Professional Documents

Culture Documents

Power Consumption Minimisation With Effective Temperature Control in Domestic Refrigerator

Power Consumption Minimisation With Effective Temperature Control in Domestic Refrigerator

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Consumption Minimisation With Effective Temperature Control in Domestic Refrigerator

Power Consumption Minimisation With Effective Temperature Control in Domestic Refrigerator

Copyright:

Available Formats

Volume 7, Issue 9, September – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Power Consumption Minimisation with

Effective Temperature Control in

Domestic Refrigerator

C. Ganesh (Guide), Nishant Sharma, Swapnil Gadekar, Piyush Chaudhari, Deepak Badhe

Mechanical Engineering Department

St. John College of Engineering & Management Palghar, India

Abstract:- The aim of this work is to experimentally liquid refrigerant and therefore reduces the temperature. The

investigate the performance of a domestic refrigerator to cycle is complete when the refrigerant flows into the

minimise power with proper control of temperature. A evaporator, from the expansion valve, as a low-pressure,

small fan is placed behind the defreezer, so as to convert low-temperature liquid.

natural flow of cold air to forced flow of cold air which

eventually would result into more efficient cooling. II. MAIN FUNCTION OF COMPONENTS

Different lengths of condenser were tested in order to

obtain reduction in power consumption. Among different A. Compressor

lengths of condenser better length of condenser is A refrigerant compressor is a machine used to compress

selected and calculations are performed.Data are the vapour refrigerant from the evaporator and to raise the

collected in order to evaluate the refrigerator pressure so that the corresponding saturation temperature is

performance. Each data was collected for a cycle of higher than that of the cooling medium.

operation for 1 hour, 2 hour, 3 hour and 24 hrs.Result B. Condenser

and analysis of Normal Refrigerator were compared The condenser is an important device used in high

with new modified refrigerator on basis of power pressure side of a refrigeration system. Its function is to

consumption and COP. Power consumption decreased dissipate the heat from the vapour refrigerant. The heat from

from 218 watt/hr to 36 watt/hr with modified the hot vapour refrigerant in a condenser is removed first by

refrigerator. transferring it to the walls of the condenser tubes and then

Keywords:- Refrigerator, R134a, Micro-Controller, from the tubes to the condensing or cooling medium.

Condenser, Refrigerator fan motor,Power Consumption, C. Expansion device

COP. The expansion device is an important device that divides

I. INTRODUCTION the high pressure side and the low pressure side of

refrigerating system. It is connected between the receivers

Refrigerator is one of the home appliance which (containing liquid refrigerant at high pressure) and the

utilizes Vapour Compression Cycle. Performance of the evaporator (containing liquid refrigerant at low pressure).

system becomes main issue and many researches are still

ongoing to evaluate and improve efficiency of the system. D. Evaporator

Therefore, this experiment presents the power consumption The evaporator is used in the low vapour side of

minimization with effective temperature control in domestic refrigeration system where liquid refrigerant from the

refrigerator. The refrigeration cycle begins with the expansion valve enters in to the evaporator & phase changes

refrigerant in the evaporator. At this stage the refrigerant in occurs. Thefunction of evaporator is absorbing heat from the

the evaporator is in liquid form and is used to absorb heat surrounding location of medium which is cooled, by means

from the product. When leaving the evaporator, the of refrigerant.

refrigerant has absorbed a quantity of heat from the product

and is a low-pressure, low-temperature vapour. This low-

pressure, low-temperature vapour is then drawn from the

evaporator by the compressor. When vapour is compressed

its temperature rises. Therefore, the compressor transforms

the vapour from a low-temperature vapour to a high-

temperature vapour, in turn increasing the pressure. This

high-temperature, high-pressure vapour is pumped from the

compressor to the condenser; where it is cooled by the

surrounding air, or in some cases by fan assistance. The

vapour within the condenser is cooled only to the point

where it becomes a liquid once more. The heat, which has

been absorbed, is then conducted to the outside air. At this

stage the liquid refrigerant is passed through the expansion Fig. 1: Refrigeration Cycle

valve. The expansion valve reduces the pressure of the

IJISRT22SEP1103 www.ijisrt.com 1476

Volume 7, Issue 9, September – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

III. EXPERIMENTAL SETUP

Consider single door old refrigerator. Connect pressure

gauges, and temperature sensors. Make sure gas evacuation

and filing is done under supervision of technician. Take

down some sets of readings without any modifications. Do

calculate coefficient of performance (COP) and power

consumption of normal refrigerator. Connect

Microcontroller in series with thermostat. Take down

readings and again calculate COP and power consumption.

After this connect small rating fan behind defreezer which

will convert natural flow of cold air to forced flow of cold

air. Again take readings and perform calculations. Also tried

connecting various lengths of condensers. Take readings and

perform calculations.

IV. METHODOLOGY

Fig. 2: Domestic Refrigerator with pressure gauges

Consider a single door refrigerator having R134a

refrigerant, take readings for 1hr, 2hr, and for 3hr.

(Normal refrigerator without any modifications)

Tabulate all readings with pressures and Temperatures.

(Pressure gauges and temperature sensors are connected at

various sections of refrigerators just to get pressure and

temperature.)

Based on the readings, calculate the work done by

compressor, refrigeration effect, heat rejected by

condenser, coefficient of performance, actual coefficient

of performance.

After this modifications, again tabulate readings for 1hr,

2hr and for 3 hr. Calculate work done by compressor,

refrigeration effect, heat rejected by condenser, coefficient

of performance, actual coefficient of performance.

Evaluate and draw the conclusion.

Evaluate and draw the conclusion. Now, connect Sub-

Zero Micro-Controller with the thermostat and change the

preset value of the thermostat.

Now, connect Evaporator Fan (low rating ampere) behind

the defreezer such that it converts natural circulation of Fig. 3: Different lengths of Condenser

cold air to forced circulation of cold air.

PERFORMANCE CALCULATIONS

Again tabulate readings for 1hr, 2hr and for 3 hr.

Calculate work done by compressor, refrigeration effect, (Normal Refrigerator for 3 hrs.)

heat rejected by condenser, coefficient of performance,

actual coefficient of performance. Evaluate and draw the Compressor work:

conclusion. No.of pulses x 3600 x 1000

= Time taken for 10 pulses x Energy meter constant× 3200

Check with the various lengths of condenser. Take

10 × 3600 ×1000

respective readings and compare with test cases. Evaluate = 53× 3200 = 218 Watt

and select the better condenser which has higher COP and

Defreezer Temperature = -11.2°C

less power consumption.

Temperature at Middle Section = 10.3°C

Finally now check test cases for all parameters (modified

Temperature at Bottom Section = 13.2 °C

refrigerator). Tabulate readings for 1hr, 2hr and for 3 hr.

Calculate work done by compressor, refrigeration effect, Mass flow rate of Refrigerant :-

heat rejected by condenser, coefficient of (Refer from R134a P-H chart)

210 210

performance,actual coefficient of performance. Evaluate 𝑚̇ = (h1 −h4) = 249.2−132.4 = 1.79 kg/min-TR

and draw the final conclusion and compare with original Theoretical Compressor Work :

refrigerator. Wc = (h2 − h1) = (292.2 − 249.2) = 43 KJ/kg

Theoretical Refrigeration effect (RE) :-

RE = (ℎ1 − ℎ4) = (249.2 – 132.4) = 116.8 KJ/kg

Coefficient of Performance :-

ℎ1 −ℎ4

COP = ℎ2 −ℎ1 = 2.714

IJISRT22SEP1103 www.ijisrt.com 1477

Volume 7, Issue 9, September – 2022 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Ideal Coefficient of Performance :- (Refer from R134a P-H chart)

TL 210 210

Ideal COP = = 4.68 𝑚̇ = = = 1.32 kg/min-TR

Th −TL (h1 −h4) 259.7−101.1

(Modified Refrigerator for 3 hrs.) : Theoretical Compressor Work :

Compressor work: Wc = (h2 − h1) = (271.4 − 259.7) = 11.7 KJ/kg

= Theoretical Refrigeration effect (RE) :-

No.of pulses x 3600 x 1000

= RE = (ℎ1 − ℎ4) = (259.7 – 101.1) = 158.6 KJ/kg

Time taken for 10 pulses x Energy meter constant× 3200

10 × 3600 ×1000 Coefficient of Performance :-

= 36.88 Watt ℎ1 −ℎ4

305 × 3200 COP = = 13.55

Defreezer Temperature = 7 °C ℎ2 −ℎ1

Ideal Coefficient of Performance :-

Temperature at Middle Section = 13.2 °C TL

Temperature at Bottom Section = 14.3 °C Ideal COP = = 15.42

Th −TL

Mass flow rate of Refrigerant :-

RESULT

Normal With MC, EF and Condenser

Details

Refrigerator of 9.85m length

Energy Consumed Per Hour (Watts) 218 36

Hours of use per Day 24 24

Energy Consumed Per Day (KWh) 5.232 0.864

Energy Consumed Per Month (KWh) 156.96 25.92

Energy Consumed Per Year (KWh) 1909.86 315.36

1 KWh cost(MSEB) ₹3 ₹3

Energy Cost Per Day (KWh) ₹ 15.696 ₹ 2.592

Energy Cost Per Month (KWh) ₹ 470.88 ₹ 77.76

Energy Cost Per Year (KWh) ₹ 5729.04 ₹ 946.08

Savings per Year - ₹ 4782.96

Table 1: Result

V. CONCLUSION Kumar Mishra, “Performance analysis of domestic

refrigerator with forced and natural

Using all the modifications-microcontroller, convection,”Pelagia Research Library Advances in

evaporator fan and 9.85m length of condenser, we came to Applied Science Research, 2015, 6(7):216-223

know that [4.] Madhuri Maheshwari, Gaurav Shrivastava, Bhanu

Normal refrigerator consumes 218 Watts/hr. Choubey, “Study on Refrigeration system designed for

Installation of Micro-controller consumes power of 41.66 low temperature,” International Journal of Scientific

Watts/hr, and Research Publications, Volume 3, Issue 2,

Installation of Evaporator Fan along with Micro-controller February 2013 1 ISSN.

consumes 55.98 Watts/hr,

And installation of 9.85m length of condenser along with

Evaporator fan & Micro-controller consumes 36.88

Watts/hr.

REFERENCES

[1.] Mr. Sagar Patil, Prof. Kiran Devade,“Energy savings

in domestic refrigerator using two

thermoelectricmodules & water cooling of

condenser,”International Journal of Innovations in

engineering research and technology(IJIERT),Volume

2, Issue 7, July-2015.

[2.] Neeraj Agrawal, Shriganesh Patila, “Experimental

Studies of a Domestic Refrigerator Using

R290/R600a Zeotropic Blends,”Neeraj

Agrawala,Shriganesh Patila , Prasant Nandab,Science

Direct, Energy Procedia Volume 109, March 2017,

Pages 425-430

[3.] Akhand Pratap Singh, Virendra Kumar, Sachin Kumar

Pandey, Mithaleshwar Yadav, Khushee Ram, Shrawan

Kumar Upadhyay, Prashant Ankur Jain and Ved

IJISRT22SEP1103 www.ijisrt.com 1478

You might also like

- 303-03A+Engine+CoolingDocument33 pages303-03A+Engine+CoolingP HandokoNo ratings yet

- Bell 429 Helicopter - High Resolution PanelDocument1 pageBell 429 Helicopter - High Resolution Panelguicordova0% (1)

- CTV-PRB006-EN (New Pressure Differential For Refrigerant Pump Chillers)Document12 pagesCTV-PRB006-EN (New Pressure Differential For Refrigerant Pump Chillers)Emerson PenaforteNo ratings yet

- Performance and Efficiency Test of A Refrigeration PlantDocument17 pagesPerformance and Efficiency Test of A Refrigeration PlantAllen Espeleta0% (1)

- GSUJ Vertical Geothermal Unit Features and BenefitsDocument2 pagesGSUJ Vertical Geothermal Unit Features and Benefitsapi-21574340No ratings yet

- Refrigeration 3Document36 pagesRefrigeration 3May Jade Genzola EsparesNo ratings yet

- Item Supplier Equipment Brand: Miraco CarrierDocument55 pagesItem Supplier Equipment Brand: Miraco Carriermostafaabdelrazik100% (1)

- The Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134ADocument7 pagesThe Influence Comparison of The Mass Refrigerant Towards Coefficient of Performance Car Air - Conditioning Systems With Refrigerant R-134Aanon_630820255No ratings yet

- Ic Engines /R&Ac Ic Engines /R&Ac: Course: Basic Civil and Mechanical EngineeringDocument55 pagesIc Engines /R&Ac Ic Engines /R&Ac: Course: Basic Civil and Mechanical EngineeringSrivikas MathesvaranNo ratings yet

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 pagesBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNo ratings yet

- Refrigeration Lab Report: Ali Rida Bachir SID 8104461Document4 pagesRefrigeration Lab Report: Ali Rida Bachir SID 8104461NARE EDMUNDNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- Design and Performance Analysis of Water PDFDocument7 pagesDesign and Performance Analysis of Water PDFDiyar NezarNo ratings yet

- AJES Vol.6 No.1 January June 2017 pp.18 22Document5 pagesAJES Vol.6 No.1 January June 2017 pp.18 22Design isotechplNo ratings yet

- EjectorDocument9 pagesEjectorManuel Gallegos CalderónNo ratings yet

- Study On Refrigeration System Designed For Low Temperature: Madhuri Maheshwari, Gaurav Shrivastava, Bhanu ChoubeyDocument3 pagesStudy On Refrigeration System Designed For Low Temperature: Madhuri Maheshwari, Gaurav Shrivastava, Bhanu Choubeymesi siahaanNo ratings yet

- Presentation 1Document47 pagesPresentation 1Abhishek KumarNo ratings yet

- 1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFDocument116 pages1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFPankaj KumarNo ratings yet

- BATCH 8 Domestic RefrigeratorDocument22 pagesBATCH 8 Domestic RefrigeratorSai RamNo ratings yet

- Final Low Temp PPT FinnaaalllDocument20 pagesFinal Low Temp PPT FinnaaalllAashish DawadiNo ratings yet

- Analysis of Multiple Evaporator Refrigeration SystemDocument3 pagesAnalysis of Multiple Evaporator Refrigeration SystemBen AhmedNo ratings yet

- Refrigeration and Heat PumpsDocument8 pagesRefrigeration and Heat PumpsFarouk BassaNo ratings yet

- Design and Analysis of Water Cooled Condenser: Sanjana V. Bharambe, Susmit A. Mulay, Suyash JadhavDocument5 pagesDesign and Analysis of Water Cooled Condenser: Sanjana V. Bharambe, Susmit A. Mulay, Suyash JadhavAungThawNyeinChanNo ratings yet

- Bahan Bejana Tekan 1Document5 pagesBahan Bejana Tekan 1Anonymous FZdJNsR9oNo ratings yet

- Performance Analysis of A Domestic Refrigerator Using Various Alternative ReffrigerantDocument12 pagesPerformance Analysis of A Domestic Refrigerator Using Various Alternative ReffrigerantGulshan SahuNo ratings yet

- Introduction of REfrigeratorDocument45 pagesIntroduction of REfrigeratorSantosh Ojha100% (2)

- Vol-1, Issue-5Document7 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- Activity No. 3: Chiller EfficiencyDocument12 pagesActivity No. 3: Chiller EfficiencyAldrian BarachinaNo ratings yet

- Refrigeration PlantDocument130 pagesRefrigeration PlantMarvin ArnaizNo ratings yet

- Module 3 - Chiller SystemDocument45 pagesModule 3 - Chiller Systemmadan karkiNo ratings yet

- Refrigeration and Air ConditioningDocument67 pagesRefrigeration and Air ConditioningJoe Kamal Raj100% (1)

- R & AC Lab ManualDocument30 pagesR & AC Lab ManualShashankNo ratings yet

- Chapter 17 - Refrigeration PDFDocument17 pagesChapter 17 - Refrigeration PDFcarleston thurgoodNo ratings yet

- Implementation of Hot Gas Bypass For RefrigerationDocument5 pagesImplementation of Hot Gas Bypass For RefrigerationhurshawNo ratings yet

- Vapor Compression Cycle (History) : (Schmidt Et Al., 2002)Document8 pagesVapor Compression Cycle (History) : (Schmidt Et Al., 2002)jess calderonNo ratings yet

- Refrigeration Test RigDocument10 pagesRefrigeration Test Rigakshayarora1909No ratings yet

- MM321 Lab 3Document5 pagesMM321 Lab 3Roshiv SharmaNo ratings yet

- Refrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusDocument22 pagesRefrigeration and Liquefaction: Instructor: Engr. Caressa Marie Frial-De JesusEmmanuel PlazaNo ratings yet

- Refrigeration and Air ConditioningDocument102 pagesRefrigeration and Air ConditioningYuvaperiyasamy MayilsamyNo ratings yet

- Experiment of Refrigeration and Air ConditioningDocument30 pagesExperiment of Refrigeration and Air ConditioningNitin KumarNo ratings yet

- Vapor Jet RefrigeratorDocument11 pagesVapor Jet RefrigeratorAlyan YousafNo ratings yet

- 6 Refrigeration Cycles EditedDocument31 pages6 Refrigeration Cycles EditederioNo ratings yet

- EN 317 - Sanidhya Anad - All Parts CombinedDocument22 pagesEN 317 - Sanidhya Anad - All Parts CombinedAtharva ChodankarNo ratings yet

- Lab Heat PumpDocument9 pagesLab Heat PumpShahran IezzatNo ratings yet

- Performance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Document14 pagesPerformance and Efficiency Test of Refrigeration Sysytem: (Mel Lab 3 Report)Yhan SombilonNo ratings yet

- Design and Fabrication of Scaled Down Innovative Mini Ice PlantDocument9 pagesDesign and Fabrication of Scaled Down Innovative Mini Ice PlantMuhammad Nur ShidiqNo ratings yet

- Vapour Compression RefrigerationDocument38 pagesVapour Compression RefrigerationArvind75% (4)

- Experiment No.3 E&EE Refrigeration System-1-4Document4 pagesExperiment No.3 E&EE Refrigeration System-1-4GauravNo ratings yet

- Case Studies in Thermal Engineering: Guilherme B. RibeiroDocument8 pagesCase Studies in Thermal Engineering: Guilherme B. Ribeirogr8khan12No ratings yet

- Ijet V2i6p2Document6 pagesIjet V2i6p2International Journal of Engineering and TechniquesNo ratings yet

- Rac Lab ManualDocument69 pagesRac Lab ManualHrshita SinghNo ratings yet

- Lecture 6 RefrigerationDocument65 pagesLecture 6 RefrigerationRamon Gerald AsiloNo ratings yet

- Exp. No. 02 Domestic Refrigerator Test Rig: Pimpri Chinchwad College of Engineering & Research, RavetDocument34 pagesExp. No. 02 Domestic Refrigerator Test Rig: Pimpri Chinchwad College of Engineering & Research, RavetAbcd EfgNo ratings yet

- TAQATI Notes Unit 4 HVACDocument16 pagesTAQATI Notes Unit 4 HVACanwarsubedar.inNo ratings yet

- A Seminar Report On Water Cooled ChillerDocument15 pagesA Seminar Report On Water Cooled ChillerSudip Sharma100% (3)

- Lec 03 RefrgerationDocument32 pagesLec 03 Refrgerationকাশী নাথNo ratings yet

- Project Repoert Test Rig OrgDocument66 pagesProject Repoert Test Rig OrgSandeep 21No ratings yet

- 16 Research PaperDocument7 pages16 Research Paperkhaja ziauddinNo ratings yet

- Refrigeration Test Ring.Document12 pagesRefrigeration Test Ring.பிரேம் ஆனந்த்No ratings yet

- Refrigerarion ImsDocument62 pagesRefrigerarion Imsdeepanshurathore2020No ratings yet

- Swami Vivekanand Institute of Engineering & Technology: Study and Performance of Domestic RefrigeratorDocument4 pagesSwami Vivekanand Institute of Engineering & Technology: Study and Performance of Domestic RefrigeratorDhiraj DhimanNo ratings yet

- Methodology To Make The Commercial Organization As TQM OrganizationDocument7 pagesMethodology To Make The Commercial Organization As TQM OrganizationMuhammad WaseemNo ratings yet

- Effectiveness of Organizing Crossing Transport Services in the Maritime Area of Riau Islands ProvinceDocument10 pagesEffectiveness of Organizing Crossing Transport Services in the Maritime Area of Riau Islands ProvinceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of the Quality of Community Satisfaction in Public Services in Tanjungpinang Class I State Detention HouseDocument13 pagesAnalysis of the Quality of Community Satisfaction in Public Services in Tanjungpinang Class I State Detention HouseInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of the Effectiveness of Based Public Services Information and Communication Technology (ICT)Document10 pagesAnalysis of the Effectiveness of Based Public Services Information and Communication Technology (ICT)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Effects of Nanoplastics on Human Health: A Comprehensive StudyDocument7 pagesEffects of Nanoplastics on Human Health: A Comprehensive StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Oral Anti-Diabetic Semaglutide: A GLP-1 RA PeptideDocument11 pagesOral Anti-Diabetic Semaglutide: A GLP-1 RA PeptideInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Zilebesiran: The First siRNA Drug Therapy for HypertensionDocument5 pagesZilebesiran: The First siRNA Drug Therapy for HypertensionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Analysis of Various Formwork SystemsDocument6 pagesDesign and Analysis of Various Formwork SystemsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyDocument8 pagesNurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Association Between Gender and Depression Among College StudentsDocument4 pagesAssociation Between Gender and Depression Among College StudentsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Salivary Diagnostics in Oral and Systemic Diseases - A ReviewDocument5 pagesSalivary Diagnostics in Oral and Systemic Diseases - A ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Shift from Traditional to Modern Building Concepts and Designs in Ringim Town: A Comparative Study of Aesthetics, Values, Functions and DurabilityDocument9 pagesShift from Traditional to Modern Building Concepts and Designs in Ringim Town: A Comparative Study of Aesthetics, Values, Functions and DurabilityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Environmental Sanitation – A Therapy for Healthy Living for Sustainable Development. A Case Study of Argungu Township Kebbi State, North Western NigeriaDocument15 pagesEnvironmental Sanitation – A Therapy for Healthy Living for Sustainable Development. A Case Study of Argungu Township Kebbi State, North Western NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Reintegration of Dairy in Daily American Diets: A Biochemical and Nutritional PerspectiveDocument1 pageReintegration of Dairy in Daily American Diets: A Biochemical and Nutritional PerspectiveInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- MSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyDocument6 pagesMSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Evaluation of Lateral and Vertical Gingival Displacement Produced by Three Different Gingival Retraction Systems using Impression Scanning: An in-Vivo Original StudyDocument6 pagesEvaluation of Lateral and Vertical Gingival Displacement Produced by Three Different Gingival Retraction Systems using Impression Scanning: An in-Vivo Original StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Biometric Security Systems Enhanced by AI: Exploring Concerns with AI Advancements in Facial Recognition and Other Biometric Systems have Security Implications and VulnerabilitiesDocument5 pagesBiometric Security Systems Enhanced by AI: Exploring Concerns with AI Advancements in Facial Recognition and Other Biometric Systems have Security Implications and VulnerabilitiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Appraisal of Nursing Care Received and it’s Satisfaction: A Case Study of Admitted Patients in Afe Babalola Multisystem Hospital, Ado Ekiti, Ekiti StateDocument12 pagesAppraisal of Nursing Care Received and it’s Satisfaction: A Case Study of Admitted Patients in Afe Babalola Multisystem Hospital, Ado Ekiti, Ekiti StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Occupational Injuries among Health Care Workers in Selected Hospitals in Ogbomosho, Oyo StateDocument6 pagesOccupational Injuries among Health Care Workers in Selected Hospitals in Ogbomosho, Oyo StateInternational Journal of Innovative Science and Research Technology100% (1)

- Prevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyDocument4 pagesPrevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- AI Robots in Various SectorDocument3 pagesAI Robots in Various SectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemDocument6 pagesFuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)Document7 pagesAn Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Dynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnDocument3 pagesDynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Importance of Early Intervention of Traumatic Cataract in ChildrenDocument5 pagesImportance of Early Intervention of Traumatic Cataract in ChildrenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Geotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioDocument10 pagesGeotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Innovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piDocument8 pagesInnovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachDocument16 pagesThe Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoDocument7 pagesIntegration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection and Prevention Systems for Ad-Hoc NetworksDocument8 pagesIntrusion Detection and Prevention Systems for Ad-Hoc NetworksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsDocument6 pagesA Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Power & Utility Report Nov-20Document545 pagesPower & Utility Report Nov-20Gaurav SinghNo ratings yet

- REFRIGERATIONDocument27 pagesREFRIGERATIONsupertpm127No ratings yet

- Uni-Aire Company ProfileDocument11 pagesUni-Aire Company Profilekothat82No ratings yet

- EN 44-3 Dual-Temperature Chillers PlantsDocument12 pagesEN 44-3 Dual-Temperature Chillers PlantsJose Pedro CostaNo ratings yet

- Manual Servicio Daewoo FR 251Document18 pagesManual Servicio Daewoo FR 251Roy García CalderonNo ratings yet

- MEng 136 - QuizDocument1 pageMEng 136 - QuizCollano M. Noel RogieNo ratings yet

- Resume LaukeshDocument5 pagesResume LaukeshlaukkeasNo ratings yet

- Pup Main Building: West Wing FloorDocument19 pagesPup Main Building: West Wing FloorDhenil ManubatNo ratings yet

- 16-1 Freezer Equip Replacement Rev2Document2 pages16-1 Freezer Equip Replacement Rev2Josephine nadarNo ratings yet

- Basic Civil and Mechanical Engineering Unit VDocument37 pagesBasic Civil and Mechanical Engineering Unit VA.R. Pradeep Kumar100% (1)

- Chillers: The Machine Which Produce The Chilled Water To Distribute It To Different SpacesDocument11 pagesChillers: The Machine Which Produce The Chilled Water To Distribute It To Different SpacesMostafa Elmaghraby 467No ratings yet

- Libretto Istruzioni Extreme - Extreme Ultra - CompressedDocument7 pagesLibretto Istruzioni Extreme - Extreme Ultra - CompressedagfranchiniNo ratings yet

- ACI 376 10 Concrete Structures For The Containment of Refrigerated Liquefied GasesDocument169 pagesACI 376 10 Concrete Structures For The Containment of Refrigerated Liquefied GasesCarmine CacchioneNo ratings yet

- Me Lab 7Document4 pagesMe Lab 7BensoyNo ratings yet

- Thermax Evaporative CondenserDocument2 pagesThermax Evaporative CondenserShubham VermaNo ratings yet

- Rajkiya Engineering College Mainpuri: Topic: Engine CoolingDocument20 pagesRajkiya Engineering College Mainpuri: Topic: Engine CoolingMastering SolidworksNo ratings yet

- Expansion ValveDocument2 pagesExpansion Valveallan lariosaNo ratings yet

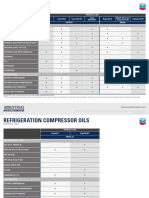

- Compressor Oil Comparison ChartDocument2 pagesCompressor Oil Comparison ChartKalezic NebojsaNo ratings yet

- 40 TPD CB 40 Rake ModelDocument1 page40 TPD CB 40 Rake ModelRAJBHAINo ratings yet

- Department of Mechanical Engineering, IIT Madras ME3103: Energy Conversion Systems Tutorial - 2Document3 pagesDepartment of Mechanical Engineering, IIT Madras ME3103: Energy Conversion Systems Tutorial - 2Harsh GuptaNo ratings yet

- Refrigerants: Market Trends and Supply Chain Assessment: Chuck Booten, Scott Nicholson, Margaret Mann Omar AbdelazizDocument79 pagesRefrigerants: Market Trends and Supply Chain Assessment: Chuck Booten, Scott Nicholson, Margaret Mann Omar AbdelazizPhúc JirouNo ratings yet

- Air Conditioner Tenders in Pan IndiaDocument8 pagesAir Conditioner Tenders in Pan IndiaCodm DutyNo ratings yet

- Manual de Instruções Samsung RL39WBMS (10 Páginas)Document5 pagesManual de Instruções Samsung RL39WBMS (10 Páginas)Marcos Antonio Muniz LoboNo ratings yet

- Heat Pump DemoDocument24 pagesHeat Pump DemoHannySyNo ratings yet

- Minibar GlobalDocument9 pagesMinibar GlobalRafael SaresNo ratings yet