Professional Documents

Culture Documents

MITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog EN

MITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog EN

Uploaded by

George DobreOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog EN

MITA - PMS K12 Open Circuit Cooling Towers For Small Medium Plants Catalog EN

Uploaded by

George DobreCopyright:

Available Formats

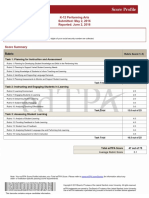

PMS K12

cooling technologies

Open

cooling towers

MITA participates in the ECP

programme for Cooling Towers.

Check ongoing validity of certificate:

www.eurovent-certification.com

PM Series - PMS with Diploma N° 16.02.002

PMS K12

SERIES

COOLING TOWER

The PMS K12 cooling towers The filling material is made of

are built entirely in fibreglass (or- self-extinguishing PVC with 12 mm

thophthalic polyester resin, rein- flute.

forced with several layers of glass The multi-blade axial fan (with

fibre matting) in order to avoid blades in plastic material reinfor-

corrosion problems due to the ced with glass fibre) grants high

fact that the tower is constantly in performances with low electrical

contact with water and it is expo- power input and low noise levels.

sed to all kinds of weather.

The structure is self-supporting The certified PMS K12 series in-

and strengthened at the points of cludes 7 models, all available with

greatest dynamic and static or without water basin, for a range

stress. Moreover, the fibreglass of cooling capacities from approx.

surface is protected by a gelcoat 62 kW to 830 kW (indicative va-

that is resistant to UV rays, hot lues referred to nominal tempe-

and cold water and abrasion due ratures conditions 40°C in, 30°C

to weather and chemicals. out, 24°C wet bulb).

The basin has a sloping bot-

tom with rounded off corners, to

enable an easy emptying to sim-

plify its cleaning.

Accessories and

construction variants

The following accessories and/or construction variants are available for all

models on request:

• three-phase heating element with control thermostat

• minimum level cut-out switch

• control panel

• manhole for easy inspection and access to the internal ccmponents.

Eurovent Certita Certification (ECC) & Cooling Technology Institute

(CTI) together provide the international certification of cooling towers.

Performance certification is the basis for end-users, consultants,

contractors, manufacturers and government to ensure correct investment

in quality products.

1 Main casing and top cap

Material:

3 Filling material

(or heat exchange surface)

Construction

orthophthalic polyester resin,

reinforced with several layers of

Material:

self-extinguishing PVC. details

glass fibre matting. Characteristics:

Characteristics: • 12 mm flute (air/water passage)

• self supporting structure streng- • reinforced top layer to better absorb

thened at the points of greatest dynamic stress caused by the under

dynamic and static stress pressure sprayed water from the

• external surface protection with nozzles.

gel-coating resistant to UV rays,

cold and hot water, abrasion due to 4 Multi-blade axial fan 6 Anti-splash louvers on air intake

weather and chemicals Material: openings

• light-weight motor support: hot dip galvanized Material:

• non corroding. steel (after all works), fan blades: fibreglass louver (on request:

plastic material, fan screening grid: PP panels in a suitable galvanized

2 Watar basin (optional) stainless steel. steel frame).

Material: Characteristics: Characteristics:

orthophthalic polyester resin, • high performance, low electrical • non corroding

reinforced with several layers of power input, low noise levels • easy to remove even after many

glass fibre matting. • directly coupled to the electric motor years of use.

Characteristics: • unalterable safety over time thanks

• external surface protection with to the fan screening grid 7 Visual inspection window

gel-coating resistant to UV rays, • non-corroding. Material:

cold and hot water, abrasion due to nylon reinforced with glass fibre

weather and chemicals 5 Hot water distribution system

• internal waterproof protection Material: 8 Bolts, nuts and washers

thanks to an impermeable, water PN 10 unified PVC, PP, PE pipes, Material:

repellent, paraffin containing polypropylene nozzles. stainless steel 304.

orthophthalic gelcoat Characteristics: Characteristics:

• sloping bottom with rounded • non-corroding • non corroding

off corners, to enable an easy • uniform and total spraying of the • easy to remove even after many

emptying to simplify its cleaning heat exchange filling pack years of use.

• light-weight • MITA exclusive nozzles design, with

• non corroding. non-clogging wide passages for a

full cone spray.

MITA participates in the ECP

programme for Cooling Towers.

Check ongoing validity of certificate:

www.eurovent-certification.com

PM Series - PMS with Diploma N° 16.02.002

PMS K12 Series with water basin PMS K12 Series without water basin

Dimensions

and

weights

A

D

D

Dimensions Water connections Nominal Total nameplate Total rated fan Weights

water flow fan motor power motor power

Model A B C D H K L M rate* per model* per model* empty in operation

mm mm mm mm Ø in Ø in Ø in Ø in l/s kW kW kg kg

with water basin

PMS 6/65 K12 2190 800 800 1500 2” 2” ¾” ½” 1,5 1,1 0,89 75 180

PMS 9/85 K12 2695 1000 1000 1900 2 ½” 2 ½” ¾” ½” 3,4 2,2 1,68 95 285

PMS 9/110 K12 2870 1200 1200 2000 3” 3” 1” ¾” 5,6 3 2,17 170 485

PMS 9/130 K12 2935 1400 1400 1900 4” 4” 1” ¾” 7,9 4 3,52 210 780

PMS 10/180 K12 3200 1740 1740 2060 4” 4” 1 ¼” 1” 12,4 5,5 4,51 410 1410

PMS 10/240 K12 3515 2100 1900 2240 4” 5” 1 ¼” 1” 15,9 7,5 6,44 525 1825

PMS 10/260 K12 3530 2300 2100 2250 5” 6” 1 ½” 1 ½” 19,9 7,5 6,82 580 1980

without water basin

PMS 6/65 K12 1670 770 770 990 2” - - - 1,5 1,1 0,89 60 80

PMS 9/85 K12 2025 980 980 1230 2 ½” - - - 3,4 2,2 1,68 75 100

PMS 9/110 K12 2240 1215 1215 1385 3” - - - 5,6 3 2,17 135 185

PMS 9/130 K12 2270 1370 1370 1270 4” - - - 7,9 4 3,52 165 225

PMS 10/180 K12 2335 1715 1715 1230 4” - - - 12,4 5,5 4,51 325 440

PMS 10/240 K12 2485 1805 2050 1235 4” - - - 15,9 7,5 6,44 430 535

PMS 10/260 K12 2550 2010 2210 1270 5” - - - 19,9 7,5 6,82 490 600

* Nominal temperature conditions: 40°C in; 30°C out; 24°C wet bulb. Technical data not binding

For data concerning other versions, please write to: export@mitact.it

PMS K12 ENG • 01-19

Gestione Qualità

cooling technologies

Certificata

ISO 9001

ISO 9001

Via del Benessere, 13

27010 Siziano (PV) - Italy

+39 0382.67599 - info@mitact.it

You might also like

- Trane Old Ycc InfoDocument32 pagesTrane Old Ycc InfoMike ZellerNo ratings yet

- PMS - D BrochureDocument4 pagesPMS - D Brochureعلي الطائيNo ratings yet

- Pe-Rt/Al/Pe-Rt Multilayer Pipe: Technische InformationDocument4 pagesPe-Rt/Al/Pe-Rt Multilayer Pipe: Technische InformationLloyd Ki'sNo ratings yet

- c11 CCCT FXV 20150914Document31 pagesc11 CCCT FXV 20150914JAirBuCerEdsNo ratings yet

- PMS-D BrochureDocument6 pagesPMS-D BrochureОливер АндовскиNo ratings yet

- DKM CP DN25-65 En1Document24 pagesDKM CP DN25-65 En1brilian pungkyNo ratings yet

- EG Valves' CatalogueDocument8 pagesEG Valves' CataloguerezajakakusumaNo ratings yet

- DP Pump CatalogueDocument16 pagesDP Pump CatalogueJust RysdanNo ratings yet

- Fincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignDocument2 pagesFincoil FBLM: Customized Auxiliary Liquid Coolers With ASME DesignSuresh Damu BhadNo ratings yet

- 3000 Brochure PDFDocument24 pages3000 Brochure PDFFarooque ShaikhNo ratings yet

- PVCMC 0501 Us PDFDocument40 pagesPVCMC 0501 Us PDFAshok SureshNo ratings yet

- Passoni PNO BushingsDocument12 pagesPassoni PNO BushingsDimitar MarkovNo ratings yet

- Rock Plast Pipe BrochureDocument28 pagesRock Plast Pipe BrochureHusna Mega JayaNo ratings yet

- Complete Piping Solutions For Applications: Jeevan Bhar Ka Saath..Document8 pagesComplete Piping Solutions For Applications: Jeevan Bhar Ka Saath..rim deNo ratings yet

- Process CryostarDocument8 pagesProcess CryostarNarayan MarndiNo ratings yet

- BAC ProdAppHBii2007SupplDocument52 pagesBAC ProdAppHBii2007SupplmihdragosNo ratings yet

- Sewage Pump AmacanDocument56 pagesSewage Pump Amacaniwangic4639100% (2)

- CPI Technical-EngDocument22 pagesCPI Technical-EngMazwan Che MansorNo ratings yet

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Document1 pageStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilNo ratings yet

- FRP Catalogue PDFDocument134 pagesFRP Catalogue PDFAnonymous EKxXjqyVHNo ratings yet

- DK DN 15÷65: PVC-CDocument16 pagesDK DN 15÷65: PVC-CovidiuNo ratings yet

- Am DDM Ups Rs Aa 0418Document4 pagesAm DDM Ups Rs Aa 0418aldariz201181No ratings yet

- DK CP enDocument20 pagesDK CP enbrilian pungkyNo ratings yet

- PowerSafe V Front Terminal - Range SummaryDocument2 pagesPowerSafe V Front Terminal - Range SummarygenikosNo ratings yet

- Spec 00542 PDFDocument4 pagesSpec 00542 PDFmir intequabNo ratings yet

- 69.nylon Fabric Duct Hosesilicone Coated Duct HoseDocument1 page69.nylon Fabric Duct Hosesilicone Coated Duct Hosewebhareggebru06No ratings yet

- Bateria Power V Safe 12v190fDocument2 pagesBateria Power V Safe 12v190fJader SuarezNo ratings yet

- RKNL-H (15-20 Ton)Document72 pagesRKNL-H (15-20 Ton)Meghana BuchiNo ratings yet

- Performance Analysis of Vpi Transformer: For ContinuousDocument6 pagesPerformance Analysis of Vpi Transformer: For ContinuousSwapan Kundu100% (1)

- GRP Pipes Fittings CatalogDocument8 pagesGRP Pipes Fittings CatalogAAF0% (1)

- TMEIC TM21 VLL Medium Voltage Vertical Motors Hi-Res 1316637884Document16 pagesTMEIC TM21 VLL Medium Voltage Vertical Motors Hi-Res 1316637884jalilemadiNo ratings yet

- Krah Tehn Juhend ENGpreviewDocument28 pagesKrah Tehn Juhend ENGpreviewQuerubin R Yolando Jr.No ratings yet

- Omega 2pg 1384.021v3-10Document2 pagesOmega 2pg 1384.021v3-10Hesham AmerNo ratings yet

- Applications: Complete Piping Solutions ForDocument8 pagesApplications: Complete Piping Solutions ForShree Swapna UllengalaNo ratings yet

- Hardware Specs DigicelDocument2 pagesHardware Specs Digicelsebax123No ratings yet

- C-PVC Hot and Cold Water SystemDocument3 pagesC-PVC Hot and Cold Water Systemarjun 11No ratings yet

- Dry Type BrochureDocument16 pagesDry Type BrochurekannuNo ratings yet

- Dunham Bush Package UnitsDocument8 pagesDunham Bush Package UnitsStephanie StewartNo ratings yet

- SPEC Pulsatron E PLUS SeriesDocument2 pagesSPEC Pulsatron E PLUS SeriesAlfonso Javier Medina PernethNo ratings yet

- Rheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesDocument48 pagesRheem Commercial Value Series Package Air Conditioner: RLKL-B Standard Efficiency SeriesJesus RequenaNo ratings yet

- Unicor 2Document52 pagesUnicor 2Lam Ch100% (1)

- Transparent Level GaugesDocument4 pagesTransparent Level GaugesAlfonso BlancoNo ratings yet

- Ahe00043en - FBLG (Radiadores Finned Coil FBLG)Document2 pagesAhe00043en - FBLG (Radiadores Finned Coil FBLG)Marco FreireNo ratings yet

- Rheem PKG RLNL-B - S11-937 - Rev1 PDFDocument56 pagesRheem PKG RLNL-B - S11-937 - Rev1 PDFWESHIMNo ratings yet

- ALLWEIR NTT40 PumpDocument12 pagesALLWEIR NTT40 PumpfaisalnadimNo ratings yet

- RKNL-G (15-25 Ton)Document64 pagesRKNL-G (15-25 Ton)Meghana BuchiNo ratings yet

- PVC Casing PipesDocument8 pagesPVC Casing Pipesamit kumar pandeyNo ratings yet

- Rip Bushing PDFDocument38 pagesRip Bushing PDFTravis Wood100% (1)

- Atlantic OPRO Classic 1.2kWDocument2 pagesAtlantic OPRO Classic 1.2kWMohammad ZeeshanNo ratings yet

- Dynaflow - GRE Piping - March 26 2009Document60 pagesDynaflow - GRE Piping - March 26 2009sammar_10100% (3)

- FlowMon Catalogue 2 PDFDocument12 pagesFlowMon Catalogue 2 PDFsimbamikeNo ratings yet

- Grid Xtreme VR Green-Series Data Sheet enDocument3 pagesGrid Xtreme VR Green-Series Data Sheet enlong bạchNo ratings yet

- Maart 2009Document60 pagesMaart 2009Ricardo MendesNo ratings yet

- Produktuebersicht EnglDocument12 pagesProduktuebersicht EnglAlkypperoeNo ratings yet

- Company Profile 2021Document36 pagesCompany Profile 2021Anonymous H9Qg1iNo ratings yet

- Rheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyDocument60 pagesRheem Commercial Classic Series Package Air Conditioner Featuring Humididry TechnologyIshfaqAhmedMayoNo ratings yet

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pages3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaNo ratings yet

- MVE Eterne Series: - 190°C Vapor StorageDocument2 pagesMVE Eterne Series: - 190°C Vapor StorageraviNo ratings yet

- Flow of Mixture in A PipelineDocument14 pagesFlow of Mixture in A PipelineGeorge DobreNo ratings yet

- PRTP Peripheral Drive Scraper BridgeDocument2 pagesPRTP Peripheral Drive Scraper BridgeGeorge DobreNo ratings yet

- Penstock Wedeco GeneralDocument6 pagesPenstock Wedeco GeneralGeorge DobreNo ratings yet

- Air Quality in Europe 2019 Tcm30 187944Document104 pagesAir Quality in Europe 2019 Tcm30 187944George DobreNo ratings yet

- Odour Control Units CarbonDocument2 pagesOdour Control Units CarbonGeorge DobreNo ratings yet

- Measurement of Odour Concentration of ImmissionsDocument6 pagesMeasurement of Odour Concentration of ImmissionsGeorge DobreNo ratings yet

- 38 Standard Odor Measure For Air QualityDocument12 pages38 Standard Odor Measure For Air QualityGeorge DobreNo ratings yet

- Enhancing VDI3940 Grid Method Via In-Field OlfactometryDocument6 pagesEnhancing VDI3940 Grid Method Via In-Field OlfactometryGeorge DobreNo ratings yet

- Energies-15-04015 - Application of Field Olfactometry To Monitor The Odour ImpactDocument15 pagesEnergies-15-04015 - Application of Field Olfactometry To Monitor The Odour ImpactGeorge DobreNo ratings yet

- FrictionLossChart PE4710 PipeDocument2 pagesFrictionLossChart PE4710 PipeGeorge DobreNo ratings yet

- Wirtz ISU 1992 W749Document143 pagesWirtz ISU 1992 W749George DobreNo ratings yet

- Solutions For Water & IndustryDocument60 pagesSolutions For Water & IndustryGeorge DobreNo ratings yet

- Cooling Tower PerformanceDocument13 pagesCooling Tower PerformanceGeorge DobreNo ratings yet

- BMS 3023 HSECPA 270mc 72barDocument15 pagesBMS 3023 HSECPA 270mc 72barGeorge DobreNo ratings yet

- W22 Three Phase Electric MotorDocument76 pagesW22 Three Phase Electric MotorGeorge DobreNo ratings yet

- Germany Power Plant Health ImpactsDocument22 pagesGermany Power Plant Health ImpactsGeorge DobreNo ratings yet

- MITA - Recommendation 9 13 - Evaporative Cooling Equipment Water Consumption Minimising - Eurovent 2019 - WebDocument11 pagesMITA - Recommendation 9 13 - Evaporative Cooling Equipment Water Consumption Minimising - Eurovent 2019 - WebGeorge DobreNo ratings yet

- Types of Shell Tube Heat ExchangersDocument7 pagesTypes of Shell Tube Heat ExchangersGeorge DobreNo ratings yet

- 2016 02 Engineers Notebook - Peterson - Open Cooling Tower DesignDocument5 pages2016 02 Engineers Notebook - Peterson - Open Cooling Tower DesignGeorge DobreNo ratings yet

- Interview Assessment FormDocument3 pagesInterview Assessment FormCristina BocanialaNo ratings yet

- Building Serverless App PythonDocument266 pagesBuilding Serverless App PythonMatei Danut100% (3)

- Indian civil services (IAS - IPS - IRS) in telugu medium - civils రాంకర్లు వాళ్ళు ఎంచుకున్న ఆప్షనల్ సబ్జెక్టుల వివరాలుDocument34 pagesIndian civil services (IAS - IPS - IRS) in telugu medium - civils రాంకర్లు వాళ్ళు ఎంచుకున్న ఆప్షనల్ సబ్జెక్టుల వివరాలుSuresh VantasalaNo ratings yet

- Muhammad Aqlan Rusaydi S2 Group Assignment MKT2013Document36 pagesMuhammad Aqlan Rusaydi S2 Group Assignment MKT2013kl2204010823No ratings yet

- Cost Benefit AnalysisDocument2 pagesCost Benefit AnalysisGarvitJainNo ratings yet

- The Compleat Gentleman PeachamDocument316 pagesThe Compleat Gentleman PeachamCezara Ripa de MilestiNo ratings yet

- Free State Will MTD For Vindictive ProsecutionDocument4 pagesFree State Will MTD For Vindictive ProsecutionRobert GouveiaNo ratings yet

- Quasi Turbine 140505201837 Phpapp01Document16 pagesQuasi Turbine 140505201837 Phpapp01pravesh singh100% (1)

- EdtpaDocument7 pagesEdtpaapi-310967404No ratings yet

- Business Finance: First Quarter Learning PacketDocument60 pagesBusiness Finance: First Quarter Learning PacketNikkie Desiongco100% (1)

- Leadership - Pob NotesDocument11 pagesLeadership - Pob NoteschloeniabNo ratings yet

- CRR & SLRDocument19 pagesCRR & SLRBalpreet KaurNo ratings yet

- Coupled Tanks - Workbook (Student) INGLÉS PDFDocument34 pagesCoupled Tanks - Workbook (Student) INGLÉS PDFDanielaLópezNo ratings yet

- Model Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangDocument6 pagesModel Delone and Mclean Dalam Aplikasi Absensi Super Hana Di PT Telkom PalembangZahwa PutriNo ratings yet

- Saep 349 PDFDocument41 pagesSaep 349 PDFRami ElloumiNo ratings yet

- A Software For Gravity Dam Stability AnalysisDocument9 pagesA Software For Gravity Dam Stability Analysislemi celemenNo ratings yet

- Submissions WESTLANDS FOREX BUREAUDocument10 pagesSubmissions WESTLANDS FOREX BUREAUCHEMOIYWO PHILEMON KIPROPNo ratings yet

- Activity Sheet in Emptech 1q Week10 Lesson 4.2 Google FormsDocument7 pagesActivity Sheet in Emptech 1q Week10 Lesson 4.2 Google FormsscuttlecrabNo ratings yet

- Chapter 10 (6) - BDocument52 pagesChapter 10 (6) - BMahfuzur RahmanNo ratings yet

- Book 1Document219 pagesBook 1Ardi AnsyahNo ratings yet

- Guidance Settlement Application SET (O)Document13 pagesGuidance Settlement Application SET (O)Amir FarooquiNo ratings yet

- 0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Document2 pages0 - 10 3 0 DBGFC 6 37 - I::.Batalog Pa&E Nqi 5 0 - Customer Part No. 11339772Miguel RojasNo ratings yet

- AR11Document241 pagesAR11Mohib Ullah YousafzaiNo ratings yet

- GCSE Higher Maths Practice Paper 2 (Calculator)Document13 pagesGCSE Higher Maths Practice Paper 2 (Calculator)priyahaasinigantiNo ratings yet

- Height WorkDocument3 pagesHeight Workssb goddaNo ratings yet

- An Example of Data Analysis: Mathematics Higher Level Internal Assessment ExplorationDocument15 pagesAn Example of Data Analysis: Mathematics Higher Level Internal Assessment ExplorationLorraine SabbaghNo ratings yet

- Terminal Pulogebang PDFDocument2 pagesTerminal Pulogebang PDFEka SanusiNo ratings yet

- ReflectionDocument1 pageReflectionThess Tecla Zerauc Azodnem100% (1)

- Review Article The Roles and Responsibilities of Management Accountants in The Era of GlobalizationDocument2 pagesReview Article The Roles and Responsibilities of Management Accountants in The Era of GlobalizationJose Fanny100% (1)

- Chicco Cortina Stroller Owner's Manual PDFDocument36 pagesChicco Cortina Stroller Owner's Manual PDFRoss Imperial CruzNo ratings yet