Professional Documents

Culture Documents

Compensation Calculation

Compensation Calculation

Uploaded by

bullerCopyright:

Available Formats

You might also like

- Almost Like Being in Love: BrigadoonDocument6 pagesAlmost Like Being in Love: BrigadoonVincentLawNo ratings yet

- Keep The Fire BurningDocument137 pagesKeep The Fire BurningJoe Farias0% (1)

- Going To A TownDocument3 pagesGoing To A TownZachary Pinkham80% (5)

- TSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life EstimationDocument11 pagesTSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life Estimationusama666No ratings yet

- Numerical Sound Synthesis: Finite Difference Schemes and Simulation in Musical AcousticsFrom EverandNumerical Sound Synthesis: Finite Difference Schemes and Simulation in Musical AcousticsNo ratings yet

- Bass Guitar Radius GaugeDocument1 pageBass Guitar Radius GaugeGabriel SchardongNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable CalculatorQuality TeamNo ratings yet

- (26-28) SGP Pipe SteelDocument3 pages(26-28) SGP Pipe SteelSugi ZhuangNo ratings yet

- Screws CapacitiesDocument1 pageScrews CapacitiesZaido Al HalabiNo ratings yet

- Hoesch (Con Parametri Per Diaframmi)Document48 pagesHoesch (Con Parametri Per Diaframmi)PinoScribdNo ratings yet

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

- 67745048-Weld-Consumable-CalculatorDocument7 pages67745048-Weld-Consumable-CalculatorAlzaki AbdullahNo ratings yet

- Ware House 20-70-8 Crane 10 Ton Structural ReportDocument34 pagesWare House 20-70-8 Crane 10 Ton Structural ReportHayman AhmedNo ratings yet

- RoofDek D159-Acoustic Load TableDocument1 pageRoofDek D159-Acoustic Load TableЙордан ЛиляновNo ratings yet

- Chart Title: 1.8 2 F (X) - 1.196395574x + 2.2184564315 R 0.9879372903Document2 pagesChart Title: 1.8 2 F (X) - 1.196395574x + 2.2184564315 R 0.9879372903Mohamad Abdul ChalimNo ratings yet

- Trench BOQ CalculationDocument4 pagesTrench BOQ CalculationbushraNo ratings yet

- Table - 8 Conductor PropertiesDocument1 pageTable - 8 Conductor PropertiesMichael DarmstaedterNo ratings yet

- Cap Screw-C Sunk DimensionsDocument1 pageCap Screw-C Sunk DimensionsTan Hui ChewNo ratings yet

- Roofdek D32S: Ultimate Section Properties To EurocodeDocument1 pageRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNo ratings yet

- 45-150 Floor Deck Data SheetDocument1 page45-150 Floor Deck Data SheetAkhil VNNo ratings yet

- Is 19781982Document5 pagesIs 19781982Padakandla SumanNo ratings yet

- To Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inDocument2 pagesTo Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inSidharthaNo ratings yet

- Shaft TorsionDocument2 pagesShaft Torsionindra purnamaNo ratings yet

- Thickness C.Document9 pagesThickness C.DUe REnsukeNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Codo 90Document1 pageCodo 90RoLopNo ratings yet

- Appendix B Pipe Piles: EI 02C097 01 Jul 97Document5 pagesAppendix B Pipe Piles: EI 02C097 01 Jul 97Waho HadakNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Coupling Forged Steel Astm A105 Class 3000 SWDocument1 pageCoupling Forged Steel Astm A105 Class 3000 SWWilliam DelgadoNo ratings yet

- (PPE/DIX. (:, Ts Building Scel SteelDocument3 pages(PPE/DIX. (:, Ts Building Scel SteelFaye EducalaneNo ratings yet

- Bolt Torque Cl4.6-Tight-TorqDocument1 pageBolt Torque Cl4.6-Tight-TorqMir AsifNo ratings yet

- Tubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SDocument3 pagesTubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SSmithSaitAlarconPintoNo ratings yet

- Tray SupportDocument4 pagesTray SupportTDPK Adit dan HarisNo ratings yet

- Sizing Asme b31.3 2008Document12 pagesSizing Asme b31.3 2008Enamul KhanNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Debit Banjir Di SungaiDocument10 pagesDebit Banjir Di SungaiLutfi RagerisNo ratings yet

- Accropode™ Design Guide Table: F F F FDocument4 pagesAccropode™ Design Guide Table: F F F FJoeNo ratings yet

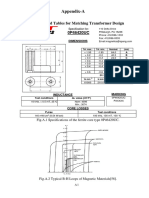

- Magnetics Design Tables: Appendix 2Document6 pagesMagnetics Design Tables: Appendix 2Gopichand GaddamNo ratings yet

- RoofDek D100 Load TableDocument1 pageRoofDek D100 Load TableRobert SzczecinskiNo ratings yet

- Metric DIN 7981 SpecDocument5 pagesMetric DIN 7981 SpecSudhanshu JainNo ratings yet

- RoofDek D153 Load TableDocument1 pageRoofDek D153 Load TableЙордан ЛиляновNo ratings yet

- Ficha Tecnica Tee ForgadoDocument1 pageFicha Tecnica Tee ForgadoAngly Rodríguez TorresNo ratings yet

- ตารางเหล็กDocument41 pagesตารางเหล็กสิทธิชัย หอมจรรย์No ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- L2 (MM) Springiness Hardness (GF) Hardness (N) L1 (MM) A1 (MM)Document3 pagesL2 (MM) Springiness Hardness (GF) Hardness (N) L1 (MM) A1 (MM)Permata Adinda PutriNo ratings yet

- Weight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasDocument2 pagesWeight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasAbhinay SoniNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- Sections - SHS - Hot Formed (BS EN 10219-1997)Document8 pagesSections - SHS - Hot Formed (BS EN 10219-1997)Bradley GoldenNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Pipe Wall Thickness Calculation-ASME B31.3Document4 pagesPipe Wall Thickness Calculation-ASME B31.3Rajul MuraliNo ratings yet

- Shear Capacity of Stainless Steel BoltsDocument2 pagesShear Capacity of Stainless Steel BoltsAnil kumar RNo ratings yet

- Socket Head Cap ScrewDocument4 pagesSocket Head Cap ScrewsarbiniNo ratings yet

- Design of Anchorage ZoneDocument6 pagesDesign of Anchorage ZoneSambhav PoddarNo ratings yet

- 16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)Document13 pages16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)fabio50002No ratings yet

- Ficha Tecnica Trolley's JVL23Document1 pageFicha Tecnica Trolley's JVL23kevin valeroNo ratings yet

- Conductor THW 90Document1 pageConductor THW 90anggelo_0203100% (1)

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Floor Deck Profile TS 47/180: Product Data SheetDocument3 pagesFloor Deck Profile TS 47/180: Product Data SheetMohamed KareemNo ratings yet

- TR 60Document3 pagesTR 60Narayanan MoorthyNo ratings yet

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocument2 pagesStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNo ratings yet

- New PssDocument4 pagesNew PssVikrant SuryaNo ratings yet

- Evaluation of External Loads On Welding Neck Flanges As Per Code Case 2901Document6 pagesEvaluation of External Loads On Welding Neck Flanges As Per Code Case 2901NirmalNo ratings yet

- The Rose Ola Gjeilo - 0001Document16 pagesThe Rose Ola Gjeilo - 0001Marie Le MaillouxNo ratings yet

- Soal Bahasa Inggris Klas XI Semester IDocument11 pagesSoal Bahasa Inggris Klas XI Semester ISujud Marwoto77% (13)

- Kagawaran NG Edukasyon: Rehiyon X1 Sangay NG Lungsod NG DabawDocument4 pagesKagawaran NG Edukasyon: Rehiyon X1 Sangay NG Lungsod NG DabawElisa LasayNo ratings yet

- PearlAFRO PDFDocument8 pagesPearlAFRO PDFJarne Claesen100% (1)

- Creative Writing: Various Elements, Techniques, and Literary Devices in Specific Forms of PoetryDocument21 pagesCreative Writing: Various Elements, Techniques, and Literary Devices in Specific Forms of PoetryNicki EspinosaNo ratings yet

- Basic Music Theory NotesDocument2 pagesBasic Music Theory NotesCharlotte Dolders100% (1)

- Bach Invention 13 A4 PDFDocument2 pagesBach Invention 13 A4 PDFBranislav PopkonstantinovićNo ratings yet

- The Sibelius Edition - Tone PoemsDocument6 pagesThe Sibelius Edition - Tone PoemsMiguel Gabriel JaritzNo ratings yet

- Market Driven Vs Driving Markets - Jaworski KohliDocument11 pagesMarket Driven Vs Driving Markets - Jaworski Kohlinenaa7770% (1)

- On The Origin of The ChitarroneDocument24 pagesOn The Origin of The ChitarroneJavier Ovejero Mayoral100% (2)

- Kinsey's Dance Resume11-2010Document1 pageKinsey's Dance Resume11-2010Kinsey ReynoldsNo ratings yet

- Cifra Club - ZZ Top - La GrangeDocument10 pagesCifra Club - ZZ Top - La GrangeRodolfo Vicente Savareses MuñozNo ratings yet

- Thanjavur Dolls Marketing SurveyDocument44 pagesThanjavur Dolls Marketing SurveyNagmani Roy100% (2)

- LF Plant STG S.p.A. Main Control PanelDocument98 pagesLF Plant STG S.p.A. Main Control Panelharetha all nassanNo ratings yet

- Scale - 24 - All Major and Minor Scales (Including Fingering For Piano)Document14 pagesScale - 24 - All Major and Minor Scales (Including Fingering For Piano)Min ParkNo ratings yet

- Catch and Release Tab by Matt Simons Tabs at U..Document3 pagesCatch and Release Tab by Matt Simons Tabs at U..vpcdgNo ratings yet

- PC3 Drum MapDocument1 pagePC3 Drum MapTaichiaikidokaNo ratings yet

- 1st Sem French Notes 2014Document46 pages1st Sem French Notes 2014prateek adnaniNo ratings yet

- Gerunds & Infinitive - ExerciseDocument12 pagesGerunds & Infinitive - ExerciseMyDuyen PhanNo ratings yet

- Graduation Programme 2018Document2 pagesGraduation Programme 2018Humberto LopezNo ratings yet

- It All Belongs To You - Deitrick HaddonDocument1 pageIt All Belongs To You - Deitrick HaddonJ.J. Carrion100% (1)

- Terjemahan Dan Soal Count On MeDocument1 pageTerjemahan Dan Soal Count On MeRusdi Mustamar100% (1)

- Dec 10 - Christmas Songs - SopranoDocument22 pagesDec 10 - Christmas Songs - SopranoDebbie TschirchNo ratings yet

- Nocturne No. 20 in C-Sharp Minor, B.49: Frédéric François ChopinDocument5 pagesNocturne No. 20 in C-Sharp Minor, B.49: Frédéric François ChopinnataliaNo ratings yet

- Send My Love (AcapellaDocument46 pagesSend My Love (AcapellaBryan LucchesiNo ratings yet

- Pantomime QuestionsDocument2 pagesPantomime Questions1038grenouilleNo ratings yet

Compensation Calculation

Compensation Calculation

Uploaded by

bullerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compensation Calculation

Compensation Calculation

Uploaded by

bullerCopyright:

Available Formats

Calculated

string action Tension Core thickness comp total comp stretch

mm N mm mm mm

E6 2.8 131 0.42 5.6 2.5

A 2.8 136 0.38 4.46 2.0

D 2.8 138 0.36 3.96 1.8

G 2.8 137 0.33 3.35 1.5

B 2.8 106 0.4 5.94 2.9

E 2.8 106 0.3 3.34 1.6

Scale (m)

0.65

Table 1. Compensation calculation for Steel Strings

calculated

string action Tension core thickness comp total comp stretch

mm N mm mm mm

E6 3.95 64.3 1.0922 3.29 0.6

A 3.8 72.1 0.889 2.88 0.6

D 3.65 70.8 0.7366 2.48 0.6

G 3.5 53.9 1.0236 4.38 0.9

B 3.35 54.6 0.818 2.75 0.5

E 3.2 73.6 0.7112 2.11 0.4

Scale (m)

0.63

MAX

4.38411728411462

min

2.11241354426538

milieu= 3.24826541419

Table 2. Calculated compensation for nylon strings

Tables to calculate required compensation per string for Steel and Nylon strings, procedure is described in American Luthe

Just fill in the data in the yellow cells and required compensation can be read from column E

they now contain an earlier dataset otherwise all ugly DIV/0 entries wil appear in the result columns E-G

Loct is string compression to drop pitch by a full octave

E is the calculated modulus of Elasticitry for Nylon string or, in the case of wound strings: it's core

ulated

comp bending

mm

3.1

2.5

2.2

1.8

3.1

1.7

ulated

comp bending Loct E

mm mm N/M^2

2.7 19.5 1.664E+09

2.3 18.0 3.051E+09

1.9 17.60 4.463E+09

3.5 10.2 3.036E+09

2.2 16.00 3.07E+09

1.7 20.00 4.379E+09

nylon strings

s described in American Lutherie, 112, pg 56-60+A11

You might also like

- Almost Like Being in Love: BrigadoonDocument6 pagesAlmost Like Being in Love: BrigadoonVincentLawNo ratings yet

- Keep The Fire BurningDocument137 pagesKeep The Fire BurningJoe Farias0% (1)

- Going To A TownDocument3 pagesGoing To A TownZachary Pinkham80% (5)

- TSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life EstimationDocument11 pagesTSU Bearing Testbed Static and Dynamic Load Modeling, Analysis and Bearing Useful Life Estimationusama666No ratings yet

- Numerical Sound Synthesis: Finite Difference Schemes and Simulation in Musical AcousticsFrom EverandNumerical Sound Synthesis: Finite Difference Schemes and Simulation in Musical AcousticsNo ratings yet

- Bass Guitar Radius GaugeDocument1 pageBass Guitar Radius GaugeGabriel SchardongNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable CalculatorQuality TeamNo ratings yet

- (26-28) SGP Pipe SteelDocument3 pages(26-28) SGP Pipe SteelSugi ZhuangNo ratings yet

- Screws CapacitiesDocument1 pageScrews CapacitiesZaido Al HalabiNo ratings yet

- Hoesch (Con Parametri Per Diaframmi)Document48 pagesHoesch (Con Parametri Per Diaframmi)PinoScribdNo ratings yet

- Appendix ADocument3 pagesAppendix ANaeemo IraqiNo ratings yet

- 67745048-Weld-Consumable-CalculatorDocument7 pages67745048-Weld-Consumable-CalculatorAlzaki AbdullahNo ratings yet

- Ware House 20-70-8 Crane 10 Ton Structural ReportDocument34 pagesWare House 20-70-8 Crane 10 Ton Structural ReportHayman AhmedNo ratings yet

- RoofDek D159-Acoustic Load TableDocument1 pageRoofDek D159-Acoustic Load TableЙордан ЛиляновNo ratings yet

- Chart Title: 1.8 2 F (X) - 1.196395574x + 2.2184564315 R 0.9879372903Document2 pagesChart Title: 1.8 2 F (X) - 1.196395574x + 2.2184564315 R 0.9879372903Mohamad Abdul ChalimNo ratings yet

- Trench BOQ CalculationDocument4 pagesTrench BOQ CalculationbushraNo ratings yet

- Table - 8 Conductor PropertiesDocument1 pageTable - 8 Conductor PropertiesMichael DarmstaedterNo ratings yet

- Cap Screw-C Sunk DimensionsDocument1 pageCap Screw-C Sunk DimensionsTan Hui ChewNo ratings yet

- Roofdek D32S: Ultimate Section Properties To EurocodeDocument1 pageRoofdek D32S: Ultimate Section Properties To EurocodeVolodymyr ShchurNo ratings yet

- 45-150 Floor Deck Data SheetDocument1 page45-150 Floor Deck Data SheetAkhil VNNo ratings yet

- Is 19781982Document5 pagesIs 19781982Padakandla SumanNo ratings yet

- To Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inDocument2 pagesTo Help Design Shafts in Torsion by Alex Slocum, Last Modified 2/12/2004 by Alex Slocum Enters Numbers in BOLD, Results inSidharthaNo ratings yet

- Shaft TorsionDocument2 pagesShaft Torsionindra purnamaNo ratings yet

- Thickness C.Document9 pagesThickness C.DUe REnsukeNo ratings yet

- Fasten BoltDocument1 pageFasten BoltSara BookerNo ratings yet

- Service DataDocument12 pagesService DataGianni DaBolognaNo ratings yet

- Codo 90Document1 pageCodo 90RoLopNo ratings yet

- Appendix B Pipe Piles: EI 02C097 01 Jul 97Document5 pagesAppendix B Pipe Piles: EI 02C097 01 Jul 97Waho HadakNo ratings yet

- Weld Consumable CalculatorDocument7 pagesWeld Consumable Calculatormed chabaneNo ratings yet

- Coupling Forged Steel Astm A105 Class 3000 SWDocument1 pageCoupling Forged Steel Astm A105 Class 3000 SWWilliam DelgadoNo ratings yet

- (PPE/DIX. (:, Ts Building Scel SteelDocument3 pages(PPE/DIX. (:, Ts Building Scel SteelFaye EducalaneNo ratings yet

- Bolt Torque Cl4.6-Tight-TorqDocument1 pageBolt Torque Cl4.6-Tight-TorqMir AsifNo ratings yet

- Tubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SDocument3 pagesTubos de Acero Inoxidable Soldables EFW ASTM A312 SCH 10S / 40S / 80SSmithSaitAlarconPintoNo ratings yet

- Tray SupportDocument4 pagesTray SupportTDPK Adit dan HarisNo ratings yet

- Sizing Asme b31.3 2008Document12 pagesSizing Asme b31.3 2008Enamul KhanNo ratings yet

- DIN 433 SpecDocument4 pagesDIN 433 SpecChris StefanouNo ratings yet

- Debit Banjir Di SungaiDocument10 pagesDebit Banjir Di SungaiLutfi RagerisNo ratings yet

- Accropode™ Design Guide Table: F F F FDocument4 pagesAccropode™ Design Guide Table: F F F FJoeNo ratings yet

- Magnetics Design Tables: Appendix 2Document6 pagesMagnetics Design Tables: Appendix 2Gopichand GaddamNo ratings yet

- RoofDek D100 Load TableDocument1 pageRoofDek D100 Load TableRobert SzczecinskiNo ratings yet

- Metric DIN 7981 SpecDocument5 pagesMetric DIN 7981 SpecSudhanshu JainNo ratings yet

- RoofDek D153 Load TableDocument1 pageRoofDek D153 Load TableЙордан ЛиляновNo ratings yet

- Ficha Tecnica Tee ForgadoDocument1 pageFicha Tecnica Tee ForgadoAngly Rodríguez TorresNo ratings yet

- ตารางเหล็กDocument41 pagesตารางเหล็กสิทธิชัย หอมจรรย์No ratings yet

- Hex Jam Nut Metric (ISO 4035)Document1 pageHex Jam Nut Metric (ISO 4035)Abu IrfanNo ratings yet

- L2 (MM) Springiness Hardness (GF) Hardness (N) L1 (MM) A1 (MM)Document3 pagesL2 (MM) Springiness Hardness (GF) Hardness (N) L1 (MM) A1 (MM)Permata Adinda PutriNo ratings yet

- Weight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasDocument2 pagesWeight of Reinforcement Steel Bars With Their Standard Cross Sectional AreasAbhinay SoniNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- Sections - SHS - Hot Formed (BS EN 10219-1997)Document8 pagesSections - SHS - Hot Formed (BS EN 10219-1997)Bradley GoldenNo ratings yet

- Pages From Astm-A194-2011pdf - CompressDocument1 pagePages From Astm-A194-2011pdf - CompressMuthazhagan SaravananNo ratings yet

- Pipe Wall Thickness Calculation-ASME B31.3Document4 pagesPipe Wall Thickness Calculation-ASME B31.3Rajul MuraliNo ratings yet

- Shear Capacity of Stainless Steel BoltsDocument2 pagesShear Capacity of Stainless Steel BoltsAnil kumar RNo ratings yet

- Socket Head Cap ScrewDocument4 pagesSocket Head Cap ScrewsarbiniNo ratings yet

- Design of Anchorage ZoneDocument6 pagesDesign of Anchorage ZoneSambhav PoddarNo ratings yet

- 16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)Document13 pages16.7 14.20 1978 54.79 ASTM A-283 Gr. C Ver Abaixo: Memorial de Cálculo de Espessura Mínima Do Costado (API 653)fabio50002No ratings yet

- Ficha Tecnica Trolley's JVL23Document1 pageFicha Tecnica Trolley's JVL23kevin valeroNo ratings yet

- Conductor THW 90Document1 pageConductor THW 90anggelo_0203100% (1)

- Metric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDocument5 pagesMetric DIN 965 Cross Recessed (Phillips) Flat Countersunk Machine ScrewsDHEERAJ413No ratings yet

- Floor Deck Profile TS 47/180: Product Data SheetDocument3 pagesFloor Deck Profile TS 47/180: Product Data SheetMohamed KareemNo ratings yet

- TR 60Document3 pagesTR 60Narayanan MoorthyNo ratings yet

- Strux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsDocument2 pagesStrux Clinch Studs and Nuts: Optimal Performance in Thin Sheet and Aluminum Sheet ApplicationsneilNo ratings yet

- New PssDocument4 pagesNew PssVikrant SuryaNo ratings yet

- Evaluation of External Loads On Welding Neck Flanges As Per Code Case 2901Document6 pagesEvaluation of External Loads On Welding Neck Flanges As Per Code Case 2901NirmalNo ratings yet

- The Rose Ola Gjeilo - 0001Document16 pagesThe Rose Ola Gjeilo - 0001Marie Le MaillouxNo ratings yet

- Soal Bahasa Inggris Klas XI Semester IDocument11 pagesSoal Bahasa Inggris Klas XI Semester ISujud Marwoto77% (13)

- Kagawaran NG Edukasyon: Rehiyon X1 Sangay NG Lungsod NG DabawDocument4 pagesKagawaran NG Edukasyon: Rehiyon X1 Sangay NG Lungsod NG DabawElisa LasayNo ratings yet

- PearlAFRO PDFDocument8 pagesPearlAFRO PDFJarne Claesen100% (1)

- Creative Writing: Various Elements, Techniques, and Literary Devices in Specific Forms of PoetryDocument21 pagesCreative Writing: Various Elements, Techniques, and Literary Devices in Specific Forms of PoetryNicki EspinosaNo ratings yet

- Basic Music Theory NotesDocument2 pagesBasic Music Theory NotesCharlotte Dolders100% (1)

- Bach Invention 13 A4 PDFDocument2 pagesBach Invention 13 A4 PDFBranislav PopkonstantinovićNo ratings yet

- The Sibelius Edition - Tone PoemsDocument6 pagesThe Sibelius Edition - Tone PoemsMiguel Gabriel JaritzNo ratings yet

- Market Driven Vs Driving Markets - Jaworski KohliDocument11 pagesMarket Driven Vs Driving Markets - Jaworski Kohlinenaa7770% (1)

- On The Origin of The ChitarroneDocument24 pagesOn The Origin of The ChitarroneJavier Ovejero Mayoral100% (2)

- Kinsey's Dance Resume11-2010Document1 pageKinsey's Dance Resume11-2010Kinsey ReynoldsNo ratings yet

- Cifra Club - ZZ Top - La GrangeDocument10 pagesCifra Club - ZZ Top - La GrangeRodolfo Vicente Savareses MuñozNo ratings yet

- Thanjavur Dolls Marketing SurveyDocument44 pagesThanjavur Dolls Marketing SurveyNagmani Roy100% (2)

- LF Plant STG S.p.A. Main Control PanelDocument98 pagesLF Plant STG S.p.A. Main Control Panelharetha all nassanNo ratings yet

- Scale - 24 - All Major and Minor Scales (Including Fingering For Piano)Document14 pagesScale - 24 - All Major and Minor Scales (Including Fingering For Piano)Min ParkNo ratings yet

- Catch and Release Tab by Matt Simons Tabs at U..Document3 pagesCatch and Release Tab by Matt Simons Tabs at U..vpcdgNo ratings yet

- PC3 Drum MapDocument1 pagePC3 Drum MapTaichiaikidokaNo ratings yet

- 1st Sem French Notes 2014Document46 pages1st Sem French Notes 2014prateek adnaniNo ratings yet

- Gerunds & Infinitive - ExerciseDocument12 pagesGerunds & Infinitive - ExerciseMyDuyen PhanNo ratings yet

- Graduation Programme 2018Document2 pagesGraduation Programme 2018Humberto LopezNo ratings yet

- It All Belongs To You - Deitrick HaddonDocument1 pageIt All Belongs To You - Deitrick HaddonJ.J. Carrion100% (1)

- Terjemahan Dan Soal Count On MeDocument1 pageTerjemahan Dan Soal Count On MeRusdi Mustamar100% (1)

- Dec 10 - Christmas Songs - SopranoDocument22 pagesDec 10 - Christmas Songs - SopranoDebbie TschirchNo ratings yet

- Nocturne No. 20 in C-Sharp Minor, B.49: Frédéric François ChopinDocument5 pagesNocturne No. 20 in C-Sharp Minor, B.49: Frédéric François ChopinnataliaNo ratings yet

- Send My Love (AcapellaDocument46 pagesSend My Love (AcapellaBryan LucchesiNo ratings yet

- Pantomime QuestionsDocument2 pagesPantomime Questions1038grenouilleNo ratings yet