Professional Documents

Culture Documents

M50 RCC Grade Mix Design C 400 - 2

M50 RCC Grade Mix Design C 400 - 2

Uploaded by

Er Dnyaneshwar PatilCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wether Reports SepDocument1 pageWether Reports SepEr Dnyaneshwar PatilNo ratings yet

- Surface RegulaDocument5 pagesSurface RegulaEr Dnyaneshwar PatilNo ratings yet

- PQC BlendingDocument6 pagesPQC BlendingEr Dnyaneshwar PatilNo ratings yet

- Batch Report - DeliveryDocument1,138 pagesBatch Report - DeliveryEr Dnyaneshwar PatilNo ratings yet

- Pour Card 2.0Document1 pagePour Card 2.0Er Dnyaneshwar PatilNo ratings yet

- RFI TemplateDocument6 pagesRFI TemplateEr Dnyaneshwar PatilNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Moisture Correction..02Document2 pagesMoisture Correction..02Er Dnyaneshwar PatilNo ratings yet

- Rough Mix Design SummaryDocument3 pagesRough Mix Design SummaryEr Dnyaneshwar PatilNo ratings yet

- M.C DailyDocument1 pageM.C DailyEr Dnyaneshwar PatilNo ratings yet

- Udd FDD Formula KtilDocument105 pagesUdd FDD Formula KtilEr Dnyaneshwar PatilNo ratings yet

- Daily Concrete Gradation RegisterDocument2 pagesDaily Concrete Gradation RegisterEr Dnyaneshwar PatilNo ratings yet

- All Agg - 2Document2 pagesAll Agg - 2Er Dnyaneshwar PatilNo ratings yet

- Daily DLC Gradation RegisterDocument2 pagesDaily DLC Gradation RegisterEr Dnyaneshwar PatilNo ratings yet

- Rfi (Road & Structures) : Structure WorkDocument9 pagesRfi (Road & Structures) : Structure WorkEr Dnyaneshwar PatilNo ratings yet

- Od 224791581829619000Document6 pagesOd 224791581829619000Er Dnyaneshwar PatilNo ratings yet

- Insurance SKU158638468362N9SWDocument5 pagesInsurance SKU158638468362N9SWEr Dnyaneshwar PatilNo ratings yet

- Loan Account Statement For 417rplhy480831Document3 pagesLoan Account Statement For 417rplhy480831Er Dnyaneshwar PatilNo ratings yet

- Traffic Volume Count: Muradpura To Aurangpura Road 8-10-2020 TO 14-10-2020Document1 pageTraffic Volume Count: Muradpura To Aurangpura Road 8-10-2020 TO 14-10-2020Er Dnyaneshwar PatilNo ratings yet

- Od 224972588366409000Document1 pageOd 224972588366409000Er Dnyaneshwar PatilNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceEr Dnyaneshwar PatilNo ratings yet

- Writeup Finalresult JE 2020 English 20052022Document4 pagesWriteup Finalresult JE 2020 English 20052022Er Dnyaneshwar PatilNo ratings yet

- Curriculum Vitae: Anjani KumarDocument6 pagesCurriculum Vitae: Anjani KumarEr Dnyaneshwar PatilNo ratings yet

M50 RCC Grade Mix Design C 400 - 2

M50 RCC Grade Mix Design C 400 - 2

Uploaded by

Er Dnyaneshwar PatilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M50 RCC Grade Mix Design C 400 - 2

M50 RCC Grade Mix Design C 400 - 2

Uploaded by

Er Dnyaneshwar PatilCopyright:

Available Formats

CONCRETE TRIAL MIX DESIGN FOR M-35 GRADE RCC

IS: 10262 - 2019

Trial mix No-01

A-1 STIPULATIONS FOR PROPORTIONING

-

a) Grade designation M 35

-

b) Type of cement OPC 43 grade conforming to IS:8112

-

c) Maximum nominal size of aggregate 20 mm

-

d) Cementitious content 340 (From Table 1700-2 of MORT&H-V)

-

e) Maximum water-cement ratio 0.450 (From Table 1700-2 of MORT&H-V)

-

f) Workability 75 - 125 mm

-

g) Exposure condition Moderate

-

h) Method of concrete placing chute

-

i) Degree of supervision Good

-

j) Type of agggregate Crushed angular aggregate

-

k) Chemical admixture type vista (Superplast HS 500)

-

l) Proposed Cement Content 400 (Chettinad OPC 43 Grade) kg/m3

-

m) Maximum cement content 450 kg/m3 (From Cl. 1703.3 of MORT&H-V)

-

A-2 TEST DATA FOR MATERIALS

-

a) Specific gravity of cement 3.150 Chettinad OPC 43 Grade

-

b) Specific gravity of coarse aggregate-20mm 2.946 KTIL Stone Quarry

-

c) Specific gravity of coarse aggregate-10mm 2.864 KTIL Stone Quarry

-

d) Specific gravity of M Sand 2.771 KTIL Stone Quarry

-

e) Specific gravity of admixture 1.090 (Superplast HS 500)

-

f) Water absorption of coarse aggregate

-

20mm 0.570 %

-

10mm 0.910 %

-

g) Water absorption of M Sand 1.320 %

-

h) Sieve analysis of coarse aggregate Conforming to Table-7 of IS: 383-2016

-

i) Blending ratio of coarse aggregate 60 : 40 (20mm:10mm)

-

j) Sieve analysis of M Sand Conforming to Zone I of Table-9 of IS: 383-20

-

A-3 TARGET STRENGTH FOR MIX PROPORTIONING

-

a) Characteristic strength ( fck ) at 28 days 35 Mpa

-

b) Target mean strength ( fcm ) at 28 days 47 Mpa (From Table 1700-5 of MORT&H-V)

-

A-4 SELECTION OF WATER CEMENT RATIO

-

a) Maximum water-cement ratio 0.450 (From Table 1700-2 of MORT&H-V)

-

b) Adopted water-cement ratio 0.380

-

A-5 CALCULATION OF CEMENT CONTENT

-

a) Adopted water-cement ratio 0.380

-

b) Adopted Cementitious content ### kg/m3

-

A-6 SELECTION OF WATER CONTENT

-

a) Maximum water content for 20mm aggregate 186.00 (From Table 4 of IS:10262-2019)

-

Asper is:10262-2019,Table No-4 Mix.Free water Content 186.00 Litrs

-

for 20 mm aggregate

(for 25 mm to 50 mm range)

Water content can be incresed by 3% per each 25mm

Slump i.e 3% Estimated water content for 125 mm slump 186+9*186/100 =202.74 Litrs

As per Super Plasticzer (vista Superplast HS 500 ) is used in the mix.

The Water content can be Reduced up to 30 percent and above

As per 6.2.4 of IS: 10262-2019

Based on trails with super plasticizer water content reduction

of 25.00 percent has been Achieved.

Hence the achived water content 202.74- 58.42 Litrs = 152.00 Litrs/m3

-

d) Final Water Content 152.00 Litrs/m3

-

A-7 PROPORTION OF VOLUME OF COARSE AGGREGATE AND FINE AGGREGATE CONTENT

a) Volume of coarse aggregate corresponding to -

0.628 (From Table 5 of IS:10262-2019)

20mm size aggregate and fine aggregate (Zone I) -

-

b) Volume of fine aggregate 0.372

-

A-8 CHEMICAL ADMIXTURE

-

a) % of Chemical Admixture 0.85 %

--

b) Chemical Admixture content by mass of cementitious materia 3.40 kg/m3

-

Concessionaire's Independent Engineer's

Representative Representative

MIX CALCULATIONS FOR M-35 GRADE (RCC)

a) Volume of Concrete = 1.000 m3

b) Volume of intrapped air in

= 0.01 m3

wet concrete

c) Volume of cement = Mass of cement 1

x

Specific gravity of cement 1000

400.00 1

x

= 3.15 1000

= 0.127 m3

d) Volume of water = Mass of water 1

x

Specific gravity of water 1000

152.00 1

x

= 1 1000

= 0.152 m3

e) Volume of chemical

= Mass of chemical admixture 1

admixture x

Specific gravity of chemical admixture 1000

3.40 1

x

= 1.090 1000

= 0.003 m3

f) Volume of all in aggregate = (a - b) - (c + d + e )

= 0.990 - 0.127 + 0.152 + 0.003

= 0.708 m3

g) Mass of 20mm aggregate = e x Vol. of CA x Sp. gravity of CA x 1000

= 0.708 x 0.377 x 2.946 x 1000

= ### kg

h) Mass of 10mm aggregate = e x Vol. of CA x Sp. gravity of CA x 1000

= 0.708 x 0.251 x 2.864 x 1000

= ### kg

i) Mass of fine aggregate = e x Vol. of FA x Sp. gravity of FA x 1000

= 0.708 x 0.372 x 2.771 x 1000

= ### kg

Design Mix Proportions

Cement Water 20mm 10mm M sand Admixture W/C Ratio

400 152 786 509 730 3.40 0.380

Concessionaire's Independent Engineer's

Representative Representative

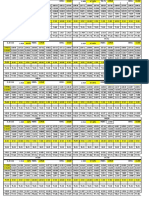

RESULTS OF TRIAL MIX FOR M-35 GRADE (RCC)

Batch Corrected

Moisture

Batch

Moisture Trial Batch

Quantity Water

Specific Adjustment Quantities(Kg)

Material Absorption Material Source

Gravity Content (Volume of Trial Batch =

(SSD) ( % ) Quantity

( % ) ( kg ) 0.040 cum)

(%)

( kg/m3 ) ( kg/m3 )

Cement 400 3.15 - - - - 400 16.00 Chettinad OPC 43 Grade

20mm 786 2.946 0.57 0.00 0.57 4.48 782 31.28 KTIL Stone Quarry

10mm 509 2.864 0.91 0.00 0.91 4.63 504 20.16 KTIL Stone Quarry

M SAND 730 2.771 1.32 0.00 1.32 9.64 720 28.80 KTIL Stone Quarry

Water 152 - - - - 18.75 171 6.84 Bore Well @ KTIL Camp

Chemical

Admixtur 3.40 1.090 - - - - 3.40 0.136 (Superplast HS 500)

e

OBSERVATIONS COMPRESSIVE STRENGTH (Mpa)

Slump (mm) Mix 7 days 10.08.2021 28 days 31.08.2021

Temp Load Strengt Load

Batch Strength

Date 30 60 . Weight h Weight

No Cube

Initial minute minute 90 minutes ( Cube ID (gm) at (gm) at

ID

s s 0

C ) Failure Failure

(MPa)

(KN) (MPa) (KN)

1 9020 901 40.04 4 9086 1250 55.56

2 9005 937 41.64 5 9132 1312 58.31

03.08.202

1 Collapse 190 160 135 29.2

1

3 8965 954 42.40 6 9084 1267 56.31

7 9132 924 41.07 10 9156 1298 57.69

8 8968 965 42.89 11 9174 1300 57.78

9 9008 895 39.78 12 9108 1289 57.29

03.08.202

2 Collapse 185 155 130 28.8 13 8971 946 42.04 16 9187 1295 57.55

1

14 8905 912 40.53 17 9164 1301 57.82

15 9046 956 42.49 18 9098 1299 57.73

Avg. Strength (MPa) 41.43 Avg. Strength (MPa) 57.34

Remarks:_______________________________________________________________________________________________________

_______

Concessionaire's Independent Engineer's

Representative Representative

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Wether Reports SepDocument1 pageWether Reports SepEr Dnyaneshwar PatilNo ratings yet

- Surface RegulaDocument5 pagesSurface RegulaEr Dnyaneshwar PatilNo ratings yet

- PQC BlendingDocument6 pagesPQC BlendingEr Dnyaneshwar PatilNo ratings yet

- Batch Report - DeliveryDocument1,138 pagesBatch Report - DeliveryEr Dnyaneshwar PatilNo ratings yet

- Pour Card 2.0Document1 pagePour Card 2.0Er Dnyaneshwar PatilNo ratings yet

- RFI TemplateDocument6 pagesRFI TemplateEr Dnyaneshwar PatilNo ratings yet

- M 40 PQC With GGBS 340-60Document6 pagesM 40 PQC With GGBS 340-60Er Dnyaneshwar PatilNo ratings yet

- Moisture Correction..02Document2 pagesMoisture Correction..02Er Dnyaneshwar PatilNo ratings yet

- Rough Mix Design SummaryDocument3 pagesRough Mix Design SummaryEr Dnyaneshwar PatilNo ratings yet

- M.C DailyDocument1 pageM.C DailyEr Dnyaneshwar PatilNo ratings yet

- Udd FDD Formula KtilDocument105 pagesUdd FDD Formula KtilEr Dnyaneshwar PatilNo ratings yet

- Daily Concrete Gradation RegisterDocument2 pagesDaily Concrete Gradation RegisterEr Dnyaneshwar PatilNo ratings yet

- All Agg - 2Document2 pagesAll Agg - 2Er Dnyaneshwar PatilNo ratings yet

- Daily DLC Gradation RegisterDocument2 pagesDaily DLC Gradation RegisterEr Dnyaneshwar PatilNo ratings yet

- Rfi (Road & Structures) : Structure WorkDocument9 pagesRfi (Road & Structures) : Structure WorkEr Dnyaneshwar PatilNo ratings yet

- Od 224791581829619000Document6 pagesOd 224791581829619000Er Dnyaneshwar PatilNo ratings yet

- Insurance SKU158638468362N9SWDocument5 pagesInsurance SKU158638468362N9SWEr Dnyaneshwar PatilNo ratings yet

- Loan Account Statement For 417rplhy480831Document3 pagesLoan Account Statement For 417rplhy480831Er Dnyaneshwar PatilNo ratings yet

- Traffic Volume Count: Muradpura To Aurangpura Road 8-10-2020 TO 14-10-2020Document1 pageTraffic Volume Count: Muradpura To Aurangpura Road 8-10-2020 TO 14-10-2020Er Dnyaneshwar PatilNo ratings yet

- Od 224972588366409000Document1 pageOd 224972588366409000Er Dnyaneshwar PatilNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceEr Dnyaneshwar PatilNo ratings yet

- Writeup Finalresult JE 2020 English 20052022Document4 pagesWriteup Finalresult JE 2020 English 20052022Er Dnyaneshwar PatilNo ratings yet

- Curriculum Vitae: Anjani KumarDocument6 pagesCurriculum Vitae: Anjani KumarEr Dnyaneshwar PatilNo ratings yet