Professional Documents

Culture Documents

p2647 PDF

p2647 PDF

Uploaded by

rajenkoleyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

p2647 PDF

p2647 PDF

Uploaded by

rajenkoleyCopyright:

Available Formats

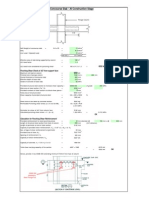

Features of 303 Stainless Steel Annealed Material

303 Stainless Steel Annealed Material Configurable Plates

(Milling)

PQ_ _ _

The stress-relief heat treatment is done.

It is effective for prevention of warp

caused by machining:

However, it has inferior corrosion resistance.

(Ex.) When PQFQM25510010

A Dimension Area Unit Price =

Price

(Surface Grinding)

PQF_ _

PQS_ _

255

Part Number

3.2

3.2

6.3

1.6

Part Number

(1) Thickness (2) A B Dimension

2-Surface Finish

Tolerance

Tolerance

P

Q

N

M

F (Milling)

PQ (Standard Size) S (Surface Grinding)

0.5mm Increment

B

AB

P

Q

N

M

15~500

(1) Thickness Tolerance

P

10~200

2-Surface Finish A B Dimension

+0.1~+0.3

0~+0.2

0.1

0.2~0

0~+0.1

Precision Standards

0.05

0.1~0

250.5mm or More +0.1~+0.6

0~+0.2

0.1

0.2~0

0~+0.5

Part Number

2-Surface Finish

S

F

Type 2-Surface Finish Thickness Tolerance A B Dimension Tolerance

(Milling)

(Surface Grinding)

0.05

0.012

PQ

T3~7.5

0.1

0.05

PQF_ _

T8~15.5

0.07

0.03

T16~25.5

0.05

0.015

T26~30

0.05

0.012

Thickness Parallelism (per 100mm)

Perpendicularity of Reference Plane

0.25

0.5~0

PQFNM

(CSC CBC CCAetc.)

300 155

20

CSC

Circumference Chamfering

0.25

Corner Cut

T

Part Number

P.92

$8.00/piece

P.92

25

CCB

CCC

25

25

Reference Plane

CBC

Changes the chamfering dimension.

Changes the chamfering dimension.

C0.2~C0.5 C0.1 or

C0.5~C1.0

C 2 , 2

Ordering Code

(Ex.)When the corners of

A and D are cut by C5

CCA5CCD5

1mm Increment Price Adder

1~ 5

6~10

11~20

21~30

31~40

41~50

Refer to Details

PQS_ _

0.15

0.1

0.05

CCA CCB CCC CCD

Cuts any corners.

1mm Increment

1 Corner Cut 50

303 Stainless Steel/304 Stainless Steel and Annealed 303 Stainless Steel/

304 Stainless Steel Flatness Variation after Machined (Reference)

0.2

CCD

25

8.00

Comparison of Flatness Variation Caused by

Upper-Lower Surface Milling Cutter

Alterations

Details

255 155 18

$8.00/piece

$2.00/piece

Express B

CCA

less

Non-Returnable P.92 A flat charge of $21.60 for 3 or more identical pieces.

CSC

M

Express T

Express A

C0.2~C0.5

Part Number

Non-Returnable P.92 A flat charge of $5.40 for 3 or more identical pieces. (Except T)

PQS_ _

0.015 per 100mm

Circumference

Standard Size

Chamfering

8.00

(Max. Value)

Item

Price Adder

PQF_ _

F (Milling)

S (Surface Grinding)

+0.1~+0.2

2647

6.5~30

250mm or Less +0.1~+0.3

F (Milling)

S (Surface Grinding)

Code

(2) A B Dimension Tolerance

2-Surface Finish

Flatness

(per 100mm)

303 Stainless Steel Annealed Material

Flatness

Type

6.3

6.3

1.6

6.3

Reference Plane

2.00

2.50

4.50

6.00

7.00

8.00

0

12

11.5

11

10.5

10

Plate Thickness after Machined (mm)

*MISUMI's internal test

303 Stainless Steel

303 Stainless Steel

Annealed Material

6-Surface Milling

304 Stainless Steel

304 Stainless Steel

Annealed Material

[Testing Method]The four materials shown above (155x155x12mm) are machined

with a milling path of 0.5mm and each of their flatness is

measured with three dimensional measuring instrument.

The test results above show that, after machined,

annealed 303 Stainless Steel/304 Stainless Steel

have better flatness than 303 Stainless Steel/304

Stainless Steel.

0.25

Volume Discount Rate

Quantity 1~4

Rate Price List

= $63.75

A

15 ~ 50

50.5~100

100.5~150

20 ~ 50

50.5~ 75

75.5~100

100.5~200

25.5~ 50

50.5~ 75

75.5~100

100.5~200

200.5~500

40.5~ 50

50.5~ 75

75.5~100

100.5~200

200.5~500

60.5~ 75

75.5~100

100.5~200

200.5~500

80.5~100

100.5~200

200.5~500

100.5~125

125.5~200

200.5~500

125.5~200

200.5~500

150.5~200

200.5~500

160.5~200

200.5~500

A

15 ~ 50

50.5~100

100.5~150

20 ~ 50

50.5~ 75

75.5~100

100.5~200

25.5~ 50

50.5~ 75

75.5~100

100.5~200

200.5~500

40.5~ 50

50.5~ 75

75.5~100

100.5~200

200.5~500

60.5~ 75

75.5~100

100.5~200

200.5~500

80.5~100

100.5~200

200.5~500

100.5~125

125.5~200

200.5~500

125.5~200

200.5~500

150.5~200

200.5~500

160.5~200

200.5~500

8.5~10

Ax0.40

Ax0.22

Ax0.18

Ax0.34

Ax0.27

Ax0.22

Ax0.15

Ax0.32

Ax0.26

Ax0.22

Ax0.18

Ax0.14

Ax0.40

Ax0.33

Ax0.27

Ax0.22

Ax0.20

Ax0.37

Ax0.31

Ax0.26

Ax0.23

Ax0.34

Ax0.28

Ax0.25

Ax0.39

Ax0.34

Ax0.32

Ax0.38

Ax0.36

Ax0.42

Ax0.41

Ax0.48

Ax0.47

10.5~12

Ax0.46

Ax0.24

Ax0.19

Ax0.35

Ax0.29

Ax0.23

Ax0.16

Ax0.34

Ax0.28

Ax0.24

Ax0.20

Ax0.16

Ax0.42

Ax0.36

Ax0.30

Ax0.24

Ax0.23

Ax0.41

Ax0.34

Ax0.28

Ax0.27

Ax0.38

Ax0.32

Ax0.29

Ax0.45

Ax0.38

Ax0.38

Ax0.44

Ax0.42

Ax0.48

Ax0.47

Ax0.56

Ax0.54

12.5~15

Ax0.49

Ax0.26

Ax0.21

Ax0.37

Ax0.29

Ax0.24

Ax0.17

Ax0.37

Ax0.32

Ax0.26

Ax0.21

Ax0.18

Ax0.47

Ax0.40

Ax0.33

Ax0.26

Ax0.24

Ax0.44

Ax0.39

Ax0.32

Ax0.30

Ax0.43

Ax0.37

Ax0.33

Ax0.51

Ax0.43

Ax0.43

Ax0.51

Ax0.48

Ax0.55

Ax0.54

Ax0.64

Ax0.62

15.5~20

Ax0.54

Ax0.29

Ax0.22

Ax0.40

Ax0.33

Ax0.26

Ax0.19

Ax0.42

Ax0.36

Ax0.31

Ax0.25

Ax0.21

Ax0.53

Ax0.46

Ax0.39

Ax0.32

Ax0.29

Ax0.52

Ax0.47

Ax0.40

Ax0.37

Ax0.51

Ax0.46

Ax0.41

Ax0.63

Ax0.54

Ax0.53

Ax0.62

Ax0.59

Ax0.69

Ax0.68

Ax0.81

Ax0.78

20.5~25

Ax0.42

Ax0.36

Ax0.29

Ax0.24

Ax0.46

Ax0.40

Ax0.35

Ax0.29

Ax0.26

Ax0.59

Ax0.52

Ax0.45

Ax0.38

Ax0.35

Ax0.60

Ax0.53

Ax0.46

Ax0.43

Ax0.61

Ax0.54

Ax0.49

Ax0.74

Ax0.64

Ax0.62

Ax0.75

Ax0.71

Ax0.82

Ax0.80

Ax0.97

Ax0.93

25.5~30

Ax0.45

Ax0.39

Ax0.32

Ax0.26

Ax0.50

Ax0.44

Ax0.39

Ax0.32

Ax0.29

Ax0.64

Ax0.57

Ax0.48

Ax0.41

Ax0.38

Ax0.65

Ax0.58

Ax0.51

Ax0.48

Ax0.67

Ax0.61

Ax0.55

Ax0.82

Ax0.72

Ax0.70

Ax0.84

Ax0.81

Ax0.92

Ax0.90

Ax1.10

Ax1.05

6.5~8

Ax0.58

Ax0.31

Ax0.24

Ax0.54

Ax0.43

Ax0.31

Ax0.23

Ax0.49

Ax0.40

Ax0.32

Ax0.24

Ax0.52

Ax0.43

Ax0.35

Ax0.26

Ax0.47

Ax0.38

Ax0.29

Ax0.41

Ax0.32

Ax0.46

Ax0.37

Ax0.40

Ax0.46

Ax0.50

8.5~10

Ax0.62

Ax0.33

Ax0.27

Ax0.54

Ax0.43

Ax0.33

Ax0.25

Ax0.50

Ax0.41

Ax0.33

Ax0.25

Ax0.20

Ax0.55

Ax0.47

Ax0.38

Ax0.29

Ax0.25

Ax0.51

Ax0.42

Ax0.33

Ax0.30

Ax0.45

Ax0.36

Ax0.31

Ax0.50

Ax0.40

Ax0.40

Ax0.46

Ax0.44

Ax0.50

Ax0.50

Ax0.56

Ax0.56

10.5~12

Ax0.70

Ax0.36

Ax0.28

Ax0.55

Ax0.44

Ax0.33

Ax0.25

Ax0.50

Ax0.43

Ax0.35

Ax0.28

Ax0.22

Ax0.61

Ax0.50

Ax0.41

Ax0.32

Ax0.28

Ax0.55

Ax0.44

Ax0.35

Ax0.34

Ax0.47

Ax0.40

Ax0.37

Ax0.58

Ax0.46

Ax0.46

Ax0.51

Ax0.49

Ax0.57

Ax0.56

Ax0.66

Ax0.64

12.5~15

Ax0.74

Ax0.38

Ax0.31

Ax0.57

Ax0.46

Ax0.35

Ax0.27

Ax0.55

Ax0.47

Ax0.37

Ax0.28

Ax0.24

Ax0.65

Ax0.54

Ax0.44

Ax0.34

Ax0.31

Ax0.59

Ax0.50

Ax0.39

Ax0.36

Ax0.55

Ax0.45

Ax0.39

Ax0.64

Ax0.52

Ax0.50

Ax0.58

Ax0.55

Ax0.65

Ax0.64

Ax0.74

Ax0.72

15.5~20

Ax0.82

Ax0.43

Ax0.32

Ax0.59

Ax0.46

Ax0.36

Ax0.28

Ax0.58

Ax0.49

Ax0.41

Ax0.32

Ax0.28

Ax0.73

Ax0.63

Ax0.52

Ax0.41

Ax0.37

Ax0.69

Ax0.59

Ax0.48

Ax0.45

Ax0.64

Ax0.54

Ax0.48

Ax0.78

Ax0.66

Ax0.62

Ax0.74

Ax0.69

Ax0.82

Ax0.80

Ax0.94

Ax0.90

20.5~25

Ax0.61

Ax0.50

Ax0.41

Ax0.35

Ax0.64

Ax0.54

Ax0.45

Ax0.36

Ax0.32

Ax0.79

Ax0.69

Ax0.58

Ax0.47

Ax0.43

Ax0.77

Ax0.67

Ax0.56

Ax0.51

Ax0.74

Ax0.63

Ax0.57

Ax0.90

Ax0.76

Ax0.73

Ax0.87

Ax0.82

Ax0.95

Ax0.93

Ax1.10

Ax1.05

25.5~30

Ax0.64

Ax0.53

Ax0.44

Ax0.38

Ax0.68

Ax0.59

Ax0.50

Ax0.39

Ax0.35

Ax0.85

Ax0.74

Ax0.62

Ax0.50

Ax0.46

Ax0.82

Ax0.71

Ax0.62

Ax0.55

Ax0.81

Ax0.70

Ax0.62

Ax0.97

Ax0.84

Ax0.80

Ax0.95

Ax0.90

Ax1.04

Ax1.02

Ax1.23

Ax1.16

25.5~40

40.5~60

60.5~80

80.5~100

100.5~125

125.5~150

150.5~160

160.5~200

25.5~40

40.5~60

60.5~80

80.5~100

100.5~125

125.5~150

150.5~160

160.5~200

For larger quantity orders "Days to Ship"

may differ from published catalog term. P.91

6.5~8

Ax0.37

Ax0.21

Ax0.16

Ax0.34

Ax0.27

Ax0.21

Ax0.14

Ax0.31

Ax0.26

Ax0.24

Ax0.16

Ax0.36

Ax0.31

Ax0.26

Ax0.20

Ax0.33

Ax0.28

Ax0.22

Ax0.30

Ax0.25

Ax0.37

Ax0.30

Ax0.34

Ax0.37

Ax0.43

20~25

20~25

5~

5%

10~19.5

10~19.5

2-Surface Surface Grinding+4-Side Milling

2648

You might also like

- 8.0 Slab Design (Aci)Document4 pages8.0 Slab Design (Aci)klynchelleNo ratings yet

- Base Plate BiaxilDocument26 pagesBase Plate BiaxilvijaystructuralNo ratings yet

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- Compression Test em 327: Mechanics of Materials Laboratory: ObjectivesDocument5 pagesCompression Test em 327: Mechanics of Materials Laboratory: Objectivesrajenkoley88% (8)

- RC Roof Beam DesignDocument5 pagesRC Roof Beam DesignSujay SantraNo ratings yet

- RC Tie Beam DesignDocument10 pagesRC Tie Beam DesignSujay Santra67% (3)

- Tata Steel Bulb Flats BroDocument11 pagesTata Steel Bulb Flats BroMd. Rafique HassanNo ratings yet

- RC One-Way Slab Design (Aci318-14)Document3 pagesRC One-Way Slab Design (Aci318-14)Sachin AgarwalNo ratings yet

- Sample Calculating For Piping Wall Thickness CalculationDocument8 pagesSample Calculating For Piping Wall Thickness CalculationsubhashNo ratings yet

- Cant SlabDocument7 pagesCant Slabsantosh-a-biraj-3307No ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- Din 17100Document4 pagesDin 17100Sheby SandyNo ratings yet

- 3 To 4: A To B: Proposed Commercial Flats On Plot 10090/22Document1 page3 To 4: A To B: Proposed Commercial Flats On Plot 10090/22Hans Hans SadzNo ratings yet

- Slab Deflection CalculationDocument2 pagesSlab Deflection CalculationAHMED SOHEL100% (1)

- Misumi Technical Data PDFDocument1 pageMisumi Technical Data PDFtnchsg100% (1)

- StaircaseDocument8 pagesStaircaseVenkat BalajiNo ratings yet

- Excel Tools To Check Beam JackettingDocument10 pagesExcel Tools To Check Beam JackettingPrakash Singh RawalNo ratings yet

- Pile CapDocument33 pagesPile CapSopheap BorohsNo ratings yet

- ASME B31.3 CalculationDocument11 pagesASME B31.3 CalculationAnonymous wIPMQ5rhNo ratings yet

- Beam Design Beam No. 95: . CC+ Sdia + Mdia/2 . D - D'Document2 pagesBeam Design Beam No. 95: . CC+ Sdia + Mdia/2 . D - D'qwertyingNo ratings yet

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Kyocera Substrates) Electronic Fine CeramicsDocument17 pagesKyocera Substrates) Electronic Fine Ceramicsmanolo_superNo ratings yet

- Beam Design: 101 30 M ('M' For Moderate, "S" For Severe, "VS" For Very Severe, "E" For Extreme) 415 40 40 456 SpanDocument11 pagesBeam Design: 101 30 M ('M' For Moderate, "S" For Severe, "VS" For Very Severe, "E" For Extreme) 415 40 40 456 SpannytenNo ratings yet

- Minimum Pipe Thickness - B31.1 - PG1Document10 pagesMinimum Pipe Thickness - B31.1 - PG1ravivarmadatla2011No ratings yet

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George Racz100% (1)

- Pipe Wall Thickness CalculationDocument8 pagesPipe Wall Thickness CalculationRAGHVENDRA PRATAP SINGH0% (1)

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- RC One Way Slab Design (ACI318-05)Document2 pagesRC One Way Slab Design (ACI318-05)emoriderNo ratings yet

- Retaining Wall DesignDocument168 pagesRetaining Wall DesignSuraj Muley0% (1)

- C55EDocument2 pagesC55EniranjanbmazireNo ratings yet

- Blind Flange Thickness CalculationDocument1 pageBlind Flange Thickness Calculationmamughal123No ratings yet

- Fin Plate - Beam To ColumnDocument78 pagesFin Plate - Beam To ColumnHemant Ramesh NarkarNo ratings yet

- Steel Connection Design - Tension ElementsDocument5 pagesSteel Connection Design - Tension ElementsSimon LsmNo ratings yet

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulNo ratings yet

- Beam Desgin SheetDocument5 pagesBeam Desgin SheetKamYingLamNo ratings yet

- Water Tank Design (Aci 318-05 & 350-01)Document5 pagesWater Tank Design (Aci 318-05 & 350-01)Arman20190% (10)

- Punching Shear Check For SlabDocument2 pagesPunching Shear Check For SlabArnab Sur50% (2)

- Subject: Design: CHD: Client:: One-WayDocument3 pagesSubject: Design: CHD: Client:: One-WayIlmtalabNo ratings yet

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- Msrit College-Magazine-Sudarshan-2015 PDFDocument158 pagesMsrit College-Magazine-Sudarshan-2015 PDFrajenkoley100% (1)

- Is 11315 11 1985Document10 pagesIs 11315 11 1985rajenkoleyNo ratings yet

- Is 12070 1987Document20 pagesIs 12070 1987rajenkoley0% (1)

- Is 5313 1980Document14 pagesIs 5313 1980rajenkoleyNo ratings yet

- Is 9143 1979Document11 pagesIs 9143 1979rajenkoleyNo ratings yet

- Is 6926 1996Document15 pagesIs 6926 1996rajenkoleyNo ratings yet

- Disclosure To Promote The Right To InformationDocument14 pagesDisclosure To Promote The Right To InformationrajenkoleyNo ratings yet

- Is 4464 1985Document21 pagesIs 4464 1985rajenkoleyNo ratings yet

- Human Factor: Transportation EngineeringDocument31 pagesHuman Factor: Transportation EngineeringrajenkoleyNo ratings yet

- Lec 10 - Traffic Stream Models2Document27 pagesLec 10 - Traffic Stream Models2rajenkoleyNo ratings yet

- Lec 3 - Vehicle MotionDocument27 pagesLec 3 - Vehicle MotionrajenkoleyNo ratings yet

- Civil Engineering Project Proposals: MembersDocument11 pagesCivil Engineering Project Proposals: Membersjesma lauditNo ratings yet

- Ex. No: 6.a Linear Search AimDocument6 pagesEx. No: 6.a Linear Search AimSARANYA.R MIT-AP/CSENo ratings yet

- Src419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionDocument45 pagesSrc419X 192-Khz Stereo Asynchronous Sample-Rate Converters: 1 Features 3 DescriptionNguyễn QuangNo ratings yet

- Al Qudra LakeDocument2 pagesAl Qudra Lakeواجد چوھدریNo ratings yet

- Impact of Efl Teachers Teaching Style On Students Academic Performance and Satisfaction: An Evidence From Public Sector Universities of KarachiDocument27 pagesImpact of Efl Teachers Teaching Style On Students Academic Performance and Satisfaction: An Evidence From Public Sector Universities of KarachiJIECEL FLORESNo ratings yet

- PR2 Qtr1 Module 2Document50 pagesPR2 Qtr1 Module 2mememew suppasitNo ratings yet

- What Is Intranet?: Document & Content ManagementDocument4 pagesWhat Is Intranet?: Document & Content Managementali muhdorNo ratings yet

- Pile Load Test MethodologyDocument4 pagesPile Load Test MethodologyAkhilesh Dwivedi100% (1)

- Where Is The LoveDocument50 pagesWhere Is The LoveEusebio YuNo ratings yet

- Experimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemDocument13 pagesExperimentalstudies On The Effects of Reduction in Gear Tooth Stiffness Lubricant Film Thicknessina Spur Geared SystemBurak TuncerNo ratings yet

- Ccs Assignment 2Document7 pagesCcs Assignment 2VINIKSHA SHREE A CSE studentNo ratings yet

- Week 2: Introduction To LiteratureDocument45 pagesWeek 2: Introduction To LiteratureEirlys NhiNo ratings yet

- Quick Charge Device ListDocument16 pagesQuick Charge Device Listlimited0% (1)

- Project (Digital Filter)Document33 pagesProject (Digital Filter)NilNo ratings yet

- Name: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019Document139 pagesName: License No License No: 2862 License Issue Date Issue Date:11/7/2007 License Expiry Date Expiry Date:10/7/2019ArabyAbdel Hamed SadekNo ratings yet

- BMW Group Annual Report 2011Document282 pagesBMW Group Annual Report 2011Harrie TholenNo ratings yet

- Therapeutic Potential of Heterocyclic Pyrimidine Scaffolds: Review Open AccessDocument29 pagesTherapeutic Potential of Heterocyclic Pyrimidine Scaffolds: Review Open AccessWalid EbaiedNo ratings yet

- DR .Sharma Ji-05Document1 pageDR .Sharma Ji-05arunNo ratings yet

- ECSS U AS 10C Rev.1 (3december2019)Document8 pagesECSS U AS 10C Rev.1 (3december2019)Mansoor ShahNo ratings yet

- Kilimo Cha MbogambogaDocument107 pagesKilimo Cha Mbogambogaazizin1994No ratings yet

- MAN Diesel: Tools For Reconditioning 52001-02Document4 pagesMAN Diesel: Tools For Reconditioning 52001-02manuel canas nunezNo ratings yet

- Identification of Nonlinear Dynamic Systems - Classical Methods Versus RBF Networks - Nelles & Isermann ACC 1995Document5 pagesIdentification of Nonlinear Dynamic Systems - Classical Methods Versus RBF Networks - Nelles & Isermann ACC 1995Vladimir StojanovićNo ratings yet

- Tascam DB 25 PinoutDocument1 pageTascam DB 25 PinoutAmro NoechiNo ratings yet

- Nidek ICE-1200Document6 pagesNidek ICE-1200QulrafMongkonsirivatanaNo ratings yet

- Steroid Use in The Elderly: Postgraduate MedicineDocument8 pagesSteroid Use in The Elderly: Postgraduate MedicineValdi DwiramaNo ratings yet

- EE Professional SubjectsDocument3 pagesEE Professional Subjectsgelly bilsNo ratings yet

- Introduction To World Religions Quiz Senior High Lesson 3Document2 pagesIntroduction To World Religions Quiz Senior High Lesson 3King of the Hil100% (3)

- First FruitsDocument32 pagesFirst FruitsRodolfo Babilonia Jr100% (3)

- 951 SignedDocument21 pages951 SignedDany GunawanNo ratings yet

- Plumb Conc.Document28 pagesPlumb Conc.Muhammad AwaisNo ratings yet