Professional Documents

Culture Documents

Component Tester Test Almost Anything

Component Tester Test Almost Anything

Uploaded by

Gayan ShashiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Component Tester Test Almost Anything

Component Tester Test Almost Anything

Uploaded by

Gayan ShashiCopyright:

Available Formats

instructables

Component Tester - Test Almost Anything !!

by baweja_akshay

Being an Electronics student or hobbyist, you may have thought of getting a tester that could test almost anything

"THE ELECTRONICS COMPONENTS, OBVIOUSLY!!"

Now what if I tell you that you can have one and that too made by yourself under INR 600 only (USD 10).

Coming upon COMPONENT TESTER so it can test almost everything, obviously not the power components because

they require more current and power which our AVR Microcontroller couldn't handle !! Oh yeah, I forgot to tell you

guys that we would be using an ATMEGA328 for our build !!

Yes, the same microcontroller which an arduino uno uses...!!

So, here's what our Component Tester can test -

1. Resistors

2. Capacitors along with their Equivalent Circuit Resistance Value (ESR)

3. Inductors

4. BJTs

5. FETs

MOSFETs

JFETs

6. Thyristors

SCRs

DIACs

TRIACs

7. IGBTs

8. Diodes

no the list doesn't end here.... it ca n t e s t Vo lt a g e upt o 50 V , it ha s a FREQ UENC Y CO UNT ER a nd a

Component Tester - Test Almost Anything !!: Page 1

FREQ UENC Y GENERAT O R T O O :D

you can also detect the IR Codes by simply putting a TSOP Sensor on its test pins.... isn't that great :D

and yeah one thing i forgot to tell you guys it do e s n' t o nly de t e ct t he co m po ne nt s it dis pla y s t he ir

re s pe ct iv e v a lue s a nd pro pe rt ie s t o o !!

No, don't thank me for such wonderful thing thank MARKUS F. the maker and developer of Component Tester and Karl-

Heinz who developed the rmware for it.

Let's Start the build and you'll explore much more on the way to build your own..!!

Step 1: Order Stuff for Build !!

with some basic components and tools you will be ready to build...!!

Ele ct ro nic Co m po ne nt s

1x 1nF (102) Ceramic Capacitor

1x 10nF (103) Ceramic Capacitor

4x 100nF (104) Ceramic Capacitor

2x 22pF (22) Ceramic Capacitor

2x 2.2uF, 50V Electrolytic Capacitor

2x 1N5819 or any other Schottky Diode with current rating of 1A

1x 7805 - 5V Voltage Regulator

1x LM336 - 2.5V Voltage Reference Diode

1x 10uH Inductor

1x BC547 Transistor

1x BC328-40 Transistor

3x 680 ohm Resistor with 0.1% Tolerance (1% Tolerance would also do)

3x 470k ohm Resistor with 0.1% Tolerance (1% Tolerance would also do)

Component Tester - Test Almost Anything !!: Page 2

NO T E: For 1% Tolerance and 5% Tolerance(not recommended but works with less accuracy) 680 ohm and 470k

ohm resistors you need to make some changes in code and try to have all resistors indicating same value on

multimeter.

UPDAT E: For those who are having problems in nding 0.1% or 1% tolerances. You can use 5% tolerances. Just buy

5-7 resistors of 5% tolerances and nd out 3 resistors having same value on the multimeter. I made another one for

you guys with 5% tolerance resistors and changes the value of resistors in code and that worked too :)

2x 3k3 ohm resistor

2x 27k ohm resistor

1x 100k ohm resistor

1x 33k ohm resistor

6x 10k ohm resistor

1x 470 ohm resistor

1x 15k ohm resistor

1x 2k2 ohm resistor

1x 200k ohm resistor

2x 1k ohm resistor

2x 10k ohm preset (Variable Resistance)

1x 8MHz Crystal Oscillator

1x ATMEGA 328/328p with Socket

1x 16X2 CHARACTER LCD

1x Rotary Encoder w/ Button Module and KNOB

1x Red LED (you can use any colour I chose Red as it it used to denote POWER)

Ha rdw a re Pa rt s

1x 16 Pin Polarized Header Cable - Relimate Connectors

3x 3 Pin Polarized Header Cable - Relimate Connectors

2x 4 Pin Polarized Header Cable - Relimate Connectors

1x 9V Battery Connector

6x Banana Jack Connectors (Female)

3x Banana Jack Connector Cable (with Male Heads)

1x Enclosure Case (I used a plastic Switch Board Enclosure Case/ Plastic Project Box)

To o ls Re quire d

Soldering Iron

Some Solder

A Single Layer PCB (because I home etched mine for this as it reduces unwanted signals and noises in

the circuit and being it a testing circuit etching your own PCB is advised for getting accurate results)

Solder Mask (optional)

Some strong cutters (to make cutouts on you enclosure)

Screwdrivers and Pliers

and some ISO-PROPYL Alcohol or Acetone would work ne to clean the ux residue on PCB (It its

necessary that you clean the ux or it may cause some unwanted errors in your Component Tester).

Component Tester - Test Almost Anything !!: Page 3

Le t ' s St a rt t he build !!

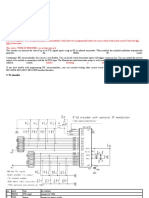

Step 2: Schematics and PCB Build !!

This is a self designed and home etched PCB...!!

I used eagle software freeware version for designing PART II :

PCB. I have attached the PCB (un-mirrored) les below

so you can download and etch them at home. For

//www.yout ube.com/embed/6uInan-TjiA

etching you can refer to other instructables on how to

go about etching process using Ferric Chloride(FeCl3).

You can Follow GreatScott's series on how to etch

PCB's using Ferric Chloride-

PART I :

UPDAT E : I've uploaded Eagle Files :)

//www.yout ube.com/embed/YJgX9Na4 rWw

Component Tester - Test Almost Anything !!: Page 4

Download

https://www.instructables.com/ORIG/FUQ/3EBI/IJPZ4SDV/FUQ3EBIIJPZ4SDV.pdf

…

Download

https://www.instructables.com/ORIG/F7B/NJ6P/IJVPUCS8/F7BNJ6PIJVPUCS8.sch

…

Download

https://www.instructables.com/ORIG/FV6/J9W4/IJVPUCRN/FV6J9W4IJVPUCRN.brd

…

Step 3: Applying the Solder-Mask Onto PCB (OPTIONAL)

If you wish to apply solder mask u can follow the below video on how to go about applying solder mask.

//www.yout ube.com/embed/Vj_cdBZO1Tk

I have attached the pad mask so to resist application of solder mask on component pads.

Component Tester - Test Almost Anything !!: Page 5

1

1. Component Pads where Solder Mask will not be UV cured

1. PCB after solder mask is applied

Download

https://www.instructables.com/ORIG/F7N/4B7H/IJQNYGNK/F7N4B7HIJQNYGNK.pdf

…

Step 4: Drilling Holes on PCB

For drilling holes on PCB you can either use a hand drill or a electric drill / drill press.

Component Tester - Test Almost Anything !!: Page 6

Step 5: Soldering Components on PCB

B e ca re f ul w hile s o lde ring t he 6 8 0 o hm s a nd 4 70 kilo - o hm s re s is t o r w hich a re t e s t re s is t o rs !!

Do not apply more solder on these resistors as that can induce some unwanted capacitance or

resistance in the circuit.

Do no t le a v e ux o n t he PCB a f t e r s o lde ring co m po ne nt s !! This may result in some

unwanted values u see on display. You can use Isopropyl Alcohol and some Cotton Buds to clean the

ux on PCB.

1. ISP Connector

2. Atmega328

Component Tester - Test Almost Anything !!: Page 7

1

1. flux residue

2. flux residue

Step 6: Preparing the Enclosure...!!

I used a plastic project box as enclosure for my COMPONENT TESTER...!!

I drilled holes for binding posts and DC jack socket then used a hot knife to make cutout for 16x2 LCD.

NO T E : desolder the grounded leg of push-button on rotary encoder module and connect that to positive side of

LED along with wires coming from the PCB

UPDAT E : For LED_START header

PIN1 - LED Negative

PIN2 - LED Positive

PIN3 - SWITCH

PIN4 - +5V

Connect 2nd Pin of switch to LED Positive

Component Tester - Test Almost Anything !!: Page 8

1

3

1. rotary encoder

2. Power LED

3. Test Points

6

1

1

4

1. to positive side of led 1. desolder the grounded leg of push-button on rotary encoder

2. TO PIN1 of Rotary Encoder Header on PCB module and connect that to positive side of LED (PURPLE WIRE)

3. TO PIN3 of Rotary Encoder Header on PCB along with wires coming from the PCB

4. From header cable on pcb

5. PIN 2 of rotary encoder header

6. To switch pin of header PCB

Component Tester - Test Almost Anything !!: Page 9

1 3 5

2 4

1. DC Power Socket

2. Power LED

3. 16x2 LCD Module with 16 pin connector cable soldered to LCD Module

4. Test Points

5. Voltage and Frequency Testing Points

Step 7: Uploading the Code to AVR

The code les are attached below as .zip le format so that you can compile an build code after making the

necessary changes in con guration les.

Now open up con g.h and make the following changes -

Component Tester - Test Almost Anything !!: Page 10

navigate to me a sure me n t se t t in gs a n d o se t s

now in this section scroll to R_ LO W and set the value of 680 ohm resistance you are

getting on you multimeter try and choose 3 680 ohm resistance with same values

showing on multimeter

now change the value of R_ HIGH i.e. the value of the 470k ohm resistances you are

getting on your multimeter be as precise as possible and try and choose 470k ohm

resistances with closest values or same values showing up on multimeter.

change RH_ O FFS E T if you want or leave it as it is. RH O set is O set for systematic

error of resistor measurement with Rh (470k)

change R_ Z ERO - Resistance of probe leads (in 0.01 Ohms).

Resistance of two probe leads in series. (Assuming all probe leads got

same/similar resistance)

change C AP_ W IRES - Capacitance of the wires between PCB and terminals (in pF).

2pF for wires 10cm long

change C AP_ PRO BELEADS - Capacitance of the probe leads connected to the tester

(in pF).

3pF for about 10cm long probe leads

9pF for about 30cm long probe leads

15pF for about 50cm long probe leads

you can go through rest of values and play-around if you are familiar with AVR and

coding. If not please do not alter anything else.

If you are facing problems opening .zip les I am sharing the Dropbox link to code -

DROPBOX_ComponentTester_CODE

UPDAT E: If you are using usbasp programmer then you need not edit the Make le else you need to goto line 54

and change

pro gra mme r = usb a sp to pro gra mme r = <yo ur pro gra mme r's n a me >

open command window in that folder where you have your code by holding shift and right click you

will see an option of Open Command Window Here click that

type in ma ke a ll

connect the Programmer with the ISP Header of Atmega328

type in ma ke uplo a d

then type ma ke fuse s

following to this type ma ke c le a n

Component Tester - Test Almost Anything !!: Page 11

NO T E : I assume that you have avrdude pre-installed in your systems. if not youhave to download a v rdude and

install it before doing above steps.

Download

https://www.instructables.com/ORIG/F1Q/2MZC/IJSX5RTA/F1Q2MZCIJSX5RTA.zip

…

Step 8: Assembling Everything As One Device

Before assembling just run everything and test one or two components so as to con rm everything is working ne.

2

1

5

4

3

1. LCD Connector

2. Test Points

3. POWER LED and Switch Connector

4. Voltage and Frequency Counter

5. Rotary Encoder Conector

6. Power Connector - 7-12V and a 9V Battery Connector

Component Tester - Test Almost Anything !!: Page 12

Step 9: HALLELUJAH !! YOU MADE ONE... :D

So you made one component tester for yourself.... you after turning the tester on.

can keep that handy on your workbench and use it to

test your components more often... UPDAT E: I have redesigned a new version of the

component tester that is super compact and can t in

UPDAT E: You can see the menu for the tester which your pocket or you can just carry it around like a

includes PWN Generation, Square Wave Generation, keychain. Do check it out!!

Frequency Counter, IR Code Detector, Calibration and

Adjustment Menu by turning the rotary encoder left

Component Tester - Test Almost Anything !!: Page 13

2

1. 10 kilo-ohm 1W resistor

2. 1 kilo-ohm 1W resistor

1

2

3

1. 100nF Ceramic Capacitor 1. LED

2. 22uF, 63V Electrolytic Capacitor

3. ESR Value being displayed for Electrolytic Capacitor

1. 2N3904 - General Purpose NPN Transistor

Inductor measurement result is not correct. what can I do now.

i've made it, but is extremly slow, any clue?

can you describe a bit more?

Component Tester - Test Almost Anything !!: Page 14

In the end, I used a copy of linux mint to upload the code to the AVR. Now the speed is correct, but

the rotary encoder still does not work.

When I deactivate the rotary encoder from the config.h file, I can use the button to navigate through

the menu, but only when I feed the circuit with the usbasp or 5v from the ISP pins. If I use a 9v

battery or an adapter I have no response from the button or the rotary encoder!

very rare. If you have any clue, I would be grateful.

Hola, espero estes bien, tambien tengo el componentester lento, me guiarias como hacerlo por

linux en VM?

Hi!

The size of the PCB file in pdf format is incorrect for me. Can someone send me the PCB file for

Sprint Layout 5.0?

very nice

Works fine ... Was just wondering why the hex and eep file incuded in the hex dir of dropbox files

are of another version of the source file in the same dropbox collection. Also wondering how to

measure voltage... Cant find in the menus ...only frequency. Thank you guys.

Lfuse FC & Hfuse D9

Hi all

I have successfully uploaded the code to the ATMega328p using my Arduino as an in-circuit

programmer. Uploading was done via the tester's on-board ISP plug.

Please see my Instructable at

https://www.instructables.com/id/Arduino-UNO-as-AtM...

I used the following commands:

make all

avrdude -c arduino -p m328p -P com1 -b 19200 -U flash:w:./${NAME}.hex:a -U

eeprom:w:./$(NAME).eep:a

make upload

avrdude -c arduino -p m328p -P com1 -b 19200 -U lfuse:w:0xfc:m

avrdude -c arduino -p m328p -P com1 -b 19200 -U hfuse:w:0xd9:m

make clean

how to make the code for Arduino???

STEP 1

------

Install AVRDude.

Component Tester - Test Almost Anything !!: Page 15

See http://www.ladyada.net/learn/avr/setup-win.html

STEP 2

------

Download and UnZip the attached ComponentTesterPgm.zip file . Remember your unzip directory.

The directory will include four files

1 - _program.bat

2 - _readme.txt

3 - ComponentTester.hex

4 - ComponentTester.eep

STEP 3

------

Set up your Arduino as a programmer.

See https://www.instructables.com/id/Arduino-UNO-as-AtMega328P-Programmer/

STEP 4

------

In the unzipped directory, double click on _program.bat.

The Command Prompt window will open, and programming of the ATMEGA328p will start.

When completed, the Command Prompt window will close.

STEP 5

------

Your ATMEGA328p is now programmed, and ready to be installed into your project.

Hi dear. thanks for tut. can you tell me wht is the fusebit for this hex file? i want to program micro

with stk500 and atmel studio

low & high & extended

thanks

I am totally grateful to you !!! I will do it with your instructions!!! Thanks!!!!

that looks great :)

I've seen in the discussions some people with difficulties to compile the code.

I agree. I think it's no so easy for the people not customed to use the clasical compilers.

What's about if I show you how to use the Arduino IDE to compile and upload the code in an

Arduino Uno? (or any Atmega 328 Arduino hardware).

Another option is to upload the code to an Arduino Uno, then take off the microprocessor from the

Arduino and put it in the PCB provided by Mr. baweja_akshay

Also it's possible to upload the Sketch in the circuit provided in this Instructable through the ISP

port.

Component Tester - Test Almost Anything !!: Page 16

It's really easy... so let's go to hands on:

1) Add an EMPTY file named "Test_Ard_Ok.ino" in the folder containing all the c and h files,

Rename the directory with the same "Test_Ard_Ok" name in the usual way (as Arduino IDE

requires it). Really the name doesn't matter, it could be "Any_Thing.ino" and the folder

"Any_Thing".

You can realize that any C or C++ code is accepted without any problem by the Arduino IDE

(taken into account you have the code adapted to an ATmega, off course).

Wow!!! That's taking us to another dimension!

Could we code in C or C++ and then compile with Arduino IDE?

Off course we can, that's what will be happening following the next steps.

2) As the Arduino IDE doesn't use the makefiles, simply delete it.

3) Now, as you don't have the makefile, it's needed to make some corrections in the config.h.

Edit it as indicated in the attached config.h (containded in the attached Test_Ard_OK.rar ) or simply

use the extracted file in the resulting directory.

All other parts of the file list remain exactly the same as the file list given in this Instructable.

4) Open the Test_Ard_Ok.ino file with the Arduino IDE. Compile and Upload

You could also compile directly loading the Test_Ard_OK.ino contained in the folder from the

attached Test_Ard_OK.rar but the goal is to learn how to do it. Doesn' it?

5) That's all folks...

I've attached two screen captures of the sketch in the Arduino IDE (result of compilation and

upload to an Arduino Uno).

The last capture is the content of the folder "Test_Ard_Ok".

In this case, I named Test_Ard_ok.ino to my Dummy File

As I pointed up before, really the name doesn't matter.

BTW I didn't build the hardware yet, Only I've tested the sketch in an Arduino Uno with the encoder

and display.

Best regards and enjoy

Hi Bro

I did all the steps. But I get this error when compiling

I've added the sketch in the original comment. Download and unrar it. Then open with the Arduino

IDE , compile in the usual way (option Arduino uno) and that's all.

Component Tester - Test Almost Anything !!: Page 17

Best Regards

Video Enquirer

Same Diagram, I've redesigned the PCB....

Can you share your schematic? I have no idea how to put a Zif connector like yours. Thanks in

advance

Hello Mr baweja akshay

I thank you for share you're design

And my question is how used square wave generation (which pins)?

Thank you again.

Hi Purmasing,

I didn't build the project, so I did't test it yet, but searching at the "extras.c" in the software, I've

found in the lines 252 to 263 an indication of using:

- probe # 2 (Pin 24 according schematic) as output and

- probe #1 (Pin 23 according schematic) or probe #3 (Pin 25 according schematic) as ground.

Be careful, don't make a short between them, I see no protection against that . The output are

directly the pins of the micro.

Best regards.

Videoinquirer

can i use arduino nano this project

If you prefer to compile and upload the project to the nano with the Arduino IDE, please see my

former discussion (#338).

Best regards

yes, you can. :)

check the svn repository: in /software/trunk you will find an already compiled firmware to use with

an arduino uno, and in /hardware you will find a folder "ArduinoUno_shield" with schematic for a

shield.

of course, you can use an uno, nano or mini pro, because all three are 328 based arduinos.

oh, and this is the newest version, 1.13k... 1.12k is now outdated...

Might you add the link for Arduino board based?

sorry for delay, but looks like i'm not get notifications... :)

the link: https://www.mikrocontroller.net/svnbrowser/transistortester/

This is the second one I made, this time I wanted to do it a little better, thank you very much for this

fantastic design.

Component Tester - Test Almost Anything !!: Page 18

Nice Project... It's Very useful... Tnx bro

Program micro guide:

install winavr :

http://zip.electrical4u.ir/n

Download AVRDUDE 6.3 file:

http://download.savannah.gnu.org/releases/avrdude/avrdude-6.3-mingw32.zip

Make a folder named test in the c windows drive and copy two

files inside the downloaded avrdude zip file

Download the tester code from the zip file top, then copy the

contents of the ComponentTester-classic-1.20m folder into the c: \ test folder

.use a usbasp compatible programmer

Connect to the computer ,

install driver and put the microc inside.

Run Windows Command Prompt and type :

c:

cd \ test

path C: \ WinAVR-20100110 \ utils \ bin

make all

make upload

make fuses

make clean

If your programmer is not usbasp, is in c: \ test

Open makefile with a notepad and change this part of the

file as your programmer.

programmer = xxxxx

hi dear

i have many error and problems in the cmd. please help me

Version 1,2 doesn't have .hex and .eep files. Can somebody share it?

Hi dear. can you help me for how to connect encoder and LED start and encoder pin on the bord.

thanks

1.2 version files.

Component Tester - Test Almost Anything !!: Page 19

Mine shuts down while I check capacitor of electrolytic type. Any solution?

Dear Akshay I made one, but the issue is while I check electrolytic capacitors my tester shuts

down by Its own. Any solution?

Hi. Any body here to help me? I need a schematic for connect encoder and led start pin on the

board. Please help me

Hi sir I made your great work.

Thank you for circuit and data.

I have one problem I buy rotary encoder and on it isn't any CLK DT SW for connect to board

Can you help me by image?

best Regard

Thanks for sharing such a nice project.

How to disable auto turn off?

Hello friend I want you help me about this

i cant push button test to main menu....please help me

to fast automatic off...how to sett time test and time automatic off

if you want delayed and slow or stable test menu then long press the switch and it will enter stable

value display mode.

baweja_akshay have your whatsapp Help me with this please

main menu as in ?? the frequency generator and calibration menu ?? if that then you need to turn

your rotary encoder towards left when it shows the value of component or no component and the

menu will appear.

sir what is the alternative for BC328-40 Transistor

Component Tester - Test Almost Anything !!: Page 20

You could find some alternative transistors here

https://alltransistors.com/crsearch.php?mat=Si&str...

you can google for similar pnp transistors.

mohmed_ahmed

ringoneckcare

what is the good software programmer to change on the code ?

Code Virsion AVR

AVR Stadio

Component Tester - Test Almost Anything !!: Page 21

You might also like

- L293D Motor Control Shield: FeaturesDocument6 pagesL293D Motor Control Shield: FeaturesJefferson HenriqueNo ratings yet

- Axia Price List 130901Document33 pagesAxia Price List 130901Stephen Walker-WeinshenkerNo ratings yet

- Abb Ag: OperationDocument6 pagesAbb Ag: OperationCosmic Garash 2No ratings yet

- Manual Livoltek GT1 10K DDocument50 pagesManual Livoltek GT1 10K DJr DinizNo ratings yet

- Cordex 110-1.1kW - Tehnicke KarakteristikeDocument34 pagesCordex 110-1.1kW - Tehnicke KarakteristikeTomislav BjelicaNo ratings yet

- Laser Security System Using GSM ModuleDocument76 pagesLaser Security System Using GSM ModuleGaurav KumarNo ratings yet

- SP Initial SeriesDocument25 pagesSP Initial SeriesJosé Arnaldo SilvaNo ratings yet

- Rcden: Service ManualDocument165 pagesRcden: Service ManualGaluh DH Chandra WdyNo ratings yet

- Service Manual SBOL100KTIII 3HVDocument57 pagesService Manual SBOL100KTIII 3HVOUAGUENOUNINo ratings yet

- MDRC29 Rev 1Document5 pagesMDRC29 Rev 1haris_fikriNo ratings yet

- MCS2000 Detailed Service 6881083C20-DDocument244 pagesMCS2000 Detailed Service 6881083C20-DBenjamin DoverNo ratings yet

- Brochure Battery Standard NiCd EBL EverExceedDocument13 pagesBrochure Battery Standard NiCd EBL EverExceedfidel gallaNo ratings yet

- Engine Safety UnitDocument2 pagesEngine Safety UnitSamo SpontanostNo ratings yet

- Varistores E3Document214 pagesVaristores E3Doris Elizabeth Rolón de EitzenNo ratings yet

- Synchronous GeneratorsDocument17 pagesSynchronous GeneratorsmouldfingerNo ratings yet

- ProSine 1800Document88 pagesProSine 1800thecupkasNo ratings yet

- MiCOM P11x - P111 PDFDocument2 pagesMiCOM P11x - P111 PDFArnavkumar JhaNo ratings yet

- Vacon 100 Application GuideDocument120 pagesVacon 100 Application GuideGilberto PootNo ratings yet

- Service Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDocument47 pagesService Manual: NSX-SZ80 NSX-SZ83 NSX-AJ80 NSX-SZ80EDjalma MotaNo ratings yet

- Offer For DAVR Spares PDFDocument6 pagesOffer For DAVR Spares PDFSukhirthan SenthilkumarNo ratings yet

- Owner'S Manual: 50 Lb. Laundry DryerDocument76 pagesOwner'S Manual: 50 Lb. Laundry DryerCollenNo ratings yet

- BL652 BL652 BL652 BL6523 3 3 3GX GX GX GX: Features DescriptionDocument18 pagesBL652 BL652 BL652 BL6523 3 3 3GX GX GX GX: Features DescriptionanimewarcrimesNo ratings yet

- Crompton GReaves Relay OvercurrentDocument2 pagesCrompton GReaves Relay OvercurrentSuranjana DasNo ratings yet

- Socomec en Netys RT M Catalogue 2015Document2 pagesSocomec en Netys RT M Catalogue 2015tariktunadNo ratings yet

- Micrex-Sx SPH HardwareDocument289 pagesMicrex-Sx SPH HardwareHerwin LatifanNo ratings yet

- Color LCD Sounder: FCV-1100LDocument52 pagesColor LCD Sounder: FCV-1100LSerge HerreroNo ratings yet

- JMR 9230 SDocument100 pagesJMR 9230 S宋翔No ratings yet

- Non-Isolated Buck APFC Offline LED Driver Description FeaturesDocument9 pagesNon-Isolated Buck APFC Offline LED Driver Description FeaturesEsmailNo ratings yet

- Lesson 10 332a PDFDocument17 pagesLesson 10 332a PDFelmer magsinoNo ratings yet

- Delta VFD L User ManualDocument16 pagesDelta VFD L User Manualdthi160880% (1)

- Main Switchboard Single Line DiagramDocument7 pagesMain Switchboard Single Line DiagramEngen MiroNo ratings yet

- Electronic Component TesterDocument6 pagesElectronic Component Tester0705224No ratings yet

- JRC JLR 8600Document163 pagesJRC JLR 8600Dino BagioNo ratings yet

- Uce-Ct220S Fault Locator: HOW TO Update TutorialDocument4 pagesUce-Ct220S Fault Locator: HOW TO Update TutorialWawan sahiriNo ratings yet

- TL494CNDocument0 pagesTL494CNNoemi MartinezNo ratings yet

- ITYS - UPS by SocomecDocument2 pagesITYS - UPS by Socomecsy4nNo ratings yet

- Vdocuments - MX Edn Design Ideas 2002Document198 pagesVdocuments - MX Edn Design Ideas 2002ciccioNo ratings yet

- BLDC Motor Driver Specification Sheet: DC12 48V ( 10%), Rated Current 20ax2Document16 pagesBLDC Motor Driver Specification Sheet: DC12 48V ( 10%), Rated Current 20ax2Pablo VelaNo ratings yet

- Thyrotronic (Russian) (1.1 MB)Document8 pagesThyrotronic (Russian) (1.1 MB)brobataNo ratings yet

- Shams Saudi SummaryDocument12 pagesShams Saudi SummaryShamsMohdNo ratings yet

- Application: Communication Unit 560CMG10Document4 pagesApplication: Communication Unit 560CMG10QuangNgocNo ratings yet

- Maximum Retail Prices: For Industrial Automation Products - AC Drives, Soft-Starters, PLC & HMIDocument27 pagesMaximum Retail Prices: For Industrial Automation Products - AC Drives, Soft-Starters, PLC & HMIPopatlal MrNo ratings yet

- GP-PRO/PBIII For Windows Device/Plc Connection ManualDocument46 pagesGP-PRO/PBIII For Windows Device/Plc Connection ManualHamdan RizqiNo ratings yet

- Rish em 1320-30-40 Multifunction MetersDocument8 pagesRish em 1320-30-40 Multifunction Metersswapnil patkar100% (1)

- 8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFDocument30 pages8MAN100072-0001 A en Technical Description Onboard DC Grid™ System Sales PDFStefanitaNo ratings yet

- FA 250 CertificateDocument12 pagesFA 250 CertificateNurocman KelikNo ratings yet

- Ardiuno Relay InterfacingDocument5 pagesArdiuno Relay InterfacingKarthikeyan TNo ratings yet

- Driver Circuits - PowerGuru - Power Electronics Information PortalDocument5 pagesDriver Circuits - PowerGuru - Power Electronics Information PortaldevchandarNo ratings yet

- Siemens Climatix IO ModuleDocument10 pagesSiemens Climatix IO Moduleamitdesai1508No ratings yet

- Construction of An Automatic Night LampDocument10 pagesConstruction of An Automatic Night Lampmekm09No ratings yet

- Uar4N: User ManualDocument40 pagesUar4N: User ManualArtur EckertNo ratings yet

- 1A, 6V 1.5Mhz, 50ua I Synchronous Step-Down ConverterDocument10 pages1A, 6V 1.5Mhz, 50ua I Synchronous Step-Down ConverterLina LinuNo ratings yet

- 【b】30240301001390 使用说明书 储能单相 sun (12 16) k sg01lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2Document48 pages【b】30240301001390 使用说明书 储能单相 sun (12 16) k sg01lp1 eu 德业英文 封面彩印 封面封底157g 内页70g铜版纸 142.5x210mm ver2.2Fajar Alam PriambudyNo ratings yet

- 33 KV VCBDocument7 pages33 KV VCBMathur Dinesh0% (1)

- 1 General Information: Model Number Short Description Servo DrivesDocument14 pages1 General Information: Model Number Short Description Servo DrivesMr.K ch100% (1)

- Public Hybrid PMC Register List V1020Document68 pagesPublic Hybrid PMC Register List V1020FenilNo ratings yet

- X Band Radar Magnetron1Document2 pagesX Band Radar Magnetron1PrashanthNo ratings yet

- Walker 4020Hbk Iss 3 Rev 0 Inc DrawingsDocument87 pagesWalker 4020Hbk Iss 3 Rev 0 Inc DrawingsQuân QuânNo ratings yet

- DIY Electronics (HK) LTD PO Box 88458, Sham Shui Po, Hong KongDocument17 pagesDIY Electronics (HK) LTD PO Box 88458, Sham Shui Po, Hong Kongrajudp100% (1)

- TDA2002 10wDocument21 pagesTDA2002 10wAlexandre S. CorrêaNo ratings yet

- Transistor Curve TracerDocument39 pagesTransistor Curve TracerGayan ShashiNo ratings yet

- Ed - Management Mo.10Document16 pagesEd - Management Mo.10Gayan ShashiNo ratings yet

- Introduction To SustainabilityDocument8 pagesIntroduction To SustainabilityGayan ShashiNo ratings yet

- Green BuildingsDocument8 pagesGreen BuildingsGayan ShashiNo ratings yet

- Lecture Notes (Economic Operation)Document100 pagesLecture Notes (Economic Operation)Gayan ShashiNo ratings yet

- Lecture Notes (Economic Operation)Document100 pagesLecture Notes (Economic Operation)Gayan ShashiNo ratings yet

- PsocDocument1 pagePsocGayan ShashiNo ratings yet

- Encoder Based On PICDocument7 pagesEncoder Based On PICAntonnio Savio LeiteNo ratings yet

- Neil Keyword For - AlikartDocument14 pagesNeil Keyword For - Alikartali kartNo ratings yet

- Revison Notes of Input OutputDocument3 pagesRevison Notes of Input OutputdeivasigamaniNo ratings yet

- Chap 1303 - AkDocument26 pagesChap 1303 - AkAbdoo ElhosinNo ratings yet

- Auto Power Switching Mains, Solar, Invertor or Generator: Humera EEEDocument19 pagesAuto Power Switching Mains, Solar, Invertor or Generator: Humera EEEHumeraNo ratings yet

- Quan Van Ha Curriculum VitaeDocument2 pagesQuan Van Ha Curriculum VitaeTaThachNo ratings yet

- BD94062FDocument35 pagesBD94062FMazalan HectorNo ratings yet

- Solar Photovoltaic Power GenerationDocument4 pagesSolar Photovoltaic Power GenerationShajith Ahamed ANo ratings yet

- Lecture 2 1 Continued 27092020 074227pmDocument8 pagesLecture 2 1 Continued 27092020 074227pmMohammad Abdul RafehNo ratings yet

- Dpscope - Build Your Own Usb/Pc-Based Oscilloscope: InstructablesDocument44 pagesDpscope - Build Your Own Usb/Pc-Based Oscilloscope: Instructablesuimarin14No ratings yet

- Smps UpsDocument1 pageSmps UpsKamaraj V.No ratings yet

- Nokia Asha 230 Service ManualDocument23 pagesNokia Asha 230 Service Manualamericano3No ratings yet

- EN1802 - Basic Electronics: S3 - Diodes, Diode Circuits and ApplicationsDocument27 pagesEN1802 - Basic Electronics: S3 - Diodes, Diode Circuits and ApplicationsShazni AhamedNo ratings yet

- Mca Seat Allotment Opening-Closing Rank of Mock RoundDocument5 pagesMca Seat Allotment Opening-Closing Rank of Mock RoundSohil GanatraNo ratings yet

- Kathrein 80010430 PDFDocument1 pageKathrein 80010430 PDFRaúl Fernández SánchezNo ratings yet

- Instructor's or Course Coordinator's Name: Harpreet SinghDocument3 pagesInstructor's or Course Coordinator's Name: Harpreet SinghNandini GuptaNo ratings yet

- ECE315 / ECE515: - Common Source Amplifier - MOSFET Amplifier DistortionDocument27 pagesECE315 / ECE515: - Common Source Amplifier - MOSFET Amplifier DistortionSHAIK MUSTHAFANo ratings yet

- Human/Machine Interface: Magelis STU and STO Small PanelsDocument19 pagesHuman/Machine Interface: Magelis STU and STO Small PanelsnaimaierNo ratings yet

- Bus Structure NewDocument35 pagesBus Structure NewAnonymous Xr7bf3un0No ratings yet

- Controlinc: Insteon Tabletop ControllerDocument15 pagesControlinc: Insteon Tabletop ControllerrandoNo ratings yet

- CMOS Layout Design Rules - Girish GidayeDocument90 pagesCMOS Layout Design Rules - Girish GidayeGIRISH GIDAYENo ratings yet

- Microcontroller: HistoryDocument13 pagesMicrocontroller: Historyrainceder100No ratings yet

- An Improved Interleaved DC-DC SEPIC Converter Based On SiC-Cascade Power Devices For Renewable Energy ApplicationsDocument6 pagesAn Improved Interleaved DC-DC SEPIC Converter Based On SiC-Cascade Power Devices For Renewable Energy ApplicationsBhawna GuptaNo ratings yet

- SFD2006T .1.2Document6 pagesSFD2006T .1.2Aisya NurcahyaNo ratings yet

- Remote Control User Manual PDFDocument2 pagesRemote Control User Manual PDFburnmanNo ratings yet

- VLSI Technology and TrendsDocument16 pagesVLSI Technology and TrendsManeesha NidigondaNo ratings yet

- 201802-DCS Wiring Diagram - REV02 - GA - 20180514 REV DDocument63 pages201802-DCS Wiring Diagram - REV02 - GA - 20180514 REV DDave Mendez0% (1)

- Logic Selection Guide PDFDocument156 pagesLogic Selection Guide PDFDANIEL-COSTEL PETCUNo ratings yet

- Xi Ip PT-1 Sample Paper-IiDocument2 pagesXi Ip PT-1 Sample Paper-IiNeelima VijayanNo ratings yet

- SCT 50 N 120Document11 pagesSCT 50 N 120JaimeNo ratings yet