Professional Documents

Culture Documents

Section-018919 Site Plumbing Utilities Performance Requirement Rev 1

Section-018919 Site Plumbing Utilities Performance Requirement Rev 1

Uploaded by

刘盘石Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section-018919 Site Plumbing Utilities Performance Requirement Rev 1

Section-018919 Site Plumbing Utilities Performance Requirement Rev 1

Uploaded by

刘盘石Copyright:

Available Formats

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

SECTION 018919 - SITE PLUMBING UTILITIES PERFORMANCE REQUIREMENTS

PART 1 GENERAL

1.1 SECTION INCLUDES

i) Compliance with sections of Division 1, General Requirements.

ii) This section 018919 forms an integral part of each section, Mechanical.

iii) Labour, materials, equipment and services to complete the work of the

Mechanical Division as further specified and as shown on the Drawings.

iv) The manufacture, supply, delivery, erection, testing, adjustment and

commissioning of the complete plumbing, drainage and fire protection

systems.

v) All of the material to provide a complete and operational installation to the

satisfaction of the Engineer. All incidental components and appurtenance

necessary for the proper operation of the system shall be provided and

installed as required whether or not they were specifically mentioned in

the Contract Documents.

1.2 DEFINITIONS

i) Reviewed: Reviewed by the Engineer; normally a design or piece of

equipment must be shown to have operated successfully for not less than

two years under conditions generally similar to those required by this

Contract. Facilities shall be given at the tender stage, if required by the

Engineer, to enable him to evaluate the equipment's features and

performance. The review of a design or piece of equipment shall be

without prejudice to the acceptance tests required after installation.

ii) Size: When related to pipe work means nominal size which generally

approximates to the bore of steel tubes and the outside diameter of

plastic tubes.

iii) "Complete installation" shall mean not only the major items of plant and

equipment conveyed by this specification, but all the incidental sundry

components necessary for the complete execution of the works and for

the proper operation of the installation, with their labour charges, whether

or not these sundry components are mentioned in detail in the tender

documents issued in connection with the contract.

iv) "As indicated", "where indicated", and "unless otherwise indicated", refer

to items or requirements which are, or may be given elsewhere in the

tender documents issued in connection with the contract, (e.g. on a

drawing, in a supplementary specification or in a schedule to this

specification).

v) Provide: Supply, install and test.

vi) Remove: Remove complete with all ancillary devices and equipment.

20 June 14 (T2E) MTS/018919/1

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

Dispose of off- site in an environmentally safe manner.

1.3 REGULATIONS

i) The Work shall accord strictly with all rules, regulations, By-laws and

requirements of all authorities having jurisdiction.

ii) Drawings and specifications should not conflict with the above

regulations but where there are apparent discrepancies the Contractor

shall notify the Engineer in writing and obtain clarification before

proceeding with the Work.

1.4 GOVERNING STANDARDS

i) The installation shall comply with all relevant statutory instruments and

regulations and in particular with the following:

a. Local Fire Authority.

b. Local Health and Safety at Work Regulations.

c. Local Control of Pollution Regulations.

d. NFPA standards.

e. British Standards.

ii) The Tender shall be based on regulations and standards current on the

date of return of tenders. If these regulations are amended or new

regulations are enacted after that date, the Engineer shall be notified

immediately.

iii) The materials, equipment and installations detailed in this specification

are based on the standards and codes of practice indicated in the

Contract Documents. In the event of a contradiction between this

specification and any applicable standard or Code of Practice, this

specification shall govern and the Engineer shall be notified immediately.

iv) Where material and equipment are specified under a particular standard

and supplied under an equivalent standard, a certificate of compliance

shall be provided to the Engineer at his request.

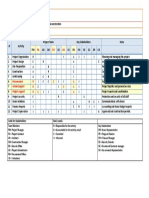

1.5 ABBREVIATIONS

i) Generally, the following abbreviations are used in this Division

AMCA : Air Movement and Control Association

ANSI : American National Standards Institute

AS : Australian Standard

ASHRAE : American Society of Heating, Refrigerating and Air

Conditioning Engineers

ASME : American Society of Mechanical Engineers

ASTM : American Society for Testing and Materials

(ASTM)

AWWA : American Water Works Association

bhp : boiler horsepower or brake horsepower

20 June 14 (T2E) MTS/018919/2

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

BS : British Standard

Btu/hr : British thermal units per hour

BWG : British Wire Gauge

ft/min : cubic feet per minute

c.i : cast iron

cm : centimeter

db : dry bulb

dB : decibel

°C : degree Celsius

D/L : diameter

hp : motor horsepower

kg : kilogram

kPa : Kilopascals

l : Litre

I/s : Litre per second

m : Metre

mm : Millimetre

ml : millilitre

NBS : National Bureau of Standards

N.C. : Noise criterion as defined by graph in ASHRAE .

NFPA : National Fire Protection Association

NPSH : Net positive Suction Head

No. : Number

o.s. and y : outside screw and yoke

Pa : Pascals

pH : hydrogen ion concentration

p/m : parts per million

RC (N) : room criterion (neutral) as defined by ASHRAE

rpm : revolutions per minute

SMACNA : Sheet Metal and Air Conditioning Contractors'

National Association

ss : Stainless steel

UL : Underwriters’ Laboratories

ULC : Underwriter’s Laboratories of Canada

W : Watts

wb : wet bulb

w.g. : water gauge

w.p. : working pressure

1.6 PERMITS, FEES INSPECTION

i) The Contractor shall obtain all required permits from the Municipality

and/or Utility to complete the work. The Contractor shall make all

submissions in a timely fashion with due regard for the requirements of

the construction schedule.

ii) The Contractor shall coordinate with Employer whom pays all fees and

charges levied by the Authorities Having Jurisdiction. The Employer shall

arrange and pay for any permits, inspections and certificates and work

carried out by the Municipality or Utilities in connection with the work.

iii) The Contractor shall perform all tests required by the Authorities Having

Jurisdiction, including those tests specified under this Division, and

submit a copy of the final approved inspection certificate for the approval

20 June 14 (T2E) MTS/018919/3

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

to the Engineer before taking over Certificate. All costs for testing to be

borne by the Employer.

iv) It is the Contractor’s responsibility to provide a comprehensive list of

standards applicable to each municipality and / or utility company

approval after getting information from the concerned authority, and to

provide compliance statements with standards before making submittals

to authorities. Any calculations sketches drawings or information required

shall be produced and provided by the contractor at no extra cost.

1.7 EXAMINATION OF SITE

i) Before submitting tenders, each trade shall examine the site to determine

the conditions which may affect the proposed work. No claims for extra

payment will be considered, because of failure to fulfill this condition.

ii) Determine in consultation with the Municipality and Utilities the location of

all existing underground services at the site. The work shall include the

interface with the airport network, determine the pipes flow rate and

pressure, location and depth of pipe size, etc.

iii) Any comments by the Tenderer on the efficiency of the design, the

availability of plant, materials and labour and the time required for the

completion of the work shall be made when the tender is returned.

1.8 EXISTING UNDERGROUND SERVICES, EXISTING ABOVEGROUND

SERVICES AND SERVICES DIVERSION WORKS

i) The Contractor shall coordinate with the Employer whom is responsible

for the disconnection, rerouting, reconnection and removal of all the

existing aboveground and underground pipes, ducts, etc. as noted and

detailed on Mechanical Site Services drawings.

ii) The Contractor shall coordinate with the Employer whom is responsible

to protect existing underground and aboveground services, including

cable and data lines, etc.

iii) The progress and phasing of work shall not disrupt the existing

Passenger Terminal Building (PTB) operation. The Contractor shall follow

the requirements of the Airport Authority for security, hoarding and hours

of work.

1.9 DRAWINGS, CHANGES AND INSTALLATION

i) The drawings shall be considered to show the general character and

scope of the work and not the exact details of the installation. The

installation shall be complete with all instruction and additions to form

part of Contract.

ii) The location, arrangement and connection of equipment and material as

shown on the drawings represent a close approximation to the intent and

requirements of the Contract. The right is reserved by the Engineer to

make changes required to accommodate conditions arising during the

progress of the work, at no extra cost to the Contract

20 June 14 (T2E) MTS/018919/4

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

iii) All piping and duct work in finished areas shall be concealed in ceiling

spaces and shafts or chased into walls. No exposed piping or duct work

shall be installed in such areas unless specifically accepted by the

Engineer.

iv) Vent pipes, exhaust hoods or other mechanical equipment mounted on

roof, or housing for such equipment, shall not be closer to the edge of

roof than a distance equal to the height of the pipe, hood or equipment;

unless specifically accepted by the Engineer.

v) The actual location of thermostats, switches, etc., shall be reviewed by

the Engineer before installation.

vi) The location and size of existing services shown on the drawings are

based on the best available information. The actual location of existing

services shall be verified in the field before work is commenced.

vii) Changes and modifications necessary to ensure coordination and to

avoid interference and conflicts with other trades, or to accommodate

existing conditions, shall be made at no extra cost to the Contract.

viii) The Contractor shall ensure that all alarm check valves, valves, fans,

pipes and ducts, etc. to be supplied by him (or by the owner) can be

installed in the available space and that there is adequate access to

admit all plant to its position and enable maintenance to be carried out on

the plant without difficulty.

ix) Special care shall be taken in areas where pour-gaps take place.

Coordinate the work schedule with the Contractor.

1.10 RECORD DRAWINGS

i) The Contractor shall clearly mark, as the job progresses, all changes and

deviations from that shown on contract drawings on two sets of prints.

After inspection and acceptance of service lines in trenches and all above

ground building services. The Contractor shall take ‘as built’

measurements, including all depths, prior to commencement of backfilling

operations. It will not be sufficient to check off line locations. Definite

measurements shall be taken for each service line. The location of buried

piping shall be shown on the drawings and dimensioned from fixed

points. Drawings shall be kept up-to-date during construction and in

addition to field measurements shall include variation orders, field

instructions and all other changes. On completion of the building, the

Contractor shall forward to the Engineer three sets of drawings (in hard

and soft copy) and one reproducible set of drawings (in hard and soft

copy) indicating all such changes and deviations. This contractor shall

include all existing information on the final record drawings.

1.11 SHOP DRAWINGS

i) Ensure that electrical, structural, reflected ceiling coordination with all

applicable trades is complete before submitting drawings for review.

ii) Installation of any equipment shall not be commenced until after the shop

drawings have been reviewed by the Engineer.

20 June 14 (T2E) MTS/018919/5

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

iii) When requested, shop drawings shall be supplemented by data

explaining the theory of operation. The Engineer may add Employer

request that this information be added to the maintenance and operating

manual.

iv) Shop drawings shall be in compliance with the requirements of “General

Notes” drawing. Shop Drawings shall indicate clearly all services and the

materials and/or equipment actually being supplied, all details of

construction, accurate dimensions, capacity operating characteristics and

performance. Each material submission shall give the identifying number

of the specific pump, fan, etc. for which it was prepared

(e.g. Fan F-7).

v) Each shop drawings for non-catalogue items shall be prepared

specifically for this project. Material submissions and brochures for

catalogue items shall be marked clearly to show the Items being

supplied.

vi) This contractor shall prepare all shop drawings related to the particular

material submittal and shall submit both the shop drawings and the

material submittal simultaneously mechanical trade. All piping (plumbing,

drainage, chilled water etc.) and duct work under this contract shall be

shown in double line.

vii) A coordinated plan and section (running the entire length) for each shaft

shall be prepared and submitted as part of shop drawings for approved.

viii) A coordinated plan and sections (to a scale of 1:200) for each

mechanical trade shall be submitted as part of shop drawings for

approval.

1.12 DRAWING SUBMISSIONS

i) Unless otherwise indicated, the Contractor shall provide the following

drawings:

ii) Seven (7) sets of prints, one set of reproducible vellum and one

electronic copy (in AutoCAD and PDF format) on disk of builder's work

drawings (to a scale of 1:50).

iii) Three sets of prints, one set of reproducible vellum and one electronic

copy (in AutoCAD and PDF format) on disk of detailed services and plant

room layout drawings (to a scale of 1:50).

iv) Three sets of prints, one set of reproducible vellum and one electronic

copy (in AutoCAD and PDF format) on disk of purpose-made diagrams

detailing separately all the composite electrical circuit and wiring layouts.

v) Three sets of prints, one set of reproducible vellum and one electronic

copy (in AutoCAD and PDF format) on disk of drawings or any variations

to the design suggested by or agreed with the Engineer.

vi) Three sets of prints, one set of reproducible vellum and one electronic

copy (in AutoCAD and PDF format) on disk of ''as installed" drawings,

20 June 14 (T2E) MTS/018919/6

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

upon completion of the work and as a condition precedent to the

certification by the Engineer that the work is complete.

vii) Builder's work drawings shall show fully dimensioned, foundation, bases

plinths, sumps, holes and sleeves details required and the overall size

and weights of the plant concerned.

viii) With the agreement of the Engineer, smaller holes, built-in fixings, etc.,

other than in plant rooms, may be marked out on site instead of on

drawings.

ix) Fully dimensioned plant room drawings shall detail for each plant room

the location of each unit, pipe routes and connections with valves and

fittings, duct routes and connection with access panels, drain

connections, electrical connections and controls. All drawings shall

include explanatory notes and shall show the required sizes of pipes and

ducts with and without insulation as applicable.

x) If abbreviations are employed for the designation of components, an

integral schedule shall be provided on the drawings to explain the

meanings of the abbreviations.

xi) Individual equipment drawings from the various manufacturers will not be

accepted in lieu of these composite plant room drawings.

xii) All drawing and coordination drawings submission in electronic copy shall

be in AutoCAD and PDF format. The submitted AutoCAD drawings shall

be on the latest version of AutoCAD available.

1.13 COORDINATION, INSTALLATION, INTERFERENCE AND SETTING

DRAWINGS

i) Coordination, Installation, interference and setting drawings dimensioned

and to scale, shall be submitted for the Engineer’s review to make clear

the work intended and to, show its relation to adjacent work and to the

work of other trades. Three copies of such drawings shall be submitted

for review, of which one will be retained by the Engineer.

ii) The drawings must be comprehensive showing all details, dimensions,

equipment, supports for services and sections through critical areas to

properly coordinate all services and work of other trades. Unless

accepted by the Engineer, all drawings must be to 1:50 scale.

iii) Site services drawing shall be prepared to show all existing services,

modification to existing services and all new services within the entire

construction area. Drawings must show all connections of new or existing

services to Airport Services Network and must be approved by the

relevant authorities. Location of all existing services shall be carefully

detailed and dimensioned on the drawings showing all sizes and invert

elevations.

iv) Drawings shall be prepared with due regard to the construction schedule

and shall be submitted to the Engineer 6 weeks before construction to

allow time for examination and review.

20 June 14 (T2E) MTS/018919/7

DIVISION 01: GENERAL REQUIREMENTS

SECTION 018919 SITE PLUMBING UTILITIES

PERFORMANCE REQUIREMENTS

v) Work shall not proceed in areas involved until after final approval of all

such drawings has been obtained.

vi) These drawings shall include all existing information.

1.14 CONTRACTOR'S TECHNICAL RESPONSIBILITIES

i) This Contractor shall provide detailed calculations for air and water flow

rate, pressure, head, electrical noise abatement and vibration control for

all equipment including FCU’s, AHU's, fans, pumps, Heat exchangers

etc. whether these are supplied by him or the owner. These calculations

shall be done prior to ordering the equipment and shall be submitted to

the Engineers for review prior to ordering such equipment. The

Contractor shall bear full responsibility for the final equipment sizing and

selection.

ii) The contractor shall provide detailed seismic restraints and supports

design for all equipment piping, duct work, etc. by engaging a specialist

consultant for this purpose. The supply and installation of all seismic

restraints supports and hangars is part of the contractor’s scope of work.

1.15 MECHANICAL SCOPE OF WORK

i) Provide a complete and workable installation, which shall include an

ACMV system, Plumbing and Sanitary system, Building Transportation

System, IBMS system and Fire Protection System to NFPA and Local

Fire Authority standards and approvals.

ii) Provide design, supply and installation of seismic supports, restraints and

hangers.

iii) When pipes pass through floors or walls which are required to be fire

resistant, the opening in the construction around the pipe shall not

exceed 25 mm average clearance and shall be fire stopped by packing

with approved fire rated material to prevent the passage of flame or

smoke. This requirement may be disregarded where pipes pass through

floors of building requiring the protection of vertical openings which shall

be enclosed with approved non-combustible walls having fire-resistance

rating in accordance with the NFPA and Local Fire Authority standards

and approvals.

20 June 14 (T2E) MTS/018919/8

You might also like

- Project Execution of Mega Projects For The Oil and Gas IndustriesDocument209 pagesProject Execution of Mega Projects For The Oil and Gas IndustriesCristhian A. S.B.100% (4)

- PTW Hot Work Uoko3aDocument3 pagesPTW Hot Work Uoko3aUmair KhanNo ratings yet

- Purpose:: Method StatementDocument10 pagesPurpose:: Method StatementIrfan ashrafNo ratings yet

- Submittal 16080.003.A - NETA Test FormsDocument34 pagesSubmittal 16080.003.A - NETA Test Formsirish sedilllNo ratings yet

- Mechanical Engineering Design Criteria PDFDocument44 pagesMechanical Engineering Design Criteria PDFmvdaulkarNo ratings yet

- Project Closure Report - New Adelaide Hospital ProjectDocument23 pagesProject Closure Report - New Adelaide Hospital ProjectSahilNo ratings yet

- Section 018919 Site Plumbing Utilities Performance RequirementDocument10 pagesSection 018919 Site Plumbing Utilities Performance Requirement刘盘石No ratings yet

- Section 018923 Site ACMV Utilities Performance RequirementsDocument9 pagesSection 018923 Site ACMV Utilities Performance Requirements刘盘石No ratings yet

- Basic Mechanical Requirements, Materials & MethodsDocument20 pagesBasic Mechanical Requirements, Materials & MethodsM GulshairNo ratings yet

- Volume 04Document661 pagesVolume 04drunk PUNISHER100% (1)

- Section 1 General Specification Acmv Installation General Requirements of Mechanical & Electrical Works 1.1 GeneralDocument40 pagesSection 1 General Specification Acmv Installation General Requirements of Mechanical & Electrical Works 1.1 GeneralThean Hai XuNo ratings yet

- 40 73 00 - PRESSURE, STRAIN, AND FORCE MEASUREMENT - Rev01Document12 pages40 73 00 - PRESSURE, STRAIN, AND FORCE MEASUREMENT - Rev01adnanyaseenzrgrNo ratings yet

- 40 72 00 - LEVEL MEASUREMENT - Rev01Document15 pages40 72 00 - LEVEL MEASUREMENT - Rev01adnanyaseenzrgrNo ratings yet

- 01-Division 15-Section 15002 Standards & Regulations-VersionDocument41 pages01-Division 15-Section 15002 Standards & Regulations-VersionKrishna Kumar100% (1)

- 40 71 00 - FLOW MEASUREMENT - Rev01Document17 pages40 71 00 - FLOW MEASUREMENT - Rev01adnanyaseenzrgrNo ratings yet

- Volumetwo PDFDocument516 pagesVolumetwo PDFDappili Mani Krishna ReddyNo ratings yet

- PART 1: General Requirement Technical Specification For Sewer NetworkDocument11 pagesPART 1: General Requirement Technical Specification For Sewer NetworkHamza AldaeefNo ratings yet

- Wika LMB Eng Ik CCB Hvac 01Document22 pagesWika LMB Eng Ik CCB Hvac 01riyadigeng19gmailcomNo ratings yet

- GS (A) - General Specification (A) For E&M ProjectDocument25 pagesGS (A) - General Specification (A) For E&M ProjectjunqiangdongNo ratings yet

- 23 08 00 Commissioning of HVACDocument10 pages23 08 00 Commissioning of HVACSoumojit SamantaNo ratings yet

- Air Conditioning System SpecificationDocument16 pagesAir Conditioning System Specification123agattarNo ratings yet

- AIIMSSPARE2FINALDocument75 pagesAIIMSSPARE2FINALBu ManNo ratings yet

- 01-Division 15-Section 15002 Standards and Regulations-Version 2.0Document41 pages01-Division 15-Section 15002 Standards and Regulations-Version 2.0Fasil ENo ratings yet

- Hangers and Supports For Hvac Piping and EquipmentDocument8 pagesHangers and Supports For Hvac Piping and EquipmentMY PCNo ratings yet

- 1767vol IIIDocument183 pages1767vol IIIKrishna ManandharNo ratings yet

- 10 400 KV PANTO Isolator R2 Jan12Document39 pages10 400 KV PANTO Isolator R2 Jan12binodeNo ratings yet

- 40 78 00 - PANEL MOUNTED INSTRUMENTS - Rev01Document12 pages40 78 00 - PANEL MOUNTED INSTRUMENTS - Rev01adnanyaseenzrgrNo ratings yet

- 10 Technical Specification (Civil) PDFDocument5 pages10 Technical Specification (Civil) PDFaee lweNo ratings yet

- SECTION 15195 Testing of Piping Rev 0Document28 pagesSECTION 15195 Testing of Piping Rev 0mohamad damerlyNo ratings yet

- Computer-Room Air ConditionersDocument19 pagesComputer-Room Air ConditionersAbdullah.N FAAliNo ratings yet

- Outline Construction Specification For Phase IV Civil Works (April 2019) 16042019 PDFDocument403 pagesOutline Construction Specification For Phase IV Civil Works (April 2019) 16042019 PDFbada bachaNo ratings yet

- Outline Construction Specification For Phase IV Civil WorksDocument396 pagesOutline Construction Specification For Phase IV Civil WorksShashank BahiratNo ratings yet

- LANL Project I.D. ( - ) Indoor Central-Station Air-Handling Units (Rev. 0, May 19, 2010) 23 7300 - 1Document27 pagesLANL Project I.D. ( - ) Indoor Central-Station Air-Handling Units (Rev. 0, May 19, 2010) 23 7300 - 1Abdullah.N FAAliNo ratings yet

- 0370H09M005H002 PDFDocument153 pages0370H09M005H002 PDFWilborg24No ratings yet

- Technical Specs of Mechanical PlanDocument4 pagesTechnical Specs of Mechanical PlanJay-Mart Dela CruzNo ratings yet

- Technical Specification - ACMV 221222Document82 pagesTechnical Specification - ACMV 221222yuzzaen.execproNo ratings yet

- 2.a - Model TS - GTR, Rev.13Document85 pages2.a - Model TS - GTR, Rev.13anilmarturiNo ratings yet

- 14 Instrument Specifications Erection Annexure-I1Document20 pages14 Instrument Specifications Erection Annexure-I1Amarjeet ChauhanNo ratings yet

- V07 (Architectural FOH Lighting)Document231 pagesV07 (Architectural FOH Lighting)Parth WankhedeNo ratings yet

- 245kV & 145kV CB-MSETCLDocument55 pages245kV & 145kV CB-MSETCLVenkatNo ratings yet

- Getco - r1 Al59 Zebra & MooseDocument27 pagesGetco - r1 Al59 Zebra & Mooseakib javed100% (1)

- Section 15300 - Fire Protection SystemDocument17 pagesSection 15300 - Fire Protection SystemKurt Darryl SabelloNo ratings yet

- 5786 - GTR 12 RevDocument77 pages5786 - GTR 12 RevAbhishek TomarNo ratings yet

- SECTION 11930 Miscellaneous Anaerobic Process Equipment: (Formerly Master Spec. Sec. 11409 - WW)Document2 pagesSECTION 11930 Miscellaneous Anaerobic Process Equipment: (Formerly Master Spec. Sec. 11409 - WW)hasanNo ratings yet

- API-510 Part 1Document79 pagesAPI-510 Part 1TPI KUWAITNo ratings yet

- HFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ADocument19 pagesHFY-GEN-CIV-SPC-0009 - B Specification For Excavation, Backfill and Compaction Code-ATahir FadhilNo ratings yet

- The Scope of Works Includes Supply of Towers and Miscellaneous Items For The Expansion of GSM Rural B-Mobile ProjectDocument13 pagesThe Scope of Works Includes Supply of Towers and Miscellaneous Items For The Expansion of GSM Rural B-Mobile ProjectjesusgameboyNo ratings yet

- Outline Construction Specification For Phase IV Civil Works Revision 1 July - 20 - klL9XY4Document409 pagesOutline Construction Specification For Phase IV Civil Works Revision 1 July - 20 - klL9XY4kishan chaturvediNo ratings yet

- TR39 Volume VDocument221 pagesTR39 Volume VRamphani NunnaNo ratings yet

- Attachment X - Specifications For Prefabrication PipingDocument25 pagesAttachment X - Specifications For Prefabrication PipingmahendraNo ratings yet

- MOH Mechanical Spec20 10Document88 pagesMOH Mechanical Spec20 10nadher albaghdadiNo ratings yet

- Section: Power Factor Correction Square D Varset™ by Schneider ElectricDocument9 pagesSection: Power Factor Correction Square D Varset™ by Schneider ElectricGem EscalanteNo ratings yet

- 4 Volume-5Document332 pages4 Volume-5Mala Seth DuttaNo ratings yet

- 23 73 00-Air Handling UnitsDocument13 pages23 73 00-Air Handling UnitsTalha BaigNo ratings yet

- 6 400KV CB PirDocument36 pages6 400KV CB PirRAPRATSINNo ratings yet

- HFY-PIP-SP-00012 X Specification For Expansion Joint - A-CommentedDocument9 pagesHFY-PIP-SP-00012 X Specification For Expansion Joint - A-CommentedVignesh PanchabakesanNo ratings yet

- AP County Adopted Codes and Design Criteria 210 201712181530520470Document38 pagesAP County Adopted Codes and Design Criteria 210 201712181530520470pedroNo ratings yet

- Plumbing Engineering SpecificationDocument37 pagesPlumbing Engineering SpecificationjhennNo ratings yet

- SECTION 11470 Darkroom Equipment Rev 0Document12 pagesSECTION 11470 Darkroom Equipment Rev 0Munir RasheedNo ratings yet

- Electrical AuxiliaryDocument121 pagesElectrical AuxiliaryGove Mojemer RedNo ratings yet

- HFY-GEN-CIV-SPC-0011 - B Specification For Platforms, Stairs, Ladders and Handrailings Code ADocument9 pagesHFY-GEN-CIV-SPC-0011 - B Specification For Platforms, Stairs, Ladders and Handrailings Code ATahir FadhilNo ratings yet

- Scope of WorkDocument6 pagesScope of WorkAice LuzadaNo ratings yet

- Karnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701Document397 pagesKarnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701harishNo ratings yet

- Section 031100 FormworkDocument10 pagesSection 031100 Formwork刘盘石No ratings yet

- Section 018926 Gen - Instruction For Elect-1Document50 pagesSection 018926 Gen - Instruction For Elect-1刘盘石No ratings yet

- Section 031513 Waterstops PDFDocument5 pagesSection 031513 Waterstops PDF刘盘石No ratings yet

- Section 018919 Site Plumbing Utilities Performance RequirementDocument10 pagesSection 018919 Site Plumbing Utilities Performance Requirement刘盘石No ratings yet

- Section 018923 Site ACMV Utilities Performance RequirementsDocument9 pagesSection 018923 Site ACMV Utilities Performance Requirements刘盘石No ratings yet

- Section-220523 Duty Valves For Plumbing Piping Rev 1Document6 pagesSection-220523 Duty Valves For Plumbing Piping Rev 1刘盘石No ratings yet

- Section-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1Document3 pagesSection-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1刘盘石No ratings yet

- Section-220500 Common Work Results For Plumbing Rev 1Document17 pagesSection-220500 Common Work Results For Plumbing Rev 1刘盘石No ratings yet

- 53 BS en 1991-1-7 2006Document70 pages53 BS en 1991-1-7 2006刘盘石100% (1)

- History of Roads and HighwaysDocument6 pagesHistory of Roads and Highwaysjesica quijanoNo ratings yet

- Astm D6103 - D6103M-17Document4 pagesAstm D6103 - D6103M-17anant11235No ratings yet

- 1 - BOQ Part IDocument5 pages1 - BOQ Part Iمهدي المقدمNo ratings yet

- Spherical TankDocument30 pagesSpherical TankNuzuliana EnuzNo ratings yet

- تقرير سبيس فريم PDFDocument11 pagesتقرير سبيس فريم PDFAli AkeelNo ratings yet

- Elbow 12 STD 90D LR - OkDocument1 pageElbow 12 STD 90D LR - OkJovianto PrisilaNo ratings yet

- 06precast ComponentsDocument1 page06precast ComponentsDhanashri MirajkarNo ratings yet

- Descoping of Works: What Is The Employer Entitled To Do?: ConstructionDocument2 pagesDescoping of Works: What Is The Employer Entitled To Do?: ConstructionAnonymous 94TBTBRksNo ratings yet

- Dimitra Papageorgiou CVDocument2 pagesDimitra Papageorgiou CVDimitra PapageorgiouNo ratings yet

- + MPM Project RACI Chart - Case StudyDocument1 page+ MPM Project RACI Chart - Case StudyPeter KoromaNo ratings yet

- Florida Building Code 2019Document59 pagesFlorida Building Code 2019Frank MartinezNo ratings yet

- Methode of StatementDocument10 pagesMethode of StatementmaninderpreetNo ratings yet

- Report InternshipDocument42 pagesReport Internshipfaiqahhannah4No ratings yet

- Math DefinitionsDocument11 pagesMath DefinitionsJohn Saniel J. EstacionNo ratings yet

- Technological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityDocument179 pagesTechnological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityS. R. perea100% (1)

- FLANGE JIS 16K SS304 & CS Rev 2Document2 pagesFLANGE JIS 16K SS304 & CS Rev 2Hendrias ari sujarwoNo ratings yet

- SAB 3122 Construction Technology and Estimating: BricksDocument10 pagesSAB 3122 Construction Technology and Estimating: BricksthamilNo ratings yet

- Dypenting Bay SectionDocument2 pagesDypenting Bay SectioncarlNo ratings yet

- 27j Scaffold PermitDocument1 page27j Scaffold PermitMohammed MinhajNo ratings yet

- Wilson2015 PDFDocument21 pagesWilson2015 PDFMaría De Los ÁngelesNo ratings yet

- CDM 2015Document8 pagesCDM 2015Nikhil PatilNo ratings yet

- Method Statement For Casting of Precast Facia Panel: - 1 - VKLR, QmeDocument3 pagesMethod Statement For Casting of Precast Facia Panel: - 1 - VKLR, QmeBalaji ManneNo ratings yet

- Case Study S-BDocument2 pagesCase Study S-BDhanushree CRNo ratings yet

- National Highways of Infrastructure Development Corporation LTDDocument30 pagesNational Highways of Infrastructure Development Corporation LTDMudit MehraNo ratings yet

- 5 Building Information Modelling and Construction Management PDFDocument168 pages5 Building Information Modelling and Construction Management PDFPablo TellaecheNo ratings yet

- Design Team NotesDocument16 pagesDesign Team NotesGerald MagomaNo ratings yet