Professional Documents

Culture Documents

Me 208 CH-3

Me 208 CH-3

Uploaded by

MohaerCopyright:

Available Formats

You might also like

- 780 CMR Ninth Edition, Base Code Amendments - 0Document211 pages780 CMR Ninth Edition, Base Code Amendments - 0anandNo ratings yet

- Steel Connection With Block DetailsDocument6 pagesSteel Connection With Block DetailsAlaaBadwyNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim Chartkhaireddin100% (1)

- Series Fastparts A4 LoDocument115 pagesSeries Fastparts A4 Loeasyvision1No ratings yet

- CP 206 SCM Rough PDFDocument37 pagesCP 206 SCM Rough PDFKumardeep SinghaNo ratings yet

- 01.01. 100mm Dia. Water Meter Assembly. (Strainer)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Strainer)Amadou MokshaNo ratings yet

- Saw Blades and Bevel Cutters For GF and RA MachinesDocument5 pagesSaw Blades and Bevel Cutters For GF and RA MachinesVan DantNo ratings yet

- Mech PropertiesDocument1 pageMech PropertiesLLNo ratings yet

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankNo ratings yet

- Steel Grades According To Japanese Standards: Mechanical PropertiesDocument2 pagesSteel Grades According To Japanese Standards: Mechanical PropertiesGANESHNo ratings yet

- Aisi 4330Document1 pageAisi 4330ahmedNo ratings yet

- Uas PLBTDocument14 pagesUas PLBTTubagus RizkyNo ratings yet

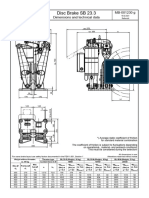

- Dellner Bubenzer SB 23.3Document2 pagesDellner Bubenzer SB 23.3AKA jeanNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- Consteel Catalogue PURLINS CPurlinDocument3 pagesConsteel Catalogue PURLINS CPurlinAnsaf AskyNo ratings yet

- 529A Deadman Anchor Type 1 PDFDocument1 page529A Deadman Anchor Type 1 PDFAnonymous sfkedkymNo ratings yet

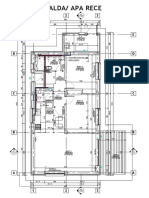

- Cheia - Ar AcmDocument1 pageCheia - Ar AcmEne CostinNo ratings yet

- Drawing Distribution: General ToleranceDocument1 pageDrawing Distribution: General ToleranceJovelyn MillaresNo ratings yet

- BS 970 En8dDocument1 pageBS 970 En8djobseekerarulkumarNo ratings yet

- DK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkDocument1 pageDK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkRajkumar SagarNo ratings yet

- Propiedades Aceros y FundicionDocument3 pagesPropiedades Aceros y FundicionintiNo ratings yet

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- BBS FormatDocument2 pagesBBS Formatjogdeep GogoiNo ratings yet

- Standard Dokumentation + SD SB28.3 En1 - 1 - 00Document126 pagesStandard Dokumentation + SD SB28.3 En1 - 1 - 00Andres GarcíaNo ratings yet

- AISI 4140 Alloy SteelDocument4 pagesAISI 4140 Alloy Steelzd55h2754kNo ratings yet

- Generador EmergenciaDocument20 pagesGenerador Emergenciajose antonio alonso lagoNo ratings yet

- Denah Rangka AtapDocument1 pageDenah Rangka AtapNanda Armadiansyah AkbarNo ratings yet

- Filler Metal SelecionDocument1 pageFiller Metal SelecionMurugananthamParamasivam100% (1)

- Astm A743 Cf8mDocument1 pageAstm A743 Cf8makdrnlNo ratings yet

- Asme Sa-29 1018Document1 pageAsme Sa-29 1018Nelson RangelNo ratings yet

- Amcrps Az26-700nDocument2 pagesAmcrps Az26-700nLázaro MagalhãesNo ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Summary of Sub Grade Test Result.... 2Document8 pagesSummary of Sub Grade Test Result.... 2AshebirNo ratings yet

- Jis C 3602 BDDocument1 pageJis C 3602 BDvedveersinghNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

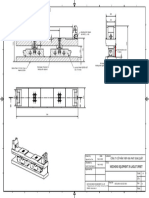

- Bill of Material: Yorke Structures LTDDocument1 pageBill of Material: Yorke Structures LTDDanrage BoodramNo ratings yet

- Rotary Twin Screw Compressor Packages: Specifications & DimensionsDocument4 pagesRotary Twin Screw Compressor Packages: Specifications & DimensionsNazeeh Abdulrhman AlbokaryNo ratings yet

- DIN G S 17 CrMo 5-5Document1 pageDIN G S 17 CrMo 5-5kaushal sagarNo ratings yet

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocument1 pageMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05No ratings yet

- AISI 4130 Alloy Steel (UNS G41300) 1Document4 pagesAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

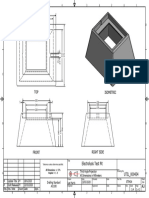

- Electrolysis Test PitDocument1 pageElectrolysis Test PitwashieNo ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Steel Sun and Planet GearDocument1 pageSteel Sun and Planet GearAmarnathNo ratings yet

- OM - DD - F - 07 Master List of DrawingsDocument10 pagesOM - DD - F - 07 Master List of DrawingssharanNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- SPCM 195Document1 pageSPCM 195Shyam J VyasNo ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Cớ Cấu Lắp Ráp Hoàn Chỉnh-1Document1 pageCớ Cấu Lắp Ráp Hoàn Chỉnh-1chuongNo ratings yet

- WSG-MF: Gearless Synchronous Lift MachineDocument2 pagesWSG-MF: Gearless Synchronous Lift MachineCristianNo ratings yet

- Legend of Building Services: Sewage Pipe Cold Water S.P C.WDocument1 pageLegend of Building Services: Sewage Pipe Cold Water S.P C.WAlin NegarăNo ratings yet

- K Standard Pinion GearDocument1 pageK Standard Pinion GearHarshal TikekarNo ratings yet

- MB 50 Englisch 3Document3 pagesMB 50 Englisch 3Jøn Bilbao MallonaNo ratings yet

- S02 - MM-#42 Columns Details - R02Document1 pageS02 - MM-#42 Columns Details - R02Mohd SiddiqNo ratings yet

- AS90Document1 pageAS90kamalNo ratings yet

- AS90Document1 pageAS90kamalNo ratings yet

- ISO ExampleDocument1 pageISO Examplethe.avishekkNo ratings yet

- NAS9349Document2 pagesNAS9349Bogdan RusuNo ratings yet

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- Republic of The Philippines: Engr. Jonathan C. BulagaoDocument5 pagesRepublic of The Philippines: Engr. Jonathan C. BulagaoMichael James ll BanawisNo ratings yet

- 2 StructuralDocument19 pages2 Structurallayaljamal2No ratings yet

- Week 5: 1. Indigenous Architecture - Malay House 2. Islamic Architecture - MasjidDocument35 pagesWeek 5: 1. Indigenous Architecture - Malay House 2. Islamic Architecture - MasjidSyairah NajihahNo ratings yet

- Concept of Plant Layout:: Bird View of A Typical PlanDocument7 pagesConcept of Plant Layout:: Bird View of A Typical PlanSunil KumarNo ratings yet

- Guide To Concrete Overlays 4th Ed WebDocument156 pagesGuide To Concrete Overlays 4th Ed WebmchilwesaNo ratings yet

- ASTM 재질분류표Document106 pagesASTM 재질분류표오덕환Oh Duckhwan100% (1)

- TDS - Glenium 110 UNDocument3 pagesTDS - Glenium 110 UNAlexi ALfred H. TagoNo ratings yet

- APA Simplified Wall Bracing MethodDocument6 pagesAPA Simplified Wall Bracing MethodklmntNo ratings yet

- Design and Development of Jig and Fixture For Tacho BracketDocument5 pagesDesign and Development of Jig and Fixture For Tacho BracketAckshayaNo ratings yet

- Method Statement For Water Proofing For Railway 24-06-2020Document5 pagesMethod Statement For Water Proofing For Railway 24-06-2020Bhavanishankar shettyNo ratings yet

- Masteremaco S 422 TdsDocument3 pagesMasteremaco S 422 TdsSanthosh KarunanithiNo ratings yet

- Mohammed Shamsuddin: Specifications and Safety As Per Standard. Construction. in ConstructionsDocument2 pagesMohammed Shamsuddin: Specifications and Safety As Per Standard. Construction. in ConstructionsAnjaan MusaafirNo ratings yet

- Elevation: Concrete Parapet With Sidewalk MountedDocument1 pageElevation: Concrete Parapet With Sidewalk Mountedjaelani sidikNo ratings yet

- New Hampshire Department of Transportation: Substructure DetailsDocument5 pagesNew Hampshire Department of Transportation: Substructure Detailsجميل عبد الله الحماطيNo ratings yet

- Lec 16-TorsionDocument10 pagesLec 16-Torsionjessa marie sayconNo ratings yet

- Strength Development of Binary Cement Concrete UsiDocument18 pagesStrength Development of Binary Cement Concrete UsiAvinash LalNo ratings yet

- 01-Seri Es 1000 General PDFDocument84 pages01-Seri Es 1000 General PDFEskindir TeshomeNo ratings yet

- Catálogo GALVAMETDocument16 pagesCatálogo GALVAMETMichael Gutiérrez EscobarNo ratings yet

- Effect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DDocument10 pagesEffect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DSubhash NaiduNo ratings yet

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsChaitanya MehtaNo ratings yet

- Cpha Members List: Botswana BORDER Continued BORDER ContinuedDocument61 pagesCpha Members List: Botswana BORDER Continued BORDER ContinuedAubel100% (1)

- 2022-03-18 BQ For Guest Bedroom Ukay Heights Bungalow .XLSMDocument15 pages2022-03-18 BQ For Guest Bedroom Ukay Heights Bungalow .XLSMawanisNo ratings yet

- BinderDocument253 pagesBinderJohnny Mopada Jr.No ratings yet

- Cup Lock Rate AnalysisDocument4 pagesCup Lock Rate AnalysisPratik Diyora100% (2)

- Calculations For Billing IpcDocument353 pagesCalculations For Billing IpcQasim Javed AwanNo ratings yet

- Unit Price As Per Drawing: TotalDocument8 pagesUnit Price As Per Drawing: TotalvikramchowdaryNo ratings yet

- ADOT 2021 Road and Bridge Construction SpecDocument1,296 pagesADOT 2021 Road and Bridge Construction SpecEric GardnerNo ratings yet

Me 208 CH-3

Me 208 CH-3

Uploaded by

MohaerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Me 208 CH-3

Me 208 CH-3

Uploaded by

MohaerCopyright:

Available Formats

Average Mechanical Properties of Typical Engineering Materialsa

(SI Units)

Moduls of Modulus of Yield Strength (MPa) Ultimate Strength (MPa) Coef. of Therm.

Materials Density R

(Mg/m3)

Elasticity E

(GPa)

Rigidity G

(GPa) Tens.

SY

Comp.b Shear Tens.

Su

Comp.b Shear

%Elongation in

50 mm specimen

Poisson’s

Ratio N

Expansion A

(10–6)/°C

Metallic

Aluminum

Wrought Alloys

2014-T6

6061-T6

2.79

2.71

73.1

68.9

27

26

414

255

414

255

172

131

469

290

469

290

290

186

10

12

0.35

0.35

23

24

Cast Iron

Alloys

Gray ASTM 20

Malleable ASTM A-197

7.19

7.28

67.0

172

27

68

–

–

–

–

–

–

179

276

669

572

–

–

0.6

5

0.28

0.28

12

12

Copper Red Brass C83400 8.74 101 37 70.0 70.0 – 241 241 – 35 0.35 18

Alloys

Magnesium

Bronze C86100 8.83 103 38 345 345 – 655 655 – 20 0.34 17

[Am 1004-T61] 1.83 44.7 18 152 152 – 276 276 152 1 0.30 26

Alloy

Structural A-36 7.85 200 75 250 250 – 400 400 – 30 0.32 12

Steel Structural A992 7.85 200 75 345 345 – 450 450 – 30 0.32 12

Alloys

Stainless 304 7.86 193 75 207 207 – 517 517 – 40 0.27 17

Tool L2 8.16 200 75 703 703 – 800 800 – 22 0.32 12

Titanium

Alloy

[Ti-6Al-4V] 4.43 120 44 924 924 – 1,000 1,000 – 16 0.36 9.4

Nonmetallic

Concrete

Low Strength 2.38 22.1 – – – 12 – – – – 0.15 11

High Strength 2.37 29.0 – – – 38 – – – – 0.15 11

Plastic Kevlar 49 1.45 131 – – – – 717 483 20.3 2.8 0.34 –

Reinforced

Wood

30% Glass

Douglas Fir

1.45

0.47

72.4

13.1

–

–

–

–

–

–

–

–

90

2.1c

131

26d

–

6.2d

–

–

0.34

0.29e

–

Select Structural

Grade

White Spruce 3.60 9.65 – – – – 2.5c 36d 6.7d – 0.31e –

a Specific values may vary for a particular material due to alloy or mineral composition,mechanical working of the specimen,or heat treatment. For a more exact value

reference books for the material should be consulted.

b The yield and ultimate strengths for ductile materials can be assumed equal for both tension and compression.

c Measured perpendicular to the grain.

d Measured parallel to the grain.

e Deformation measured perpendicular to the grain when the load is applied along the grain.

Average Mechanical Properties of Typical Engineering Materialsa

(U.S. Customary Units)

Specific Moduls of Modulus of Yield Strength (ksi) Ultimate Strength (ksi) Coef. of Therm.

Materials Weight

(lb/in3)

Elasticity E

(103) ksi

Rigidity G

(103) ksi Tens.

SY

Comp.b Shear Tens.

Su

Comp.b Shear

%Elongation in

2 in. specimen

Poisson’s

Ratio N

Expansion A

(10–6)/°F

Metallic

2014-T6 0.101 10.6 3.9 60 60 25 68 68 42 10 0.35 12.8

Aluminum

Wrought Alloys 6061-T6 0.098 10.0 3.7 37 37 19 42 42 27 12 0.35 13.1

Cast Iron

Alloys

Gray ASTM 20

Malleable ASTM A-197

0.260

0.263

10.0

25.0

3.9

9.8

–

–

–

–

–

–

26

40

96

83

–

–

0.6

5

0.28

0.28

6.70

6.60

Copper Red Brass C83400 0.316 14.6 5.4 11.4 11.4 – 35 35 – 35 0.35 9.80

Alloys

Bronze C86100 0.319 15.0 5.6 50 50 – 35 35 – 20 0.34 9.60

Magnesium

[Am 1004-T61] 0.066 6.48 2.5 22 22 – 40 40 22 1 0.30 14.3

Alloy

Structural A-36 0.284 29.0 11.0 36 36 – 58 58 – 30 0.32 6.60

Steel

Alloys

Structural A992 0.284 29.0 11.0 50 50 – 65 65 – 30 0.32 6.60

Stainless 304 0.284 28.0 11.0 30 30 – 75 75 – 40 0.27 9.60

Tool L2 0.295 29.0 11.0 102 102 – 116 116 – 22 0.32 6.50

Titanium

Alloy

[Ti-6Al-4V] 0.160 17.4 6.4 134 134 – 145 145 – 16 0.36 5.20

Nonmetallic

Concrete

Low Strength

High Strength

0.086

0.086

3.20

4.20

–

–

–

–

–

–

1.8

5.5

–

–

–

–

–

–

–

–

0.15

0.15

6.0

6.0

Plastic Kevlar 49 0.0524 19.0 – – – – 104 70 10.2 2.8 0.34 –

Reinforced 30% Glass 0.0524 10.5 – – – – 13 19 – – 0.34 –

Wood Douglas Fir 0.017 1.90 – – – – 0.30c 3.78d 0.90d – 0.29e –

Select Structural

Grade

White Spruce 0.130 1.40 – – – – 0.36c 5.18d 0.97d – 0.31e –

a Specific

values may vary for a particular material due to alloy or mineral composition,mechanical working of the specimen,or heat treatment. For a more exact value

reference books for the material should be consulted.

b The yield and ultimate strengths for ductile materials can be assumed equal for both tension and compression.

c Measured perpendicular to the grain.

d Measured

e Deformation

parallel to the grain.

measured perpendicular to the grain when the load is applied along the grain.

You might also like

- 780 CMR Ninth Edition, Base Code Amendments - 0Document211 pages780 CMR Ninth Edition, Base Code Amendments - 0anandNo ratings yet

- Steel Connection With Block DetailsDocument6 pagesSteel Connection With Block DetailsAlaaBadwyNo ratings yet

- API Valve Trim ChartDocument2 pagesAPI Valve Trim Chartkhaireddin100% (1)

- Series Fastparts A4 LoDocument115 pagesSeries Fastparts A4 Loeasyvision1No ratings yet

- CP 206 SCM Rough PDFDocument37 pagesCP 206 SCM Rough PDFKumardeep SinghaNo ratings yet

- 01.01. 100mm Dia. Water Meter Assembly. (Strainer)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Strainer)Amadou MokshaNo ratings yet

- Saw Blades and Bevel Cutters For GF and RA MachinesDocument5 pagesSaw Blades and Bevel Cutters For GF and RA MachinesVan DantNo ratings yet

- Mech PropertiesDocument1 pageMech PropertiesLLNo ratings yet

- Api600 Valve Trim ChartDocument2 pagesApi600 Valve Trim ChartBoankNo ratings yet

- Steel Grades According To Japanese Standards: Mechanical PropertiesDocument2 pagesSteel Grades According To Japanese Standards: Mechanical PropertiesGANESHNo ratings yet

- Aisi 4330Document1 pageAisi 4330ahmedNo ratings yet

- Uas PLBTDocument14 pagesUas PLBTTubagus RizkyNo ratings yet

- Dellner Bubenzer SB 23.3Document2 pagesDellner Bubenzer SB 23.3AKA jeanNo ratings yet

- Trim Number Chart API Valve PDFDocument2 pagesTrim Number Chart API Valve PDFtungxuanbrNo ratings yet

- Consteel Catalogue PURLINS CPurlinDocument3 pagesConsteel Catalogue PURLINS CPurlinAnsaf AskyNo ratings yet

- 529A Deadman Anchor Type 1 PDFDocument1 page529A Deadman Anchor Type 1 PDFAnonymous sfkedkymNo ratings yet

- Cheia - Ar AcmDocument1 pageCheia - Ar AcmEne CostinNo ratings yet

- Drawing Distribution: General ToleranceDocument1 pageDrawing Distribution: General ToleranceJovelyn MillaresNo ratings yet

- BS 970 En8dDocument1 pageBS 970 En8djobseekerarulkumarNo ratings yet

- DK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkDocument1 pageDK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkRajkumar SagarNo ratings yet

- Propiedades Aceros y FundicionDocument3 pagesPropiedades Aceros y FundicionintiNo ratings yet

- ASTM A 108 Grade 1020Document1 pageASTM A 108 Grade 1020juan ormacheaNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)UmerNo ratings yet

- BBS FormatDocument2 pagesBBS Formatjogdeep GogoiNo ratings yet

- Standard Dokumentation + SD SB28.3 En1 - 1 - 00Document126 pagesStandard Dokumentation + SD SB28.3 En1 - 1 - 00Andres GarcíaNo ratings yet

- AISI 4140 Alloy SteelDocument4 pagesAISI 4140 Alloy Steelzd55h2754kNo ratings yet

- Generador EmergenciaDocument20 pagesGenerador Emergenciajose antonio alonso lagoNo ratings yet

- Denah Rangka AtapDocument1 pageDenah Rangka AtapNanda Armadiansyah AkbarNo ratings yet

- Filler Metal SelecionDocument1 pageFiller Metal SelecionMurugananthamParamasivam100% (1)

- Astm A743 Cf8mDocument1 pageAstm A743 Cf8makdrnlNo ratings yet

- Asme Sa-29 1018Document1 pageAsme Sa-29 1018Nelson RangelNo ratings yet

- Amcrps Az26-700nDocument2 pagesAmcrps Az26-700nLázaro MagalhãesNo ratings yet

- Astm A351 CF8MDocument1 pageAstm A351 CF8MnadeemNo ratings yet

- Summary of Sub Grade Test Result.... 2Document8 pagesSummary of Sub Grade Test Result.... 2AshebirNo ratings yet

- Jis C 3602 BDDocument1 pageJis C 3602 BDvedveersinghNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- ASTM A297 Grade HHDocument1 pageASTM A297 Grade HHinfo.nulyproNo ratings yet

- Bill of Material: Yorke Structures LTDDocument1 pageBill of Material: Yorke Structures LTDDanrage BoodramNo ratings yet

- Rotary Twin Screw Compressor Packages: Specifications & DimensionsDocument4 pagesRotary Twin Screw Compressor Packages: Specifications & DimensionsNazeeh Abdulrhman AlbokaryNo ratings yet

- DIN G S 17 CrMo 5-5Document1 pageDIN G S 17 CrMo 5-5kaushal sagarNo ratings yet

- Material - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural SteelDocument1 pageMaterial - IS 2062 E 350: Standard Specification For Hot Rolled Medium and High Tensile Structural Steelaniketgupta05No ratings yet

- AISI 4130 Alloy Steel (UNS G41300) 1Document4 pagesAISI 4130 Alloy Steel (UNS G41300) 1shubham soni100% (1)

- Electrolysis Test PitDocument1 pageElectrolysis Test PitwashieNo ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Steel Sun and Planet GearDocument1 pageSteel Sun and Planet GearAmarnathNo ratings yet

- OM - DD - F - 07 Master List of DrawingsDocument10 pagesOM - DD - F - 07 Master List of DrawingssharanNo ratings yet

- Aisi 4140 Alloy Steel (Uns g41400)Document4 pagesAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaNo ratings yet

- SPCM 195Document1 pageSPCM 195Shyam J VyasNo ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Cớ Cấu Lắp Ráp Hoàn Chỉnh-1Document1 pageCớ Cấu Lắp Ráp Hoàn Chỉnh-1chuongNo ratings yet

- WSG-MF: Gearless Synchronous Lift MachineDocument2 pagesWSG-MF: Gearless Synchronous Lift MachineCristianNo ratings yet

- Legend of Building Services: Sewage Pipe Cold Water S.P C.WDocument1 pageLegend of Building Services: Sewage Pipe Cold Water S.P C.WAlin NegarăNo ratings yet

- K Standard Pinion GearDocument1 pageK Standard Pinion GearHarshal TikekarNo ratings yet

- MB 50 Englisch 3Document3 pagesMB 50 Englisch 3Jøn Bilbao MallonaNo ratings yet

- S02 - MM-#42 Columns Details - R02Document1 pageS02 - MM-#42 Columns Details - R02Mohd SiddiqNo ratings yet

- AS90Document1 pageAS90kamalNo ratings yet

- AS90Document1 pageAS90kamalNo ratings yet

- ISO ExampleDocument1 pageISO Examplethe.avishekkNo ratings yet

- NAS9349Document2 pagesNAS9349Bogdan RusuNo ratings yet

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- Republic of The Philippines: Engr. Jonathan C. BulagaoDocument5 pagesRepublic of The Philippines: Engr. Jonathan C. BulagaoMichael James ll BanawisNo ratings yet

- 2 StructuralDocument19 pages2 Structurallayaljamal2No ratings yet

- Week 5: 1. Indigenous Architecture - Malay House 2. Islamic Architecture - MasjidDocument35 pagesWeek 5: 1. Indigenous Architecture - Malay House 2. Islamic Architecture - MasjidSyairah NajihahNo ratings yet

- Concept of Plant Layout:: Bird View of A Typical PlanDocument7 pagesConcept of Plant Layout:: Bird View of A Typical PlanSunil KumarNo ratings yet

- Guide To Concrete Overlays 4th Ed WebDocument156 pagesGuide To Concrete Overlays 4th Ed WebmchilwesaNo ratings yet

- ASTM 재질분류표Document106 pagesASTM 재질분류표오덕환Oh Duckhwan100% (1)

- TDS - Glenium 110 UNDocument3 pagesTDS - Glenium 110 UNAlexi ALfred H. TagoNo ratings yet

- APA Simplified Wall Bracing MethodDocument6 pagesAPA Simplified Wall Bracing MethodklmntNo ratings yet

- Design and Development of Jig and Fixture For Tacho BracketDocument5 pagesDesign and Development of Jig and Fixture For Tacho BracketAckshayaNo ratings yet

- Method Statement For Water Proofing For Railway 24-06-2020Document5 pagesMethod Statement For Water Proofing For Railway 24-06-2020Bhavanishankar shettyNo ratings yet

- Masteremaco S 422 TdsDocument3 pagesMasteremaco S 422 TdsSanthosh KarunanithiNo ratings yet

- Mohammed Shamsuddin: Specifications and Safety As Per Standard. Construction. in ConstructionsDocument2 pagesMohammed Shamsuddin: Specifications and Safety As Per Standard. Construction. in ConstructionsAnjaan MusaafirNo ratings yet

- Elevation: Concrete Parapet With Sidewalk MountedDocument1 pageElevation: Concrete Parapet With Sidewalk Mountedjaelani sidikNo ratings yet

- New Hampshire Department of Transportation: Substructure DetailsDocument5 pagesNew Hampshire Department of Transportation: Substructure Detailsجميل عبد الله الحماطيNo ratings yet

- Lec 16-TorsionDocument10 pagesLec 16-Torsionjessa marie sayconNo ratings yet

- Strength Development of Binary Cement Concrete UsiDocument18 pagesStrength Development of Binary Cement Concrete UsiAvinash LalNo ratings yet

- 01-Seri Es 1000 General PDFDocument84 pages01-Seri Es 1000 General PDFEskindir TeshomeNo ratings yet

- Catálogo GALVAMETDocument16 pagesCatálogo GALVAMETMichael Gutiérrez EscobarNo ratings yet

- Effect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DDocument10 pagesEffect of Lateral Torsional Buckling On Web Tapered I-Beams: CR CR CR DSubhash NaiduNo ratings yet

- Masteremaco N 303 TdsDocument2 pagesMasteremaco N 303 TdsChaitanya MehtaNo ratings yet

- Cpha Members List: Botswana BORDER Continued BORDER ContinuedDocument61 pagesCpha Members List: Botswana BORDER Continued BORDER ContinuedAubel100% (1)

- 2022-03-18 BQ For Guest Bedroom Ukay Heights Bungalow .XLSMDocument15 pages2022-03-18 BQ For Guest Bedroom Ukay Heights Bungalow .XLSMawanisNo ratings yet

- BinderDocument253 pagesBinderJohnny Mopada Jr.No ratings yet

- Cup Lock Rate AnalysisDocument4 pagesCup Lock Rate AnalysisPratik Diyora100% (2)

- Calculations For Billing IpcDocument353 pagesCalculations For Billing IpcQasim Javed AwanNo ratings yet

- Unit Price As Per Drawing: TotalDocument8 pagesUnit Price As Per Drawing: TotalvikramchowdaryNo ratings yet

- ADOT 2021 Road and Bridge Construction SpecDocument1,296 pagesADOT 2021 Road and Bridge Construction SpecEric GardnerNo ratings yet