Professional Documents

Culture Documents

21 26 10

21 26 10

Uploaded by

Filip F.0 ratings0% found this document useful (0 votes)

22 views4 pagesOxygen CMM

Original Title

21-26-10

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOxygen CMM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

22 views4 pages21 26 10

21 26 10

Uploaded by

Filip F.Oxygen CMM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

[= [ee |

SERVICE

COMPONENT

MAINTENANCE SHEET

NON-RETURN VALVE

P/N 41100D01

1. Manufacturer

ABG-SEMCA S.A.

408, Avenue des Etats-Unis

B.P. 2010

31016 TOULOUSE Cedex

FRANCE

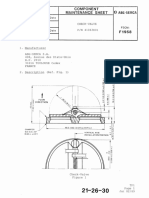

2. Description (Ref. Fig. 1)

sao

Zea

(2.781. 103798 mi

i

73

28} §

s:01 se} §

: g2| 3

(ease w 038s a:

7 —

30

oa L sso

(0.149 10 0.165 in.)

VERTICAL Axis,

INSTALLATION

Position

(0.11410 0.118

Locarine

HOLE

$

&| 2

| =

Non-Return Valve

Figure 1

TP1

21-26-10 538903

@ ABG-SEMCA

COMPONENT MAINTENANCE SHEET

41100)

DO1

A. The non-return valve fitted to a line admits the air supply

downstream the air conditioning system and prevents reverse

flow if the fluid supply is

interrupted.

B. The non-return valve consists of a cylindrical body

supporting a spindle complete with two pivoting flaps. Flaps

are kept against their seat machined on body by a return

spring.

C. For attachment, non-return valve body is machined with a

flanged end.

Technical Data

A. Dimensions

Refer to figure 1.

B. Weight

0,210 kg (0.462 1b).

C. Pressures

- Working fluid : air.

- Crack opening pressure

~ Pressure drop on ground :

20°C (68°F).

D. Temperatures

Operating temperature range

Maintenance

< 2 mb (0.029 psi).

3 mb (0.0435 psi) with a

10 kg/min air flow (22.04 lb/min), 1013 mb (14.68 psig) at

+ O°C to +80°C (+32°F to +176°F).

A. On aircraft : not applicable.

B. Repair : if damaged, unit will be replaced by a new one.

Cleaning

Clean unit using an approved chlorinated solvent

(trichloroethane (OT620C and/or MIL-T-81533/A) .

21-26-10

Page 2

Jun 02/89

© ABG-SEMCA

COMPONENT MAINTENANCE SHEET

41100D01

Test

A.

Functional Check

With its axle in the vertical position, check flaps move

freely and check they are returned by spring into their

closing position.

B. Internal Leakage Test (Ref. Fig. 2)

(2) Test equipment

Use a test set-up including :

- a pressure gage capable of reading a 1 bar (14.5 psig)

pressure,

- a flowmeter for a 2 l/min to 20 1/min (0.0704 cu.ft/min

to 0.704 cu.ft/min) reading,

~ a shut-off valve,

- a pressure source delivering 0,5 bar (7.25 psig) with a

10 l/min (0.352 cu.ft/min) airflow,

- a test box made up of two half-shells fixed by a clamp.

(2) Test method

(a) Apply a 0,5 bar (7.25 psig) test pressure downstream

non-return valve, read on pressure gage.

(b) Check leakage read on flowmeter does not exceed

8,3 l/min (0.292 cu.ft/min).

Storage

A, General

(2) Pack unit according to the ATA 300, class 2, standard.

(2) No special storage conditions required.

B. Storage Life

over 10 years.

C. Destorage

Unpack unit : perform a visual check.

21-26-10 “ad

Jun 02/89

© ABG-SEMCA

COMPONENT MAINTENANCE SHEET

41100D01

SHUT-OFF VALVE

ain pnessune

PRESSURE GAGE

TEST BOX

NON-RETURN VALVE

CLAMP

PREFORMED PACKING. FLOWMETER

Internal Leakage Check

Figure 2

21-26-10 aes

gun 02/89

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SB 25434 Assessment Form - AP - CAT3Document10 pagesSB 25434 Assessment Form - AP - CAT3Filip F.No ratings yet

- SB 25443 Assessment Form - NA - CAT7Document11 pagesSB 25443 Assessment Form - NA - CAT7Filip F.100% (1)

- Component Maintenance Manual With Illustrated Parts List: Dual Distributor ValveDocument223 pagesComponent Maintenance Manual With Illustrated Parts List: Dual Distributor ValveFilip F.No ratings yet

- 21 26 30Document4 pages21 26 30Filip F.No ratings yet

- Component Maintenance Manual With Illustrated Parts List: Electrical ActuatorDocument147 pagesComponent Maintenance Manual With Illustrated Parts List: Electrical ActuatorFilip F.No ratings yet

- EASA Components CategoriesDocument1 pageEASA Components CategoriesFilip F.No ratings yet