Professional Documents

Culture Documents

Mobile Crane

Mobile Crane

Uploaded by

SHARAFUDHEEN TKOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile Crane

Mobile Crane

Uploaded by

SHARAFUDHEEN TKCopyright:

Available Formats

الــفـــريــــق

الســتــشــــارات

الســـالمــــة 004-IB

TEAM SAFETY CONSULTANTS

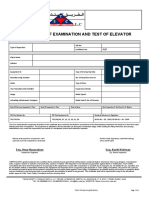

CERTIFICATE OF EXAMINATION AND TEST OF MOBILE CRANE

Job No.: Certificate No.:

Client Name & Address: Name & Address of Maker or Supplier of Equipment::

Location: Survey Requested by: Type of Inspection:

Serial Model No.: Year of Manufacture / Put Into Use:

Owner Distinguishing Mark/Plate No.: Type of Crane : Type of Boom:

Capacity: Make & Type of Derricking Interlock: Make & Type of Automatic Safe Load Indicator:

SAFE WORKING LOAD(S) (PROOF TESTING): (i) (ii) (iii) (iv)

In the case of a crane with a variable operating radius (including a crane with a derricking jib Length of Jib Radius Test Load Safe Working Load

or with inter-changeable jibs of different lengths), the safe working load at various radii of the (m) (m) (Tonne) (Tonne)

jib trolley or crab must be given in column (iv). Test loads at various radii should be given in

column (iii) and in the case of safe working load which has been calculated without the

application of test load “NIL” should be entered in that column.

Wire Rope Dia.: No’s of Ram:

No. of Falls/Reeve: Hook block Capacity:

Degree/Rotation: Counter Weight:

In case of a crane with a derricking jib or jibs the maximum radius at which the jib

or jibs may be worked in

Defects or Deficiencies Noted and Alterations or Repairs Required Before Putting

The Crane Into Service.

:.TSC Test Method No TSC Test Equipment No.: Reference Regulations:

BS 7121 – 2 – 1 : 2012

TSC/ITP/01 TSC/EQ/03, 05, 07, 10, 15, 28 BS 7121 – 2 – 3 : 2012

Date of Previous Test: Date of Inspection: Date of Issue: Date of Expiry:

*Certificate becomes invalid, if any alteration/major repair/modernization made on the Mobile Crane in which case it must be re-examined and re-tested.

THIS IS TO CERTIFY THAT the Undersigned, a competent representative, did, attend to examine this equipment in accordance to the aforementioned standard to ascertain

its safe working load and that the examination indicated that the said equipment has no indigenous injury or sighted deformation and the safe working load of the said

equipment as either identified or test proof loaded is shown. The equipment is satisfactory for its intended use within the limits specified and at the time of inspection was

found to be satisfactory for further use, provided there is continuous maintenance applied, implementation of our remarks & recommendations and qualified operators

employed.

Name and position of person who Authorized signatory authenticating

carried out the inspection and test: :this certificate

Eng. Mark Victorino Eng. Abdul Aziz

Inspection Engineer Technical Manager

CERTIFICATE is granted subject to the condition that is understood and agreed that nothing herein contained shall be deemed to relieve any designer, manufacturer, seller,

supplier, repairer or operator of any warranty, express or implied. This inspection is not intended as guarantee against failure or malfunction. Team Safety Consultants will not

be held responsible for any damage to the equipments or parts after examination or accident due to improper use. No liability for use, operation and for any hidden defects or

information related to the equipment and inspection done is assumed by the inspector or Team Safety Consultants. Any person not a party to the contract pursuant to which

this document is delivered may not assert claims against Team Safety Consultants for any liability arising out of errors or omissions which may be contained in said document

TSC-F-17A (Rev.20) (05/01/2022) Page 1 of 2

and in connection with any activities for which it may provide. This certificate shall not be reproduced except in the full without written approval of the Team Safety

Consultants and the receiving client.

TEAM SAFETY CONSULTANTS, TRADE LICENSE NO. 500714, AL-GARHOUD, P. O. BOX: 112349, DUBAI - UAE, TEL: 04-2828868, FAX: 04-2865265

EMAIL: info@teamsafetyconsultants.ae, WEBSITE: http://tsc-uae.ae/

Continuation of Job No.: Certificate No.:

FINDINGS SECTION

Findings Target Date:

Supplementary:

a. Periodic maintenance required as per the manufacturer instruction.

b. For safe operation, operator and others shall be follow the manufacturer safety instruction.

c. Competent / Certified person only allowed to operate this equipment.

d. Certified Lifting accessories are only allowed to use for lifting purpose.

e. Required / suitable PPE must be worn before use the equipment.

f. Equipment operation should be verified by the operator / maintenance team before starting the work and after completion of the work, If any fault observe do

not continue the work.

g. If any abnormal condition / sound observed from the equipment during the time of operation, the concerned person should be informed to the maintenance

provider, client, building maintenance and safety personnel.

Note:

a. In accordance with EIAC-RQ-IB-001, conditional based validity certificate is issued, Certificate become invalid in case of not rectify the finding within target date, in which case it

must be inspection again.

b. This is the client responsibility shall be respond / inform to TSC for the Re-inspection or submit the evidence within the target date given in the inspection certificate.

c. This is the client responsibility to adhere the supplementary points at all the time but not limited.

TSC-F-17A (Rev.20) (05/01/2022) Page 2 of 2

You might also like

- Certificate of Visual Examination and Mpi: Description of Equipment Crane HookDocument12 pagesCertificate of Visual Examination and Mpi: Description of Equipment Crane HookMichael OkwuwaNo ratings yet

- CS Form No. 7 Clearance FormDocument6 pagesCS Form No. 7 Clearance FormPark SungNo ratings yet

- 1a. Crawler CraneDocument2 pages1a. Crawler CraneSHARAFUDHEEN TKNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- Cert - Mobile Crane 30T - LOLER - Model Rok300Document2 pagesCert - Mobile Crane 30T - LOLER - Model Rok300Rafael Lecu100% (1)

- SN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentDocument1 pageSN. 20859 Webbing Sling WLL 8t Length 3m: Certificate of A Thorough Examination of Lifting EquipmentorizaNo ratings yet

- Certificate of Proof Test of Lifting EquipmentDocument2 pagesCertificate of Proof Test of Lifting EquipmentAhmed Hassan100% (1)

- JC International Limited: Certificate of Visual ExaminationDocument9 pagesJC International Limited: Certificate of Visual ExaminationMichael OkwuwaNo ratings yet

- LP-0008 - Load and Off-Load Rental MEWP 17teDocument6 pagesLP-0008 - Load and Off-Load Rental MEWP 17teRustam36No ratings yet

- Gpa Critical Lift Permit: (Crane Driver/Lift Supervisor)Document4 pagesGpa Critical Lift Permit: (Crane Driver/Lift Supervisor)Mongia MoghiNo ratings yet

- Assessment For - RiggersDocument3 pagesAssessment For - RiggersShakeb RahmanNo ratings yet

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDocument21 pagesLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- The 12 Golden Rules: Safety at WorkDocument11 pagesThe 12 Golden Rules: Safety at WorkStacey FejerNo ratings yet

- Grinding Machine Check ListDocument4 pagesGrinding Machine Check Listjignesh sutariyaNo ratings yet

- Crane InspectionDocument2 pagesCrane InspectionAdhy DarmawanNo ratings yet

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- International Limited: 0.61mtr X 1.41mtrs (Length X Width X Height) C/W 4 Lifting PointsDocument1 pageInternational Limited: 0.61mtr X 1.41mtrs (Length X Width X Height) C/W 4 Lifting PointsMichael OkwuwaNo ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- Lull Telehandler 944-E42Document200 pagesLull Telehandler 944-E42Allan DelormeNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Crane Inspection Form: Carry-In CertificateDocument2 pagesCrane Inspection Form: Carry-In CertificateWisnu Suryo Andriyanto AndriyantoNo ratings yet

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistDocument2 pagesM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- Fork Lift - Risk Assessment - ExampleDocument4 pagesFork Lift - Risk Assessment - Exampleعلي المرزوقNo ratings yet

- D Shackle Inspection ChecklistDocument16 pagesD Shackle Inspection ChecklistAbhilash PattanaikNo ratings yet

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane Checklistchandral86No ratings yet

- Bar Cutting Machine Safety Inspection ChecklistDocument1 pageBar Cutting Machine Safety Inspection ChecklistsanjeetNo ratings yet

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- Tractor Checklist MonthlyDocument1 pageTractor Checklist MonthlySivaram DasariNo ratings yet

- Critical Lift Plan For Overhead Cranes: (Net Load)Document6 pagesCritical Lift Plan For Overhead Cranes: (Net Load)Alex Sandro Borges PereiraNo ratings yet

- Chain Pulley Block or Chain Hoist Safety Dos and Don'tsDocument5 pagesChain Pulley Block or Chain Hoist Safety Dos and Don'tsAkram BadranNo ratings yet

- Crawler CraneDocument1 pageCrawler Craneعبدالله القصيرNo ratings yet

- Crane Inspection Checklist RevDocument1 pageCrane Inspection Checklist RevMuhammadHaziqHaiqalNo ratings yet

- 89 Gas and Oilfield Safety Inspection ChecklistDocument14 pages89 Gas and Oilfield Safety Inspection Checklistdilip matalNo ratings yet

- RT Cranes and Lifting StandardDocument4 pagesRT Cranes and Lifting StandardJohn KalvinNo ratings yet

- UWA Online Health and Safety InductonDocument5 pagesUWA Online Health and Safety InductongcldesignNo ratings yet

- International Limited International Limited: JC JCDocument5 pagesInternational Limited International Limited: JC JCMichael OkwuwaNo ratings yet

- GD380A-L ListDocument6 pagesGD380A-L ListNam Won HongNo ratings yet

- Load Test CertificateDocument1 pageLoad Test Certificatemkt mechoceanNo ratings yet

- Critical Lift PlanDocument2 pagesCritical Lift PlanMd Wãșéèm ÁkrãmNo ratings yet

- Boom Concrete Pump ChecklistDocument2 pagesBoom Concrete Pump ChecklistVilky VargheseNo ratings yet

- Daily Crane Inspection OHS PR 009 FM 01 033Document1 pageDaily Crane Inspection OHS PR 009 FM 01 033cmrig74100% (1)

- Manual Handling TBT PDFDocument1 pageManual Handling TBT PDFNaiduSatyanarayanaNaiduNo ratings yet

- Inspection Checklist Overhead Crane PDFDocument2 pagesInspection Checklist Overhead Crane PDFMOST PASONNo ratings yet

- NLP 296 LoadingUnloading Positioning of Pipe Stack 500TDocument8 pagesNLP 296 LoadingUnloading Positioning of Pipe Stack 500TAhmed AliNo ratings yet

- Lifting Equipment ChecklistDocument4 pagesLifting Equipment ChecklistRuzaini Mohamed100% (1)

- Defect / Non Compliance Report: International LimitedDocument20 pagesDefect / Non Compliance Report: International LimitedMichael OkwuwaNo ratings yet

- Lifting Team Organisation ChartDocument1 pageLifting Team Organisation ChartGricNo ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Wire Rope Cutting ChartDocument8 pagesWire Rope Cutting ChartAkash SharmaNo ratings yet

- Mewps Operator Practical Only Assessment Sheets 2021 MercuryDocument4 pagesMewps Operator Practical Only Assessment Sheets 2021 MercuryWILLIAM KEAGUE100% (1)

- Mobile Crane Test Procedure.Document4 pagesMobile Crane Test Procedure.Deepak GehlotNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift ChecklistmiaicarbaNo ratings yet

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Document2 pagesUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengNo ratings yet

- Lifting Hoisting Hazard HuntDocument1 pageLifting Hoisting Hazard Hunt曹庆园100% (1)

- GEW Method Statement PDFDocument2 pagesGEW Method Statement PDFAzhar MushtaqNo ratings yet

- Lifting Equipements Checklist-1Document59 pagesLifting Equipements Checklist-1Mahmud ShalehudinNo ratings yet

- Bar Bending Machine Safety Inspection ChecklistDocument1 pageBar Bending Machine Safety Inspection ChecklistsanjeetNo ratings yet

- ForkliftDocument2 pagesForkliftSHARAFUDHEEN TKNo ratings yet

- Window CradleDocument2 pagesWindow CradleSHARAFUDHEEN TKNo ratings yet

- Vehicle LiftDocument2 pagesVehicle LiftSHARAFUDHEEN TKNo ratings yet

- Chain BlockDocument2 pagesChain BlockSHARAFUDHEEN TKNo ratings yet

- Foot LoopDocument2 pagesFoot LoopSHARAFUDHEEN TKNo ratings yet

- MewpDocument2 pagesMewpSHARAFUDHEEN TKNo ratings yet

- Belay DevicesDocument2 pagesBelay DevicesSHARAFUDHEEN TKNo ratings yet

- Bumper CarDocument2 pagesBumper CarSHARAFUDHEEN TKNo ratings yet

- HarnessDocument2 pagesHarnessSHARAFUDHEEN TKNo ratings yet

- RopesDocument2 pagesRopesSHARAFUDHEEN TKNo ratings yet

- ELEVATOR ConstructionDocument2 pagesELEVATOR ConstructionSHARAFUDHEEN TKNo ratings yet

- HelmetDocument2 pagesHelmetSHARAFUDHEEN TKNo ratings yet

- Torque VerificationDocument2 pagesTorque VerificationSHARAFUDHEEN TKNo ratings yet

- TankDocument1 pageTankSHARAFUDHEEN TKNo ratings yet

- EQUIPMENT or MACHINERYDocument1 pageEQUIPMENT or MACHINERYSHARAFUDHEEN TKNo ratings yet

- LPG DetectorDocument2 pagesLPG DetectorSHARAFUDHEEN TKNo ratings yet

- Earth PitDocument2 pagesEarth PitSHARAFUDHEEN TKNo ratings yet

- LadderDocument2 pagesLadderSHARAFUDHEEN TKNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- 11.thermic Fluid HeaterDocument2 pages11.thermic Fluid HeaterSHARAFUDHEEN TKNo ratings yet

- Pat TestDocument1 pagePat TestSHARAFUDHEEN TKNo ratings yet

- 3.hot Water GeneratorDocument2 pages3.hot Water GeneratorSHARAFUDHEEN TKNo ratings yet

- Team Safety Consultants: Examination and Test of Steam DryerDocument1 pageTeam Safety Consultants: Examination and Test of Steam DryerSHARAFUDHEEN TKNo ratings yet

- 4.lorry LoaderDocument3 pages4.lorry LoaderSHARAFUDHEEN TKNo ratings yet

- Lifting GearDocument2 pagesLifting GearSHARAFUDHEEN TKNo ratings yet

- 10.engine GeneratorDocument2 pages10.engine GeneratorSHARAFUDHEEN TKNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Concrete PumpsDocument2 pagesConcrete PumpsSHARAFUDHEEN TKNo ratings yet

- Expansion TankDocument2 pagesExpansion TankSHARAFUDHEEN TKNo ratings yet

- 11.thermic Fluid HeaterDocument2 pages11.thermic Fluid HeaterSHARAFUDHEEN TKNo ratings yet

- Steam DryerDocument1 pageSteam DryerSHARAFUDHEEN TKNo ratings yet

- Earth Moving EquipmentsDocument2 pagesEarth Moving EquipmentsSHARAFUDHEEN TKNo ratings yet

- Pat TestDocument2 pagesPat TestSHARAFUDHEEN TKNo ratings yet

- Travels in The Great Desert of Sahara, in The Years of 1845 and 1846 by Richardson, James, 1806-1851Document12 pagesTravels in The Great Desert of Sahara, in The Years of 1845 and 1846 by Richardson, James, 1806-1851Gutenberg.orgNo ratings yet

- People of The Philippines Vs TrestizaDocument83 pagesPeople of The Philippines Vs TrestizaFrancis De CastroNo ratings yet

- Sex Crimes Group 2Document18 pagesSex Crimes Group 2Tammy YahNo ratings yet

- Maharashtra Ownership Apartment Act 1970Document12 pagesMaharashtra Ownership Apartment Act 1970AshitaNo ratings yet

- Kensonic V UnilineDocument12 pagesKensonic V UnilineJuhainah TanogNo ratings yet

- Ishwar Khandelwal Vs Amrapali InfrastructureDocument4 pagesIshwar Khandelwal Vs Amrapali Infrastructurev_singh28No ratings yet

- Amity Business School: MBA, Semester 2 Legal Aspects of Business Ms. Shinu VigDocument14 pagesAmity Business School: MBA, Semester 2 Legal Aspects of Business Ms. Shinu Vigrohitk225No ratings yet

- Plessy V FergusonDocument3 pagesPlessy V FergusonHaniel ShamNo ratings yet

- Philippine National Police: Nature of The Crime Total (Date Committed + Late Report)Document1 pagePhilippine National Police: Nature of The Crime Total (Date Committed + Late Report)pnp bantayNo ratings yet

- Roberts Vs PapioDocument30 pagesRoberts Vs PapioanonNo ratings yet

- Salibo V WardenDocument2 pagesSalibo V WardenJoannalyn Libo-onNo ratings yet

- Bihar Government Estates (Khas-Mahal) Manual, 1953Document87 pagesBihar Government Estates (Khas-Mahal) Manual, 1953sumitekkajhcNo ratings yet

- Memo, Office Order, Office CircularDocument16 pagesMemo, Office Order, Office CircularSonia Chauhan100% (5)

- Timeline of Events: Demand Letter Was Sent To The Accused Enforcing The Child'sDocument3 pagesTimeline of Events: Demand Letter Was Sent To The Accused Enforcing The Child'sMark DungoNo ratings yet

- Warrant AgreementDocument44 pagesWarrant Agreementlcdo1958No ratings yet

- Gautier, MS - Jerry Cooksey Lawsuit Against City and Police Chief Dante ElbinDocument11 pagesGautier, MS - Jerry Cooksey Lawsuit Against City and Police Chief Dante ElbinElaine VechorikNo ratings yet

- Professional Ethics ContentsDocument4 pagesProfessional Ethics ContentsCA 4UNo ratings yet

- United States v. Dana Sander, 4th Cir. (2016)Document3 pagesUnited States v. Dana Sander, 4th Cir. (2016)Scribd Government DocsNo ratings yet

- All India Service (AIS) ManualDocument844 pagesAll India Service (AIS) ManualRajiv Ranjan100% (2)

- Roehm v. Wal-Mart Stores, Incorporated - Document No. 22Document7 pagesRoehm v. Wal-Mart Stores, Incorporated - Document No. 22Justia.comNo ratings yet

- Lejano vs. PeopleDocument62 pagesLejano vs. PeopleRachele GreeneNo ratings yet

- Kcs Act 1969Document187 pagesKcs Act 1969HvffNo ratings yet

- Case 4Document6 pagesCase 4Manong RongcalesNo ratings yet

- Superintendent ContractDocument8 pagesSuperintendent ContractinforumdocsNo ratings yet

- DAR Application For ExemptionDocument1 pageDAR Application For ExemptionMaria100% (2)

- Malangas v. Zaide (Case Brief)Document2 pagesMalangas v. Zaide (Case Brief)nikkisalsNo ratings yet

- Starkville Dispatch Eedition 12-10-19Document12 pagesStarkville Dispatch Eedition 12-10-19The DispatchNo ratings yet

- Islamization and Legal Reform in Pakistan, 1979-1989Document17 pagesIslamization and Legal Reform in Pakistan, 1979-1989saadatusmaniNo ratings yet

- Breaking Open of A Locker072Document5 pagesBreaking Open of A Locker072sri arjunNo ratings yet