Ti max. 0.020 N max. 0.0200

M1/M2 DIN 17100 / EN 10025 / General machine construction

1.1165 30 Mn 5 A5 SAE 1330 SCMn 2 min. 0.27 0.15 1.20

30 Mn 5 max. 0.34 0.40 1.50 0.035 0.035 0.30

DIN 17205 / General machine construction SEW 550 - 28Mn6

1.8917 TStE 500 ASTM A225 K11523 min. 0.10 0.10 1.40 0.02 0.50 0.020

TStE 500 max. 0.18 0.50 1.70 0.015 0.005 0.30 0.80 0.100 0.012 0.050 0.05 Cu max. 0.20 N max. 0.0150 H 2 max. 0.0002

DIN 17103 / General machine construction / High-tensile tempering steel / suitable for welding

(1.0432) C21 ASTM A105 min. 0.18 0.15 0.90

A 105 max. 0.22 0.30 1.05 0.025 0.010 0.30 0.40 0.120 0.01 0.02 Ti max. 0.05 Cu max. 0.20

ASTM A105 / For usage in offshore industries / flanges, ball valves

Modified analysis ASTM A350 LF2 min. 0.17 0.15 1.00 0.020

LF2 max. 0.20 0.30 1.30 0.015 0.015 0.30 0.40 0.120 0.03 0.02 Cu max. 0.40

ASTM A350 / For usage in offshore industries / flanges, ball valves

Modified analysis ASTM A350LF2 min. 0.20 0.15 1.10 0.020

LF2 M1 max. 0.24 0.30 1.35 0.015 0.015 0.20 0.25 0.060 0.03 0.050 0.02 Cu max. 0.20 N max. 0.0200

ASTM A350 / For usage in offshore industries / flanges, ball valves

1.0566 TStE 355 min. 0.13 0.15 0.90 0.15 0.15 0.020 Cu max. 0.165 As max. 0.080

LF2 M10 max. 0.17 0.30 1.35 0.025 0.005 0.25 0.25 0.10 0.01 0.040 0.02 N max. 0.0150

ASTM A350 / DIN 17103 / For usage in offshore industries / flanges, ball valves

API 5L min. 0.09 0.15 1.25 0.15 0.05 0.020 0.03 Cu max. 0.20 N 0.007– 0.012

X 65 max. 0.12 0.35 1.40 0.015 0.003 0.15 0.12 0.20 0.07 0.040 0.05 Ti max. 0.020 Sn max. 0.035

API 5 LX / Flanges / good weldability / A 694 F 65

The chemical analysis conform to STOOSS purchasing specifications. The comparative national designations may differ Details on material application are for description purposes only. They are provided to the best of our knowledge,

from the STOOSS analysis and are purely for information purposes. but without any guarantee. Special agreements in writing are always required.

You might also like

- Micro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full ChapterDocument67 pagesMicro Econ 6 Principles of Microeconomics 6Th Edition William A Mceachern Full Chapterchristine.parsons231100% (6)

- Astm A240 A240m 23Document7 pagesAstm A240 A240m 23Venkatesh KumarNo ratings yet

- Din 17102 PDFDocument10 pagesDin 17102 PDFEvriMert RüzgArdaNo ratings yet

- Applied Biopharmaceutics & Pharmacokinetics, 5th EditionDocument1 pageApplied Biopharmaceutics & Pharmacokinetics, 5th Editionbencleese14% (7)

- Mill'S Test Certificate ACC. TO EN 10204 / 3.1Document2 pagesMill'S Test Certificate ACC. TO EN 10204 / 3.1Durulsan MakinaNo ratings yet

- Annex A: (Normative)Document6 pagesAnnex A: (Normative)calvente27No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- EMEA Catafor Formulation BROCHURE - 2015 Copie 270934Document4 pagesEMEA Catafor Formulation BROCHURE - 2015 Copie 270934Duc NguyenNo ratings yet

- Business Research DissertationDocument102 pagesBusiness Research DissertationDedalu SelaluNo ratings yet

- Method Statement For Demolation and Installation of Chain Link Fencing & Boundery Wall For Site Temporary Facilites ClientDocument8 pagesMethod Statement For Demolation and Installation of Chain Link Fencing & Boundery Wall For Site Temporary Facilites ClienteshwarNo ratings yet

- Atlas Housing V Dream PropertyDocument103 pagesAtlas Housing V Dream PropertyElizabeth LauNo ratings yet

- Sae 5115Document1 pageSae 5115Tatumi SobueNo ratings yet

- Low Alloy Steels Part2 PDFDocument1 pageLow Alloy Steels Part2 PDFnedunchiNo ratings yet

- Low Alloy Steels Part2Document1 pageLow Alloy Steels Part2fedaquiNo ratings yet

- Tpmcsteel: Welded Pipe For Pressure PurposeDocument2 pagesTpmcsteel: Welded Pipe For Pressure Purpose兆緯No ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4kazdanoNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Product Code:: Pkg/Ro/41 Special SteelsDocument9 pagesProduct Code:: Pkg/Ro/41 Special SteelsPranav TripathiNo ratings yet

- Mild Steels Voestalpine EN 09082019Document5 pagesMild Steels Voestalpine EN 09082019Alma Aliza VillaberNo ratings yet

- Chemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRDocument2 pagesChemical Composition: Si Fe Cu MN MG Ni ZN SN Ti PB CRQuality teamNo ratings yet

- Material Tech SpecsDocument8 pagesMaterial Tech SpecsSachin JawaleNo ratings yet

- Casting Material Alloy Steel G20Mn5 EN 1.6220Document3 pagesCasting Material Alloy Steel G20Mn5 EN 1.6220nethaji nethajiNo ratings yet

- Heat Exchanger Tubes From T LDocument2 pagesHeat Exchanger Tubes From T LFaizan KhanNo ratings yet

- Ferritic and Martensitic Casting MaterialsDocument2 pagesFerritic and Martensitic Casting MaterialsSinan YıldızNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- MetalfaesDocument2 pagesMetalfaesviyfNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data Sheetispat_jagadeeshNo ratings yet

- Sepction - 2Document4 pagesSepction - 2k koradiaNo ratings yet

- SMD2920 Surface Mount PTC Devices: Electrical CharacteristicsDocument8 pagesSMD2920 Surface Mount PTC Devices: Electrical CharacteristicsMisho MishoNo ratings yet

- TG S50 PDFDocument1 pageTG S50 PDFIvan RocoNo ratings yet

- Alambron CHQDocument4 pagesAlambron CHQJavier GranadosNo ratings yet

- Aceros-SCHNORR-DIN EN 10232-4 PDFDocument1 pageAceros-SCHNORR-DIN EN 10232-4 PDFDebani OchoaNo ratings yet

- Engineering DetailDocument30 pagesEngineering DetailSatyaprakash PrakashNo ratings yet

- High Strength Steel Tubes For Structural and Engineering ApplicationsDocument12 pagesHigh Strength Steel Tubes For Structural and Engineering ApplicationsA LettristeNo ratings yet

- Venvu 116Document1 pageVenvu 116ronaldb322No ratings yet

- Buderus Edelstahl Presentation PDFDocument15 pagesBuderus Edelstahl Presentation PDFMustafa Mert SAMLINo ratings yet

- Durehete 1055Document5 pagesDurehete 1055alextentwenty100% (1)

- Certificado Bothwell Ca1469Document1 pageCertificado Bothwell Ca1469erssonNo ratings yet

- Tubes Sicam PDFDocument28 pagesTubes Sicam PDFDobrica PetrovicNo ratings yet

- #Kobelco Welding Hand BookDocument1 page#Kobelco Welding Hand BookIradahNo ratings yet

- Sgps Id01 CalcDocument48 pagesSgps Id01 Calcsaroat moongwattanaNo ratings yet

- Casting AlloysDocument2 pagesCasting Alloysgalvaosilva100% (1)

- Fdocuments - in - Jindal Steel Product Catalogue - MergeDocument62 pagesFdocuments - in - Jindal Steel Product Catalogue - MergephanikrishnabNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Valve MOC and ImportantDocument22 pagesValve MOC and ImportantUdhayakumar VenkataramanNo ratings yet

- Equalent Material GradesDocument16 pagesEqualent Material GradesLesle GpNo ratings yet

- Design: Technical DetailsDocument4 pagesDesign: Technical DetailsDanialNo ratings yet

- WS412Document7 pagesWS412Martin OusephNo ratings yet

- Steel SpecificationsDocument3 pagesSteel SpecificationsMazlan MansorNo ratings yet

- WS410Document7 pagesWS410Martin OusephNo ratings yet

- Micro Alloyed Steels Voestalpine EN 30102020Document4 pagesMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociNo ratings yet

- Micro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpaDocument4 pagesMicro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpacurtisvaleroNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- 38 MN VS6Document3 pages38 MN VS6Jaison JacobNo ratings yet

- HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Document4 pagesHPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127 HPL/TC/T/2010/14127Er Umesh RohitNo ratings yet

- Spring MaterialsDocument3 pagesSpring MaterialsS. VeeravelNo ratings yet

- DC 01Document1 pageDC 01sobheysaidNo ratings yet

- 1.0SMB SeriesDocument6 pages1.0SMB SeriesPablo AllosiaNo ratings yet

- Chemical Elements - DNVGL-B101 Vs EN 10025-4Document5 pagesChemical Elements - DNVGL-B101 Vs EN 10025-4Sudeep DsouzaNo ratings yet

- PayslipDocument2 pagesPaysliprajdeep singhNo ratings yet

- Analysis of GATE 2010Document25 pagesAnalysis of GATE 2010aloo_12345No ratings yet

- ProjectDocument61 pagesProjectgoodvijay143No ratings yet

- Door Building in Details: InstallationDocument53 pagesDoor Building in Details: InstallationkockioNo ratings yet

- 8-Human Rights and Magna CartaDocument47 pages8-Human Rights and Magna CartaRichard Cagadas MabolocNo ratings yet

- Hari Devops 3YDocument5 pagesHari Devops 3YHari KrishnaNo ratings yet

- Compliance Check For Section 206AB & 206CCA - FAQsDocument7 pagesCompliance Check For Section 206AB & 206CCA - FAQsSushil KumarNo ratings yet

- Brian CA March 12Document13 pagesBrian CA March 12scott.maisonNo ratings yet

- Ilan Group Operation Enterprise: Imran AminuddinDocument1 pageIlan Group Operation Enterprise: Imran AminuddinIzhar AminuddinNo ratings yet

- RCC Teen - Task 5 - BandwidthDocument2 pagesRCC Teen - Task 5 - BandwidthRares AndreiNo ratings yet

- Alcatel-Lucent Omniswitch 6360: Stackable Gigabit Ethernet Lan Switch FamilyDocument9 pagesAlcatel-Lucent Omniswitch 6360: Stackable Gigabit Ethernet Lan Switch FamilyredNo ratings yet

- SL-53625 Rev02 07-08Document111 pagesSL-53625 Rev02 07-08Abdul Aziz ShawnNo ratings yet

- Gripping, Prying and TwistingDocument8 pagesGripping, Prying and TwistingLeslie Joy Anastacio VizcarraNo ratings yet

- Auction News Journal 3.1.14Document15 pagesAuction News Journal 3.1.14Etrans 1No ratings yet

- Pantallas HITACHI DP 6X Training PackageDocument92 pagesPantallas HITACHI DP 6X Training PackagericardoNo ratings yet

- Food and Cash Crops Social ScienceDocument19 pagesFood and Cash Crops Social ScienceSUKIRTHI K 19RBAR064No ratings yet

- Taxation: Bmbes 2020 Barangay Micro Business Enterprise BMBE Law's ObjectiveDocument3 pagesTaxation: Bmbes 2020 Barangay Micro Business Enterprise BMBE Law's Objectivekris mNo ratings yet

- Impact of Compensation and Reward SystemDocument88 pagesImpact of Compensation and Reward SystemDhanshri KavatkarNo ratings yet

- Scientific Programme 83Document8 pagesScientific Programme 83lakshminivas PingaliNo ratings yet

- Calina - Patterson - Resistance To Change Discussion Handout #1Document2 pagesCalina - Patterson - Resistance To Change Discussion Handout #1Calina PattersonNo ratings yet

- Family Service and Progress Record: Daughter SeptemberDocument29 pagesFamily Service and Progress Record: Daughter SeptemberKathleen Kae Carmona TanNo ratings yet

- Q4 Module 8.2Document14 pagesQ4 Module 8.2Derick0% (1)

- VBC East South Hall Renovations Contract FINAL 2024Document46 pagesVBC East South Hall Renovations Contract FINAL 2024Kayode CrownNo ratings yet

- Data Bulletin Variable Frequency Drives and Short-Circuit Current RatingsDocument12 pagesData Bulletin Variable Frequency Drives and Short-Circuit Current Ratingsrenzo_aspa_orgNo ratings yet