Professional Documents

Culture Documents

Specification For Precast Chamber

Specification For Precast Chamber

Uploaded by

Tai ChoonCopyright:

Available Formats

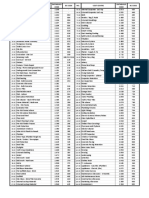

You might also like

- JKR20710 0001 11 PDFDocument13 pagesJKR20710 0001 11 PDFGeneNo ratings yet

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- Road Design ReportDocument21 pagesRoad Design ReportZaidi MohamadNo ratings yet

- Body Corporate Guidelines PDFDocument17 pagesBody Corporate Guidelines PDFmaNo ratings yet

- Upvc Pipe For Strom Water Above Ground Elevated HighwayDocument75 pagesUpvc Pipe For Strom Water Above Ground Elevated HighwayutkarshsabberwalNo ratings yet

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 10805 MS-SIRIM-190716 PDFDocument85 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 10805 MS-SIRIM-190716 PDFHimura_No ratings yet

- Summary Average Price Sabah Ok T 09Document12 pagesSummary Average Price Sabah Ok T 09Jayson TeeNo ratings yet

- Schedule of Rates 2011 Rev1Document144 pagesSchedule of Rates 2011 Rev1Screen BiruNo ratings yet

- Section 06 1000 Rough CarpentryDocument5 pagesSection 06 1000 Rough CarpentryNibras MohamedNo ratings yet

- Twin Waterfalls EC E BrochureDocument31 pagesTwin Waterfalls EC E BrochurecalkahNo ratings yet

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- Checklist For Prebond of Confined AreaDocument2 pagesChecklist For Prebond of Confined Areamukesh patel0% (1)

- Specification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFDocument6 pagesSpecification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFMOHD JIDINo ratings yet

- Specification For Ductile Iron Pillar HydrantsDocument12 pagesSpecification For Ductile Iron Pillar HydrantsyogeswaranNo ratings yet

- NOTE-Spec. For Ductile Iron Pipes1 K9-K12Document32 pagesNOTE-Spec. For Ductile Iron Pipes1 K9-K12binunalukandamNo ratings yet

- Raudhah Ded PiaiDocument26 pagesRaudhah Ded PiaiAshiteru BestNo ratings yet

- 5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Document51 pages5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Mohd Muzani MustafaNo ratings yet

- Roundabout Design GuidelinesDocument76 pagesRoundabout Design GuidelinesDalibor StanicNo ratings yet

- 7 JKR SPJ 2011-S7Document8 pages7 JKR SPJ 2011-S7Carwen WongNo ratings yet

- RTVM 2018Document152 pagesRTVM 2018Cheeloon NgoNo ratings yet

- OKA G45 RC - Square PilesDocument4 pagesOKA G45 RC - Square PilesTee Bun PinNo ratings yet

- Specification For Suppliers PDFDocument7 pagesSpecification For Suppliers PDFalep azizNo ratings yet

- Reinforcement CouplersDocument24 pagesReinforcement Couplersvishalgore100% (1)

- BQ PmuDocument5 pagesBQ PmuAzamOthman100% (1)

- IWK Guide On FeeDocument1 pageIWK Guide On FeeJohnyReubenNo ratings yet

- PilingDocument34 pagesPilingHariz HilmanNo ratings yet

- SPECIFICATION OF FITTINGS FOR HOT TAPPING WORK Material - CompressedDocument20 pagesSPECIFICATION OF FITTINGS FOR HOT TAPPING WORK Material - CompressedTom YeeNo ratings yet

- PEMBANGUNAN TEPI JALAN-scribdDocument15 pagesPEMBANGUNAN TEPI JALAN-scribdSITI KHADIJAH BINTI OTHMAN (JKR)No ratings yet

- MS 628-3 2014 - PrepdfDocument7 pagesMS 628-3 2014 - PrepdfMay OngNo ratings yet

- 2023-Nov One-Day Workshop On Becoming A PE & The New Outcome-Based PAE - Preparation of Documentations For SubmissionDocument83 pages2023-Nov One-Day Workshop On Becoming A PE & The New Outcome-Based PAE - Preparation of Documentations For Submissionabiyu95No ratings yet

- Mos Silt FenceDocument4 pagesMos Silt FenceKi KaNo ratings yet

- R&D ContohDocument26 pagesR&D ContohfeedNo ratings yet

- Pdc8 Checklist StatusDocument1 pagePdc8 Checklist StatusNusaibah YusofNo ratings yet

- NOTA KURSUS TAHUN 2006 - Pengiraan Kadar Alir Menggunakan HP - 05-07-2006 To 27-07-2006Document149 pagesNOTA KURSUS TAHUN 2006 - Pengiraan Kadar Alir Menggunakan HP - 05-07-2006 To 27-07-2006elffie yunusNo ratings yet

- Steel Fabric PropertiesDocument2 pagesSteel Fabric PropertiesDennis Tan100% (1)

- JKR SIRIM PrePDFDocument4 pagesJKR SIRIM PrePDFkhairul AnwarNo ratings yet

- Specification For Calcium Hypochlorite1Document5 pagesSpecification For Calcium Hypochlorite1Danial RH AbtahiNo ratings yet

- Jabatan Kerja Raya: Manual On Traffic Control Devices Temporary Signs and Work Zones ControlDocument4 pagesJabatan Kerja Raya: Manual On Traffic Control Devices Temporary Signs and Work Zones ControlHatim ShamsudinNo ratings yet

- Safety Measures CIDB RefDocument38 pagesSafety Measures CIDB RefJohnnyNo ratings yet

- JKR - PK (O) .04 SKC - As.4b1Document2 pagesJKR - PK (O) .04 SKC - As.4b1Mohd Kamal TajudinNo ratings yet

- Signature of Owner: Borang PDC 2Document8 pagesSignature of Owner: Borang PDC 2Mageswary KunalanNo ratings yet

- JKR Sarawak Geotextile SpecificationDocument23 pagesJKR Sarawak Geotextile Specificationglomac puchongNo ratings yet

- Bill of Quantities: IndexDocument42 pagesBill of Quantities: IndexLe JennieNo ratings yet

- MS 1064 PT 8 2001 Confirmed Prepdf PDFDocument5 pagesMS 1064 PT 8 2001 Confirmed Prepdf PDFFauziah AzizNo ratings yet

- The Conditions For Water Reticulation PlansDocument1 pageThe Conditions For Water Reticulation PlansedwinhlcNo ratings yet

- BD 3394Document18 pagesBD 3394jrobert123321No ratings yet

- Mill and Pave Latest 5 Sep 2017Document69 pagesMill and Pave Latest 5 Sep 2017Ibnuyusoff77100% (1)

- SPECIFICATION FOR HIGH DENSITY POLYETHYLENE PIPEWORKS FINAL APRIL 2019 Edited PDFDocument29 pagesSPECIFICATION FOR HIGH DENSITY POLYETHYLENE PIPEWORKS FINAL APRIL 2019 Edited PDFalep azizNo ratings yet

- NGSB Method Statement - RoadworkDocument8 pagesNGSB Method Statement - RoadworkFitrikamarudin mpppsaNo ratings yet

- Ms 229 2009 Timber PDFDocument5 pagesMs 229 2009 Timber PDFGnabBangNo ratings yet

- SDocument79 pagesSzainaru razaliNo ratings yet

- Arahan Teknik-Cawangan Jalan - Jabatan Kerja Raya MalaysiaDocument6 pagesArahan Teknik-Cawangan Jalan - Jabatan Kerja Raya MalaysiaKelly ObrienNo ratings yet

- PenampangLandDevelopment Ladps071001Document30 pagesPenampangLandDevelopment Ladps071001wbmoininNo ratings yet

- EW3D User ManualDocument55 pagesEW3D User ManualSim Khoon AunNo ratings yet

- M&E-TOR (Rev - May2015)Document53 pagesM&E-TOR (Rev - May2015)Sara Ikhwan Nor SalimNo ratings yet

- Akta Air 1920Document20 pagesAkta Air 1920Dinar Ismail100% (1)

- RTVM 2014Document276 pagesRTVM 2014Che Amri Che AzmiNo ratings yet

- SOR Civil 2010Document26 pagesSOR Civil 2010Zool HilmiNo ratings yet

- Bem Professional Fees PDFDocument1 pageBem Professional Fees PDFgavin siaNo ratings yet

- ECOSEPT P-Series CatalogueDocument2 pagesECOSEPT P-Series Catalogueaniza zazaNo ratings yet

- Ajiya Glass Product Presentation 2023Document51 pagesAjiya Glass Product Presentation 2023Cheng Gi NiNo ratings yet

- Specification For Marker PostsDocument5 pagesSpecification For Marker PostsTai ChoonNo ratings yet

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet

- Method of Statement For Concrete WorksDocument15 pagesMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- 2 UME MagazineDocument8 pages2 UME MagazineEverton J. O. SmithNo ratings yet

- Housing Typology in Manali, Himachal PradeshDocument22 pagesHousing Typology in Manali, Himachal PradeshAyshwarya Suresh100% (1)

- Fallingwater - Structure and Design PDFDocument20 pagesFallingwater - Structure and Design PDFSADIA SAMINo ratings yet

- Serenity Series: Recessed Panel Wall SystemDocument2 pagesSerenity Series: Recessed Panel Wall SystemLuis PalaciosNo ratings yet

- The History and Aesthetic Development of BridgesDocument20 pagesThe History and Aesthetic Development of BridgesPasan PramudithaNo ratings yet

- Five Stars Hotel HamidaDocument129 pagesFive Stars Hotel Hamidashachika100% (1)

- Building Technology 1 Concrete AggregatesDocument20 pagesBuilding Technology 1 Concrete AggregatesJoshua ManalastasNo ratings yet

- Floor Truss Span TablesDocument2 pagesFloor Truss Span TablesTucker KellyNo ratings yet

- Structural ResidenceDocument4 pagesStructural Residence2226558No ratings yet

- Slab BridgeDocument10 pagesSlab BridgeGolam Mostofa50% (2)

- Introduction To Structural Analysis For Architecture StudentsDocument120 pagesIntroduction To Structural Analysis For Architecture StudentsHarold Taylor100% (2)

- Hidden Corbel SystemDocument1 pageHidden Corbel SystemFalah BaridNo ratings yet

- Architectural Vocabulary and Building Materials - Trial1Document27 pagesArchitectural Vocabulary and Building Materials - Trial1PranavNo ratings yet

- Phenial Estimates and DataDocument26 pagesPhenial Estimates and Datadinesh kumarNo ratings yet

- 15arc34 (1) 61 PDFDocument1 page15arc34 (1) 61 PDFSham ParitNo ratings yet

- Site Planning PrinciplesDocument10 pagesSite Planning PrinciplesSujata PhezongNo ratings yet

- Architecture - June 2022Document14 pagesArchitecture - June 2022ArtdataNo ratings yet

- Build 158 24 Build Right Gully TrapsDocument2 pagesBuild 158 24 Build Right Gully Trapsjason mossNo ratings yet

- Colin Rowe: Space As Well-Composed IllusionDocument19 pagesColin Rowe: Space As Well-Composed IllusionMiruna ElisabetaNo ratings yet

- Cost CodesDocument1 pageCost CodesKwen Codizal MendozaNo ratings yet

- 200 Houses DataDocument227 pages200 Houses Databokkaramesh1979No ratings yet

- Intense Tropical Cyclone Berguitta4Document8 pagesIntense Tropical Cyclone Berguitta4Cielo Janine VelasquezNo ratings yet

- Summary Progressing ReportDocument30 pagesSummary Progressing Reportchhean vichhaiNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Structural AnalysisDocument51 pagesStructural AnalysisStephen A. CuizonNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet

Specification For Precast Chamber

Specification For Precast Chamber

Uploaded by

Tai ChoonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specification For Precast Chamber

Specification For Precast Chamber

Uploaded by

Tai ChoonCopyright:

Available Formats

SPECIFICATION FOR PRE CAST CHAMBER

MATERIAL REQUIREMENTS

SPECIFICATION SAJ OT/ PC/ 001

(REV 6.0/12.2018)

QUALITY ASSURANCE DEPARTMENT

RANHILL SAJ SDN BHD

Ref.No : OT/PC/001

Date : 24/12/2018

Total Pages : 5/5

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT

OF RANHILL SAJ SDN BHD

QUALITY ASSURANCE DEPARTMENT RANHILL SAJ SDN BHD

SAJ SPECIFICATION FOR PRE CAST CHAMBER

TABLE OF CONTENT

Contents Page

Table of Content 2

1.0 General 3

2.0 Material 3

3.0 Concrete 4

4.0 Design and Dimension 4

5.0 Mandatory Marking 4

6.0 Pre-Delivery Inspection 5

7.0 Certification 5

Table 1 Oxide Composition of a Portland cement 3

Table 2 Grade of Concrete 4

SAJ OT/PC/001 (Rev. 6.0/12.2018)

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT OF RANHILL SAJ SDN

BHD

2

QUALITY ASSURANCE DEPARTMENT RANHILL SAJ SDN BHD

SPECIFICATION FOR PRE CAST CHAMBER

1.0 General

1.1 This specification is applicable to precast concrete chamber for water work accordingly to

Malaysian Standard, MS EN 206:2016, Concrete – Specification, Performance, Production and

Conformity.

2.0 Material

2.1 All precast concrete chamber shall meet all requirements specified and have no significant

change in color, flexibility or integrity after coating.

2.2 The cement use shall be Type I of Portland Cement as defined in EN 197-1, classified as

general purpose and high content of Tricalcium Silicate, C3S. Table 1 shows the oxide and mineral

compositions of typical Type I Portland cement.

Table 1: Oxide Composition of a Portland Cement

Oxide Range (wt %)

(OPC Type I-V)

CaO 60.2 – 66.3

SiO2 18.6 – 23.4

Al2O3 2.4 – 6.3

Fe2O3 1.3 – 6.1

MgO 0.6 – 4.8

P2O5 -

TiO2 -

Na2O 0.05 – 1.20

K2O (Na2O equiv)

SO3

Loss on Ignition -

Insoluble Residue -

Free CaO -

The loss on ignition is the weight lost when the cement was heated to 1000°C. The

insoluble residue is the mass of material that is not dissolved by acid.

The free CaO (often called the “free lime”) is the amount of calcium oxide present as CaO that is, not

bound into the cement minerals.

2.3 Aggregates for concrete shall be obtained from an approved source and shall conform to the

requirements of BS EN 12620. Type and categories for aggregates such as grading, flakiness,

freeze/thaw resistance, abrasion resistance, fines shall be declared for marker post purpose.

2.4 Mixing Water for concrete shall be conforming to EN 1008. Combination with potable water

or ground water should be use as mixing water for concrete.

2.5 Steel Reinforcement shall be free from rust conforming to BS 4449.

SAJ OT/PC/001 (Rev. 6.0/12.2018)

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT OF RANHILL SAJ SDN

BHD

3

QUALITY ASSURANCE DEPARTMENT RANHILL SAJ SDN BHD

3.0 Concrete

3.1 Grade of concrete for use in the work shall be as shown in the table below;

SAJ OT/PC/001 (Rev. 6.0/12.2018)

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT OF RANHILL SAJ SDN

BHD

4

QUALITY ASSURANCE DEPARTMENT RANHILL SAJ SDN BHD

Table 2: Grade of Concrete

Concrete Maximum Characteristics Characteristics Minimum Maximum Free

Grade Aggregates Strength at 7 Strength at 28 Cement Content, Water /

Size, mm days, min, days, min, kg/m3 Cement Ratio

2 2

N/mm N/mm

30 20 20 30 400 0.51

3.2 In design and establishing approved mixes of concrete for any parts shall be keep

strictly within the limitation on free water/cement ratios which may be shown on the drawing or

expressly stated elsewhere as applying to concrete for particular part of the works.

4.0 Design and Dimension

Refer to SAJ standard drawing no SAJ/STD/CH/13.

5.0 Mandatory Marking

5.1 Manufacturer name or marks are required on every layer of chamber. The marks shall be

printed at the inside of chamber.

5.2 All SAJ lettering and symbols shall comply with SAJ standard drawing no SAJ/SD/CH/13.

6.0 Pre-Delivery Inspection

6.1 It is the responsibility of the tenderer to inform SAJ for inspection purposes

during manufacturing and before delivery.

6.2 SAJ reserved the right to inspect and witness the testing of product offered without notice.

6.3 At anytime, when requested, the supplier is to provide SAJ a sample of the product offered for

evaluation purposes. All costs shall be borne by the supplier.

6.4 If at any time the supplier fails to deliver the required sample, the products is deemed fail to

meet the specification.

SAJ OT/PC/001 (Rev. 6.0/12.2018)

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT OF RANHILL SAJ SDN

BHD

5

QUALITY ASSURANCE DEPARTMENT RANHILL SAJ SDN BHD

7.0 Certification

7.1 Manufacturer and/or supplier of the product are required to provide the copy of the test

report from concrete laboratory for new/renewal application of certification.

7.2 Tests report required should be those tests conducted within a year period. Suppliers are

advised to submit Concrete Mix Design Proposal including Summary of Batch Weight per cubic

meter of concrete.

7.3 SAJ has the right to refuse offer or reject supply if those documents required are not

enclosed or results provided are not complied with SAJ requirement.

7.4 SAJ has the right to evaluate the product and performance for every application

SAJ OT/PC/001 (Rev. 6.0/12.2018)

NO CHANGES ALLOWED WITHOUT THE PERMISSION OF QUALITY ASSURANCE DEPARTMENT OF RANHILL SAJ SDN

BHD

6

You might also like

- JKR20710 0001 11 PDFDocument13 pagesJKR20710 0001 11 PDFGeneNo ratings yet

- Mix Design DLC-DelDocument9 pagesMix Design DLC-DelSanjay Constructions100% (1)

- Road Design ReportDocument21 pagesRoad Design ReportZaidi MohamadNo ratings yet

- Body Corporate Guidelines PDFDocument17 pagesBody Corporate Guidelines PDFmaNo ratings yet

- Upvc Pipe For Strom Water Above Ground Elevated HighwayDocument75 pagesUpvc Pipe For Strom Water Above Ground Elevated HighwayutkarshsabberwalNo ratings yet

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 10805 MS-SIRIM-190716 PDFDocument85 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 10805 MS-SIRIM-190716 PDFHimura_No ratings yet

- Summary Average Price Sabah Ok T 09Document12 pagesSummary Average Price Sabah Ok T 09Jayson TeeNo ratings yet

- Schedule of Rates 2011 Rev1Document144 pagesSchedule of Rates 2011 Rev1Screen BiruNo ratings yet

- Section 06 1000 Rough CarpentryDocument5 pagesSection 06 1000 Rough CarpentryNibras MohamedNo ratings yet

- Twin Waterfalls EC E BrochureDocument31 pagesTwin Waterfalls EC E BrochurecalkahNo ratings yet

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- Checklist For Prebond of Confined AreaDocument2 pagesChecklist For Prebond of Confined Areamukesh patel0% (1)

- Specification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFDocument6 pagesSpecification For Polyaluminium Chloride - Lpac - Used in Potable Water Supply PDFMOHD JIDINo ratings yet

- Specification For Ductile Iron Pillar HydrantsDocument12 pagesSpecification For Ductile Iron Pillar HydrantsyogeswaranNo ratings yet

- NOTE-Spec. For Ductile Iron Pipes1 K9-K12Document32 pagesNOTE-Spec. For Ductile Iron Pipes1 K9-K12binunalukandamNo ratings yet

- Raudhah Ded PiaiDocument26 pagesRaudhah Ded PiaiAshiteru BestNo ratings yet

- 5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Document51 pages5833b509 Bbc8 4f4f 9b4a 513bc0a8000a Standard Drawings Vol. 1Mohd Muzani MustafaNo ratings yet

- Roundabout Design GuidelinesDocument76 pagesRoundabout Design GuidelinesDalibor StanicNo ratings yet

- 7 JKR SPJ 2011-S7Document8 pages7 JKR SPJ 2011-S7Carwen WongNo ratings yet

- RTVM 2018Document152 pagesRTVM 2018Cheeloon NgoNo ratings yet

- OKA G45 RC - Square PilesDocument4 pagesOKA G45 RC - Square PilesTee Bun PinNo ratings yet

- Specification For Suppliers PDFDocument7 pagesSpecification For Suppliers PDFalep azizNo ratings yet

- Reinforcement CouplersDocument24 pagesReinforcement Couplersvishalgore100% (1)

- BQ PmuDocument5 pagesBQ PmuAzamOthman100% (1)

- IWK Guide On FeeDocument1 pageIWK Guide On FeeJohnyReubenNo ratings yet

- PilingDocument34 pagesPilingHariz HilmanNo ratings yet

- SPECIFICATION OF FITTINGS FOR HOT TAPPING WORK Material - CompressedDocument20 pagesSPECIFICATION OF FITTINGS FOR HOT TAPPING WORK Material - CompressedTom YeeNo ratings yet

- PEMBANGUNAN TEPI JALAN-scribdDocument15 pagesPEMBANGUNAN TEPI JALAN-scribdSITI KHADIJAH BINTI OTHMAN (JKR)No ratings yet

- MS 628-3 2014 - PrepdfDocument7 pagesMS 628-3 2014 - PrepdfMay OngNo ratings yet

- 2023-Nov One-Day Workshop On Becoming A PE & The New Outcome-Based PAE - Preparation of Documentations For SubmissionDocument83 pages2023-Nov One-Day Workshop On Becoming A PE & The New Outcome-Based PAE - Preparation of Documentations For Submissionabiyu95No ratings yet

- Mos Silt FenceDocument4 pagesMos Silt FenceKi KaNo ratings yet

- R&D ContohDocument26 pagesR&D ContohfeedNo ratings yet

- Pdc8 Checklist StatusDocument1 pagePdc8 Checklist StatusNusaibah YusofNo ratings yet

- NOTA KURSUS TAHUN 2006 - Pengiraan Kadar Alir Menggunakan HP - 05-07-2006 To 27-07-2006Document149 pagesNOTA KURSUS TAHUN 2006 - Pengiraan Kadar Alir Menggunakan HP - 05-07-2006 To 27-07-2006elffie yunusNo ratings yet

- Steel Fabric PropertiesDocument2 pagesSteel Fabric PropertiesDennis Tan100% (1)

- JKR SIRIM PrePDFDocument4 pagesJKR SIRIM PrePDFkhairul AnwarNo ratings yet

- Specification For Calcium Hypochlorite1Document5 pagesSpecification For Calcium Hypochlorite1Danial RH AbtahiNo ratings yet

- Jabatan Kerja Raya: Manual On Traffic Control Devices Temporary Signs and Work Zones ControlDocument4 pagesJabatan Kerja Raya: Manual On Traffic Control Devices Temporary Signs and Work Zones ControlHatim ShamsudinNo ratings yet

- Safety Measures CIDB RefDocument38 pagesSafety Measures CIDB RefJohnnyNo ratings yet

- JKR - PK (O) .04 SKC - As.4b1Document2 pagesJKR - PK (O) .04 SKC - As.4b1Mohd Kamal TajudinNo ratings yet

- Signature of Owner: Borang PDC 2Document8 pagesSignature of Owner: Borang PDC 2Mageswary KunalanNo ratings yet

- JKR Sarawak Geotextile SpecificationDocument23 pagesJKR Sarawak Geotextile Specificationglomac puchongNo ratings yet

- Bill of Quantities: IndexDocument42 pagesBill of Quantities: IndexLe JennieNo ratings yet

- MS 1064 PT 8 2001 Confirmed Prepdf PDFDocument5 pagesMS 1064 PT 8 2001 Confirmed Prepdf PDFFauziah AzizNo ratings yet

- The Conditions For Water Reticulation PlansDocument1 pageThe Conditions For Water Reticulation PlansedwinhlcNo ratings yet

- BD 3394Document18 pagesBD 3394jrobert123321No ratings yet

- Mill and Pave Latest 5 Sep 2017Document69 pagesMill and Pave Latest 5 Sep 2017Ibnuyusoff77100% (1)

- SPECIFICATION FOR HIGH DENSITY POLYETHYLENE PIPEWORKS FINAL APRIL 2019 Edited PDFDocument29 pagesSPECIFICATION FOR HIGH DENSITY POLYETHYLENE PIPEWORKS FINAL APRIL 2019 Edited PDFalep azizNo ratings yet

- NGSB Method Statement - RoadworkDocument8 pagesNGSB Method Statement - RoadworkFitrikamarudin mpppsaNo ratings yet

- Ms 229 2009 Timber PDFDocument5 pagesMs 229 2009 Timber PDFGnabBangNo ratings yet

- SDocument79 pagesSzainaru razaliNo ratings yet

- Arahan Teknik-Cawangan Jalan - Jabatan Kerja Raya MalaysiaDocument6 pagesArahan Teknik-Cawangan Jalan - Jabatan Kerja Raya MalaysiaKelly ObrienNo ratings yet

- PenampangLandDevelopment Ladps071001Document30 pagesPenampangLandDevelopment Ladps071001wbmoininNo ratings yet

- EW3D User ManualDocument55 pagesEW3D User ManualSim Khoon AunNo ratings yet

- M&E-TOR (Rev - May2015)Document53 pagesM&E-TOR (Rev - May2015)Sara Ikhwan Nor SalimNo ratings yet

- Akta Air 1920Document20 pagesAkta Air 1920Dinar Ismail100% (1)

- RTVM 2014Document276 pagesRTVM 2014Che Amri Che AzmiNo ratings yet

- SOR Civil 2010Document26 pagesSOR Civil 2010Zool HilmiNo ratings yet

- Bem Professional Fees PDFDocument1 pageBem Professional Fees PDFgavin siaNo ratings yet

- ECOSEPT P-Series CatalogueDocument2 pagesECOSEPT P-Series Catalogueaniza zazaNo ratings yet

- Ajiya Glass Product Presentation 2023Document51 pagesAjiya Glass Product Presentation 2023Cheng Gi NiNo ratings yet

- Specification For Marker PostsDocument5 pagesSpecification For Marker PostsTai ChoonNo ratings yet

- SABIC ConcreteDocument14 pagesSABIC ConcreteBasker BaluNo ratings yet

- Method of Statement For Concrete WorksDocument15 pagesMethod of Statement For Concrete WorksAhmed Ibrahim100% (1)

- 2 UME MagazineDocument8 pages2 UME MagazineEverton J. O. SmithNo ratings yet

- Housing Typology in Manali, Himachal PradeshDocument22 pagesHousing Typology in Manali, Himachal PradeshAyshwarya Suresh100% (1)

- Fallingwater - Structure and Design PDFDocument20 pagesFallingwater - Structure and Design PDFSADIA SAMINo ratings yet

- Serenity Series: Recessed Panel Wall SystemDocument2 pagesSerenity Series: Recessed Panel Wall SystemLuis PalaciosNo ratings yet

- The History and Aesthetic Development of BridgesDocument20 pagesThe History and Aesthetic Development of BridgesPasan PramudithaNo ratings yet

- Five Stars Hotel HamidaDocument129 pagesFive Stars Hotel Hamidashachika100% (1)

- Building Technology 1 Concrete AggregatesDocument20 pagesBuilding Technology 1 Concrete AggregatesJoshua ManalastasNo ratings yet

- Floor Truss Span TablesDocument2 pagesFloor Truss Span TablesTucker KellyNo ratings yet

- Structural ResidenceDocument4 pagesStructural Residence2226558No ratings yet

- Slab BridgeDocument10 pagesSlab BridgeGolam Mostofa50% (2)

- Introduction To Structural Analysis For Architecture StudentsDocument120 pagesIntroduction To Structural Analysis For Architecture StudentsHarold Taylor100% (2)

- Hidden Corbel SystemDocument1 pageHidden Corbel SystemFalah BaridNo ratings yet

- Architectural Vocabulary and Building Materials - Trial1Document27 pagesArchitectural Vocabulary and Building Materials - Trial1PranavNo ratings yet

- Phenial Estimates and DataDocument26 pagesPhenial Estimates and Datadinesh kumarNo ratings yet

- 15arc34 (1) 61 PDFDocument1 page15arc34 (1) 61 PDFSham ParitNo ratings yet

- Site Planning PrinciplesDocument10 pagesSite Planning PrinciplesSujata PhezongNo ratings yet

- Architecture - June 2022Document14 pagesArchitecture - June 2022ArtdataNo ratings yet

- Build 158 24 Build Right Gully TrapsDocument2 pagesBuild 158 24 Build Right Gully Trapsjason mossNo ratings yet

- Colin Rowe: Space As Well-Composed IllusionDocument19 pagesColin Rowe: Space As Well-Composed IllusionMiruna ElisabetaNo ratings yet

- Cost CodesDocument1 pageCost CodesKwen Codizal MendozaNo ratings yet

- 200 Houses DataDocument227 pages200 Houses Databokkaramesh1979No ratings yet

- Intense Tropical Cyclone Berguitta4Document8 pagesIntense Tropical Cyclone Berguitta4Cielo Janine VelasquezNo ratings yet

- Summary Progressing ReportDocument30 pagesSummary Progressing Reportchhean vichhaiNo ratings yet

- T.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateDocument3 pagesT.T.I. - Tubacex Tubos Inoxidables, S.A.: Mill Test CertificateMANUFACTURER OF FORGED FLANGES AND PIPE FITTINGSNo ratings yet

- Structural AnalysisDocument51 pagesStructural AnalysisStephen A. CuizonNo ratings yet

- For Gate EstimateDocument6 pagesFor Gate EstimateMarkko Buaya TalonNo ratings yet