Professional Documents

Culture Documents

Bake+Info Info Danish+Pastries

Bake+Info Info Danish+Pastries

Uploaded by

okosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bake+Info Info Danish+Pastries

Bake+Info Info Danish+Pastries

Uploaded by

okosCopyright:

Available Formats

Danish Pastries

> INFORMATION SHEET

DEFINITION

Originally a special pastry that used yeasted dough for extra aeration, filled with butter, sugar, raw marzipan and peel. Now refers to

almost any sweet breakfast pastry. Usually a light, flaky pastry containing custard, jam and/or fruit. It may have an icing glaze with fine

chocolate decoration.

HISTORY

The origin of the Danish is ascribed by the Danish Confectioners, Bakers and Chocolate makers Association to a strike amongst

the bakery workers in Danish bakeries in 1850. The strike forced bakery owners to hire foreign workers, including Austrian bakers.

Unfamiliar with the Danish baking recipes, they baked pastries from their native recipes. Amongst these Austrian pastries were

Plundergebäck, which became quite popular in Denmark. Later this recipe was changed by Danish bakers, increasing the amount of fat

(by adding more egg) which resulted in what is today known as the Danish. In different countries they have different names: the Danish

call them Wienerbrod (Vienna bread) and the Austrians call them Kopenhagener (Copenhagen, after the Danish capital). They were

introduced to America by bakers from Denmark.

INGREDIENTS

INGREDIENT FUNCTION & SPECIFICATIONS (*Based on flour content.)

Flour Bread flour with protein content of 11.5–12%. If the protein content is too high the Danish will be tough to

eat. Strong flour can be blended with 30% pastry flour to improve extensibility of dough during laminating.

Sugar Added as sugar or high fructose corn syrup (HFCS). Affects the water absorption – high sugar dough absorbs

less water but slows yeast activity. Yeast addition increases as sugar levels increase.

Roll-in fat Butter or margarine is as much as 50% of flour weight. Fat contributes significantly to the flavour and colour.

Butter is preferred but cost and limitations with processing temperature range mean margarine is frequently

used.

Dough fat Improves dough handling properties and the tenderness of the pastry crumb. Can be butter in butter dough,

margarine or vegetable shortening in regular pastry dough. Amount ranges from 8% (lean dough) to 20% (very

rich dough).

Yeast Leavens the dough during proofing and develops flavour during fermentation. Amount added depends on sugar

levels in dough and tolerance of specific yeast strain to high sugar dough.

Salt Amount added depends on type of roll-in fat used. (1.5–2%)*

Water Necessary to form a dough from the dry ingredients. Due to the amount of handling that dough for Danish

pastries undergoes during processing the dough should not be softer than roll-in fat. Dough water absorption is

usually in range of 51–59%*.

Dairy solids Including milk solids, replacers and whey products which aid crust colour development and add a rich flavour.

These ingredients need to be heat treated to denature those proteins which could react with gluten and weaken

the structure. Typically added at 4–8%*.

Eggs Added at 5–8%* in dry or liquid form to strengthen and prevent collapse during baking. The more fillings/

toppings added to the pastry then the more eggs need to be added to dough.

Flavouring Although the main flavour comes from fillings, topping and icings some bakers like to add vanilla and/or citrus

flavour to the dough.

Dough conditioners These are used to mellow the dough to improve handling skills and strengthen the dough so it can support

fillings/toppings. Examples would be sodium stearoyl lactylate (SSL) for strengthening and sodium metabisulfite

for relaxing the dough.

Crumb softeners Monoglcyerides of saturated fatty acids are efficient crumb softeners and also lubricate the gluten matrix to

assist with the laminating and make-up stages.

BIRT DANISH PASTRIES INFORMATION SHEET | V1.0 2011 >1

Danish Pastries

> INFORMATION SHEET

PROCESSING

PROCESS DETAILS

Preparing dough The dough ingredients are all combined and mixed in one stage. As gluten development occurs during the

lamination stage, dough development during mixing is not important. The dough tends to be very soft and have

low water absorption.

Laminating Danish dough is laminated with roll-in fat to produce a multitude of dough layers separated by films of fat. The

roll-in fat is usually added without much delay after mixing, although the dough can be left for 20–30 minutes to

rest for hydration. There are two methods that are outlined below:

1. Traditional or English method. The fat is spread or spotted over 2/3 of the dough which has been sheeted

into rectangle shape. The uncovered portion of the dough sheet is folded over half of the fat covered portion

and the other half is then folded over the doubled up dough portion, resulting in three layers of dough with two

layers of fat sandwiched between them. After 30 minutes rest in the retarder the layered dough is sheeted to a

uniform thickness of 1.3–2cm. The dough piece is then given a 3-fold (half turn) by folding one-third of dough

sheet over centre section and then the third section of dough piece is folded over doubled up section. After 30

minutes rest in retarder the sheeting and folding process is repeated to achieve a total of 54 layers which is

sufficient for a dough containing 17–30% roll in fat. The number of folds vary based on amount of roll in fat and

can be as much as 108 layers.

2. Automated Equipment is now available which extrudes dough and roll-in fat simultaneously and laminates

the dough to any desired number of fat layers in the dough. The processing is designed to occur while minimising

stress on dough and results in continuous processing and make-up without delay. The dough is mixed at

15–18ºC to retard yeast action. In-line retarding systems are available which enable dough processing under

less than ideal conditions. This equipment is usually part of a totally automated production line for Danish

production.

Make-up After retarding for several hours the dough is ready for makeup. The dough makeup is best at 13–16ºC. It is

important to reduce the thickness of the dough gradually using a sheeter to avoid rupturing layers. The flakiness

of the Danish can be adversely affected if the dough is reduced too quickly. Once sheeted there are a number of

ways in which the dough can be made up, including: crimping, oiling, curling, filling or twisting, dependent on

desired end product. There are a large range of different shapes including pinwheels, envelopes and turnovers.

Fillings These can be applied before or after proofing. Fillings need to be oven- and package-stable through proper

adjustment of water activity. The filling should not break down into the icing or dough. A large amount of filling is

used relative to the dough weight, ranging from 30–50% depending on end quality of the Danish.

Proofing This is a crucial step as if proofed at too high a temperature the shortening bleeds out while over proofing can

cause collapse of the product from the oven. Danish should be proofed at 29–32ºC with a relative humidity of

65–70% for 55–60minutes. They should be proofed to 2–2.5x their original size.

Topping Common to spray or brush pastries with mild egg wash to improve the appearance. Fruit toppings must contain

sufficient sugar to avoid them boiling during baking.

Baking Tend to be baked at lower temperatures than equivalent products made from sweet dough. Leaner dough is

baked hotter than rich, high sugar dough. Danish sweet rolls may be baked at 200–210ºC in a gas fired reel

oven. However, baking temperatures and times are dependent on the oven used and the size of the baked

product as well as quantity of filling .

Icing Adds sweetness to the end product and compliments other flavours and tastes in the pastry. Icing is added

when the Danish is still warm as this gives the icing a high gloss and enables it to penetrate into the flake before

setting which adds to eating quality. Also aids the shelf life of the product.

BIRT DANISH PASTRIES INFORMATION SHEET | V1.0 2011 >2

Danish Pastries

> INFORMATION SHEET

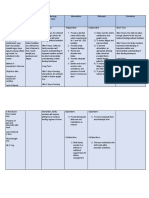

TROUBLE SHOOTING

PROBLEM PROBABLE CAUSE REMEDY

Butter breaks Butter too cold Condition butter to 14–16ºC before use.

through dough Dough too soft Reduce water in dough so same consistency as butter at 14–16ºC.

Harsh sheeting reduction Use gradual and even sheeting reduction

Butter oozes out Butter too warm Condition butter to 14–16ºC before use.

from dough Dough too warm Chill dough.

Dough too tight Increase water in dough.

Butter melts Proofer too warm Reduce power temperature to 30–32ºC.

during proof Insufficiently laminated Laminate with minimum of three book folds.

Baked pastries Irregular laminating Use butter sheets.

are misshapen Butter too hard Condition butter to 14–16ºC before use.

Oven too hot Bake Danish at 200–210ºC in a gas fired reel oven.

Rolled out too thinly or quickly Use gradual and even sheeting reduction.

Baked pastries Insufficiently laminated Laminate with minimum of three book folds.

show fatty patches Excess roll-in butter Reduce roll-in butter (max 75% flour weight).

inside

Pastry sticks to Insufficient dusting Use more flour for dusting during sheeting.

sheeting rollers Room too warm Work in cooler room or at cooler time of day

Pastry topples Too few folds Increase number of folds.

during baking Dough pieces too thick Roll slightly thinner.

Tough end product Too little layering butter Increase butter (max. 75% flour weight).

Too little dough butter Increase dough butter.

Baking temperature too low Bake Danish at 200–210ºC in a gas fired reel oven

REFERENCES

Barrett I 1991. Room for Improvement. Bakers Review November 1991.

Blyth W 1976. Danish – a much misunderstood line. Baking Industries Journal September 1976.

Cleven F, Fluckinger W 1980. Danish pastry. CCB Rev. Choc. Confec. & Bakery 6/80 Vol 5, No. 2.

Doerry W 1997. Technology of producing danish pastries (sweet rolls and coffee cakes). AIB Research Department Technical Bulletin.

Volume XIX, Issue 10.

Goodsell GR 1985. Making danish basics that determine quality results. Bakers Digest May 31 1985.

New Zealand Dairy Board 2000. A guide to solving faults that occur during the production of Danish Pastries and Croissants.

BIRT DANISH PASTRIES INFORMATION SHEET | V1.0 2011 >3

You might also like

- Get LeanDocument89 pagesGet LeanZizo Aboshadi100% (4)

- The Beginning of Infinity by David Deutsch - PDF DriveDocument2 pagesThe Beginning of Infinity by David Deutsch - PDF DriveRenata JakielaszekNo ratings yet

- Learn & Master Piano - Lesson Book PDFDocument104 pagesLearn & Master Piano - Lesson Book PDFDavlun87% (23)

- Anne Cazor Master French Pastry PDFDocument458 pagesAnne Cazor Master French Pastry PDFTarak Zayani100% (6)

- S E FP Meal Building BlocksDocument3 pagesS E FP Meal Building BlocksSharan Sahota100% (3)

- Taste of Home Ultimate Baking Cookbook: 575+ Recipes, Tips, Secrets and Hints for Baking SuccessFrom EverandTaste of Home Ultimate Baking Cookbook: 575+ Recipes, Tips, Secrets and Hints for Baking SuccessNo ratings yet

- Cookie FormulationDocument11 pagesCookie Formulationnaspterboy100% (3)

- KGM Biscuitmachine Recipes ENG Scribd 4Document45 pagesKGM Biscuitmachine Recipes ENG Scribd 4Peggy Bracken StagnoNo ratings yet

- Eduard Kort Damn Good Music Production TipsDocument55 pagesEduard Kort Damn Good Music Production TipsokosNo ratings yet

- Information Sheet: Danish PastriesDocument3 pagesInformation Sheet: Danish Pastriesdefa reyNo ratings yet

- Unit 6 PastryDocument29 pagesUnit 6 PastryRicardo HarveyNo ratings yet

- Bake+Info Info Yeast+Raised+DoughnutsDocument3 pagesBake+Info Info Yeast+Raised+DoughnutsTomNo ratings yet

- Pies & Pastry 1: Information SheetDocument3 pagesPies & Pastry 1: Information SheetCwt ChanNo ratings yet

- (All Purpose Flour Can Be Used. Experiment With Different Types of Flour) (Should You Use Pastrex Super, Then Freezing The Fat Is Not Required)Document3 pages(All Purpose Flour Can Be Used. Experiment With Different Types of Flour) (Should You Use Pastrex Super, Then Freezing The Fat Is Not Required)Linaden FernanNo ratings yet

- Short Crust PastryDocument12 pagesShort Crust PastrysarathNo ratings yet

- W12 - Module 010 Preparation of Pastry ProductsDocument22 pagesW12 - Module 010 Preparation of Pastry ProductsRonalyn C. CariasNo ratings yet

- Presentation 1Document16 pagesPresentation 1Raquel GervacioNo ratings yet

- Croissant and Danish PastryDocument6 pagesCroissant and Danish PastryokosNo ratings yet

- BakeInfo Info CakesDocument3 pagesBakeInfo Info CakesSQF PractitionerNo ratings yet

- Pastry Basics Chapter 14: Presented By: Patricia Cassandra DijanDocument29 pagesPastry Basics Chapter 14: Presented By: Patricia Cassandra DijanReggie Ann PerezNo ratings yet

- Compilation of Modules and Activities: Submitted ToDocument36 pagesCompilation of Modules and Activities: Submitted ToLogatic Marian JoyNo ratings yet

- 2003 - Pastry Types and ProductionDocument6 pages2003 - Pastry Types and Productionbanksy idNo ratings yet

- Pate Brisee and PuffDocument14 pagesPate Brisee and Puffleonevill cadanoNo ratings yet

- Baking Book by CTDocument10 pagesBaking Book by CTRutendo ShamuyariraNo ratings yet

- Pastry Puff MakingDocument80 pagesPastry Puff MakingYip AlexNo ratings yet

- Pastry and Pastry ProductsDocument6 pagesPastry and Pastry ProductsMercy KoriemaNo ratings yet

- Bread and Pastry ProcedureDocument25 pagesBread and Pastry ProceduregabyculinarNo ratings yet

- Post Test. 3.1. Menganalisis Puff PastryDocument7 pagesPost Test. 3.1. Menganalisis Puff PastryGans PopoNo ratings yet

- 5 Types of CakesDocument11 pages5 Types of Cakesapi-274028046No ratings yet

- Basic Steps in Yeast Dough ProductionDocument26 pagesBasic Steps in Yeast Dough Productionraymond marcos100% (1)

- Bakery: Laminated DoughsDocument15 pagesBakery: Laminated DoughsTemet Nosche100% (1)

- Prepare and Produce Pastry ProductsDocument11 pagesPrepare and Produce Pastry ProductsMa. Rochelle Cabrales100% (1)

- BPPDocument6 pagesBPPMillen LaganaNo ratings yet

- Learning PastryDocument18 pagesLearning PastryTemmyNo ratings yet

- Bake+Info Info Biscuits PDFDocument3 pagesBake+Info Info Biscuits PDFmandeep6871No ratings yet

- Module 2 in Bread and Pastry Production NCIIDocument9 pagesModule 2 in Bread and Pastry Production NCIIMark Andrew Manalo Gaela100% (2)

- 8 Recipes For Sponge BiscuitsDocument3 pages8 Recipes For Sponge Biscuitsjamaljamal20No ratings yet

- Prepare, Cook and Finish Pastry ProductsDocument22 pagesPrepare, Cook and Finish Pastry ProductsShashank Shekhar100% (1)

- Baking Fundamentals - Notes & RecipesDocument14 pagesBaking Fundamentals - Notes & RecipesRutendo ShamuyariraNo ratings yet

- Cereal Tech From CakesDocument48 pagesCereal Tech From Cakesgrace mwenjeNo ratings yet

- Baking TechniquesDocument7 pagesBaking TechniquesRovie Valdez100% (1)

- Information Sheet 4 Baking SodaDocument5 pagesInformation Sheet 4 Baking SodaMheg Sophia HockkinsNo ratings yet

- Second Quarter Handout Bread and Pastry ProductionDocument8 pagesSecond Quarter Handout Bread and Pastry ProductionJeb PampliegaNo ratings yet

- Day 2-Laminated DoughDocument18 pagesDay 2-Laminated Doughnatoalvarez.appleNo ratings yet

- Basic Foods Ii Report (2.1 Types of Dough and Their Characteristics)Document4 pagesBasic Foods Ii Report (2.1 Types of Dough and Their Characteristics)Marcos DmitriNo ratings yet

- Baking UpdateDocument2 pagesBaking UpdateAchyut TripathiNo ratings yet

- 2ssc Abb PubDocument3 pages2ssc Abb PubO.L.D.E.No ratings yet

- Pies Background InfoDocument4 pagesPies Background InfojammNo ratings yet

- Pies and Pastries: The Following Are Some Examples of PieDocument8 pagesPies and Pastries: The Following Are Some Examples of PieNurfasya AtiqahNo ratings yet

- Recipe Customer Survey FormDocument10 pagesRecipe Customer Survey FormPhượng TườngNo ratings yet

- Dmk3013-Edible O&F Products Unit 3: Shortening: By: Nor Aziyan Binti Mohd NasirDocument25 pagesDmk3013-Edible O&F Products Unit 3: Shortening: By: Nor Aziyan Binti Mohd NasirNityantiniNo ratings yet

- Cakes-Biscuits: Food and Agriculture Organization of The United NationsDocument5 pagesCakes-Biscuits: Food and Agriculture Organization of The United NationsafhbsavhkuydagkydNo ratings yet

- Cakes - Types of CakesDocument4 pagesCakes - Types of Cakestrang đàmNo ratings yet

- Cakes: Basic FormulaDocument5 pagesCakes: Basic FormulaKayon BrownNo ratings yet

- Pastry Methods: English Method Scotch-All in MethodDocument1 pagePastry Methods: English Method Scotch-All in MethodNuno EspadaNo ratings yet

- Pastry, Cakes and CookiesDocument9 pagesPastry, Cakes and CookiesMheg Sophia HockkinsNo ratings yet

- Characteristics of Bread and PastryDocument17 pagesCharacteristics of Bread and PastryOubli BonheurNo ratings yet

- Bakery Products and Rice MillingDocument19 pagesBakery Products and Rice Millingabhishek.ajmaniNo ratings yet

- Pies and Pastry Foods II PDFDocument23 pagesPies and Pastry Foods II PDFKyle OyaoNo ratings yet

- Bagel ProductionDocument2 pagesBagel ProductiondekaymailNo ratings yet

- 8065-02 - 212 - 2 Prepare, Cook and Finish Bakery ProductsDocument23 pages8065-02 - 212 - 2 Prepare, Cook and Finish Bakery ProductsPriya Anton FernandoNo ratings yet

- Temperature Use For Different Types of CakesDocument24 pagesTemperature Use For Different Types of CakesVanesa EscoberNo ratings yet

- Difference Between Dough and BatterDocument3 pagesDifference Between Dough and BatterShaki ZulfiqarNo ratings yet

- Taste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreFrom EverandTaste of Home Breads: 100 Oven-Fresh Loaves, Rolls, Biscuits and MoreNo ratings yet

- French Patisserie Pleasures: Sweet Treats from Parisian BakeriesFrom EverandFrench Patisserie Pleasures: Sweet Treats from Parisian BakeriesNo ratings yet

- Croissant and Danish PastryDocument6 pagesCroissant and Danish PastryokosNo ratings yet

- Danbook 2Document18 pagesDanbook 2okosNo ratings yet

- Baking Soda BookDocument64 pagesBaking Soda Bookokos100% (1)

- Protein Quality in Wheat:: Ramunė KuktaitėDocument44 pagesProtein Quality in Wheat:: Ramunė KuktaitėokosNo ratings yet

- Borla 2004 BakingDocument8 pagesBorla 2004 BakingokosNo ratings yet

- Effect of Bread Dough Mixing Method On Rye Bread QualityDocument12 pagesEffect of Bread Dough Mixing Method On Rye Bread QualityokosNo ratings yet

- Fulltext01 2Document88 pagesFulltext01 2okosNo ratings yet

- 2010 Pivot Table Resources PDFDocument8 pages2010 Pivot Table Resources PDFokosNo ratings yet

- Yeast Sour Dough Starter 081310Document12 pagesYeast Sour Dough Starter 081310okosNo ratings yet

- School F: Sound EngineeringDocument46 pagesSchool F: Sound EngineeringokosNo ratings yet

- Test & Measurement Microphone: OverviewDocument2 pagesTest & Measurement Microphone: OverviewokosNo ratings yet

- Transducer TutorialDocument33 pagesTransducer TutorialokosNo ratings yet

- Food Security in IndiaDocument17 pagesFood Security in IndiaTUSHAR DASHNo ratings yet

- Indian Pregnancy Diet Plan For Women - Max HospitalDocument5 pagesIndian Pregnancy Diet Plan For Women - Max HospitalAzhar MandhraNo ratings yet

- MineralsDocument13 pagesMineralsAima AzharNo ratings yet

- Shawarma Nutritional ValueDocument1 pageShawarma Nutritional ValueUche UgwuNo ratings yet

- Blood Type A DietDocument9 pagesBlood Type A DietShindi Magno Rivera100% (4)

- English Task Nia SintaDocument8 pagesEnglish Task Nia SintaevibekamalayNo ratings yet

- The Control of Partitioning Between Protein and FaDocument19 pagesThe Control of Partitioning Between Protein and FaChoi Joon-HyunNo ratings yet

- Knorr Puts Focus On Natural Ingredients PDFDocument4 pagesKnorr Puts Focus On Natural Ingredients PDFMuhammad AreebNo ratings yet

- Nutrition Intervention in Infancy Group 4Document56 pagesNutrition Intervention in Infancy Group 4Cristelle Joy RebocaNo ratings yet

- Juan Pasamar Gutierrez - EVAU XMASDocument2 pagesJuan Pasamar Gutierrez - EVAU XMASjuan.pasgutNo ratings yet

- GoldenLine - Starter Cultures - en - 01Document11 pagesGoldenLine - Starter Cultures - en - 01Michelle BrancoNo ratings yet

- Comparative Analysis of Amul India and Mother Dairy OmDocument16 pagesComparative Analysis of Amul India and Mother Dairy OmSagar GuptaNo ratings yet

- Coconut Oil Is The Healthiest Oil On Earth! ... Says Dr. Bruce Fife, A Naturopathic Doctor and The The Author ofDocument2 pagesCoconut Oil Is The Healthiest Oil On Earth! ... Says Dr. Bruce Fife, A Naturopathic Doctor and The The Author ofVivek VPNo ratings yet

- Nestle - The Infant Formula Controversy: International Marketing Case Study For Final ExamDocument16 pagesNestle - The Infant Formula Controversy: International Marketing Case Study For Final Examjojo SumantiNo ratings yet

- Food Exchanges TrackerDocument1 pageFood Exchanges TrackerJanice Miller TerzisNo ratings yet

- Health PE Student Book Grade 3.compressedDocument48 pagesHealth PE Student Book Grade 3.compressedMeryel CaramoanNo ratings yet

- Quiz Unit 2 ( ( (CALIFICABLE) ) ) - Revisión Del IntentoDocument9 pagesQuiz Unit 2 ( ( (CALIFICABLE) ) ) - Revisión Del IntentoMauricio MontañezNo ratings yet

- Nutrition LectureDocument30 pagesNutrition LectureJovelle Sto.domingo100% (1)

- Diabetes Mellitus NCPDocument6 pagesDiabetes Mellitus NCPJOHN CARLO APATANNo ratings yet

- Progressive Research PaperDocument14 pagesProgressive Research Paperapi-504422824No ratings yet

- EUGENE ANGEL and KIERDocument13 pagesEUGENE ANGEL and KIERwynferd ssNo ratings yet

- Linda McCartneys Vegetarian Home Cooking by Linda McCartney (McCartney, Linda)Document454 pagesLinda McCartneys Vegetarian Home Cooking by Linda McCartney (McCartney, Linda)anawmb91100% (2)

- Periodic Chart of Amino Acids: His AspDocument1 pagePeriodic Chart of Amino Acids: His Aspagressiv barbieNo ratings yet

- Canadas Food Guide Serving SizesDocument2 pagesCanadas Food Guide Serving SizesVictor EstradaNo ratings yet

- Digestive SystemDocument41 pagesDigestive SystemRotsen B. VelascoNo ratings yet

- Kitchen BasicsDocument99 pagesKitchen BasicsLlanevie Azel V. Zamora-Niez100% (1)

- BSN2 2FNCP2Document2 pagesBSN2 2FNCP2Kobe ManuelNo ratings yet