Professional Documents

Culture Documents

DMF50174ZNB FW

DMF50174ZNB FW

Uploaded by

Nemesys TOFCopyright:

Available Formats

You might also like

- Meet The Machines of The Future PDFDocument162 pagesMeet The Machines of The Future PDFmusthaziz93% (14)

- Installation Guide For Product Link PL121SR and PL321Document116 pagesInstallation Guide For Product Link PL121SR and PL321ricardocanoNo ratings yet

- MicrDocument7 pagesMicrPrasanna NiyadagalaNo ratings yet

- LCD Module Specification: First Edition Production Div. Approved byDocument17 pagesLCD Module Specification: First Edition Production Div. Approved byAntonio Gianfrnco Rivas NegronNo ratings yet

- LCD DMF 50316NB FW 5Document17 pagesLCD DMF 50316NB FW 5technicahmettNo ratings yet

- Dmf5001ny Ly Aie PDFDocument17 pagesDmf5001ny Ly Aie PDFPTCNo ratings yet

- Optrex DMF 5001Document15 pagesOptrex DMF 5001PTCNo ratings yet

- DMF5001NF-SEW DatasheetDocument17 pagesDMF5001NF-SEW Datasheetfernando david diaz ruiz diazNo ratings yet

- LCD Module Technical Specification: T.YuchiDocument17 pagesLCD Module Technical Specification: T.YuchiAsad AhmedNo ratings yet

- LCD Module Technical Specification: OptrexDocument17 pagesLCD Module Technical Specification: OptrexCapitanSalamiNo ratings yet

- DMF 5001nyl Seb Ave BDNDocument17 pagesDMF 5001nyl Seb Ave BDNVladimirNo ratings yet

- LCD Module Specification: DMC20481NY-LYDocument15 pagesLCD Module Specification: DMC20481NY-LYBeroxi MihaiNo ratings yet

- Dmf5005n Coe DDN Eng 3Document16 pagesDmf5005n Coe DDN Eng 3roozbehxoxNo ratings yet

- Pantalla Info Completa Claa150xg-01-ChunghwapicturetubesDocument17 pagesPantalla Info Completa Claa150xg-01-ChunghwapicturetubesYessenia PerezNo ratings yet

- LCD Datasheet LQ150X1LG92Document17 pagesLCD Datasheet LQ150X1LG92home madeNo ratings yet

- Displaytech-240320dl 03a440753dDocument17 pagesDisplaytech-240320dl 03a440753dBrad FrancNo ratings yet

- GLM240128Document35 pagesGLM240128api-3700809No ratings yet

- M215OG64-183-1901 带TP (CSOT)Document24 pagesM215OG64-183-1901 带TP (CSOT)jaime l cruz sNo ratings yet

- Claa170ea 07Document21 pagesClaa170ea 07Test TestNo ratings yet

- Product Specifications: Displaytech LTDDocument17 pagesProduct Specifications: Displaytech LTDCarlos Lara CastroNo ratings yet

- CLAA170ES01Document21 pagesCLAA170ES01A.b. JethavaNo ratings yet

- LCD Module Technical Specification: First EditionDocument32 pagesLCD Module Technical Specification: First Editionmarco antonioNo ratings yet

- CLAA102NA0ACWDocument16 pagesCLAA102NA0ACWIvan BenginNo ratings yet

- Clab215fa01 ChunghwapicturetubesDocument12 pagesClab215fa01 ChunghwapicturetubesSalomon GonzalezNo ratings yet

- 64128k Cog Series-V10Document19 pages64128k Cog Series-V10megaadyNo ratings yet

- Mikroe 3904Document17 pagesMikroe 3904kushliakNo ratings yet

- 162E Series Displaytech SpecDocument23 pages162E Series Displaytech SpecrochaseletronicaNo ratings yet

- G190ean01 0Document28 pagesG190ean01 0kalanghoNo ratings yet

- LCD SpecDocument21 pagesLCD SpecKC KiewNo ratings yet

- Product Specifications: Displaytech LTDDocument20 pagesProduct Specifications: Displaytech LTDPwter KovacsNo ratings yet

- LCD Module Specification: First Edition Production Div. Approved byDocument18 pagesLCD Module Specification: First Edition Production Div. Approved bySanty JijonNo ratings yet

- Vacuum Fluorescent Display Specification: Model CU20026-TW200ADocument17 pagesVacuum Fluorescent Display Specification: Model CU20026-TW200AMikhailNo ratings yet

- Data Image: Corporation CTP Module SpecificationDocument42 pagesData Image: Corporation CTP Module SpecificationImadMehdiNo ratings yet

- Mitsubishi - AA101TA12 - DatasheetDocument25 pagesMitsubishi - AA101TA12 - DatasheetaylinaykanNo ratings yet

- AA104VC08 MitsubishiDocument23 pagesAA104VC08 MitsubishiJosé AdelinoNo ratings yet

- Tm12864h6ccwgwa1 G-1 (Wo PCB)Document32 pagesTm12864h6ccwgwa1 G-1 (Wo PCB)Feroz KhanNo ratings yet

- TX31D203VM0EAB DatasheetDocument36 pagesTX31D203VM0EAB DatasheetMIGUELNo ratings yet

- 4 GLM 24064Document19 pages4 GLM 24064api-3700809No ratings yet

- 2SC1213AKBDocument10 pages2SC1213AKBafdgtdsghfNo ratings yet

- Chunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PDocument27 pagesChunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PandymustopaNo ratings yet

- T370HW02 Ve - 20081113Document29 pagesT370HW02 Ve - 20081113Tran Van Thien0% (1)

- LCD Claa102na0acwDocument17 pagesLCD Claa102na0acwgnomeNo ratings yet

- Panel CPT CLAA220WA09 0 (DS)Document20 pagesPanel CPT CLAA220WA09 0 (DS)Hoson AkNo ratings yet

- Infineon IPB60R040C7 DS v02 - 00 EN 1622423Document15 pagesInfineon IPB60R040C7 DS v02 - 00 EN 1622423geoffffNo ratings yet

- Nec Inverter 104pw191Document10 pagesNec Inverter 104pw191samee 692No ratings yet

- Chimei N173O6 L02Document29 pagesChimei N173O6 L02alelujaNo ratings yet

- CLAA216WA01 PanalDocument25 pagesCLAA216WA01 PanalGursharan SinghNo ratings yet

- 8.0 Inch IPS MIPI 800x1280 AML08021016-31DDocument13 pages8.0 Inch IPS MIPI 800x1280 AML08021016-31DcalvinkleinwuNo ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconFhidli Sang Pangeran BiruNo ratings yet

- TX31D203VM0EABDocument33 pagesTX31D203VM0EABMIGUELNo ratings yet

- ArduinoDocument15 pagesArduinoAlvarez TomasNo ratings yet

- Infineon IPW60R018CFD7 DS v02 - 00 ENDocument14 pagesInfineon IPW60R018CFD7 DS v02 - 00 ENdineshNo ratings yet

- Infineon Ipw60r040c7 Ds v02 00 enDocument15 pagesInfineon Ipw60r040c7 Ds v02 00 enshivguptaNo ratings yet

- Technical Data: NPN Power Silicon TransistorDocument2 pagesTechnical Data: NPN Power Silicon TransistorHoThanhLoiNo ratings yet

- CLAA150XP01Document22 pagesCLAA150XP01adjustmentNo ratings yet

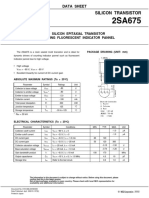

- Silicon Transistor: PNP Silicon Epitaxial Transistor For Driving Fluorescent Indicator PannelDocument5 pagesSilicon Transistor: PNP Silicon Epitaxial Transistor For Driving Fluorescent Indicator PannelpiroNo ratings yet

- N156B6 L08Document31 pagesN156B6 L08JozefNo ratings yet

- CLAA089NA0ACWDocument18 pagesCLAA089NA0ACWczypigNo ratings yet

- LGDocument28 pagesLGabdessNo ratings yet

- LCD Module Mcc162a4 5Document17 pagesLCD Module Mcc162a4 5alfredo de la hozNo ratings yet

- Technical Data: NPN Power Silicon TransistorDocument3 pagesTechnical Data: NPN Power Silicon TransistorMarco FrigerioNo ratings yet

- ENG Commercial Fishing Brochure 2020Document8 pagesENG Commercial Fishing Brochure 2020Nemesys TOFNo ratings yet

- SP14Q002 A1 HitachiDocument22 pagesSP14Q002 A1 HitachiNemesys TOFNo ratings yet

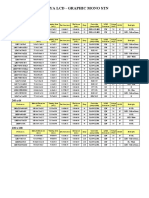

- LCD Shortform (Mono Module)Document3 pagesLCD Shortform (Mono Module)Nemesys TOFNo ratings yet

- BUK213Document16 pagesBUK213Nemesys TOFNo ratings yet

- General Description: Integrated Circuit Systems, IncDocument10 pagesGeneral Description: Integrated Circuit Systems, IncNemesys TOFNo ratings yet

- CL GD6245Document147 pagesCL GD6245Nemesys TOFNo ratings yet

- HY5118160BTC60Document8 pagesHY5118160BTC60Nemesys TOFNo ratings yet

- XCMG Truck Crane Qy25k IIDocument6 pagesXCMG Truck Crane Qy25k IINemesys TOF100% (1)

- Infineon D81C90 DS v01 - 97 enDocument41 pagesInfineon D81C90 DS v01 - 97 enNemesys TOFNo ratings yet

- Intel TE28F160S570Document51 pagesIntel TE28F160S570Nemesys TOFNo ratings yet

- Atomic Line Width: 1. The Uncertainty PrincipleDocument5 pagesAtomic Line Width: 1. The Uncertainty PrincipleMuhammad Abdullah KhanNo ratings yet

- Bh-0.66 I TransformadoresDocument4 pagesBh-0.66 I TransformadoresChint BoliviaNo ratings yet

- Yellowcard Ultradur B4406 G6 (%)Document2 pagesYellowcard Ultradur B4406 G6 (%)sygabrielaNo ratings yet

- Introdution To ComputersDocument6 pagesIntrodution To ComputersCh Mohsan Javaid75% (12)

- B737-3 ATA 23 L3 REVB New OriginalDocument99 pagesB737-3 ATA 23 L3 REVB New OriginalINFO WORKLINK100% (1)

- Available Fault Current Selective CoordinationDocument59 pagesAvailable Fault Current Selective Coordinationtidjani86No ratings yet

- Bipolar Junction TransistorDocument17 pagesBipolar Junction TransistorRonald Andrei DaguioNo ratings yet

- Moure 2015Document91 pagesMoure 2015prasNo ratings yet

- Brochure - Innova Biological Laboratory ShakersDocument24 pagesBrochure - Innova Biological Laboratory Shakersamoussa83No ratings yet

- Philips 170c6fs Chassis Sh6Document78 pagesPhilips 170c6fs Chassis Sh6videosonNo ratings yet

- AcousticsDocument34 pagesAcousticsanuj seth50% (2)

- GP Half Assignment (The Book Has No Place in Modern Society Discuss)Document2 pagesGP Half Assignment (The Book Has No Place in Modern Society Discuss)FreckleNo ratings yet

- B Tech Fresher RESUMEDocument2 pagesB Tech Fresher RESUMEadarshthapasya0% (1)

- Benzene (Arene) Notes On Chemical ReactionsDocument33 pagesBenzene (Arene) Notes On Chemical ReactionsdanielmahsaNo ratings yet

- Construction and Working Principles of BLDC MotorDocument24 pagesConstruction and Working Principles of BLDC Motormahadeva prasad m sNo ratings yet

- Siesta I TS 10650E-90 UK Apr08Document114 pagesSiesta I TS 10650E-90 UK Apr08manualslib100% (8)

- Electronic Circuits Unit-2Document37 pagesElectronic Circuits Unit-2Siddhasen PatilNo ratings yet

- Factsheet Smart Document en Camera 330 - ENGDocument2 pagesFactsheet Smart Document en Camera 330 - ENGvsvNo ratings yet

- INPA PrintFile Na - FsDocument3 pagesINPA PrintFile Na - Fsdragontiger4773No ratings yet

- 05 September-October 2000 QEXDocument68 pages05 September-October 2000 QEXPisu Miau Pisu Miau100% (1)

- GW-Instek PSM Series Prog Power Supply 82SM-60030MADocument31 pagesGW-Instek PSM Series Prog Power Supply 82SM-60030MARichard BedellNo ratings yet

- IcDocument7 pagesIcMuzakki SathorNo ratings yet

- CP 32G SeriesDocument2 pagesCP 32G SeriesAmalia AzariskaNo ratings yet

- Mitsubishi FG15N Electric System ManualDocument42 pagesMitsubishi FG15N Electric System ManualПетр100% (2)

- Sbe Elec PDFDocument17 pagesSbe Elec PDFRajan Mullappilly100% (1)

- Embedded Systems Project IdeasDocument7 pagesEmbedded Systems Project IdeasmuzammiliqbalNo ratings yet

- TK302 - Eagle R45.0 EPAP R15.0 - V6.0Document261 pagesTK302 - Eagle R45.0 EPAP R15.0 - V6.0Fred_SPbNo ratings yet

DMF50174ZNB FW

DMF50174ZNB FW

Uploaded by

Nemesys TOFOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DMF50174ZNB FW

DMF50174ZNB FW

Uploaded by

Nemesys TOFCopyright:

Available Formats

First Edition Approved by Production Div.

Apr 25, 2000

Checked by Quality Assurance Div.

LCD Module Specification Final Revision

Checked by Design Engineering Div.

*******

Prepared by Production Div.

Type No. DMF-50174ZNB-FW

Table of Contents

1. General Specifications .............................................................................2

2. Electrical Specifications...........................................................................3

3. Optical Specifications ..............................................................................8

4. I/O Terminal...........................................................................................10

5. Test..........................................................................................................12

6. Appearance Standards............................................................................13

7. Code System of Production Lot ..........................................................16

8. Type Number..........................................................................................16

9. Applying Precautions .............................................................................16

10. Precautions Relating Product Handling................................................17

11. Warranty..................................................................................................18

Revision History

Rev. Date Page Comment

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 1/18

1.General Specif ications

Operating Temp. : min. 0℃ ~ max. 50℃

Storage Temp. : min. -20℃ ~ max. 60℃

Dot Pixels : 320 (W) × 240 (H) dots

Dot Size : 0.33 (W) × 0.33 (H) mm

Dot Pitch : 0.36 (W) × 0.36 (H) mm

Viewing Area : 122.0 (W) × 92.0 (H) mm

Outline Dimensions : 174.0* (W) × 112.0 (H) × 14.0 max. (D) mm

* Without CFL Cable

Weight : 300g max.

LCD Type : NTD-11437

( STN / Blue-mode / Transmissive )

Viewing Angle : 6:00

Data Transfer : 4-bit parallel data transfer

Backlight : Cold Cathode Fluorescent Lamp (CFL) × 1

Drawings : Dimensional Outline UE-20762A

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 2/18

2.Electrical Specif ications

2.1.Absolute Maximum Ratings

VSS=0V

Parameter Symbol Conditions Min. Max. Units

Supply Voltage VCC-VSS - -0.3 7.0 V

(Logic)

Supply Voltage VCC-VEE - 0 35.0 V

(LCD Drive)

Input Voltage VI - -0.3 VCC+0.3 V

2.2.DC Characteristics

Ta=25℃, VSS=0V

Parameter Symbol Conditions Min. Typ. Max. Units

Supply Voltage VCC-VSS - 4.5 - 5.5 V

(Logic)

VCC-VEE - 27.1 - 32.0 V

Supply Voltage

(LCD Drive) VCC-VADJ Shown in 3.1 V

High Level VIH VCC=5.0V±10% 0.8×VCC - VCC V

Input Voltage

Low Level VIL VCC=5.0V±10% 0 - 0.2×VCC V

Input Voltage

ICC VCC-VSS=5.0V - 6.0 15.0 mA

Supply Current

IEE VCC-VADJ=23.3V - 5.5 10.0 mA

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 3/18

2.3.AC Characteristics

VCC=5.0V±10%

Parameter Symbol Min. Max. Units

CP Frequency fCP - 6.0 MHz

Clock Pulse Width tWC 50 - ns

Load Pulse Width tWL 63 - ns

Data Setup Time tSETUP 30 - ns

Data Hold Time tHOLD 30 - ns

Clock Pulse Setup Time tCL 80 - ns

Clock Pulse Hold Time tLC 0 - ns

Rise/Fall Time tr, tf - Note 1 ns

FLM Setup Time tFDS 100 - ns

FLM Hold Time tFDH 100 - ns

Note 1:The rise and fall times (tr, tf ) must satisfy the following relationships (①and ②).

1

①tr, tf< - tWC

2fCP

②tr, tf< 50 ns

LOAD

tWL

tr tf

tCL tLC

tWC

CP tWC

tr tf

tSETUP tHOLD

D0~D3

tFDS tFDH

FLM

This module contain these capacitors. Please be careful about timing characteristics.

FLM

1000pF

LP

470pF

M

1000pF

VSS

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 4/18

2.4.Timing Chart

T=0.0595ms typ.

LP

CP

D0

~

SEG SEG SEG SEG SEG SEG SEG SEG

313~ 317~ 1~ 5~ #1 DATA 313~ 317~ 1~ 5~

D3 316 320 4 8 316 320 4 8

FLM

LP

(Reduction)

240×T

FLM

(Reduction)

2.5.Comparison of Display and Data

SEG1 SEG320

#1 D3 D2 D1 D0 D1 D0

TOP VIEW

D0~D3

#240

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 5/18

2.6.Power Supply ON/OFF Sequence

2.6.1.ON Sequence

SIGNAL LEVEL

VCC

VCC VSS

0≦t

VCC

SIGNAL VSS

0≦t

VCC

VADJ

VSS

VEE

VADJ

VEE

0≦t

VCC

DISPOFF VSS

2.6.2.OFF Sequence

LEVEL SIGNAL

VCC

VSS VCC

0≦t

VCC

VSS SIGNAL

0≦t

VCC

VADJ

VSS

VEE

VADJ

VEE

0≦t

VCC

VSS DISPOFF

Please maintain the above sequence when turning on and off the power supply of the module.

If DISPOFF is supplied to the module while internal alternate signal for LCD driving (M) is

unstable, DC component will be supplied to the LCD panel. This may cause damage the LCD

module.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 6/18

2.7.Lighting Specifications

Ta=25℃

Parameter Symbol Conditions Min. Typ. Max. Units Notes

Lamp Voltage VL - - 220 - Vrms 1

Lamp Current IL - 4.0 5.0 6.0 mArms 2

Starting Voltage VS - - 630 - Vrms 3

Surface Luminance L IL=5.0mA 40 50 - cd/㎡ 4

Average Life TAL IL=5.0mA 10000 15000 - hrs 5

Note 1 : The voltage ( r.m.s. ) to maintain the electric discharge of the lamp. It is measured after lighting for

3 minutes .

Note 2 : The current ( r.m.s. ) to flow through the lamp with the electric discharge. It is measured after

lighting for 3 minutes.

Note 3 : The voltage at starting the electric discharge when the voltage is increased gradually from 0V.

Note 4 : Surface Luminance is specified by the initial data of luminance measured at the center of display

surface after 20 minutes power on. ( All ON pattern )

Note 5 : CFL life is defined as the time for which the initial luminance is attenuated by 50% of the

luminance value. Average Life representes the time elapsed at the point of time when the residual

ratio becomes below 50% when plural lamps are lighted in comparison with the definition of life

mentioned above.

I C

N VS VL F

V L

IL

CFL Testing Circuit

Recommended Inverter : S-12561 ( Produced by ELEVAM ) CXA-L10L ( Produced by TDK)

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 7/18

3.Optical Specif ications

3.1.LCD Driving Voltage

Parameter Symbol Conditions Min. Typ. Max. Units

Recommended Ta= 0℃ - - 27.1 V

LCD Driving Voltage VCC-VADJ Ta=25℃ 21.7 23.3 24.9 V

Note 1 Ta=50℃ 19.9 - - V

Note 1 : Voltage (Applied actual waveform to LCD Module) for the best contrast. The range of

minimum and maximum shows tolerance of the operating voltage. The specified contrast ratio and

response time are not guaranteed over the entire range.

3.2.Optical Characteristics

Ta=25℃, 1/240 Duty, 1/14 Bias, VD=23.3V (Note 4), θ= 0 ゚, φ=-゚

Parameter Symbol Conditions Min. Typ. Max. Units

Contrast Ratio Note 1 CR θ= 0 ゚, φ=-゚ - 4 -

Viewing Angle Shown in 3.3

Response Rise Note 2 TON - - 100 200 ms

Time Decay Note 3 TOFF - - 360 540 ms

Note 1 : Contrast ratio is definded as follows.

CR = LON / LOFF

LON : Luminance of the ON segments

LOFF : Luminance of the OFF segments

Note 2 : The time that the luminance level reaches 90% of the saturation level from 0% when ON

signal is applied.

Note 3 : The time that the luminance level reaches 10% of the saturation level from 100% when OFF

signal is applied.

Note 4 : Definition of Driving Voltage VD

VD=VCC-VADJ-VBE

Assuming that the typical driving waveforms shown below are applied to the LCD Panel at

1/A Duty - 1/B Bias ( A : Duty Number, B : Bias Number ). Driving voltage VD is definded

as the voltage VO-P when the contrast ratio (CR=LON / LOFF) is at its maximum.

VO-P

( B-2 )×VO-P / B

1 / ( f F× A ) 1 / fF

〈ON SIGNAL〉 〈OFF SIGNAL〉

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 8/18

3.3.Definition of Viewing Angle and Optimum Viewing Area

・Point ● shows the point where contrast ratio is measured. : θ= 0 ゚, φ=-゚

・Driving condition : 1/240 Duty, 1/14 Bias, VD=23.3V, fF=70Hz

90 ゚

135 ゚ 45 ゚

φ θ 90 ゚

180 ゚ 10 20 30 40 50 (φ= 0 ゚)

θ φ

180 ゚ 0゚

225 ゚ 315 ゚

270 ゚

270 ゚

・Area shows typ. CR≧2

3.4.System Block Diagram

Temperature Chamber

Rotation Table (θ,φ)

Photometer

#1980A WB φ LCD

Optical Fiber

Computer Control Unit &

Waveform Generator

Halogen bulb

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 9/18

4.I/O Terminal

4.1.Pin Assignment

CN1,CN2

No. Symbol Level Function

1 FLM H/L First Line Marker

2 LP H/L Data Latch Signal

3 CP H/L Clock Signal for Shifting Data

4 M H/L Alternate Signal for LCD Drive

5 VADJ ― Voltage Level for LCD Contrast Adjustment

6 VCC ― Power Supply for Logic

7 VSS ― Power Supply (0V, GND)

8 VEE ― Power Supply for LCD Drive

9 D0 H/L Display Data

10 D1 H/L Display Data

11 D2 H/L Display Data

12 D3 H/L Display Data

13 DISPOFF H/L Display Control Signal H : Display on L : Display off

14 NC - Non-connection

CN3

No. Symbol Level Function

1 FL HOT - Power Supply for CFL (HOT)

2 NC - Non-connection

3 NC - Non-connection

4 FL GND - Power Supply for CFL (GND)

4.2.Example of Power Supply

It is recommended to apply a potentiometer for the contrast adjust due to the tolerance

of the driving voltage and its temperature dependence.

VCC VCC (+Voltage)

R1

VADJ VR

MODULE

R2

VEE VEE (-Voltage)

VSS VSS (0V)

R1+R2+VR=10~20K Ω

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 10/18

4.3.Block Diagram

Row Driver 240 LCDP

FLM LC79431D × 3

or equivalent 320 × 240 dots

3

320

LP

3

Column Driver

M

LC79401D × 4

DISPOFF

or equivalent

CP

4

D0~D3

M Circuit

VCC

VSS

Bias Circuit To LSI

VADJ

VEE

FL HOT CFL Backlight

FL GND

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 11/18

5.Test

No change on display and in operation under the following test condition.

No. Parameter Conditions Notes

1 High Temperature Operating 50℃±2℃, 96hrs (operation state)

2 Low Temperature Operating 0℃±2℃, 96hrs (operation state) 3

3 High Temperature Storage 60℃±2℃, 96hrs 4

4 Low Temperature Storage -20℃±2℃, 96hrs 3, 4

5 Damp Proof Test 40℃±2℃, 90~95%RH, 96hrs 3, 4

6 Vibration Test Total fixed amplitude : 1.5mm 5

Vibration Frequency : 10~55Hz

One cycle 60 seconds to 3 directions of X, Y, Z for

each 15 minutes

7 Shock Test To be measured after dropping from 60cm high on

the concrete surface in packing state.

Dropping method corner dropping

F A corner : once

E D Edge dropping

G C

B,C,D edge : once

B A

Face dropping

60cm E,F,G face : once

Concrete Surface

Note 1 : Unless otherwise specified, tests will be conducted under the following condition.

Temperature : 20±5℃

Humidity : 65±5%

Note 2 : Unless otherwise specified, tests will be not conducted under functioning state.

Note 3 : No dew condensation to be observed.

Note 4 : The function test shall be conducted after 4 hours storage at the normal temperature and humidity

after removed from the test chamber.

Note 5 : Vibration test will be conducted to the product itself without putting it in a container.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 12/18

6.Appearance Standards

6.1.Inspection conditions

The LCD shall be inspected under 40W white fluorescent light.

The distance between the eyes and the sample shall be more than 30cm.

All directions for inspecting the sample should be within 45 ゚ against perpendicular line.

45゚

6.2.Definition of applicable Zones

A Zone Bezel Flame

B Zone

C Zone

A Zone : Active display area

B Zone : Area from outside of "A Zone" to validity viewing area

C Zone : Rest parts

A Zone + B Zone = Validity viewing area

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 13/18

6.3.Standards

No. Parameter Criteria

1 Black and (1) Round Shape

White Spots, Zone Acceptable Number

Foreign Substances Dimension (mm) A B C

D ≦0.1 * * *

0.1 < D ≦0.2 3 5 *

0.2 < D ≦0.25 2 3 *

0.25< D ≦0.3 0 1 *

0.3 < D 0 0 *

D = ( Long + Short ) / 2 * : Disregard

(2) Line Shape

Zone Acceptable Number

X (mm) Y (mm) A B C

- 0.03≧W * * *

2.0≧L 0.05≧W 3 3 *

1.0≧L 0.1 ≧W 3 3 *

- 0.1 <W In the same way (1)

X : Length Y : Width * : Disregard

Total defects shall not exceed 5.

2 Air Bubbles

(between glass Zone Acceptable Number

& polarizer) Dimension (mm) A B C

D ≦ 0.3 * * *

0.3 < D ≦ 0.4 3 * *

0.4 < D ≦ 0.6 2 3 *

0.6 < D 0 0 *

* : Disregard

Total defects shall not exceed 3.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 14/18

No. Parameter Criteria

3 The Shape of Dot (1) Dot Shape (with Dent)

0.15≧

As per the sketch of left hand.

(2) Dot Shape (with Projection)

Should not be connected to next dot.

(3) Pin Hole

X

(X+Y) / 2≦0.2mm

Y

(Less than 0.1mm is no counted.)

(4) Deformation

Y (X+Y) / 2≦0.2mm

Total acceptable number : 1/dot, 5/cell

(Defect number of (4) : 1pc.)

4 Polarizer Scratches Not to be conspicuous defects.

5 Polarizer Dirts If the stains are removed easily from LCDP surface, the module is not

defective.

6 Complex Foreign Black spots, line shaped foreign substances or air bubbles between

Substance Defects glass & polarizer should be 5pcs maximum in total.

7 Distance between D≦0.2 : 20mm or more

Different Foreign 0.2<D : 40mm or more

Substance Defects

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 15/18

7.Code System of Production Lot

The production lot of module is specified as follows.

□ □ □ □ □ □

Factory Number (Numeral)

Factory Code (Alphabet)

Production Week (1~5)

Production Month (1~9, X, Y, Z)

Production Year (Lower 2 digits)

8.Type Number

The type number of module is specified on the back of module as follows.

DMF-50174 ZNB-FW

Stamp

Etching or Printing

9.Applying Precautions

Please contact us when questions and/or new problems not specified in this specifications arise.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 16/18

10.Precautions Relating Product Handling

The Following precautions will guide you in handling our product correctly.

1) Liquid crystal display devices

① The liquid crystal display device panel used in the liquid crystal display module is made of plate

glass. Avoid any strong mechanical shock. Should the glass break handle it with care.

② The polarizer adhering to the surface of the LCD is made of a soft material.

Guard against scratching it.

2) Care of the liquid crystal display module against static electricity discharge.

① When working with the module, be sure to ground your body and any electrical equipment you may

be using. We strongly recommend the use of anti static mats ( made of rubber ), to protect work

tables against the hazards of electrical shock.

② Avoid the use of work clothing made of synthetic fibers. We recommend cotton clothing or other

conductivity-treated fibers.

③ Slowly and carefully remove the protective film from the LCD module, since this operation can

generate static electricity.

3) When the LCD module alone must be stored for long periods of time:

① Protect the modules from high temperature and humidity.

② Keep the modules out of direct sunlight or direct exposure to ultraviolet rays.

③ Protect the modules from excessive external forces.

4) Use the module with a power supply that is equipped with an overcurrent protector circuit,

since the module is not provided with this protective feature.

5) Do not ingest the LCD fluid itself should it leak out of a damaged LCD module. Should hands

or clothing come in contact with LCD fluid, wash immediately with soap.

6) Conduc1tivity is not guaranteed for models that use metal holders where solder connections

between the metal holder and the PCB are not used. Please contact us to discuss appropriate

ways to assure conductivity.

7) For models which use CFL:

① High voltage of 1000V or greater is applied to the CFL cable connector area.

Care should be taken not to touch connection areas to avoid burns.

② Protect CFL cables from rubbing against the unit and thus causing the wire jacket to become worn.

③The use of CFLs for extended periods of time at low temperatures will significantly shorten their

service life.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 17/18

8) For models which use touch panels:

①Do not stack up modules since they can be damaged by components on neighboring modules.

②Do not place heavy objects on top of the product. This could cause glass breakage.

9) For models which use COG,TAB,or COF:

①The mechanical strength of the product is low since the IC chip faces out unprotected from the rear.

Be sure to protect the rear of the IC chip from external forces.

②Given the fact that the rear of the IC chip is left exposed, in order to protect the unit from electrical

damage, avoid installation configurations in which the rear of the IC chip runs the risk of making

any electrical contact.

10) Models which use flexible cable, heat seal, or TAB:

①In order to maintain reliability, do not touch or hold by the connector area.

②Avoid any bending, pulling, or other excessive force, which can result in broken connections.

11.Warranty

This product has been manufactured to your company’s specifications as a part for use in your company’s

general electronic products. It is guaranteed to perform according to delivery specifications. For any other

use apart from general electronic equipment, we cannot take responsibility if the product is used in medical

devices, nuclear power control equipment, aerospace equipment, fire and security systems, or any other

applications in which there is a direct risk to human life and where extremely high levels of reliability are

required. If the product is to be used in any of the above applications, we will need to enter into a separate

product liability agreement.

① We cannot accept responsibility for any defect, which may arise from additional manufacturing of

the product (including disassembly and reassembly), after product delivery.

② We cannot accept responsibility for any defect, which may arise after the application of strong

external force to the product.

③ We cannot accept responsibility for any defect, which may arise due to the application of static

electricity after the product has passed your company’s acceptance inspection procedures.

④ When the product is in CFL models, CFL service life and brightness will vary according to the

performance of the inverter used, leaks, etc. We cannot accept responsibility for product

performance, reliability, or defect, which may arise.

⑤ We cannot accept responsibility for intellectual property of a third party, which may arise through the

application of our product to your assembly with exception to those issues relating directly to the

structure or method of manufacturing of our product.

⑥ Optrex will not be held responsible for any quality guarantee issue for defect products judged as

Optrex-origin longer than 2 (two) years from Optrex production or 1(one) year from Optrex, Optrex

America, Optrex Europe, Display LC delivery which ever comes later.

DMF-50174ZNB-FW (AT) No.2000-0166 OPTREX

OPTREX CORPORATION Page 18/18

You might also like

- Meet The Machines of The Future PDFDocument162 pagesMeet The Machines of The Future PDFmusthaziz93% (14)

- Installation Guide For Product Link PL121SR and PL321Document116 pagesInstallation Guide For Product Link PL121SR and PL321ricardocanoNo ratings yet

- MicrDocument7 pagesMicrPrasanna NiyadagalaNo ratings yet

- LCD Module Specification: First Edition Production Div. Approved byDocument17 pagesLCD Module Specification: First Edition Production Div. Approved byAntonio Gianfrnco Rivas NegronNo ratings yet

- LCD DMF 50316NB FW 5Document17 pagesLCD DMF 50316NB FW 5technicahmettNo ratings yet

- Dmf5001ny Ly Aie PDFDocument17 pagesDmf5001ny Ly Aie PDFPTCNo ratings yet

- Optrex DMF 5001Document15 pagesOptrex DMF 5001PTCNo ratings yet

- DMF5001NF-SEW DatasheetDocument17 pagesDMF5001NF-SEW Datasheetfernando david diaz ruiz diazNo ratings yet

- LCD Module Technical Specification: T.YuchiDocument17 pagesLCD Module Technical Specification: T.YuchiAsad AhmedNo ratings yet

- LCD Module Technical Specification: OptrexDocument17 pagesLCD Module Technical Specification: OptrexCapitanSalamiNo ratings yet

- DMF 5001nyl Seb Ave BDNDocument17 pagesDMF 5001nyl Seb Ave BDNVladimirNo ratings yet

- LCD Module Specification: DMC20481NY-LYDocument15 pagesLCD Module Specification: DMC20481NY-LYBeroxi MihaiNo ratings yet

- Dmf5005n Coe DDN Eng 3Document16 pagesDmf5005n Coe DDN Eng 3roozbehxoxNo ratings yet

- Pantalla Info Completa Claa150xg-01-ChunghwapicturetubesDocument17 pagesPantalla Info Completa Claa150xg-01-ChunghwapicturetubesYessenia PerezNo ratings yet

- LCD Datasheet LQ150X1LG92Document17 pagesLCD Datasheet LQ150X1LG92home madeNo ratings yet

- Displaytech-240320dl 03a440753dDocument17 pagesDisplaytech-240320dl 03a440753dBrad FrancNo ratings yet

- GLM240128Document35 pagesGLM240128api-3700809No ratings yet

- M215OG64-183-1901 带TP (CSOT)Document24 pagesM215OG64-183-1901 带TP (CSOT)jaime l cruz sNo ratings yet

- Claa170ea 07Document21 pagesClaa170ea 07Test TestNo ratings yet

- Product Specifications: Displaytech LTDDocument17 pagesProduct Specifications: Displaytech LTDCarlos Lara CastroNo ratings yet

- CLAA170ES01Document21 pagesCLAA170ES01A.b. JethavaNo ratings yet

- LCD Module Technical Specification: First EditionDocument32 pagesLCD Module Technical Specification: First Editionmarco antonioNo ratings yet

- CLAA102NA0ACWDocument16 pagesCLAA102NA0ACWIvan BenginNo ratings yet

- Clab215fa01 ChunghwapicturetubesDocument12 pagesClab215fa01 ChunghwapicturetubesSalomon GonzalezNo ratings yet

- 64128k Cog Series-V10Document19 pages64128k Cog Series-V10megaadyNo ratings yet

- Mikroe 3904Document17 pagesMikroe 3904kushliakNo ratings yet

- 162E Series Displaytech SpecDocument23 pages162E Series Displaytech SpecrochaseletronicaNo ratings yet

- G190ean01 0Document28 pagesG190ean01 0kalanghoNo ratings yet

- LCD SpecDocument21 pagesLCD SpecKC KiewNo ratings yet

- Product Specifications: Displaytech LTDDocument20 pagesProduct Specifications: Displaytech LTDPwter KovacsNo ratings yet

- LCD Module Specification: First Edition Production Div. Approved byDocument18 pagesLCD Module Specification: First Edition Production Div. Approved bySanty JijonNo ratings yet

- Vacuum Fluorescent Display Specification: Model CU20026-TW200ADocument17 pagesVacuum Fluorescent Display Specification: Model CU20026-TW200AMikhailNo ratings yet

- Data Image: Corporation CTP Module SpecificationDocument42 pagesData Image: Corporation CTP Module SpecificationImadMehdiNo ratings yet

- Mitsubishi - AA101TA12 - DatasheetDocument25 pagesMitsubishi - AA101TA12 - DatasheetaylinaykanNo ratings yet

- AA104VC08 MitsubishiDocument23 pagesAA104VC08 MitsubishiJosé AdelinoNo ratings yet

- Tm12864h6ccwgwa1 G-1 (Wo PCB)Document32 pagesTm12864h6ccwgwa1 G-1 (Wo PCB)Feroz KhanNo ratings yet

- TX31D203VM0EAB DatasheetDocument36 pagesTX31D203VM0EAB DatasheetMIGUELNo ratings yet

- 4 GLM 24064Document19 pages4 GLM 24064api-3700809No ratings yet

- 2SC1213AKBDocument10 pages2SC1213AKBafdgtdsghfNo ratings yet

- Chunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PDocument27 pagesChunghwa Picture Tubes, Ltd. Technical Specification: Model: CLAA170EA07PandymustopaNo ratings yet

- T370HW02 Ve - 20081113Document29 pagesT370HW02 Ve - 20081113Tran Van Thien0% (1)

- LCD Claa102na0acwDocument17 pagesLCD Claa102na0acwgnomeNo ratings yet

- Panel CPT CLAA220WA09 0 (DS)Document20 pagesPanel CPT CLAA220WA09 0 (DS)Hoson AkNo ratings yet

- Infineon IPB60R040C7 DS v02 - 00 EN 1622423Document15 pagesInfineon IPB60R040C7 DS v02 - 00 EN 1622423geoffffNo ratings yet

- Nec Inverter 104pw191Document10 pagesNec Inverter 104pw191samee 692No ratings yet

- Chimei N173O6 L02Document29 pagesChimei N173O6 L02alelujaNo ratings yet

- CLAA216WA01 PanalDocument25 pagesCLAA216WA01 PanalGursharan SinghNo ratings yet

- 8.0 Inch IPS MIPI 800x1280 AML08021016-31DDocument13 pages8.0 Inch IPS MIPI 800x1280 AML08021016-31DcalvinkleinwuNo ratings yet

- 2N3906 General Purpose Transistors: PNP SiliconDocument7 pages2N3906 General Purpose Transistors: PNP SiliconFhidli Sang Pangeran BiruNo ratings yet

- TX31D203VM0EABDocument33 pagesTX31D203VM0EABMIGUELNo ratings yet

- ArduinoDocument15 pagesArduinoAlvarez TomasNo ratings yet

- Infineon IPW60R018CFD7 DS v02 - 00 ENDocument14 pagesInfineon IPW60R018CFD7 DS v02 - 00 ENdineshNo ratings yet

- Infineon Ipw60r040c7 Ds v02 00 enDocument15 pagesInfineon Ipw60r040c7 Ds v02 00 enshivguptaNo ratings yet

- Technical Data: NPN Power Silicon TransistorDocument2 pagesTechnical Data: NPN Power Silicon TransistorHoThanhLoiNo ratings yet

- CLAA150XP01Document22 pagesCLAA150XP01adjustmentNo ratings yet

- Silicon Transistor: PNP Silicon Epitaxial Transistor For Driving Fluorescent Indicator PannelDocument5 pagesSilicon Transistor: PNP Silicon Epitaxial Transistor For Driving Fluorescent Indicator PannelpiroNo ratings yet

- N156B6 L08Document31 pagesN156B6 L08JozefNo ratings yet

- CLAA089NA0ACWDocument18 pagesCLAA089NA0ACWczypigNo ratings yet

- LGDocument28 pagesLGabdessNo ratings yet

- LCD Module Mcc162a4 5Document17 pagesLCD Module Mcc162a4 5alfredo de la hozNo ratings yet

- Technical Data: NPN Power Silicon TransistorDocument3 pagesTechnical Data: NPN Power Silicon TransistorMarco FrigerioNo ratings yet

- ENG Commercial Fishing Brochure 2020Document8 pagesENG Commercial Fishing Brochure 2020Nemesys TOFNo ratings yet

- SP14Q002 A1 HitachiDocument22 pagesSP14Q002 A1 HitachiNemesys TOFNo ratings yet

- LCD Shortform (Mono Module)Document3 pagesLCD Shortform (Mono Module)Nemesys TOFNo ratings yet

- BUK213Document16 pagesBUK213Nemesys TOFNo ratings yet

- General Description: Integrated Circuit Systems, IncDocument10 pagesGeneral Description: Integrated Circuit Systems, IncNemesys TOFNo ratings yet

- CL GD6245Document147 pagesCL GD6245Nemesys TOFNo ratings yet

- HY5118160BTC60Document8 pagesHY5118160BTC60Nemesys TOFNo ratings yet

- XCMG Truck Crane Qy25k IIDocument6 pagesXCMG Truck Crane Qy25k IINemesys TOF100% (1)

- Infineon D81C90 DS v01 - 97 enDocument41 pagesInfineon D81C90 DS v01 - 97 enNemesys TOFNo ratings yet

- Intel TE28F160S570Document51 pagesIntel TE28F160S570Nemesys TOFNo ratings yet

- Atomic Line Width: 1. The Uncertainty PrincipleDocument5 pagesAtomic Line Width: 1. The Uncertainty PrincipleMuhammad Abdullah KhanNo ratings yet

- Bh-0.66 I TransformadoresDocument4 pagesBh-0.66 I TransformadoresChint BoliviaNo ratings yet

- Yellowcard Ultradur B4406 G6 (%)Document2 pagesYellowcard Ultradur B4406 G6 (%)sygabrielaNo ratings yet

- Introdution To ComputersDocument6 pagesIntrodution To ComputersCh Mohsan Javaid75% (12)

- B737-3 ATA 23 L3 REVB New OriginalDocument99 pagesB737-3 ATA 23 L3 REVB New OriginalINFO WORKLINK100% (1)

- Available Fault Current Selective CoordinationDocument59 pagesAvailable Fault Current Selective Coordinationtidjani86No ratings yet

- Bipolar Junction TransistorDocument17 pagesBipolar Junction TransistorRonald Andrei DaguioNo ratings yet

- Moure 2015Document91 pagesMoure 2015prasNo ratings yet

- Brochure - Innova Biological Laboratory ShakersDocument24 pagesBrochure - Innova Biological Laboratory Shakersamoussa83No ratings yet

- Philips 170c6fs Chassis Sh6Document78 pagesPhilips 170c6fs Chassis Sh6videosonNo ratings yet

- AcousticsDocument34 pagesAcousticsanuj seth50% (2)

- GP Half Assignment (The Book Has No Place in Modern Society Discuss)Document2 pagesGP Half Assignment (The Book Has No Place in Modern Society Discuss)FreckleNo ratings yet

- B Tech Fresher RESUMEDocument2 pagesB Tech Fresher RESUMEadarshthapasya0% (1)

- Benzene (Arene) Notes On Chemical ReactionsDocument33 pagesBenzene (Arene) Notes On Chemical ReactionsdanielmahsaNo ratings yet

- Construction and Working Principles of BLDC MotorDocument24 pagesConstruction and Working Principles of BLDC Motormahadeva prasad m sNo ratings yet

- Siesta I TS 10650E-90 UK Apr08Document114 pagesSiesta I TS 10650E-90 UK Apr08manualslib100% (8)

- Electronic Circuits Unit-2Document37 pagesElectronic Circuits Unit-2Siddhasen PatilNo ratings yet

- Factsheet Smart Document en Camera 330 - ENGDocument2 pagesFactsheet Smart Document en Camera 330 - ENGvsvNo ratings yet

- INPA PrintFile Na - FsDocument3 pagesINPA PrintFile Na - Fsdragontiger4773No ratings yet

- 05 September-October 2000 QEXDocument68 pages05 September-October 2000 QEXPisu Miau Pisu Miau100% (1)

- GW-Instek PSM Series Prog Power Supply 82SM-60030MADocument31 pagesGW-Instek PSM Series Prog Power Supply 82SM-60030MARichard BedellNo ratings yet

- IcDocument7 pagesIcMuzakki SathorNo ratings yet

- CP 32G SeriesDocument2 pagesCP 32G SeriesAmalia AzariskaNo ratings yet

- Mitsubishi FG15N Electric System ManualDocument42 pagesMitsubishi FG15N Electric System ManualПетр100% (2)

- Sbe Elec PDFDocument17 pagesSbe Elec PDFRajan Mullappilly100% (1)

- Embedded Systems Project IdeasDocument7 pagesEmbedded Systems Project IdeasmuzammiliqbalNo ratings yet

- TK302 - Eagle R45.0 EPAP R15.0 - V6.0Document261 pagesTK302 - Eagle R45.0 EPAP R15.0 - V6.0Fred_SPbNo ratings yet