Professional Documents

Culture Documents

Regenerative Research 1-1-2012!58!61 MAT

Regenerative Research 1-1-2012!58!61 MAT

Uploaded by

Pranesh MCopyright:

Available Formats

You might also like

- Specifications: Carbon DioxideDocument2 pagesSpecifications: Carbon DioxideShofi100% (1)

- PP Topas Blend Mech PropertiesDocument7 pagesPP Topas Blend Mech PropertiesmnsticksNo ratings yet

- Performance Recycled ThermoplasticsDocument6 pagesPerformance Recycled ThermoplasticsEmani V R Murthy100% (1)

- 02 23413 Abedalwafa PDFDocument18 pages02 23413 Abedalwafa PDFJabid LoteroNo ratings yet

- 1 s2.0 S2211379720319847 MainDocument7 pages1 s2.0 S2211379720319847 MaindavidemeulliNo ratings yet

- Microfisura, GranularDocument22 pagesMicrofisura, GranularDardo OdelloNo ratings yet

- Cunha 2023 Smart Mater. Struct. 32 085016Document13 pagesCunha 2023 Smart Mater. Struct. 32 085016moacy.silvaNo ratings yet

- Porosity Measurement MethodsDocument18 pagesPorosity Measurement MethodsmahaNo ratings yet

- Membrane Bioreactor TMP Rise and Characterization of Biocake Structure Using CLSM Image Analysis PDFDocument9 pagesMembrane Bioreactor TMP Rise and Characterization of Biocake Structure Using CLSM Image Analysis PDFmwflatleyNo ratings yet

- Li 2010Document13 pagesLi 2010O LNo ratings yet

- A Review of Stimuli-Responsive Shape Memory Polymer CompositesDocument24 pagesA Review of Stimuli-Responsive Shape Memory Polymer CompositesHozefa DhilaNo ratings yet

- 68 - FTIR-ATR Spectroscopic, Thermal and Microstructural Studies On Polypropylene-Glass Fiber CompositesDocument8 pages68 - FTIR-ATR Spectroscopic, Thermal and Microstructural Studies On Polypropylene-Glass Fiber Compositesayoub fsaNo ratings yet

- Research Articles: Sequence-Controlled PolymersDocument8 pagesResearch Articles: Sequence-Controlled PolymersValentina OssaNo ratings yet

- Feature: JournalDocument12 pagesFeature: JournalmahbubeNo ratings yet

- JMSR2539691664569800Document13 pagesJMSR2539691664569800rezaferidooni00No ratings yet

- A Critical Review of Fracture MechanicsDocument27 pagesA Critical Review of Fracture MechanicsVujadin AleksicNo ratings yet

- Dissertation PolymereDocument8 pagesDissertation PolymerePaperWritingHelpOnlineCanada100% (1)

- Computers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoDocument11 pagesComputers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoAnimo- CityNo ratings yet

- (2008) Microporous Membranes Obtained From Polypropylene Blend Films by StretchingDocument11 pages(2008) Microporous Membranes Obtained From Polypropylene Blend Films by StretchingsateeshbondaNo ratings yet

- Pinar Yilgor Et Al - 3D Plotted PCL Scaffolds For Stem Cell Based Bone Tissue EngineeringDocument8 pagesPinar Yilgor Et Al - 3D Plotted PCL Scaffolds For Stem Cell Based Bone Tissue EngineeringHutsDMNo ratings yet

- Effect of Micro-Mold Cavity Dimension On Structure and Property of Polylactic Acid/Polycaprolactone Blend Under Microinjection Molding ConditionsDocument20 pagesEffect of Micro-Mold Cavity Dimension On Structure and Property of Polylactic Acid/Polycaprolactone Blend Under Microinjection Molding ConditionsMaialen Espinal ViguriNo ratings yet

- AIChE Journal - 2015 - ZhangDocument15 pagesAIChE Journal - 2015 - ZhangShardul RahatadeNo ratings yet

- Nano Fibrous Scaffolds ElectrospunDocument10 pagesNano Fibrous Scaffolds Electrospuninfo.pz7497No ratings yet

- Papaleo 2009Document11 pagesPapaleo 2009Joel Montalvo AcostaNo ratings yet

- 2023 Periodica 67 2023 232 241 E1709Document10 pages2023 Periodica 67 2023 232 241 E1709alina.tlekkabylova270202No ratings yet

- Use of Multiscale Zirconium Alloy Deformation Models - 2017 - Journal of ComputaDocument23 pagesUse of Multiscale Zirconium Alloy Deformation Models - 2017 - Journal of ComputaMedina PabloNo ratings yet

- Thermal Analysis On Characterization of Polycaprolactone (PCL) - Chitosan Scaffold For Tissue EngineeringDocument5 pagesThermal Analysis On Characterization of Polycaprolactone (PCL) - Chitosan Scaffold For Tissue Engineeringijsret100% (1)

- The Journal of Supercritical FluidsDocument9 pagesThe Journal of Supercritical FluidsMarco D'AntuonoNo ratings yet

- FEBS Letters - 2020 - Turk - The Promise and The Challenges of Cryo Electron TomographyDocument19 pagesFEBS Letters - 2020 - Turk - The Promise and The Challenges of Cryo Electron Tomographyyaraloay2020No ratings yet

- Jamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesDocument8 pagesJamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesHutsDMNo ratings yet

- Fracture Mechanics of Protein Materials: mbuehler@MIT - EDUDocument13 pagesFracture Mechanics of Protein Materials: mbuehler@MIT - EDUMohd NashriqNo ratings yet

- 1 s2.0 S0142961212000944 MainDocument11 pages1 s2.0 S0142961212000944 Main도경민No ratings yet

- Reniers - 2019 - J. - Electrochem. - Soc. - 166 - A3189 Review and Performance Comparison of Mechanical-Chemical Degradation of LIbDocument13 pagesReniers - 2019 - J. - Electrochem. - Soc. - 166 - A3189 Review and Performance Comparison of Mechanical-Chemical Degradation of LIbJerry WuNo ratings yet

- A Generic Microstructure-Explicit Model of Creep IDocument11 pagesA Generic Microstructure-Explicit Model of Creep IVenkatesh PandianNo ratings yet

- Mechanical Strength and Biocompatibility of Bredigite (Ca7MgSi4O16)Document8 pagesMechanical Strength and Biocompatibility of Bredigite (Ca7MgSi4O16)Jean AndradeNo ratings yet

- 2022 Interpretable Machine Learning For KnowledgeDocument10 pages2022 Interpretable Machine Learning For KnowledgekeyachemNo ratings yet

- The 3D Structure of Real Polymer FoamsDocument10 pagesThe 3D Structure of Real Polymer FoamsArun SundarNo ratings yet

- Materials & Design: ArticleinfoDocument9 pagesMaterials & Design: ArticleinfoAadelNo ratings yet

- Photosensitive Biodegrable Polymers For Tissue Engineering ApplicationsDocument8 pagesPhotosensitive Biodegrable Polymers For Tissue Engineering ApplicationsPor una Patria NuevaNo ratings yet

- Journal Pre-Proof: Journal of Molecular StructureDocument21 pagesJournal Pre-Proof: Journal of Molecular StructureraulNo ratings yet

- Art:10.1140/epje/e2005 00021 2Document8 pagesArt:10.1140/epje/e2005 00021 2Matthew LeachNo ratings yet

- Macro Materials Eng - 2021 - Kong - Control of Polymer Properties by Entanglement A ReviewDocument20 pagesMacro Materials Eng - 2021 - Kong - Control of Polymer Properties by Entanglement A Reviewhuac5828No ratings yet

- Pauza 2021Document35 pagesPauza 2021Harris DanielNo ratings yet

- Materials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdDocument10 pagesMaterials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdJabid LoteroNo ratings yet

- 1 s2.0 S0093641318306244 MainDocument12 pages1 s2.0 S0093641318306244 MainBaykal AltayNo ratings yet

- Dynamic Roughness APFDocument12 pagesDynamic Roughness APFJoaquinNo ratings yet

- Moha Patra 2011Document14 pagesMoha Patra 2011sssdaitNo ratings yet

- Collagen Structures Fabricated by Laser Direct Writing Via Two-Photon Polymerization For Enhanced OsteogenesisDocument18 pagesCollagen Structures Fabricated by Laser Direct Writing Via Two-Photon Polymerization For Enhanced Osteogenesispopescu vasilicaNo ratings yet

- Core-Shell Nanoparticle Interface and Wetting PropertiesDocument9 pagesCore-Shell Nanoparticle Interface and Wetting PropertiesDulce GradillaNo ratings yet

- AP IR VH - PE Au - Pol21Document28 pagesAP IR VH - PE Au - Pol21Vangelis HarmandarisNo ratings yet

- Deformation and Failure in Semi-Crystalline Polymer SystemsDocument53 pagesDeformation and Failure in Semi-Crystalline Polymer SystemsMuhammad AhmadNo ratings yet

- Lattice Boltzmann Method Development of PEMFC in MDocument6 pagesLattice Boltzmann Method Development of PEMFC in Memonome2190No ratings yet

- 05 05 PDFDocument10 pages05 05 PDFghoul chemistNo ratings yet

- Polymer: D. Hossain, M.A. Tschopp, D.K. Ward, J.L. Bouvard, P. Wang, M.F. HorstemeyerDocument13 pagesPolymer: D. Hossain, M.A. Tschopp, D.K. Ward, J.L. Bouvard, P. Wang, M.F. Horstemeyer张宏No ratings yet

- 4 - Analysis of Wind Turbine Blades Aeroelastic Performance Under Yaw ConditionsDocument12 pages4 - Analysis of Wind Turbine Blades Aeroelastic Performance Under Yaw ConditionsMayra ZezattiNo ratings yet

- (2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerDocument13 pages(2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerIsabel CamusNo ratings yet

- Article Relationships Material Properties PDFDocument24 pagesArticle Relationships Material Properties PDFeduardo_umNo ratings yet

- Isotropically Small Crystalline Lamellae Induced by High Biaxial-Stretching Rate As A Key Microstructure For Super-Tough Polylactide FilmDocument12 pagesIsotropically Small Crystalline Lamellae Induced by High Biaxial-Stretching Rate As A Key Microstructure For Super-Tough Polylactide FilmLong LeNo ratings yet

- 1 s2.0 S0264127516301071 MainDocument13 pages1 s2.0 S0264127516301071 MainHouda FoulahNo ratings yet

- Biocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodDocument10 pagesBiocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodSreedhar PugalendhiNo ratings yet

- Biomimetic Principles and Design of Advanced Engineering MaterialsFrom EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNo ratings yet

- CTC Continuous Transposed Cable 2017 2 PDFDocument5 pagesCTC Continuous Transposed Cable 2017 2 PDFNishikanta MallickNo ratings yet

- Topic 3 - Strength Analysis of Beams According To ACI Code PDFDocument17 pagesTopic 3 - Strength Analysis of Beams According To ACI Code PDFRea May De La TorreNo ratings yet

- UG Pipe CheckingDocument6 pagesUG Pipe Checkingnoto.sugiartoNo ratings yet

- Department of Chemical and Environmental Engineering Universiti Putra MalaysiaDocument15 pagesDepartment of Chemical and Environmental Engineering Universiti Putra MalaysiaMohd Azman SuwandiNo ratings yet

- Porvair Sinterflo Brochure - UKDocument8 pagesPorvair Sinterflo Brochure - UKAndrew HillNo ratings yet

- Soil MCQsDocument16 pagesSoil MCQsAli Raza100% (1)

- Boiling Heat TransferDocument8 pagesBoiling Heat TransferHaidarNo ratings yet

- Surface TextureDocument53 pagesSurface TextureJayant SisodiaNo ratings yet

- Piping Theory As Per ASME B31.3 PROCESS PIPINGDocument107 pagesPiping Theory As Per ASME B31.3 PROCESS PIPINGDeen first sdiNo ratings yet

- Design of PurlinsDocument7 pagesDesign of Purlinsjiyad100% (1)

- Panfleto 165-2017 - Instrumentation For Chlorine ServiceDocument30 pagesPanfleto 165-2017 - Instrumentation For Chlorine ServiceLucas OliverNo ratings yet

- Atomic Absorption Spectrophotometry Cookbook Section 1Document25 pagesAtomic Absorption Spectrophotometry Cookbook Section 1Absheen ZamanNo ratings yet

- Structural Steel DesignDocument8 pagesStructural Steel DesignNassim SabriNo ratings yet

- Vickers Hardness TestDocument9 pagesVickers Hardness TestMoiz Amir100% (1)

- Astm A106 A106m 19Document6 pagesAstm A106 A106m 19Milady OyuelaNo ratings yet

- 8008 1 PDFDocument6 pages8008 1 PDFraji357No ratings yet

- Frigaard2017 Article BinghamSModelInTheOilAndGasIndDocument24 pagesFrigaard2017 Article BinghamSModelInTheOilAndGasIndCoolProphetNo ratings yet

- Tai Lieu SV AV2Document54 pagesTai Lieu SV AV2nguyenthanhtruc01060209No ratings yet

- Boiler ManualDocument22 pagesBoiler Manualengrasadullah000No ratings yet

- MSDS SUN Combi. S-321Document5 pagesMSDS SUN Combi. S-321kunalNo ratings yet

- Chemplasa Ebs L-205F-TdsDocument1 pageChemplasa Ebs L-205F-TdsÁnh Nguyễn100% (1)

- Stress-Strain Behavior Concrete Confined Overlapping Hoops Strain Rates PDFDocument15 pagesStress-Strain Behavior Concrete Confined Overlapping Hoops Strain Rates PDFMaqMaikNo ratings yet

- Design of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000Document4 pagesDesign of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000MaheshNo ratings yet

- BRM Flex Hone Catalog 2011Document64 pagesBRM Flex Hone Catalog 2011altexsteveNo ratings yet

- P BLOCK Class 12Document26 pagesP BLOCK Class 12Parth BajajNo ratings yet

- Welding FLAWSDocument86 pagesWelding FLAWSrohitbhat2345100% (1)

- Investigation 6b eDocument12 pagesInvestigation 6b eMBOTAKE LawsonNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Bunker Fuel Oil Specifications2010Document5 pagesBunker Fuel Oil Specifications2010onejako12No ratings yet

Regenerative Research 1-1-2012!58!61 MAT

Regenerative Research 1-1-2012!58!61 MAT

Uploaded by

Pranesh MOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Regenerative Research 1-1-2012!58!61 MAT

Regenerative Research 1-1-2012!58!61 MAT

Uploaded by

Pranesh MCopyright:

Available Formats

Regenerative Research 1(1) 2012 58-61

MATHEMATICAL MODELING ON DEGRADATION OF 3D TISSUE ENGINEERING

SCAFFOLD MATERIALS

Hoque ME*, Yong LC, Ian P

Department of Mechanical, Materials and Manufacturing Engineering

University of Nottingham Malaysia Campus

ARTICLE INFO ABSTRACT

Computer simulation could be a novel approach to inspect biomaterials for tissue

Submitted: 29-02-2012 engineering applications. This study performs a mathematical simulation on 3D scaffold to

Accepted: 24-05-2012 investigate their degradation behaviors.

*Corresponding Author: Md Enamul

Hoque Scaffold models consisted of various biopolymers were investigated. Polycaprolactone

(PCL), poly(lactic-co-glycolic acid) (PLGA), poly(lactic acid) (PLA), and polyethylene

Email:

glycol (PEG) were taken into consideration to build the scaffold models. The in vitro

Enamul.Hoque@nottingham.edu.my

degradation rate and change in molecular weight with respect to time were investigated for

different scaffold models. The simulation was performed using MATLAB R2010b

(MathWorks).

KEYWORDS Upon degradation, the molecular weights of the scaffolds were changed significantly. The

results indicate that the scaffolds’ material nature influence the degradation rate and

lifetime. This simulation results help to predict the scaffold life span, and ultimately to

Computational Model, select an optimal design of a scaffold for particular tissue engineering application.

Tissue Engineering,

Scaffold, The type of biopolymer and their degradation rate play significant role in determining

Degradation, optimal scaffold for tissue engineering applications. Mathematical modelling has the

Biopolymer potential to generate a statistically perfect instant molecular weight decay curve. Scaffolds

may also be optimized to suit site-specific loading requirements indicating the need for

greater control over scaffold manufacturing techniques.

1.0 Introduction for the growth of cells and tissues in growth [6-7]. So far,

there is no systematic study that has been conducted alone to

There is a persistent challenge associated with the modeling, assess how the exact match of mechanical properties is indeed

design and fabrication of tissue engineering scaffolds to meet crucial for optimal tissue regeneration [8]. For instance, since

various biological and biophysical conditions in regenerative mechanical properties are intimately related to the porosity of

tissues. For example, designing load bearing scaffolds for porous structures, a stiffer and less porous scaffold will

bone and cartilage tissue applications is a complicated process provide a better integration with the surrounding natural

[1-5]. Bone and cartilage tissue scaffolds usually have tissues, or a more flexible and porous one will allow cells to

complex architecture, porosity, pore size, shape, and attach and proliferate in a more efficient way [9-10].

interconnectivity in order to provide the needed structural

integrity, strength, transport, and an ideal micro-environment So far in this research, most of the interactions between

biomaterials and scaffolds are simulated through the

Regenerative Research Vol1 Issue1 June 2012 58

definition of structure properties, such as scaffold stiffness or calculated by mathematical software, MATLAB R2010b

pore size [11-12]. In tissue engineering (TE) scaffolds (MathWorks) for any particular biopolymer. In simulation

design, the possibilities of scaffolds design are huge. procedures, all MW and degradation rate constants were taken

Computer models can only be as good as the input data, into consideration [15-16] to calculate the effective rate

which need to be sufficient. More experimental tests and constant for degradation of each polymer.

biological information are needed to validate scaffold design

more precisely. Therefore, it becomes necessary to include 3.0 Results and Discussion

such properties in a computer model to model effectively the

integration between biomaterials and surrounding tissues. The degradation kinetic is biphasic; the first phase of

degradation occurs by diffusion of water to the amorphous

Based on literature review done so far, we have found that regions and subsequent hydrolysis. The second phase begins

limited studies have performed degradation of TE scaffold. So as water penetrates and hydrolyzes the more crystalline

far, only simulations of a perfusion bioreactor and basic regions. The degree of crystallinity of the polymer is

mechanical studies have been investigated [13-14]. By potentially important because it is generally recognized that

understanding the degradation characteristics which are hydrolysis is restricted to the amorphous phase of the

optimal for each of these scaffolds, we will be able to design polymer. However, the similar crystallinities of the materials

better scaffolds by customizing specific design of the scaffold used in this study would appear to rule out a morphological

for each material type. This paper mainly presents the explanation for the rate differences.

degradation rate and lifetime prediction of biopolymers by

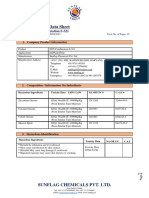

mathematical model. Table 1 Chemical structure and microstructure of biodegradable polymers

2.0 Materials and Methods

Biodegradable polymer Microstructure

The pre-assumptions of the simulation process are that the

entire samples are dried, dissolved, and the molecular weights Poly(lactic acid) (PLA)

of chains in the samples are calculated. The bulk polymer in Semicrystalline

surface-eroding polymers remains unaffected during

degradation; only the surface-attacked polymer is degraded.

Here, we assumed that the entire polymer is experiencing a

reduction in molecular weight; this is the characteristic feature

Polycaprolactone (PCL)

of bulk erosion.

Semicrystalline

In degradation analysis, the rate of degradation can be

expressed as functions of mass and time, i.e.

M = M0e-kt (1) Polyethylene glycol (PEG)

Where, M and Mo are the initial and final masses of the Semicrystalline

polymer, k is degradation rate constant and t is time,

respectively.

Poly(lactide-co-glycolide) (PLGA)

The useful lifetime of biopolymer can be expressed as

Amorphous

functions of change toward the critical molecular weight

(MW) i.e.

MW = MW0e-kt (2)

MW is molecular weight of the biopolymer and MWo is the

Table 1 shows the chemical structures and microstructures of

critical molecular weight and t is the useful lifetime of the

biodegradable polymers. The kinetic of MW change is used to

polymer.

determine when the materials have degraded to completely

Based on the rate equations for scaffold degradation soluble products —this is by far the longest possible time the

described, mathematical simulation for biomaterials samples could serve as a scaffold. The biodegradation

degradation properties was conducted. Hence, the value of properties of polylactide (PLA), polycaprolactone (PCL),

MW change and useful lifetime of the biopolymer can be polyethylene glycol (PEG) and poly(lactide-co-glycolide)

(PLGA) are summarised in Table 2. Simulation results reveal

Regenerative Research Vol1 Issue1 June 2012 59

that these materials rank in terms of their rate of degradation 1.9 x 10-3 hr-1. PLGA degrades because the mixture of lactide

as follows: PLA < PCL < PEG < PLGA. and glycolide repeat units in the chain prevents

Table 2 Comparison of biomaterials’ degradation properties

Critical Mw to be

Degradation rate constant Initial Mw wt Maximum useful

Polymers eliminated

/ hr-1 /kDa lifetime (years)

/kDa

PCL 9.65 x 10-5 5 61.8 3

PLGA 1.9 x 10-3 1.2 24.6 66 days

PLA 7.4 x 10-5 5 10.8 3.2

PEG 6 x 10-4 4 10 63 days

This ranking can be rationalized via the chemical and crystallization, which is more readily attacked by water. Due

physicochemical factors that control degradation rates. All of to the dependence of the degradation rate of PLGA

the materials are comprised of degradable ester linkages; copolymers on pH, a phenomenon known as autocatalysis

biopolymers cannot be differentiated based on purely bond occurs where the carboxylic group further induces

differences. The two slowest-degrading materials have a degradation. For large-scale polymers, autocatalysis causes

number of factors lowering their degradation rate. They are heterogeneous degradation where the pH decreases in the

both semicrystalline –PCL and PLA, which are much more center of the polymer, and a difference in the degradation rate

quickly degraded than the other materials due to the greatly are created.

enhanced entry of water into the hydrophilic domains.

PCL is aliphatic polyester which has been shown to degrade

by random hydrolytic separate from its ester groups, and

under certain circumstances, by enzymatic degradation. There

is a linear relationship between weight loss and lactic acid

release suggesting surface erosion. It is similar to PLA in that,

it degrades into a critical MW of 5000 as shown in Figure 1.

However, PCL degrades a bit slower than PLA. The

degradation rate constant for PCL and PLA are 9.65 x 10-5 hr-

1

and 7.4 x 10-5 hr-1, respectively. For PCL and PLA, too little

degradation occurs over the time. Therefore, these materials

can serve more than 3 years.

PEG is a highly hydrophilic, linear, unsaturated polymer

composed of alternating PEG. PEG block gives its

hydrophilicity. In addition, the properties of PEG are Fig. 1 Percentage weight loss vs time for degradation of PLGA, PCL, PLA

controlled by the molecular weight of the PEG. and PEG

Increase of MW of PEG results in less crosslinking. The MW This estimated time is clearly far-outside limit of useful

of PEG here is 10000, and the degradation rate constant is 6 x lifetime. Any real device will lose mechanical integrity

10-4 hr -1. significantly before the MW have degraded to this extreme

limit, and thus the actual lifetime in many applications may be

The final type of biopolymer discussed, PLGA is the significantly shorter. These results provide a platform to

copolymer of PGA and PLA. PGA is highly crystalline, predict and optimize scaffolds’ biodegradation kinetics, thus

hydrophilic, linear aliphatic polyester. As such, it has a high reducing the number of experimental studies necessary to

melting point and a relatively low solubility in most common validate design performance. Experimentally validating this

organic solvents. The degradation rate constant of PLGA is

Regenerative Research Vol1 Issue1 June 2012 60

model would involve implanting a scaffold into a bone defect 6) Hutmacher DW. Scaffolds in tissue engineering bone and

in an animal model and making histological measurements of cartilage. Biomaterials. 2000; 21: 2529-43.

tissue phenotype at several time points.

7) Hoque, M. E., Chuan, Y. L. & Pashby, I. Extrusion based

4.0 Conclusion rapid prototyping technique - An advanced platform for tissue

engineering scaffold fabrication. Biopolymers. 2012; 97: 83.

The results presented in this paper show that the type of

biopolymer and their degradation rate play significant role in 8) Moroni L, Schotel R, Sohier J, de Wijn JR, van Blitterswijk

determining optimal scaffold for TE applications. CA. Polymer hollow fiber three-dimensional matrices with

Mathematical modelling has the potential to generate a controllable cavity and shell thickness. Biomaterials. 2006;

statistically perfect instant molecular weight decay curve. 27: 5918-26.

Scaffolds may also be optimized to suit site-specific loading

9) Cioffi M, Galbusera F, Raimondi MT. An in silico

requirements indicating the need for greater control over

bioreactor for simulating laboratory experiments in tissue

scaffold manufacturing techniques. The future of

engineering. Biomed Microdevices. 2008; 10: 547-54.

computational models applied to TE is very promising with

the establishment of more powerful and realistic models that

10) Hoque, M. E., Chuan, Y. L., Pashby, I., Hwei, A. N. M. &

can simulate more accurately the biological processes. In the

Idrus, R. Process Optimization to Improve the Processing of

future, degradation studies of the TE scaffolds are needed to

Poly(DL-Lactide-co-Glycolide) into 3D Tissue Engineering

simulate the dynamic loading conditions of the in vitro

Scaffolds. International Federation for Medical and Biological

system. The degradation properties are important for

Engineering. 2011; 35: 836.

predicting the lifetime of biomaterials and components.

Accelerated tests are available to help understand the aging 11) Kerl, J., Parittotokkaporn, T., Frasson, L., Oldfield, M.,

processes in materials under a variety of conditions. With Rodriguez Y Baena, F. & Beyrau, F. Tissue deformation

special attention to scaffold design and rapid prototyping analysis using a laser based digital image correlation

technique, scaffold could be fabricated successfully for technique. Journal of the Mechanical Behavior of Biomedical

further cell culture and animal tests. Materials. 2012; 6: 159-165.

References 12) Erdemir, A., Guess, T. M., Halloran, J., Tadepalli, S. C. &

Morrison, T. M. Considerations for reporting finite element

1) Melchels FPW, Bertoldi K, Gabbrielli R, Velders AH, analysis studies in biomechanics. Journal of Biomechanics.

Feijen J, Grijpma DW. Mathematically defined tissue (In press)

engineering scaffold architectures prepared by

stereolithography. Biomaterials. 2010; 31: 6909-16. 13) Sandino C, Planell JA, Lacroix D. A finite element study

of mechanical stimuli in scaffolds for bone tissue engineering.

2) Liao J, Guo X, Grande-Allen KJ, Kasper FK, Mikos AG. J Biomech. 2008; 41: 1005-14.

Bioactive polymer/extracellular matrix scaffolds fabricated

with a flow perfusion bioreactor for cartilage tissue 14) Pitt CG, Zhong-wei G. Modification of the rates of chain

engineering. Biomaterials. 2010; 31: 8911-20. cleavage of poly([epsilon]-caprolactone) and related

polyesters in the solid state. J Control Release. 1987; 4: 283-

3) Jeong CG, Hollister SJ. A comparison of the influence of 92.

material on in vitro cartilage tissue engineering with PCL,

PGS, and POC 3D scaffold architecture seeded with 15) Shiaw-Guang Hu D, Liu H-J. Effect of soft segment on

chrondrocytes. Biomaterials. 2010;31:4304-12. degradation kinetics in polyethylene glycol/poly(l-lactide)

block copolymers. Polymer Bulletin. 1993; 30: 669-76.

4) Dai W, Kawazoe N, Lin X, Dong J, Chen G. The influence

of structural design of PLGA/collagen hybrid scaffolds in 16) Suggs LJ, Moore SA, Mikos AG. In: Mark JE, editor.

cartilage tissue engineering. Biomaterials. 2010; 31: 2141-52. Physical Properties of Polymers Handbook. Cincinnati:

Springer Science. 2007.

5) Drury JL, Mooney DJ. Hydrogels for tissue engineering:

scaffold design variables and applications. Biomaterials.

2003; 24: 4337-51.

Regenerative Research Vol1 Issue1 June 2012 61

You might also like

- Specifications: Carbon DioxideDocument2 pagesSpecifications: Carbon DioxideShofi100% (1)

- PP Topas Blend Mech PropertiesDocument7 pagesPP Topas Blend Mech PropertiesmnsticksNo ratings yet

- Performance Recycled ThermoplasticsDocument6 pagesPerformance Recycled ThermoplasticsEmani V R Murthy100% (1)

- 02 23413 Abedalwafa PDFDocument18 pages02 23413 Abedalwafa PDFJabid LoteroNo ratings yet

- 1 s2.0 S2211379720319847 MainDocument7 pages1 s2.0 S2211379720319847 MaindavidemeulliNo ratings yet

- Microfisura, GranularDocument22 pagesMicrofisura, GranularDardo OdelloNo ratings yet

- Cunha 2023 Smart Mater. Struct. 32 085016Document13 pagesCunha 2023 Smart Mater. Struct. 32 085016moacy.silvaNo ratings yet

- Porosity Measurement MethodsDocument18 pagesPorosity Measurement MethodsmahaNo ratings yet

- Membrane Bioreactor TMP Rise and Characterization of Biocake Structure Using CLSM Image Analysis PDFDocument9 pagesMembrane Bioreactor TMP Rise and Characterization of Biocake Structure Using CLSM Image Analysis PDFmwflatleyNo ratings yet

- Li 2010Document13 pagesLi 2010O LNo ratings yet

- A Review of Stimuli-Responsive Shape Memory Polymer CompositesDocument24 pagesA Review of Stimuli-Responsive Shape Memory Polymer CompositesHozefa DhilaNo ratings yet

- 68 - FTIR-ATR Spectroscopic, Thermal and Microstructural Studies On Polypropylene-Glass Fiber CompositesDocument8 pages68 - FTIR-ATR Spectroscopic, Thermal and Microstructural Studies On Polypropylene-Glass Fiber Compositesayoub fsaNo ratings yet

- Research Articles: Sequence-Controlled PolymersDocument8 pagesResearch Articles: Sequence-Controlled PolymersValentina OssaNo ratings yet

- Feature: JournalDocument12 pagesFeature: JournalmahbubeNo ratings yet

- JMSR2539691664569800Document13 pagesJMSR2539691664569800rezaferidooni00No ratings yet

- A Critical Review of Fracture MechanicsDocument27 pagesA Critical Review of Fracture MechanicsVujadin AleksicNo ratings yet

- Dissertation PolymereDocument8 pagesDissertation PolymerePaperWritingHelpOnlineCanada100% (1)

- Computers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoDocument11 pagesComputers and Structures: M. de Giorgi, A. Carofalo, V. Dattoma, R. Nobile, F. PalanoAnimo- CityNo ratings yet

- (2008) Microporous Membranes Obtained From Polypropylene Blend Films by StretchingDocument11 pages(2008) Microporous Membranes Obtained From Polypropylene Blend Films by StretchingsateeshbondaNo ratings yet

- Pinar Yilgor Et Al - 3D Plotted PCL Scaffolds For Stem Cell Based Bone Tissue EngineeringDocument8 pagesPinar Yilgor Et Al - 3D Plotted PCL Scaffolds For Stem Cell Based Bone Tissue EngineeringHutsDMNo ratings yet

- Effect of Micro-Mold Cavity Dimension On Structure and Property of Polylactic Acid/Polycaprolactone Blend Under Microinjection Molding ConditionsDocument20 pagesEffect of Micro-Mold Cavity Dimension On Structure and Property of Polylactic Acid/Polycaprolactone Blend Under Microinjection Molding ConditionsMaialen Espinal ViguriNo ratings yet

- AIChE Journal - 2015 - ZhangDocument15 pagesAIChE Journal - 2015 - ZhangShardul RahatadeNo ratings yet

- Nano Fibrous Scaffolds ElectrospunDocument10 pagesNano Fibrous Scaffolds Electrospuninfo.pz7497No ratings yet

- Papaleo 2009Document11 pagesPapaleo 2009Joel Montalvo AcostaNo ratings yet

- 2023 Periodica 67 2023 232 241 E1709Document10 pages2023 Periodica 67 2023 232 241 E1709alina.tlekkabylova270202No ratings yet

- Use of Multiscale Zirconium Alloy Deformation Models - 2017 - Journal of ComputaDocument23 pagesUse of Multiscale Zirconium Alloy Deformation Models - 2017 - Journal of ComputaMedina PabloNo ratings yet

- Thermal Analysis On Characterization of Polycaprolactone (PCL) - Chitosan Scaffold For Tissue EngineeringDocument5 pagesThermal Analysis On Characterization of Polycaprolactone (PCL) - Chitosan Scaffold For Tissue Engineeringijsret100% (1)

- The Journal of Supercritical FluidsDocument9 pagesThe Journal of Supercritical FluidsMarco D'AntuonoNo ratings yet

- FEBS Letters - 2020 - Turk - The Promise and The Challenges of Cryo Electron TomographyDocument19 pagesFEBS Letters - 2020 - Turk - The Promise and The Challenges of Cryo Electron Tomographyyaraloay2020No ratings yet

- Jamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesDocument8 pagesJamie L Ifkovits, Robert F Padera and Jason A Burdick - Biodegradable and Radically Polymerized Elastomers With Enhanced Processing CapabilitiesHutsDMNo ratings yet

- Fracture Mechanics of Protein Materials: mbuehler@MIT - EDUDocument13 pagesFracture Mechanics of Protein Materials: mbuehler@MIT - EDUMohd NashriqNo ratings yet

- 1 s2.0 S0142961212000944 MainDocument11 pages1 s2.0 S0142961212000944 Main도경민No ratings yet

- Reniers - 2019 - J. - Electrochem. - Soc. - 166 - A3189 Review and Performance Comparison of Mechanical-Chemical Degradation of LIbDocument13 pagesReniers - 2019 - J. - Electrochem. - Soc. - 166 - A3189 Review and Performance Comparison of Mechanical-Chemical Degradation of LIbJerry WuNo ratings yet

- A Generic Microstructure-Explicit Model of Creep IDocument11 pagesA Generic Microstructure-Explicit Model of Creep IVenkatesh PandianNo ratings yet

- Mechanical Strength and Biocompatibility of Bredigite (Ca7MgSi4O16)Document8 pagesMechanical Strength and Biocompatibility of Bredigite (Ca7MgSi4O16)Jean AndradeNo ratings yet

- 2022 Interpretable Machine Learning For KnowledgeDocument10 pages2022 Interpretable Machine Learning For KnowledgekeyachemNo ratings yet

- The 3D Structure of Real Polymer FoamsDocument10 pagesThe 3D Structure of Real Polymer FoamsArun SundarNo ratings yet

- Materials & Design: ArticleinfoDocument9 pagesMaterials & Design: ArticleinfoAadelNo ratings yet

- Photosensitive Biodegrable Polymers For Tissue Engineering ApplicationsDocument8 pagesPhotosensitive Biodegrable Polymers For Tissue Engineering ApplicationsPor una Patria NuevaNo ratings yet

- Journal Pre-Proof: Journal of Molecular StructureDocument21 pagesJournal Pre-Proof: Journal of Molecular StructureraulNo ratings yet

- Art:10.1140/epje/e2005 00021 2Document8 pagesArt:10.1140/epje/e2005 00021 2Matthew LeachNo ratings yet

- Macro Materials Eng - 2021 - Kong - Control of Polymer Properties by Entanglement A ReviewDocument20 pagesMacro Materials Eng - 2021 - Kong - Control of Polymer Properties by Entanglement A Reviewhuac5828No ratings yet

- Pauza 2021Document35 pagesPauza 2021Harris DanielNo ratings yet

- Materials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdDocument10 pagesMaterials Science and Engineering C: Stephen R. Baker, Soham Banerjee, Keith Bonin, Martin GutholdJabid LoteroNo ratings yet

- 1 s2.0 S0093641318306244 MainDocument12 pages1 s2.0 S0093641318306244 MainBaykal AltayNo ratings yet

- Dynamic Roughness APFDocument12 pagesDynamic Roughness APFJoaquinNo ratings yet

- Moha Patra 2011Document14 pagesMoha Patra 2011sssdaitNo ratings yet

- Collagen Structures Fabricated by Laser Direct Writing Via Two-Photon Polymerization For Enhanced OsteogenesisDocument18 pagesCollagen Structures Fabricated by Laser Direct Writing Via Two-Photon Polymerization For Enhanced Osteogenesispopescu vasilicaNo ratings yet

- Core-Shell Nanoparticle Interface and Wetting PropertiesDocument9 pagesCore-Shell Nanoparticle Interface and Wetting PropertiesDulce GradillaNo ratings yet

- AP IR VH - PE Au - Pol21Document28 pagesAP IR VH - PE Au - Pol21Vangelis HarmandarisNo ratings yet

- Deformation and Failure in Semi-Crystalline Polymer SystemsDocument53 pagesDeformation and Failure in Semi-Crystalline Polymer SystemsMuhammad AhmadNo ratings yet

- Lattice Boltzmann Method Development of PEMFC in MDocument6 pagesLattice Boltzmann Method Development of PEMFC in Memonome2190No ratings yet

- 05 05 PDFDocument10 pages05 05 PDFghoul chemistNo ratings yet

- Polymer: D. Hossain, M.A. Tschopp, D.K. Ward, J.L. Bouvard, P. Wang, M.F. HorstemeyerDocument13 pagesPolymer: D. Hossain, M.A. Tschopp, D.K. Ward, J.L. Bouvard, P. Wang, M.F. Horstemeyer张宏No ratings yet

- 4 - Analysis of Wind Turbine Blades Aeroelastic Performance Under Yaw ConditionsDocument12 pages4 - Analysis of Wind Turbine Blades Aeroelastic Performance Under Yaw ConditionsMayra ZezattiNo ratings yet

- (2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerDocument13 pages(2023) (Thoudam) Effect of Topology On The Collapse Transition and The Instantaneous Shape of A Model HeteropolymerIsabel CamusNo ratings yet

- Article Relationships Material Properties PDFDocument24 pagesArticle Relationships Material Properties PDFeduardo_umNo ratings yet

- Isotropically Small Crystalline Lamellae Induced by High Biaxial-Stretching Rate As A Key Microstructure For Super-Tough Polylactide FilmDocument12 pagesIsotropically Small Crystalline Lamellae Induced by High Biaxial-Stretching Rate As A Key Microstructure For Super-Tough Polylactide FilmLong LeNo ratings yet

- 1 s2.0 S0264127516301071 MainDocument13 pages1 s2.0 S0264127516301071 MainHouda FoulahNo ratings yet

- Biocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodDocument10 pagesBiocompatibility and Biodegradation Studies of PCL/ B-TCP Bone Tissue Scaffold Fabricated by Structural Porogen MethodSreedhar PugalendhiNo ratings yet

- Biomimetic Principles and Design of Advanced Engineering MaterialsFrom EverandBiomimetic Principles and Design of Advanced Engineering MaterialsNo ratings yet

- CTC Continuous Transposed Cable 2017 2 PDFDocument5 pagesCTC Continuous Transposed Cable 2017 2 PDFNishikanta MallickNo ratings yet

- Topic 3 - Strength Analysis of Beams According To ACI Code PDFDocument17 pagesTopic 3 - Strength Analysis of Beams According To ACI Code PDFRea May De La TorreNo ratings yet

- UG Pipe CheckingDocument6 pagesUG Pipe Checkingnoto.sugiartoNo ratings yet

- Department of Chemical and Environmental Engineering Universiti Putra MalaysiaDocument15 pagesDepartment of Chemical and Environmental Engineering Universiti Putra MalaysiaMohd Azman SuwandiNo ratings yet

- Porvair Sinterflo Brochure - UKDocument8 pagesPorvair Sinterflo Brochure - UKAndrew HillNo ratings yet

- Soil MCQsDocument16 pagesSoil MCQsAli Raza100% (1)

- Boiling Heat TransferDocument8 pagesBoiling Heat TransferHaidarNo ratings yet

- Surface TextureDocument53 pagesSurface TextureJayant SisodiaNo ratings yet

- Piping Theory As Per ASME B31.3 PROCESS PIPINGDocument107 pagesPiping Theory As Per ASME B31.3 PROCESS PIPINGDeen first sdiNo ratings yet

- Design of PurlinsDocument7 pagesDesign of Purlinsjiyad100% (1)

- Panfleto 165-2017 - Instrumentation For Chlorine ServiceDocument30 pagesPanfleto 165-2017 - Instrumentation For Chlorine ServiceLucas OliverNo ratings yet

- Atomic Absorption Spectrophotometry Cookbook Section 1Document25 pagesAtomic Absorption Spectrophotometry Cookbook Section 1Absheen ZamanNo ratings yet

- Structural Steel DesignDocument8 pagesStructural Steel DesignNassim SabriNo ratings yet

- Vickers Hardness TestDocument9 pagesVickers Hardness TestMoiz Amir100% (1)

- Astm A106 A106m 19Document6 pagesAstm A106 A106m 19Milady OyuelaNo ratings yet

- 8008 1 PDFDocument6 pages8008 1 PDFraji357No ratings yet

- Frigaard2017 Article BinghamSModelInTheOilAndGasIndDocument24 pagesFrigaard2017 Article BinghamSModelInTheOilAndGasIndCoolProphetNo ratings yet

- Tai Lieu SV AV2Document54 pagesTai Lieu SV AV2nguyenthanhtruc01060209No ratings yet

- Boiler ManualDocument22 pagesBoiler Manualengrasadullah000No ratings yet

- MSDS SUN Combi. S-321Document5 pagesMSDS SUN Combi. S-321kunalNo ratings yet

- Chemplasa Ebs L-205F-TdsDocument1 pageChemplasa Ebs L-205F-TdsÁnh Nguyễn100% (1)

- Stress-Strain Behavior Concrete Confined Overlapping Hoops Strain Rates PDFDocument15 pagesStress-Strain Behavior Concrete Confined Overlapping Hoops Strain Rates PDFMaqMaikNo ratings yet

- Design of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000Document4 pagesDesign of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000MaheshNo ratings yet

- BRM Flex Hone Catalog 2011Document64 pagesBRM Flex Hone Catalog 2011altexsteveNo ratings yet

- P BLOCK Class 12Document26 pagesP BLOCK Class 12Parth BajajNo ratings yet

- Welding FLAWSDocument86 pagesWelding FLAWSrohitbhat2345100% (1)

- Investigation 6b eDocument12 pagesInvestigation 6b eMBOTAKE LawsonNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Bunker Fuel Oil Specifications2010Document5 pagesBunker Fuel Oil Specifications2010onejako12No ratings yet