Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

40 viewsCad Cam Manual

Cad Cam Manual

Uploaded by

Its meCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ME MT Lecture NotesDocument135 pagesME MT Lecture NotesIts meNo ratings yet

- VIIDocument1 pageVIIIts meNo ratings yet

- Iv Sem-Ot-Ameb12-Syllabus-FfDocument3 pagesIv Sem-Ot-Ameb12-Syllabus-FfIts meNo ratings yet

- Revised - Schedule - B.Tech - IV - Semester - CIE - II - June - 2021 1Document1 pageRevised - Schedule - B.Tech - IV - Semester - CIE - II - June - 2021 1Its meNo ratings yet

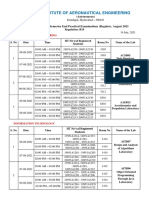

- Schedule of B Tech IV Sem End Practical Examinations Regular AugustDocument5 pagesSchedule of B Tech IV Sem End Practical Examinations Regular AugustIts meNo ratings yet

- B.Tech V Sem CIE-I Exam ScheduleDocument2 pagesB.Tech V Sem CIE-I Exam ScheduleIts meNo ratings yet

- HT 8Document4 pagesHT 8Its meNo ratings yet

- RAC TheoryDocument24 pagesRAC TheoryIts meNo ratings yet

- Manali Leh LadakhDocument9 pagesManali Leh LadakhIts meNo ratings yet

- B.tech V and Vi Semester Academic Calendar 2021-2022Document2 pagesB.tech V and Vi Semester Academic Calendar 2021-2022Its meNo ratings yet

- RAC ProblemsDocument12 pagesRAC ProblemsIts meNo ratings yet

Cad Cam Manual

Cad Cam Manual

Uploaded by

Its me0 ratings0% found this document useful (0 votes)

40 views67 pagesOriginal Title

cad cam manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

40 views67 pagesCad Cam Manual

Cad Cam Manual

Uploaded by

Its meCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 67

INSTITUTE OF AERONAUTICAL ENGINEERING

(Autonomous)

Dundigal, Hyderabad - 500 043

Lab Manual

CAD-CAM LABORATORY (AMEB26)

Prepared by

Mr. M Prasuasti Reppy

DEPARTMENT OF MECHANICAL E:

INSTITUTE OF AERONAUTICAL ENGINEERE

July 23, 2022

Contents

Content

1

3

INTRODUCTION

1.1 Introduction

1.1.1 Student Responsibilities

1.1.2 Responsibilities of Faculty Teaching the Lab Course

1.1.3 Laboratory In-charge Responsibilities

1.14 Course Coordinator Responsibilities

1.2 Lab Policy and Grading

1.3 Course Goals and Objectives

1.4. Use of Laboratory Instruments

1.4.1 Instrument Protection Rules

14.2 The Laboratory Worksheets

14.3 Worksheet

144 Formatting and Style

14.5 The Laboratory Files/Reports

146 CONCLUSIONS

14.7 PROBING FURTHER QUESTIONS

LAB-1 Introduction to CATIA

2.1 Introduction

2.2 Objective

2.3 Prelab Preparation:

24 Equipment needed

2.5 About CAD/CAM

2.5.1 DESIGN PROCESS AND ROLE OF CAD:

2.6 SOLID MODELLING

2.6.1 Advantages of Solid Modeling

2.6.2 REQUIREMENTS FOR MODELING ASSEMBLING

2.7 CAD/CAB/CAM Data Exchange

28 Commonly Used CAD Data Exchange Format:

2.9 Base Features in Part Modelling

2.10 Editing and Engineering Features in Part Modelling

2.11 Probing Further Questions

LAB-2 DRAFTING OF SIMPLE 2D DRAWINGS

3.1, Introduction

3.2. Objective

3.3 Prelab Preparation

3.4 Equipment needed

3.5. Procedure

3.6 Result

3.7. Further Probing Experiments

4 LAB-3 SOLID MODELING

4.1 Objective

4.2 Prelab Preparation:

4.3. Equipment necded

44 CATIA Commands Used

45° Procedure

45.1 FLANGE:

452 SHAFT AND KEY:

453 BOLT AND NUT:

454 ASSEMBLY

45.5 DETAILED DRAWING

4.6 RESULT

4.7 Probing Further Questions

LAB-4 CREATING ORTHOGRAPHIC VIEWS FROM SOLID MODELS

5.1 Objective

5.2 Prelab Preparation:

5.3 Equipment needed

54 CATIA Commands Used

5.5 Procedure

1 BODY

5.5.2 Valve Seat

Valve

eMBLY

‘TAILED DRAWING

5.7 Probing Further Questions

LAB-5 Introduction to Ansys

6.1 Introduction

6.2 Objective

6.3 Prelab Preparation:

6.4 Equipment needed

6.5 Problem Statement:

6.6 Procedure

6.7 POSTPROCESSING: VIEWING THE RESULTS

6.8 Results:

6.9 Further Probing Experiments

LAB-6 TRUSSES AND BEAMS

7.1 Introduction

7.2 Objective

7.3. Prelab Preparation:

7.4 Equipment needed

7.5 Problem Statement

7.6 Procedure

7.7 POSTPROCI

78 Results:

7.9 Problem Statement 2:

7.10 Problem Statement 3:

7.11 Further Probing Experiments

SING: VIEWING THE RESULTS

28

29

34

34

36

38,

8 LAB-7 SHELL STRUCTURES

8.1 Introduction

8.2 Objective

83. Prelab

8.4 Equipment Required

8.5. Problem Statement

8.6 Solution

8.6.1 Case (a) Procedure for BEAM model:

8.6.2 Nodal solution

8.6.3 Reaction solution

8.6.4 Element Solu

8.6.5 Case b) Procedure for PIPE model:

8.7 Result:

8.8 Probing Further Questions

9 LAB-8 HEAT TRANSFER ANALYSIS

9.1 Introduction

8.2 Objective

9.3 Prelab Preparation:

9.4 Equipment needed

9.5 Procedure

9.6 Further Probing Experiments

10 LAB-9 INTRODUCTION TO COMPUTER Nt

10.1 INTRODUCTION

10.1.1 Student Responsibilities

10.1.2. Responsibilities of Faculty Teaching the Lab Course

10.1.3 Laboratory In-charge Responsibilities

10.1.4 Course Coordinator Responsibilities

10.2 Lab Policy and Grading

10.3 Course Goals and Objectives

10.4 Use of Laboratory Instruments

MERICAL CONTROL

11 LAB-10 CNC LATHE I

11.1 Introduction

11.2 Objective

11.3 Prelab Preparation:

11.4 Equipment needed

11.5 Background

116 Procedure

11.7 Further Probing Experiments

12 LAB-11 CNC MILLING I

12.1 Introduction

12.2 Objective

123 Prelab Preparation:

12.4 Equipment needed

12.5 Background

12.6 Procedure

12.7 Further Probing Experiments

13 LAB-12 CAM SOFTWARE

39

39

39

39,

39

39

39

4l

4l

41

41

43

43,

a4

44

44

44

44

ar

60

60

61

13.1 Introduction

13.2. Objective

13.3 Prelab Preparation;

13.4 Equipment needed

13.5 Background

13.6 Procedure

13.7 Further Probing Experiments

6

él

61

61

61

62

62

INTRODUCTION

1.1 Introduction

This course is intended to enhance the learning experience of the student in topics encountered,

in Manufacturing Processes. This lab provides students experiential learning with the nature

and technique of manufacturing processes Manufacturing is the backbone of any industrialized

nation, We introduce four basic production processes for producing desired shape of a product.

These are casting, machining, welding and deformation processes. It inculcates knowledge and

skill to the preparing a wooden pattern to completion of a casting, Also, understand the welding.

and press working processes Students can set up and operate machines, manufacture parts,

measure process variables, and inspect manufactured parts. Skills acquired from time in the lab

are integrated with prior and subsequent learning of other engineering topics such as engineering,

materials and quality planning and control. How the student performs in the lab depends on

his/her preparation, participation and teamwork,

1.1.1 Student Responsibilities

‘The student is expected to come prepared for each lab.Lab preparation includes understanding.

the lab experiment from the lab manual and reading the related textbook material.

Students have to write the allotted experiment for that particular week in the work sheets

given and carry them to the Lab. In case of any questions or problems with the preparation,

students can contact the Faculty Teaching the Lab course, but in a timely manner.

Students have to be in formal dress code, wear shoes and lab coat for the Laboratory Class

After the demonstration of experiment by the faculty, student has to perform the experiment

individually. They have to note down the observations in the observation Tables drawn in work,

sheets, do the calculations and analyze the results

Active participation by each student in lab activities is expected. The student is expected

to ask the Faculty any questions they may have related to the experiment

‘The student should remain alert and use commonsense while performing the lab experi-

ment. They ate also responsible for keeping a professional and accurate record of the lab experi-

ments in the files provided.

1.1.2 Responsibilities of Faculty Teaching the Lab Course

‘The Faculty shall be completely familiar with each lab prior to the laboratory. He/She shall pro-

vide the students with details regarding the syllabus and safety review during the first week.Lab

experiments should be checked in advance to make sure that everything is in working order. The

Faculty should demonstrate and explain the experiment and answer any questions posed by the

students Faculty have to supervise the students while they perform the lab experiments. The

Faculty is expected to evaluate the lab worksheets and grade them based on their practical skills

and understanding of the experiment by taking Viva Voce. Evaluation of work sheets has to

be done in a fair and timely manner to enable the students, for uploading them online through

their CMS login within the stipulated time.

1.1.3. Laboratory In-charge Responsibilities

‘The Laboratory In-charge should ensure that the laboratory is properly equipped, ic., the

Faculty teaching the lab receive any equipment/components necessary to perform the experi-

ments. He/She is responsible for ensuring that all the necessary equipment for the lab is available

and in working condition. ‘Ihe Laboratory In-charge is responsible for resolving any problems

that are identified by the teaching Faculty or the students.

1.1.4 Course Coordinator Responsibilities

‘The course coordinator is responsible for making any necessary corrections in Course Description

and lab manual. He/She has to ensure that it is continually updated and available to the students

in the CMS learning Portal

1.2 Lab Policy and Grading

‘The student should understand the following policy:

ATTENDANCE: Attendance is mandatory as per the academic regulations

LAB RECORD’s: The student must:

1. Write the work sheets for the allotted experiment and keep them ready before the beginning

of eachlab.

2. Keep all work in preparation of and obtained during lab.

3. Perform the experiment and record the observations in the worksheets

4. Analyze the resultsand get the work sheets evaluated by the Faculty.

5. Upload the evaluated reports online from CMS LOGIN within the stipulated time.

Grading Policy:

‘The final grade of this course is awarded using the criterion detailed in the academic regula

tions. A lange portion of the student's grade is determined in the comprehensive final exam of

the Laboratory couse (SEE PRACTICALS) resulting in a requirement of understanding the

concepts and procedure of each lab experiment for successful completion of the lab course.

Pre-Requistes and Co-Requis

‘The lab course is to be taken during the same semester as AMEBOS, but receives a separate

grade. If AMEBOS is dropped, then AMEBO6 must be dropped as well. Students are required,

to have completed both AMEBO1, AMEBO3 and AMEBO4 with a C or better grade in each.

Students are also assumed to have completed a programming class and be familiar with the use

of a computer-based word processor

Note that the instructor reserves the right to alter any part of this information at their discre-

tion. Any changes will be anounced in class and distributed in writing to the students prior to

the changes taking effect

1.3 Course Goals and Objectives

‘The goal of this laboratory is to determine the experiential learning with the nature and tect

nique of computer aided engineering technology. we introduce basics of computer graphies and,

computer aided production processes for producing desired shape of a product. Students ean

set up and operate machines, manufacture parts, measure process variables, and inspect man-

ufactured parts, Skills acquired from time in the lab are integrated with prior and subsequent

Jearning of other engineering topies such as engineering materials and quality planning and con-

trol. At the end of the course students ean able to make the product or prototype by using this

laboratory equipment’s

1. The Importance of manufacturing processes in the day-to-day life, and study the basic

manufacturing techniques and tools used for production,

2. The information related to various manufacturing methodologies for production of defect

free manufacturing components,

3. Enhance the developmental use of computer aided manufacturing processes to application

of real time products with economical production.

1.4 Use of Laboratory Instruments

‘One of the major goals of this lab is to familiarize the student with the proper equipment and

techniques for making mechanical measurements. Some understanding of the lab instruments is

necessary to avoid personal or equipment damage. By understanding the device’s purpose and.

following a few simple rules, costly mistakes can be avoided. You have already, in AMEBO6,

earned these rules, but they are repeated for convenience and emphasis below. Most of the in-

strumentation used in this laboratory is implemented through various manufacturing processes

concepts,

In general, all devices have physical limits. These limits are specified by the device manufacturer

and are referred to as the device rating. The ratings are usually expressed in terms of voltage

limits, current limits, or power limits, It is up to the engineer to make sure that in device

operation, these ratings (Limit values) are not exceeded,

‘The following rules provide a guideline for instrument protection.

1.4.1 Instrument Protection Rules

1, New students must receive an orientation on lab operating procedures before working in

a lab.

2. Students shall publish a safety checklist for equipment for which they are responsible.

3. Students must read the safety checklist for each piece of equipment before operating it

Ensure you know the location of the emergency stop button before starting equipment

4. Always depressurize accumulators or pneumatic reservoirs before working on fluid power

apparatus.

5. Check the application pressure, system pressure, and component pressure before connect~

ing a system to a pump or pressure source. The maximum operating pressures are listed,

on equipment labels or published on manufacturer websites.

6. Periodically check hoses for leakage, cracks, kinks, or breaks.

7. Test your equipment for leaks at low pressure before raising the pressure to the operating.

pressure,

8. All components shall operate within manufacturer's specifications.

9. Equipment shall incorporate an emergency stop or emergency return control, whichever

provides maximum safety.

10. Emergency stops shall be readily accessible under all conditions of working and shall

operate immediately.

11, Equipment shall be designed so that loss of electrical, pneumatic and/or hydraulic power

shall not cause a hazard,

12. Pump inlet temperatures should not exceed 600C when maximum ambient temperatures

exist.

13. Rotating parts shall be guarded to provide adequate protection against hazard.

14. Flexible hoses shall only be used where necessary. Their length shall be minimized and they

shall be protected from abrasion. If failure causes a hazard, the hose shall be restrained,

or shielded.

1.4.2. The Laboratory Worksheets

Students must record their experimental values in the provided tables in this laboratory manual

and reproduce them in the lab reports, Reports are integral to recording the methodology

and results of an experiment. In engineering practice, the laboratory notebook serves as an

invaluable reference to the technique used in the lab and is essential when trying to duplicate a

result or write a report. Therefore, it is important to learn to keep accurate data. Make plots

of data and sketches when these are appropriate in the recording and analysis of observations.

Note that the data collected will be an accurate and permanent record of the data obtained

during the experiment and the analysis of the results. You will need this record when you are

ready to prepare a lab report.

1.4.3. Worksheet

Reports are the primary means of communicating your experience and conclusions to other

professionals, In this course you will use the lab report to inform your LTA about what you did

and what you have leamed from the experience. Engineering results are meaningless unless they

can be communicated to others, You will be directed by your LTA to prepare a lab report on a

few selected lab experiments during the semester. Your assignment might be different from your

lab partner’s assignment. Your laboratory report should be clear and concise. The lab report

shall be typed on a word processor. As a guide, use the format on the next page. Use tables,

diagrams, sketches, and plots, as necessary to show what you did, what was observed, and what.

conclusions you can draw from this. Even though you will work with one or more lab partners,

your report will be the result of your individual effort in order to provide you with practice in

technical communication,

1.4.4 Formatting and Style

1, The lab report shall be typed in a word processor.

2. All page margins must be 1.25 inches. All content (including text, figures, tables, ete.)

must fit within the margins.

3. Body text should be double-spaced

4, Basic text should be in 12-point size in a commonly used text font.

5. Set your main text justified (with even left/right margins)

6. The first line of each paragraph should have a left indent,

7. All the tables should have titles and should be numbered. Tables should be labelled

numerically as Table 1, Table 2, etc. ‘Table captions appear above the table. ‘The column,

headings should be labeled with the units specified

8. Graphs should be presented as figures. All the figures should have titles and should be

numbered. Figure captions appear below the figure. Graphs should have labelled axes and,

clearly show the scales and units of the axes.

9. All the figures and tables must be centered on the page.

10. All the figures and tables in your report must be referenced in your discussion. References

to figures in the main body of the text are usually written in abbreviated form (c.g. ‘see

Fig. 1”)

11, Use MS-Word equation (under Insert Equation menu), MathType, or a similar tool to

type formulas.

12. If you need to copy a schematic or figure from the lab manual to your report, use Copy

and Pastefunction or take a screenshot by using Sniping Tool in MS-Windows.

13. Do not place screenshots of your lab notebook in the report! Diagrams, tables, calculations,

etc. must be generated using the existing tools in the word processor.

1.4.5 The Laboratory Files/Reports

COVER PAGE: Cover page must include lab name and number, your name, your lab partner's

name, and the date the lab was performed,

OBJECTIVE: Clearly state the experiment objective im your own words.

EQUIPMENT USED: Indicate which equipment was used in performing the experiment.

FOR EACH PART OF THE LAB; Write the lab’s part number and title in bold font.

Firstly, describe the problem that you studied in this part, give an introduction of the theory,

and explain why you did this experiment. Do not lift the text from the lab manual; use your

own words.

Secondly, describe the experimental setup and procedures. Do not follow the lab manual in listing

out individual pieces of equipment and assembly instructions. That is not relevant information

in a lab report! Instead, describe the circuit as a whole (preferably with diagram), and explain

how it works, Your description should take the form of a narrative, and include information not

present in the manual, sich as descriptions of what happened during intermediate steps of the

experiment.

‘Thirdly, explain your findings. This is the most important part of your report, because here,

you show that you understand the experiment beyond the simple level of completing it. Explain

(compare expected results with those obtained). Analyse (analyze experimental error), Tnterpret

(explain your results in terms of theoretical issues and relate to your experimental objectives).

This part includes tables, graphs, and sample calculations. When showing calculations, it is

usual to show the general equation, and one worked example. All the results should be presented

oven if there is any inconsistency with the theory. Tt should be possible to understand what is

going on by just reading through the text paragraphs, without looking at the figures. Every

figure/table must be referenced and discussed somewhere in the text.

Finally, provide a summary of what was learned from this part of the laboratory experiment. If

the results seem unexpected or unreliable, discuss them and give possible explanations

1.4.6 CONCLUSIONS

The conclusion section

hould provide a take-home message summing up what has been learn

from the experiment:

# Briefly restate the purpose of the experiment (¢!

question it was seeking to answer)

Identify the main find

68 (answer to the research question)

# Note the main limitations that are relevant to the interpretation of the results

« Summarise what the experiment has contributed to your understanding of the problem.

1.4.7 PROBING FURTHER QUESTIONS

Questions pertaining to this lab must be answered at the end of laboratory report.

LAB-1 Introduction to CATIA

2.1 Introduction

CAD/CAM (computer-aided design and computer-aided manufacturing) refers to computer soft-

ware that is used to both design and manufacture products.CAD is the use of computer tech-

nology for design and design documentation, CAD/CAM applications are used to both design

a product and program manufacturing processes, specifically, CNC machining. CAM software

uses the models and assemblies created in CAD software to generate tool paths that drive the

machines that turn the designs into physical parts, CAD/CAM software is most often used for

machining of prototypes and finished parts.

2.2 Objective

Know the basic fimetions of a CAD Software, concept

historical development, definition, advantages of comput

seometrical modelling and simulations,

xr aided simulations in Real-time.

2.3 Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process

‘The students are expected to be prepared with the basies of machine design and manufacturing

processes.

2.4 Equipment needed

Nil

2.5 About CAD/CAM

Computer Aided Design and Computer Aided Manufacture is the way things are made these

days. Without this technology, we wouldn’t have the range and quality of products available

or, at least, they wouldn't be available at a price most of us can afford. Hand-building and

manual techniques still very much have their place and Design Education needs to treasure

and foster these skills so that future generations will have the hands-on skills to understand

the man-made world and provide the next generation of engineers, designers and technicians.

All of these professionals will be using CAD-CAM techniques or CAD-CAM products in their

work, alongside practical hands-on skill. Design and Technology education has to reflect modern

practice so it is crucial that students have the opportunity to use real CAD-CAM tools in their

designing and making

2.5.1 DESIGN PROC!

SS AND ROLE OF CAD:

# Recognition of need

# Definition of problem

© Synthesis

© Analysis and optimization

© Evaluation

# Presentation

2.6 SOLID MODELLING

A solid modeling system is usually an interactive computer graphies system that is intended to

create true three-dimensional components and assemblies. Recent advances in CAD software,

computers, and graphical displays have made it possible to use solid representations of compo-

nents being considered in the design process. These solid models can be employed in numerous

ways.

2.6.1 Advantages of Solid Modeling

A realistic visual display: By producing a shaded visible surface image of the solid, solid mod-

elling allows a designer to see exactly what has been created. Easy to deal with different views:

Once a part has been created, we have the ability to rotate, shade, section, or produce almost

any view required by a designer. Single associated model database: The solid modeler pro-

vides the only database suitable for all CAD operations. Almost all information needed for part

generation is contained in the solid model. The algorithm should be able to ensure that it repre-

sents physically possible shape that is complete and unambiguous applications. e.g., automatic

generation of a mesh for a finite element analysis.

2.6.2. REQUIREMENTS FOR MODELING ASSEMBLING

1. Part modelling and analysis: The part analysis includes the material type, mass and inertial

properties, functional properties of the faces, etc.

2. Hierarchical relationships:An assemble tree and assemble sequence must be given.

3. Mating conditions: There are two methods for specifying mating conditio:

Firstly Specify the location and orientation of each part in the assembly, together with the

representation of the part itself, by providing a 4 x 4 homogeneous transformation ma-

trix. (ie., transformation from MCS to WCS). Secondly, Specify the spatial relationships

between its individual parts as mating conditions.

2.7. CAD/CAE/CAM Data Exchange

Computer databases are now replacing paper blueprints in defining product geometry and non-

geometry for all phases of product design, analysis, and manufacturing. It becomes increasingly

important to find effective procedures for transferring data among CAD/CAB/CAM systems.

‘The need to exchange modeling data is directly motivated by the need to integrate and automate

the design and manufacturing process to obtain the maximum benefits from CAD/CAE/CAM.

systems.

Four Types of Modelling Data to be transferred:

1. Shape data consists of both geometrical and topological information as well as part fea-

tures. Entity attributes such as font, colour, and layer as well as annotation is considered part of

the entity geometrical information. Topological information applies only to products described.

via solid modelling. Features allow high-level concept communication about parts.

Examples are hole, flange, web, pocket, chamfer, ete.

2, Non-Shape data inchides graphics data such as shaded images, and model global data. as

measuring units of the database and the resolution of storing the database numerical values,

3. Design data has to do with the information that designers generate from geometric models

for analysis purposes. e.g., mass property and finite element mesh data.

4, Manufacturing data consists of information such as tooling, NC tool paths, tolerance, process

planning, tool design, and bill of materials,

2.8 Commonly Used CAD Data Exchange Format:

IGES (Initial Graphics Exchange Specification)

® PDES (Product Data Exchange Using STEP)

# IGES is focused on CAD-to-CAD exchange where primarily shape and non-shape data

were to be transferred from one system to another

# PDES is previous called Product Data Exchange Standard. It is for the exchange of

complete product descriptions which covers the four types of modelling data (ie., shape,

non-shape, design and manufacturing)

# Other data exchange interfaces include: STL, Neutral, SET, BCAD, VDA, STEP, PDGS,

CATIA, Render, CGM, VRML, PATRAN, TIFF, ete.

2.9 Base Features in Part Modelling

L. Pad: Pad in third axis of the profile

A-1-png

he profile about axis of symmetry

1-2. png

3

4,

Blend / Loft: Blending of different cross sections along a path

Lab Manual ‘Template/Chapters/1-3. png

‘Sweep: Pad of a cross section along a path

Lab Nanual Template/Chapters/1-4.png.

2.10 Editing and Engineering Features in Part Modelling

1

2

2.11

1

2

Round: Modify the sharp edge to emved edge

Chamfer: Modify the sharp edge to flat edge

Shell: Removes a surface or surfaces from the solid then hollows out the inside of the solid,

Ieaving a shell of a specified wall thickness.

Rib: Special type of protrusion to create a thin fin or web

Cut: Remove the undesirable portion from the basic part

Lab Manual Template/Chapters/1-5.png

Hole: Remove cylindrical portion from the basic part

Pattern: Create instances of the selected feature by varying some specified dimensions

Probing Further Questions

Write about requirements to develop a drawing CATIA?

State is general post processor

Lab Manual Yemplate/Chapters/1-6.png

LAB-2 DRAFTING OF SIMPLE 2D DRAWINGS

3.1 Introduction

Every modelled part file defines the geometry of a real part; that is either bought or manu-

factured. For this reason, all parts need to be correctly identified with a part number defined

according to company standards. This will help when files are saved, as CATIA will automat-

ically apply the part number to the file name, It also help with instantiation at assembly level

because CATIA defines the instance number according to the part number of the file instantiated

in the assembly.

3.2 Objective

Know the basic functions of a CAD Software, concept of geometrical modelling and simulations,

historical development, definition, advantages of computer aided simulations in Realtime.

Lab Manual ‘Jomplate/Chapters/2. png

3.3 Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

‘The students are expected to be prepared with the basies of machine design and manufacturing

processes.

3.4 Equipment needed

Desktop Computer with atleast 2B RAM with mouse and printer

3.5 Procedure

1. Select the XY plane (the plane the profile will be sketched on). Reference Step 3 for

information on selecting planes.

2. Enter the Sketcher Work Bench. Reference Step 4. 3. Sketch the profile of the part. Hint:

use the Profile tool

3. Anchor the lower left hand corner of the sketch.

4. Constrain the profile to match the dimensions shown above. Reference Step 18 for con-

straining a profile.

5. Exit the Sketcher Work Bench, return to the Part Design Work Bench (the 3D environ-

ment). Reference Step 21 for exiting the Sketcher Work Bench and entering the Part

Design Work Bench.

6. Once in the Part Design Work Bench pad the profile to the dimension has shown (2”)

Reference Step 22 for padding a profile

Save the part.

3.6 Result

‘The geometrical model of required dimension is created using CATIA software

Lab Manual Template/Chapters/2. png

3.7. Further Probing Experiments

1. State the difference between node and element

2. Write about element

LAB-3 SOLID MODELING

sectionIntroduction Every modelled part file defines the geometry of a real part; that is either

bought or manufactured, For this reason, all parts need to be correctly identified with a part

number defined according to company standards, This will help when files are saved, as CATIA

will automatically apply the part number to the file name, It also help with instantiation at

assembly level because CATIA defines the instance number according to the part number of the

file instantiated in the assembly

4.1 Objective

‘To draw the detail view of the flange coupling and assemble the parts by us

V5 R20.0 software and obtain its r

assembly.

ng the CATIA

ective views.Also ‘To find the mass properties of the final

Lab Manual ‘TJemplate/Chapters/3.png

4.2 Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

‘The students are expected to be prepared with the basies of machine design and manufacturing

processes.

4.3. Equipment needed

Desktop Computer with atleast 2GB RAM with mouse and printer

4.4 CATIA Commands Used

Sketch, pad, shaft, Patten, Mate, Align, Helical Sweep, Round, Chamfer ete,

4.5 Procedure

PART DRAWING:

4.5.1 FLANGE:

1. Draw the sectional view of the flange in the sketcher mode.

2. Draw the middle axis line for the purpose of using shaft command and make the flange.

3. Make the keyway and holes by using pad material remove command.

4, Round the sharp edges of the flange by using round tool command.

4.5.2. SHAFT AND KEY:

1. Use pad command to make the shaft and the keyway.

2. Use pad command to make the key.

4.5.3. BOLT AND NUT:

1, Use the pad command makes the bolt head and shank of the bolt,

2. Use the helical sweep command makes the thread in bolt shank.

3. Use the pad and helical sweep command make the mut with thread,

4.5.4 AS

EMBLY

Use the mate, align, insert and pattern commands to assemble the flange coupling.

4.5.5 DETAILED DRAWING

Use the drawing mode makes the respective views and bill of materials.

4.6 RESULT

‘Thus the Detail View of the Flange Coupling along with its respective views and mass properties

has been found

4.7 Probing Further Questions

1. What is Thermal Analysis?

2. What is the difference between Structural Analysis and Thermal Analysis?

3. What is node?

LAB-4 CREATING ORTHOGRAPHIC VIEWS FROM SOLID

MODELS

sectionIntroduetion Every modelled part file defines the geometry of a real part; that is cither

bought or manufactured. For this reason, all parts need to be correctly identified with a part

number defined according to company standards. This will help when files are saved, as CATIA,

will automatically apply the part number to the file name. It also help with instantiation at

assembly level because

ATIA defines the instance number according to the part number of the

file instantiated in the assembly.

5.1 Objective

‘To draw the detail view of the flange coupling and assemble the parts by using the CATIA

V5 R20.0 software and obtain its respective views.Also To find the mass properties of the final

assembly.

Lab Manual ‘TJemplate/Chapters/4. png

5.2 Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

‘The students are exp

1d to be prepared with the basics of machine design and manufact:

processes.

5.3. Equipment needed

Desktop Computer with atleast 2GB RAM with mouse and printer

5.4 CATIA Commands Used.

Sketch, pad, shaft, Pattern, Mate, Align, Helical Sweep, Round, Chamfer ete,

5.5 Procedure

PART DRAWING:

5.5.1 BODY

# Draw the cross section of the body and revolve it,

# Draw the concentric circles of the fork and remove materials.

# Draw the flange part of the body and pad it

5.5.2 Valve Seat

Use the shaft command makes the Valve Seat of the Non Return Valve

5.

Valve

Use the shaft command makes the Valve Seat of the Non Return Valve,

5.5.4 ASSEMBLY

Use the mate, align, insert and pattern commands to assemble the Non Return Valve,

5.5.5 DETAILED DRAWING

Use the drawing mode makes the respective views and bill of materials

5.6 RESULT

‘Thus the Detail View of the Non Return Valve and then its respective views have been drawn.

5.7 Probing Further Questions

1L. White about ANSYS?

2. Discuss the uses of ANSYS software? item Define Structural Analysis?

LAB-5 Introduction to Ansys

6.1 Introduction

Every time you deliver a product to a customer, you are promising them that it will work as

advertised and make their life easier in some way. Using ANSYS engineering simulation software

to design your products enstres that you can keep that promise, with every product and every

order for every customer,

6.2 Objective

‘The learning objective is to be able to rum a Static Structural solution on a model composed of

line (beam) and surface (shell) bodies. This essentially consists of developing knowledge on the

dedicated preprocessing and postprocessing tools associated with these body types.

6.3 Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

The students are expected to be prepared with the basies of machine design and manufacturing

processes

6.4 Equipment needed

Desktop Computer with atleast 2B RAM with mouse and printer

6.5 Problem Statement:

‘To determine the stresses acting on a cantilever beam with a point load of 750 N acting at one

of its ends and perpendicular to the axis of the beam.

© Young's modulus = 265

© Poisson's ratio = 0.3

# Length of the beam = 2 m = 2000 mm.

@ Breadth of the beam = 80 mm.

Height of the beam

6.6 Procedure

From the Main menu select preferences

Select + structural and press OK

From the main menu select Pre-processor

Element type > Add / edit/Delete + Add -+ BEAM ~ 2D > Elastic 3 +Apply -»Close. Material

properties -> material > models > Structural > Linear + Elastic Isotropic EX = 205; PRXY

=03

From the main memu select Pre-processor

Sections + Beam + Common Sections > Select > subtype as Rectangular section > Enter B

= 100, H =50 > Apply > Preview

Real + constants + Add + Add > Ok + Geometric Properties + Area = 5000, Izz = 4170000,

Height = 40 + Ok + Close

From the main menu select Pre-processor Modelling

© Create the key points in the Works

\ce Create -» Key points > in active CS

X [0 [2000 |

Yoro

Click APPLY to all the points and for the last point click OK

© Create LINES using the Key points

Create + Lines > Lines -» Straight Line + Click on Key points to generate lines Select

Plot controls from menu bar + Capture image ~ file save as and save your file.

Meshing the Geometry

From the main menu select Meshing

Meshing > Size controls + Manual size + Lines + Alll lines ~ Number of element divisions = 20

Click OK

Meshing > Mesh > Lin

= pick all

SOLUTION PHASE: ASSIGNING LOADS AND SOLVING

From the ANSYS main men open Solution sohition Analysis type + new analysis ~ Static

Defining loads at the Key points

Solution > Define Loads > Apply + Structural + Displacement + On key points Left end —

ALL DOF arrested

Solution + Define loads + Apply + Structural + Force/moment > On key Points Right end —

Apply a load of FY = -750 N

Select Plot controls from menu bar > Capture image + file save as and save your file

Solving the system Solution> Solve-> Cunrent LS

Lab Manual Template/Pictures/image052.png

Lab Manual Tenplate/Pictures/image048. png

Figure 6.1: Model

Lab Manual Tenplate/Pictures/image050. png

Figure 6.2: Meshing Model

Lab Manual Tenplate/Pictures/image052. png

Figure 6.3: Meshed Model with nodes

Lab Manual Tenplate/Pictures/image054.png

Figure 6.4: Model with boundary conditions

Lab Manual Template/Pictures/image058.png

Figure 6.5: Deformed and undeformed Model

6.7 POSTPROCESSING: VIEWING THE RESULTS

Deformation

From the main memu select General post processing

General post processing +Plot Results Deformed Shape

Select > ‘Def + undef edge’ and click ‘OK’ to view both the deformed and the undeformed,

object.

Nodal solution

From the Utility menu select PLOT

PLOT + Results > Contour plot + Nodal solution - DOF solution ~ ¥ component of displace-

ment ~ OK

Lab Manual Tenplate/Pictures/image060.png

Figure 6.6: Y-Component displacement of the Model

6.8 Results:

6.9 Further Probing Experiments

1. If a cantilever beam has a uniformly distributed load, will the bending moment diagram

be quadratic or cubic?

2. Name the element type used for beams?

3. Define Analysis and its Purpose?

4, What are the modules in Ansys Programming?

LAB-6 TRUSSES AND BEAMS

7.1 Introduction

Every time you deliver a product to a customer, you are promising them that it will work as

advertised and make their life easier in some way. Using ANSYS engineering simulation software

to design your products ensures that you can keep that promise, with every product and every

order for every customer,

7.2 Objective

‘The learning objective is to be able to run a Static Structural solution on a model composed of

trusses and beams. This essentially consists of developing knowledge on the dedicated prepro-

cessing and postprocessing tools associated with these body types.

7.3. Prelab Preparation:

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

‘The students are expected to be prepared with the basies of machine design and manufacturing

processes

7.4 Equipment needed

Desktop Computer with atleast 2GB RAM with mouse and printer

7.5 Problem Statement

‘To determine the nodal deflections, reaction forces, and stress of the indeterminate truss system,

when it is subjected to a load of 2000 N.

GIVEN DATA:

+ Young's modulus — 2e5 — 3250mm2

+ Poisson's ratio = 0.3,

7.6 Procedure

PREPROCESSING

From the Main menu

select preferences Select structural and press OK

From the main menu select Preprocessor

Element type> Add / edit/Delete-» Add-> Link - 2D spar 8-> ok close Real constants Add

Geometric Properties Area = 3250

Material properties + material models Structural+ Linear+ Elastic Isotropic EX = 265:

PRXY — 03

From the main menu select Pre-processor Modelling.

# Create the key points in the Workspace

Pre-processor + Modelling + Create + Nodes > In active CS

Click APPLY to all the points and for the last point click OK

* Create LINES using the Elements

Pre-processor + Modelling > Create > Elements > Auto numbered + through nodes

select node 1&2 > apply + 2&3 + apply > 3&4 + apply > 18&5 > apply > 5&2 > apply

» 2&6 + apply > 643 -» apply > 3&7 -> apply + 7&4 > apply 5&6 + apply 6&7 > ok

> close

SOLUTION PHASE: ASSIGNING LOADS AND SOLVING

From the ANSYS main menu open Solution Solution

Analysis type > new analysis - Static

Defining loads at the Key points

Solution + Define Loads + Apply > St

1&4 + ok + select All DOF + ok

Left end ~ ALL DOF arrested

Solution -+ Define loads > Apply > Structural -» Force/moment + On nodes Select node 2&3

» ok FY direction > Give force value as 2000 N + ok -> close

uctural > Displacement + On nodes + select node >

tem Solition

Solving the sy

Solve > Current LS

7.7 POSTPROCESSIN

VIEWING THE RESULTS

Deformation From the main menu select General post processing

General post processing Plot Results Deformed Shape

Select Def + undef edge’ and click ‘OK’ to view both the deformed and the undeformed object

Nodal solution From the Utility menu select PLOT

PLOT = Results -+ Contour plot + Nodal solution + DOF solution >

placement + OK

component of dis-

Lab Nanual Template/Pictures/image067. png

Figure 7.1: TRUSS (KEY POINTS MODEL)

Lab Nanual Template/Pictures/image070. png

Figure 7.2: TRUSS (LINE MODEL)

Lab Manual Template/Pictures/image073. png

Lab Manual Template/Pictures/image075. png

Figure 7.3: Deformed and undeformed Model

Lab Manual Template/Pictures/image077. png

Figure 74: Y-Component displacement of the Model

7.8 Result:

DMX =

SMN =

7.9 Problem Statement 2:

To find the displacement, maximum, minimum stresses induced in a given cantilever beam and

draw the shear force and bending moment diagrams by using ANSYS tool, also list the results

according to the given loads.

Procedure

‘Main menu

preferences

Lab Manual Template/Pictures/image079. png

check structural

Pre-processor:

1. Main menu > preprocessor > elemer

elastic3 > click ok > close.

e > add/edit /delete > Add > select Beam -2D

2. Main menu > pre-processor > Real constraints > Add/Edit/Delete > Add > Click ok >

Enter the following values Area=1, Area moment of Inertia (IZ%) =1/12, Height=1, >

lick ok > close,

3. Main menu > pre-processor > Material properties > Material model > structural > linear >

clastic > isotropic > enter Ex as 2E5 & PRXY as 0.3 > click ok > close.

4. Main menu > pre-processor > modelling > create > nodes > Inactive CS > (Enter Xi¥iZ

location values) as shown in the figure starting from node-1 i.c., 0, 0, 0 and 10,0,0 thus

two nodes are created. [Main menu > pre-processor > modelling > create > clement > auto

numbered > through nodes (select node by node and middle click) with this elements are

cxeated

Solution:

1. Solution > define loads > Apply > structural > displacement > pick on nodes (Pick the

node which are to be constrained with direction) > middle click > select DOF or UX or

UY or UZ as required > click ok.

2. Pick node-1 > middle click > select all DOF since to constrain the beam,

3. Solution > define loads > Apply > structural > force/moment > on nodes > select node >

middle click > select FX and FY or MZ depending on the problem > click ok. In the above

problem load acting downwards i.e, in negative Y-direction at node -2 of about 10N,

General post processor:

Lab Manual Tenplate/Pictures/image031 . png

1. General post processor > element table > define table > add select by sequence number >

enter SMISC , 2,4,6,8,12 one after the other > click ok > close

2. General post processor > plot results > deformed shape > click ok.

3. General post processor > plot results > contour plot > nodal solution > click ok

4. General post processor > plot results > contour plot > element solution > click ok

General post processor > plot results > contour plot > line element results > use the

Combination 2,8 for shear force diagram and 6,12 for bending moment diagram.

General post processor > plot results > vector plot > predefined > click ok

General post processor > list results > nodal solution > click ok

9. General post processor > list results > clement solution > click ok.

Result: Thus the analysis on the given beam is performed using ANSYS tool, Shear force

Jbending moment diagrams are captured and values are noted,

7.10 Problem Statement 3:

‘To find the displacement, maximum, minimum stresses induced in a given cantilever beam with

uniformly distributed load and point loads and draw the shear force and bending moment dia-

grams by using ANSYS tool, also list the results according to the given loads. Procedure

‘Main menu > preferences > check structural

Pre-processor:

1. Main menu > pre-processor > element type > add/edit /delete > Add > select Beam -2D

elastic3 > click ok > close.

2. Main menu > pre-processor > Real constraints > Add/Bdit/Delete > Add > Click ok >

Enter the following values Area=1, Area moment of Inertia (122) =1/12, Height=1, >

click ok > close

3. Main menu > pre-processor > Material properties > Material model > structural > linear >

clastic > isotropic > enter Ex as 2E5 & PRXY as 0.3 > click ok > close.

4, Main menu > pre-processor > modelling > create > nodes > Inactive CS > (Enter Xi¥iZ

location values) as shown in the figure starting from node-1 ice., 0,0,0 and 1,0,0, 2.5,0,0,

4.5,0,0, 5,0,0 thus five nodes are created

5. Main menu > pre-processor > modelling > create > element > auto numbered > through

nodes (select node by node and middle click) with this elements are created.

Solution:

1. Solution > define loads > Apply > structural > displacement > pick on nodes (Pick the

node which are to be constrained with direction) > middle click > select DOF or UX or

UY or UZ as required > click ok

2. Pick node-1 > middle click > select all DOF since to constrain the beam,

3. Solution > define loads > Apply > structural > force/moment > on nodes > select node >

middle click

select FX and FY or MZ depending on the problem > click ok. In the above problem load

acting downwards i. in negative Y-direction at node -2 and 5 of about 3tones and 2.5

tones

4, Solution > define loads > apply > structural > pressure (applied or uniformly distributed

load) > on beams > select beam middle click(Hnter pressure value at the both ends) i.e.,

at 1& J, enter 1 and 1

click ok

6. Solution > solve > click ok

General post processor

1. General post processor > element table > define table > add select by sequence number >

enter SMISC, 2, 4, 6,8,12 one after the other > click ok > close.

2, General post processor > plot results > deformed shape > click ok,

3. General post processor > plot results > contour plot > nodal solution > click ok

4, General post processor > plot results > contour plot > element solution > click ok. I

5. General post processor > plot results > contour plot > line element results > use the

Combination 2,8 for shear force diagram and 6,12 for bending moment diagram,

General post processor > plot results > vector plot > predefined > click ok

General post processor > list results > nodal solution > click ok,

9. General post processor > list results > element solution > click ok

Result: Thus the analysis on the given beam is performed using ANSYS tool, Shear force,

bending moment diagrams are captured and values are noted.

7.11 Further Probing Experiments

wi

2, What is pre processor?

3. What is post processor?

4, What is modelling?

5. What type of options we use in preferences?

6. ANSYS is it a tool or software?

7. What is the difference between Animation and Modelling?

8. What is DOF?

9. How to create a Node?

10. How to create an Element

is nodal solution?

LAB-7 SHELL STRUCTURES

8.1 Introduction

Every time you deliver a product to a customer, you are promising them that it will work as

advertised and make their life easier in some way. Using ANSYS engineering simulation software

to design your products ensures that you can keep that promise, with every product and every

order for every customer,

8.2 Objective

The learning objective is to be able to run a Static Structural solution on a model composed of

shell structures. This essentially consists of developing knowledge on the dedicated preprocessing

and postprocessing tools associated with these body types.

8.3 Prelab

As a process, Computer-aided Design (CAD) is used after manual design and analysis process.

The students are expected to be prepared with the basies of machine design and manufacturing

processes

8.4 Equipment Required

Desktop Computer with atleast 2GB RAM with mouse and printer

8.5 Problem Statement

A Stopped shaft is subjected to torque as shown in fig. Determine the angle of twist at the

free end and twist in each portion in degrees. Also find the maximum shear stress in each step.

‘Young's modulus=208GPa, poisons ratio=0.3,

Lab Manual ‘Jemplate/Chapters/7-1.png

8.6 Solution

8.6.1 Case (a) Procedure for BEAM model:

1. Preferences - structural - Ok

10.

1.

12

13.

.

16.

17.

18.

19.

20.

Lab Manual Template/Chapters/7-1-1.png

Preprocessor - ELEMENT type - Add/edit/delete - add - Beam- 3D finite strain - OK

CLOSE

Preprocessor - Material Props -Material Model -Structural - Elastic-Isotropic- EX=208

GPa, PRXY=0.3-0K

Preprocessor - Section - Beam -Common Sections. On the beam Tool dialog box, enter

'1' for ID, ‘Sectionl” for Name, Choose Hollow Cross-Section for Sub-Type, enter Ri=40,

Ro=50 Apply,

‘On the beam Tool dialog box, enter '2! for ID, "Section?" for Name, Choose Circular Solid,

Cross-Section for Sub-Type, Enter R=40, Apply

On the beam Tool dialog box, enter '3' for ID, ‘Section3”

Cross-Section for Sub-Type, enter R=30, ok.

Preprocessor -Modeling- Create - Nodes - In active C'S - Node No:=1, X=0,

Apply Node No:=2, X=300, Y=0, Z=0 - Apply Node No:

Node No:=4, X=1200,Y=0, Z=0 - OK

Preprocessor - Modeling - Create - elements -Element Attributes- Section number-Section1-

OK

Preprocessor - Modeling - Create - elements Thru Nodes - 1 and 2 nodes - OK

Preprocessor - Modeling - Create - elements -Element Attributes-Section number-

Section2-OK

Preprocessor - Modeling - Create - elements Thru Nodes - Pick 2 and 3 nodes - OK

Preprocessor - Modeling - Create - elements -Element Attributes-Section number-Section3-

ok

Preprocessor - Modeling - Create - elements Thru Nodes - Pick 3 and 4 nodes - OK

Utility Menu - PlotCtrls-Style-Size and Shape - On Size and Shape dialog box tum ON

[/ESHAPE] display of Element and click OK.

In the Utility Menu, select Plot- Elements.

Switch to isometric view using the pan-Zoom-Rotate dialog box.

Preprocessor-Loads-Define Loads-Apply-Structural- Displacement- On Nodes-select Nodel-

OK-ALLDOF-OK

Preprocessor-Loads-Define Loads-Apply-Structural- Force/Moment- On Nodes-select Node2-

OK-Direction of force/mom=MX, Value= 3e6-Apply

Preprocessor-Loads-Define Loads-Apply-Structural-Force/Moment - On Nodes-select Node3-

OK-Direction of force/mom=MX, Value= -2¢6-Apply

21. Preprocessor-Loads-Define Loads-Apply-Structural-Force/Moment -On Nodes-select Nodet-

OK-Direction of force/mom=MX, Value= 106-OK

22. Solution-Solve-Current LS-OK, Close Solution Done Window

8.6.2. Nodal solution

1. General Postproc-Plot result-Contour Plot-NodalSolu, On the Contour Nodal Solution

Data dialog box, Nodal solution-DOF Solution- Select Rotation vector sum-OK

2. General postprocessor-List Results-Nodal Solutions-OK-DOF Solution-Rotation vector sum-

OK (in radians)

Lab Manual Template/Chapters/7-2. png

8.6.3 Reaction solution

3. General Postproc-List results-Reaction Solution-All Ttems-OK

8.6.4 Element Solution

table - Define table - Add - set user label for item =

lect SMISC, 4 (Type 4

set user label for item = TQI7, select item, comp, results

MISC, 17 (Type 17 after selecting SMISC) -

1. General post processor - Elemen

'TQ4, select item, comp, results data item = by sequence number-

after selecting SMISC) - Apply

data item = by sequence number- select,

Apply - OK - Close

2. General Post Processor - Element Table - List Element Table - Select TQ4, TQI7-OK -

Note the Torsional Moments in N-mm

Lab Manual ‘Template/Chapters/7-5. png

3. General Post Processor - Plot results -Contour plot- Element Table - Select TQ4, TQU7-OK

NOTE: We can only find torsional moments as we are using BEAM element. We ean get

shear stresses in each portion by using PIPE288 element

8.6.5 Case b) Procedure for PIPE model:

1. Preferences - structural - Ok

2. Preprocessor - ELEMENT type - Add/edit /delete - add - Pipe- 3D finite strain - OK -

Options - Hoop strain treatment = Thick shell - OK - CLOSE

10.

ive

12

13.

uu.

15.

16.

17.

18,

19.

Preprocessor - Material Props -Material Model -Struetural - Elastie-Isotropic- EX=208GPa,

PRXY=0.3-0K

Preprocessor - Section - Pipe -Add - Add pipe section with ID = 1, ok - Section nami

Section1, Pipe diameter = 100, Wall thickness = 10, Apply - Add pipe section with ID

, ok - Section name = Section2, Pipe diameter = 80, Wall thickness = 40, Apply -

Add pipe section with ID = 3, ok - Section name = Section3, Pipe diameter ), Wall

thickness = 30, Ok (Close the warning message)

Preprocessor -Modeling- Create - Nodes - In active CS - Node No:=1, , a -

Apply Node No:=2, X=300, Y=0, Z=0 - Apply Node No:=3, X=700, Y=0, Z=0 - Apply

Node No:=4, X=1200,Y: Z=0 - OK

Preprocessor - Modeling - Create - elements Element Attributes- Section mamber-Section]-

OK

Preprocessor - Modeling - Create - elements Thru Nodes - 1 and 2 nodes - OK

Preprocessor - Modeling - Create - elements -Element Attributes-Section number- Section2-

OK

Preprocessor - Modeling - Create - elements Thru Nodes - Pick 2 and 3 nodes - OK

Preprocessor - Modeling - Create - elements -Element Attributes-Section number-Section3-

OK

Preprocessor - Modeling - Create - elements Thru Nodes - Pick 3 and 4 nodes - OK

Utility Menu - PlotCtrls-Style-Size and Shape - On Size and Shape dialog box turn ON

[/ESHAPE] display of Element and click OK.

In the Utility Menu, select Plot- Elements.

Switch to isometric view using the pan-Zoom-Rotate dialog box.

Preprocessor-Loads-Define Loads- Apply- Structural- Displacement- On Nodes-select Nodel-

OK-ALLDOF-OK

Preprocessor-Loads-Define Loads- Apply- Structural- Force/Moment- On Nodes-select Node2-

OK-Direction of force/mom=MX, Value= 3e6-Apply

Preprocessor-Loads-Define Loads- Apply- Structural-Force/Moment - On Nodes-select Node3-

OK-Direction of force/mom=MX, Value= -2cé-Apply

Preprocessor-Loads-Define Loads- Apply- Structural-Force/Moment -On Nodes-select Noded-

OK-Direction of force/mom=MX, Value= leG-OK Sohution-Solve-Current LS-OK, Close

Solution Done Window.

General postprocessor-List Results-Nodal Solutions-OK-DOF Solution-Rotation vector sum-

OK (in radians)

Lab Manual ‘TJemplate/Chapters/7-6. png

Lab Manual ‘TJemplate/Chapters/7-7.png

20. General Postproc-List results-Reaction Solution-All Ttems-OK

21, General post processor - Element table - Define table - Add - set user label for item

TQ4, select item, comp, results data item = hy sequence number- select SMISC, 4 (Type 4

after selecting SMISC) - Apply - set user label for item = TQI7, select item, comp, results

data item = by sequence number- select SMISC, 17 (Type 17 after selecting SMISC) -

Apply - OK - Close

22. General Post Processor - Element Table - List Element Table - Select TQ4, TQU7-OK -

Note the Torsional Moments in N-mm.

Lab Manual ‘jexplate/Chapters/7-8.png

23. General Post Processor - Plot results -C

ress -OK

jour plot- Elemental Solu - Stress - XY shear

8.7 Result:

‘The analysis have been proceesed using Ansys software

8.8 Probing Further Questions

1. Ansys needs the final element model(FEM) for its final solution. (/F)

2. Element attributes must be set before meshing the solid model. (T/F)

3. Ina plane strain, the strain in the direction of thickness is assumed to be zero.(T/F)

LAB-8 HEAT TRANSFER ANALYSIS

9.1 Introduction

Heating up a steel bar from one end and holding the other end in hand, you will soon feel

the increased temperature, This indicates one of the heat transfer mode, thermal conduction.

‘Thermal conduction transfers heat energy by collision of particles within a body. In engineering,

thermal conduetion is mathematically deseribed by Fourier’s law,

9.2 Objective

‘The learning objective is to be able to run a Static Structural solution on a model composed of

shell structures. This essentially consists of developing knowledge on the dedicated preprocessing

and postprocessing tools associated with these body types.

9.3 Prelab Preparation:

1, Pre-processing:

‘* Define element type. (Plane55 element, which is a 2-D, 4node element)

Define material properties. (Thermal Conductivity )

# Create keypoints

# Create an area through keypoints

© Specify mesh density controls. (We will specify numbers of element divisions along lines.)

4 Mesh the area to create nodes and elements

2. Solution:

«© Specify convection boundary conditions

«# Specify zero heat flux through lines of symmetry.

# Solve

3. Pre-processing

‘Plot the temperature distribution

# List locations of these center nodes

4 List the temperatures at each of these nodes. Re-analysis

y node number.

‘# Modify Mesh / Re-analyze. (Primarily repeating earlier steps.)

« Exit the ANSYS program,

faving all data

9.4 Equipment needed

ANSYS Software

9.5 Procedure

1

Change jobname, On the Utility Menu across the very top of the screen, select: File -

Change Jobname Enter? Name”, and click on “OK”,

Lab Manual ‘Template/Chapters/8-1. png,

Define element type: Preprocessor - Element Type - Add/Bdit/Delete Click on “Add”

‘The “Library of Element Types” menu appears, as shown, Scroll down to highlight “Ther

mal Solid”, and “Quad dnode 55” as shown, Click on “OK”, then “Close”. Note that in

ANSYS, this element is sometimes referred to as “Plane55”, because it is a 2-D planar

clement, and it is element type 55 in the ANSYS element library

Lab Manual ‘Template/Chapters/8-2. png

Define material properties: Preprocessor - Material Properties - -Constant- Isotropic “OK”

for material set number 1, then enter 25 for KXX (thermal conductivity), then click on

“OK”, KXX is th

only material property needed for this analysis,

Create keypoints: There are several options available for creating the basic geometry. The

method that will be employed involves creating “keypoints”, then generating an area, with

comers defined by the keypoints. Select: Preprocessor - -Modeling- Create - Keypoints

- In Active CS... Fill in the fields as shown at the top of the next page, then click

“APPLY”. When you click on “Apply”, the command is issued to create keypoint number

1 at (x,y,2)=(- 0.005,0.003,0). Note that when the Z field is left blank, in this case, the

blank space defaults to zero, which is desired. Since you clicked on “Apply”, instead

of “OK”, then the keypoint creation box remains open. Create keypoint number 2 at

Lab Manual ‘Template/Chapters/8-3. png

(%x2)=(.008,.003,0), using the input shown below. After entering the input, again, elick

on “APPLY”

Create 6 total key points in the same manner. The locations for all 6 are shown in the

following table. When the final key point is exeated, click on “OK” instead of “APPLY”

“OK issues the command and also closes the key point creation box.

Before moving on, it is probably a good idea to check the keypoint locations. Along the

top toolbar:

Choose: List - Keypoints - Coordinates Only. A box should open up with the keypoint

location information. If any keypoint is not in the correct location, at this point, you

Lab Manual Tjemplate/Chapters/8-4.png

Lab Manual ‘Jemplate/Chapters/8-S.png

can just reissue the keypoint creation command for that particular keypoint. To do this,

choose: Preprocessor - - Modeling- Create - Keypoints - In Active CS... Fill in the correct

information for that particular keypoint in the box, and click “OK”. The keypoint will

be moved to the correct location. If you have some keypoint incorrectly numbered above

number 6, this will not cause a problem. Just be sure you have keypoint numbers 1 thru 6

located correctly. You can close the box listing the keypoint locations, by clicking, in that

listing box, on “File- Close”

Create an area through key points

Lab Manual ‘TJemplate/Chapters/8-6. png.

Specify mesh density controls.

‘Choose: Preprocessor - -Meshing- Size Controls - -Lines- Picked Lines The picking menu

(below left) appears. On the graphies window, click on the top horizontal line (this is one

with end keypoints 1 and 2), to highlight it. Then, elick “OK? in the picking ment, Then,

the "Element Size” ment (below right) appears. Enter “S” for “NDIV", as shown, then

click “OK”

Preprocessor - -Meshing- Mesh - Areas - Free A picking menu appears. Select “Pick All”

‘The area will be meshed. You will see a number of small quadrilaterals drawn inside the

area. Each small quadrilateral is a “finite element”, There are four nodes associated with,

cach individual clement.

Apply convection boundary conditions: Solution - -Loads- Apply - -Thermal- Convection,

- On Lines A picking menu appears, Highlight the top horizontal line (with end keypoints

1 and 2), then click on “OK” in the picking menu, The box on the next page appears

Enter “1000” for “Film Coefficient” and 1700 for “Bulk temperature”, as shown, and click

on “OK”, Repeat the process to apply the 200 W/(in2 -K) film coefficient and the 400

K bulk temperature to the horizontal line, with end keypoints 3 and 4, and also to the

vertical line with end keypoints 4 and 5,

Specify zero heat flux boundary conditions: Solution - -Loads- Apply - -Thermal- Heat

Flux - On Lines A picking menu appears. Highlight three lines: the line with end keypoints

1-6; the line with end keypoints 2-3, and the line with end keypoints 5-6. When all

Lab Manual Jjemplate/Chapters/8~7.png

three lines are highlighted, just click “OK” in the picking menu, then in the box that

subsequently opens, just click “OK”. By default, this will specify a heat flux of zero along,

these three lines, which is consistent with the symmetry of the problem,

10. Solve the problem: Solution -Solve- Current LS Click “OK” in the “Solve Current Load

Step” Box. Soon after clicking “OK”, you should see a note in a yellow box saying “Solution

is done!” You may close this yellow box

11. Plot the temperature distribution: General Postproc - Plot Results -Contour Plot- Nodal

Solu The box below appears. Highlight “DOF solution” and “Temperature TEMP”, as

shown, and click “OK”. In the graphics window, a plot, as shown at the bottom, should,

appear. This is a temperature distribution color contour plot: Note that the temperature

values

Lab Nanual Template/Chapters/8-8.png

12, List the locations of the nodes. On the top “Utility Menu

List the temperatures at cach of these nodes. General Postproc - List Results - Nodal

Solution In the box that appears, highlight ‘DOF Solution” and “Temperature TEMP”,

as shown, then click “OK”

Lab Manual ‘Template/Chapters/8-9. png

9.6 Further Probing Experiments

1. Define Conduction 2. Units of Thermal conductivity 3. Basic law for conduction. 4. Define

thermal resistance

LAB-9 INTRODUCTION TO COMPUTER NUMERICAL CON-

TROL

10.1 INTRODUCTION

‘The basic functions of a machine tool, concept of numerical control, historical development

definition, advantages of CNC machine tools

Computer-aided Manufacturing (CAM) is the term used to describe the use of computer-

ined systems to control the operations at a manufacturing plant. ‘These computerized systems

assist manufacturers in various operations such as planning, transportation, management, and.

storage. CAM helps manufacturers improve their time to market capabilities, and create precise

dimensions

10.1.1 Student Responsibilities

‘The student is expected to come prepared for each lab.Lab preparation includes understanding

the lab experiment from the lab manual and reading the related textbook material,

Students have to write the allotted experiment for that particular weck in the work sheets

given and carry them to the Lab. In case of any questions or problems with the preparation,

students can contact the Faculty Teaching the Lab course, but in a timely manner

Students have to be in formal dress code, wear shoes and lab coat for the Laboratory Class.

After the demonstration of experiment by the faculty, student has to perform the experiment

individually. They have to note down the observations in the observation Tables drawn in work

sheets, do the calculations and analyze the results

Active participation by each student in lab activities is expected. The student is expected

to ask the Faculty any questions they may have related to the experiment.

‘The student should remain alert and use commonsense while performing the lab experi-

ment. They are also responsible for keeping a professional and accurate record of the lab experi-

ments in the files provided

10.1.2 Responsibilities of Faculty Teaching the Lab Course

‘The Faculty shall be completely familiar with each lab prior to the laboratory. He/She shall pro-

vide the students with details regarding the syllabus and safety review during the first week. Lab

experiments should be checked im advance to make sure that everything is in working order. The

Faculty should demonstrate and explain the experiment and answer any questions posed by the

students Faculty have to supervise the students while they perform the lab experiments. The

Faculty is expected to evaluate the lab worksheets and grade them based on their practical skills

and understanding of the experiment by taking Viva Voce. Evaluation of work sheets has to

be done in a fair and timely manner to enable the students, for uploading them online through.

their CMS login within the stipulated time.

10.1.3 Laboratory In-charge Responsibilities

‘The Laboratory In-charge should ensure that the laboratory is properly equipped, i.c., the

Faculty teaching the lab receive any equipment/components necessary to perform the experi-

ments. He/She is responsible for ensuring that all the necessary equipment for the lab is available

and in working condition. ‘Ihe Laboratory In-charge is responsible for resolving any problems

that are identified by the teaching Faculty or the students.

10.1.4 Course Coordinator Responsibilities

‘The course coordinator is responsible for making any necessary corrections in Course Description

and lab manual. He/She has to ensure that it is continually updated and available to the students

in the CMS leaming Portal

10.2. Lab Policy and Grading

‘The student should understand the following policy:

ATTENDANCE: Attendance is mandatory as per the academic regulations

LAB RECORD’s: The student must:

1. Write the work sheets for the allotted experiment and keep them ready before the beginning

of eachlab.

2. Keep all work in preparation of and obtained during lab.

3. Perform the experiment and record the observations in the worksheets

nalyze the results and get the work sheets evaluated by the Faculty.

Upload the evaluated reports online from CMS LOGIN within the stipulated time.

Grading Policy:

‘The final grade of this course is awarded using the criterion detailed in the academic regula

tions. A large portion of the student's grade is determined in the comprehensive final exam of

the Laboratory comse (SEE PRACTICALS) resulting in a requirement of understanding the

concepts and procedure of each lab experiment for successful completion of the lab course.

Pre-Requistes and Co-Requisties:

‘The lab course is to be taken during the same semester as AMEII5, but receives a separate

grade.

10.3 Course Goals and Objectives

Today, every manufacturing plant uses at least a type of CAD-CAM system to control their

operations. Here are the various advantages they can avail by using these software applications.

Improves Machining Capabilities: By using a CAD-CAM system, manufacturers can improve

their machining capabilities. For example, when a manufacturer takes up a complex S-axis ma-

chining task, they rely on the combination software to create a tool path for machining projects

such as molding. The CAM system automates the process, and makes it easier for manufacturers