Professional Documents

Culture Documents

Steps of Hvac Desgin

Steps of Hvac Desgin

Uploaded by

Mo EmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steps of Hvac Desgin

Steps of Hvac Desgin

Uploaded by

Mo EmadCopyright:

Available Formats

What GOVEREN the solutions codes ASHRAE

Detailed Zoning & Load

Estimate

location ex. Egypt

Study the load

application ex. residential ex. villa

equipment APPLICATION OVERVIEW

loads from the drawing

التوزيع Throw

piping beams and structure study

CFM 5- from HAP we get :

selection Indoor temperature / humidity

NC ex. air terminal : grills from client or from application

review the concept of design design

spread Conditions, outdoor design basis

1-study the project

drop ex. operation rooms in hospital

Acoustic design criteria

need very low NC

if their changes in mechanical Space design conditions

CALCUALTE the real reequipment

requirement Exhaust Air Challenges

Ventilation Treated or untreated

Outdoor equipment locations

Energy design criteria IF AVAILABLE

Duct routing

STEPS OF HVAC special design required by the customer

Air terminal 6-DRAFTING & Modeling

DESGIN

Requirements

EX. FCU, AHU or VAV Inner parts of HVAC

Piping use step one to get the loads

2-PRE CALCULATION (RULE OF THUMP ) get the loads from the drawing

Duct rerouting

based on area +above

access and

servicing of components

Remodeling reasons STEP 2+ STEP1+coordination with

between mechanical and other 7-Remodeling Input

Clashes interior design if available

machinal discipline

HVAC system design concept

energy efficiency Output

mechanical requirements

solve the clash Clash report 8-Clash detection 3-Concpet of design

No double line

9-other drawings,

Preliminary Specs, MEANING: final id

ex. schedule of equipment

Standard details Drawings,

Schedules

No final calculation

10-BOQ &Cost Estimate

4-Calucation using HAP

STEPS OF HVAC DESGIN

1. What GOVEREN the solutions

1.1. codes

1.1.1. ASHRAE

2. 1-study the project

2.1. APPLICATION OVERVIEW

2.1.1. location

2.1.1.1. ex. Egypt

2.1.2. application

2.1.2.1. ex. residential

2.1.2.1.1. ex. villa

2.1.3. loads

2.1.3.1. from the drawing

2.1.4. piping

2.1.4.1. beams and structure study

2.2. Space design conditions

2.2.1. Indoor temperature / humidity design

2.2.1.1. from client or from application

2.2.2. Conditions, outdoor design basis

2.2.3. Acoustic design criteria

2.2.3.1. ex. operation rooms in hospital need very low NC

2.2.4. Exhaust Air Challenges

2.2.5. Ventilation

2.2.5.1. Treated or untreated

2.2.6. Energy design criteria IF AVAILABLE

2.2.7. special design required by the customer

2.3. Requirements

3. 2-PRE CALCULATION (RULE OF THUMP )

3.1. use step one to get the loads

3.2. get the loads from the drawing

3.3. based on area +above

4. 3-Concpet of design

4.1. Input

4.1.1. STEP 2+ STEP1+coordination with interior design if available

4.2. Output

4.2.1. HVAC system design concept

4.2.2. mechanical requirements

4.3. MEANING:

4.3.1. No double line

4.3.2. final id

4.3.3. No final calculation

5. 4-Calucation using HAP

6. 10-BOQ &Cost Estimate

7. 9-other drawings, Preliminary Specs, Standard details Drawings, Schedules

7.1. ex. schedule of equipment

8. 7-Remodeling

8.1. Remodeling reasons

8.1.1. Duct rerouting

8.1.2. access and servicing of components

8.1.3. Clashes

8.1.3.1. between mechanical and other machinal discipline

8.1.4. energy efficiency

8.2. 8-Clash detection

8.2.1. Clash report

8.2.1.1. solve the clash

9. 6-DRAFTING & Modeling

9.1. Outdoor equipment locations

9.2. Duct routing

9.3. Air terminal

9.4. Inner parts of HVAC

9.4.1. EX. FCU, AHU or VAV

9.5. Piping

10. 5- from HAP we get :

10.1. Detailed Zoning & Load Estimate

10.2. Study the load

10.3. review the concept of design

10.3.1. selection

10.3.1.1. equipment

10.3.1.2. ex. air terminal : grills

10.3.1.2.1. Throw

10.3.1.2.1.1. التوزيع

10.3.1.2.2. CFM

10.3.1.2.3. NC

10.3.1.2.4. spread

10.3.1.2.5. drop

10.3.2. if their changes in mechanical requirement

10.3.2.1. CALCUALTE the real reequipment

You might also like

- Parts of The House and Furniture - 40028 PDFDocument1 pageParts of The House and Furniture - 40028 PDFAndres Jesus Moreno AriasNo ratings yet

- 000.265.8820 Activity Based Flow Diagram Electrical Eng Load ListDocument1 page000.265.8820 Activity Based Flow Diagram Electrical Eng Load Listvladimir rosas ayalaNo ratings yet

- Vent Calcs-For SustainabilityDocument1 pageVent Calcs-For SustainabilityZiadAbedNo ratings yet

- Development of Mobile Application For Prestressed Reinforce Concrete Girder Design Using Google FlutterDocument10 pagesDevelopment of Mobile Application For Prestressed Reinforce Concrete Girder Design Using Google FlutterEarl Vergille Petiluna ReveloNo ratings yet

- (LS) ANNEX - 2 - Compliance - and - Deviation - TableDocument3 pages(LS) ANNEX - 2 - Compliance - and - Deviation - TableVô CảmNo ratings yet

- FloorPlanStandard RestaurantCEBDocument1 pageFloorPlanStandard RestaurantCEBIskas NektariosNo ratings yet

- ZEE Engineering Newsletter 2009Document4 pagesZEE Engineering Newsletter 2009jesusgameboyNo ratings yet

- Project Proces S Flow 02 01: Cons Truc Tion Cons Truc Tion Desig N Pre-Desig NDocument1 pageProject Proces S Flow 02 01: Cons Truc Tion Cons Truc Tion Desig N Pre-Desig NAnghelikaaaNo ratings yet

- CIVIL Inspection & Test PlanDocument84 pagesCIVIL Inspection & Test PlantalemwamartineNo ratings yet

- 2D Scramjet Inlet IterationDocument8 pages2D Scramjet Inlet IterationDevNo ratings yet

- A0E6G5 - Volume 2 Development Plan Part 2Document41 pagesA0E6G5 - Volume 2 Development Plan Part 2junNo ratings yet

- Introduction To Air-Insulated Substations: Koji KawakitaDocument6 pagesIntroduction To Air-Insulated Substations: Koji KawakitaKURAKULA VIMAL KUMARNo ratings yet

- ETEEAP BS ME Project Management - 2022-2023-2Document8 pagesETEEAP BS ME Project Management - 2022-2023-2Roderick P. ManaigNo ratings yet

- Instrument General Requirements: Project Specification 601Document2 pagesInstrument General Requirements: Project Specification 601Maura ApostolacheNo ratings yet

- WInd Load ProcedureDocument24 pagesWInd Load ProcedureTarek AbulailNo ratings yet

- F Dykes Katherine - DtuDocument28 pagesF Dykes Katherine - DtuMahdi MahnazNo ratings yet

- Nsp16e8a64a-5 Rev96df1bDocument5 pagesNsp16e8a64a-5 Rev96df1bapi-341407707No ratings yet

- Standard Four-Storey SCHL BLDG POWDocument152 pagesStandard Four-Storey SCHL BLDG POWAl Patrick Dela CalzadaNo ratings yet

- Design Notes:: Commonwealth of PennsylvaniaDocument1 pageDesign Notes:: Commonwealth of PennsylvaniaHDNo ratings yet

- 4PDocument1 page4Pwlv hugoNo ratings yet

- Cab-E-11 - Inspection For Ductbank DBDocument1 pageCab-E-11 - Inspection For Ductbank DBAjmal RoshanNo ratings yet

- Specification For Instrument Cable: Pecification For Nstrument AbleDocument18 pagesSpecification For Instrument Cable: Pecification For Nstrument Ableamini_mohiNo ratings yet

- Estmation of Main DimensionsDocument12 pagesEstmation of Main Dimensionsmarkconnery5No ratings yet

- Data Center in General by Matthew Sacha 20210224Document1 pageData Center in General by Matthew Sacha 20210224Matthew SachaNo ratings yet

- Conceptualization Site Location: Architectural Design ConsiderationsDocument1 pageConceptualization Site Location: Architectural Design ConsiderationsDevkalpaNo ratings yet

- Gao2016 Numerical Modeling of Flow Through PorousDocument5 pagesGao2016 Numerical Modeling of Flow Through Porousaaron prakashNo ratings yet

- Sample Pour-In-Place™ 1 Up System LayoutDocument5 pagesSample Pour-In-Place™ 1 Up System LayoutPablo StapsNo ratings yet

- Plano Advance PDFDocument10 pagesPlano Advance PDFjonatancgNo ratings yet

- Structures, Structural Dynamics and Materials ConferenceDocument15 pagesStructures, Structural Dynamics and Materials ConferenceBogdan PashistyNo ratings yet

- Multistory Buildings Will: For That PartitionDocument1 pageMultistory Buildings Will: For That PartitionjosNo ratings yet

- Projects - 2023 09 26 SERCDocument24 pagesProjects - 2023 09 26 SERCcute biterNo ratings yet

- Projects - 2024 01 09 SERCDocument27 pagesProjects - 2024 01 09 SERCdckien2002No ratings yet

- Exploration and ReservoirDocument67 pagesExploration and Reservoirusman nawaz100% (1)

- By The ASCE Task Committee On Design Criteria For Composite Structures in Steel and Concrete ABSTRACT: This Commentary Complements The "Proposed Specification For StrucDocument25 pagesBy The ASCE Task Committee On Design Criteria For Composite Structures in Steel and Concrete ABSTRACT: This Commentary Complements The "Proposed Specification For StrucPrapa KaranNo ratings yet

- 05 Compliance Assurance Plan For May 2024 Rev 0Document3 pages05 Compliance Assurance Plan For May 2024 Rev 0sidhanathsingh5No ratings yet

- 07-Appendix - I To SCC - Vol-IDocument18 pages07-Appendix - I To SCC - Vol-Isarat mishraNo ratings yet

- Sample Schedule (TCG)Document37 pagesSample Schedule (TCG)Aldrin MacaraegNo ratings yet

- Steel Stack Design Case StudyDocument7 pagesSteel Stack Design Case StudyPetersonNo ratings yet

- Disassemble 2Document1 pageDisassemble 2Batalla, Frencee Shine A.No ratings yet

- The Stages of Mine DesignDocument8 pagesThe Stages of Mine DesignMichael David Altamirano MackenzieNo ratings yet

- GH2023 - 5876 Saturin & Minh Enhancing Efficiency of Geotechnical Design For Offshore MonopileDocument7 pagesGH2023 - 5876 Saturin & Minh Enhancing Efficiency of Geotechnical Design For Offshore MonopileMinh Nguyen-AnhNo ratings yet

- CAPEX Budgetting ToolDocument17 pagesCAPEX Budgetting ToolAbdallah AlnourNo ratings yet

- Softwares For Transmission Pole FoundationDocument3 pagesSoftwares For Transmission Pole FoundationYan YanNo ratings yet

- Comparison of RCC and RBC Slab System.Document1 pageComparison of RCC and RBC Slab System.Saleem MughalNo ratings yet

- Edoc Corrective Action Plan 2016Document2 pagesEdoc Corrective Action Plan 2016musewejamesoumaNo ratings yet

- Campion Crane-SafetyDocument23 pagesCampion Crane-Safetymartahan manurungNo ratings yet

- Tecon BrochureDocument18 pagesTecon BrochureAjitesh MishraNo ratings yet

- George Vepa 1997 Deflection Response Models For Cracked Rigid PavementsDocument8 pagesGeorge Vepa 1997 Deflection Response Models For Cracked Rigid PavementsABHINAV KUMARNo ratings yet

- PMC O&mDocument7 pagesPMC O&mRaman KumarNo ratings yet

- Area 06 WP 34Document1 pageArea 06 WP 34Vishnudas MgNo ratings yet

- Approved Use Matrix - GSADocument1 pageApproved Use Matrix - GSANagarjuna Reddy MNo ratings yet

- Effective StressDocument33 pagesEffective StressshahidNo ratings yet

- MaterialsDocument358 pagesMaterialsGianCarloCatanGadong100% (2)

- Java Self-Evaluation FormDocument5 pagesJava Self-Evaluation FormYurii ProrokNo ratings yet

- Modul 3 Perencanaan ProyekDocument60 pagesModul 3 Perencanaan Proyekbryant sNo ratings yet

- Project Process Flow Chart: Pre Design Phase Design Phase Construction Phase Post Construction PhaseDocument1 pageProject Process Flow Chart: Pre Design Phase Design Phase Construction Phase Post Construction PhaseAnghelikaaaNo ratings yet

- Additional Terms and Conditions For Vehicle Hiring Services Through Gem (BID No. GEM/2023/B/) For Eil KHPL ProjectDocument6 pagesAdditional Terms and Conditions For Vehicle Hiring Services Through Gem (BID No. GEM/2023/B/) For Eil KHPL ProjectlaxmithetenderNo ratings yet

- SearchEngine2 PDFDocument61 pagesSearchEngine2 PDFThaku KishorNo ratings yet

- 2019.05.23 LCA Timeline Diagram SpreadDocument1 page2019.05.23 LCA Timeline Diagram SpreadRoxanne BouletNo ratings yet

- Conners Howe 2012 Supersonic Inlet Shaping For Dramatic Reductions in Drag and Sonic Boom StrengthDocument24 pagesConners Howe 2012 Supersonic Inlet Shaping For Dramatic Reductions in Drag and Sonic Boom StrengthVishnu RamNo ratings yet

- Data QuestionsDocument3 pagesData QuestionsMo EmadNo ratings yet

- VIEWSDocument3 pagesVIEWSMo EmadNo ratings yet

- Big DataDocument3 pagesBig DataMo EmadNo ratings yet

- ERDDocument3 pagesERDMo EmadNo ratings yet

- Data MiningDocument3 pagesData MiningMo EmadNo ratings yet

- Data Analysis ConceptsDocument3 pagesData Analysis ConceptsMo EmadNo ratings yet

- DBMSDocument3 pagesDBMSMo EmadNo ratings yet

- DBMSDocument4 pagesDBMSMo EmadNo ratings yet

- What Is The Difference Between A Data Warehouse and Big DataDocument3 pagesWhat Is The Difference Between A Data Warehouse and Big DataMo EmadNo ratings yet

- SELECTION Parameters OF COOLING UNITDocument3 pagesSELECTION Parameters OF COOLING UNITMo EmadNo ratings yet

- Autocad Mep FeaturesDocument3 pagesAutocad Mep FeaturesMo EmadNo ratings yet

- Tables of DesignDocument3 pagesTables of DesignMo EmadNo ratings yet

- Selection of FansDocument3 pagesSelection of FansMo EmadNo ratings yet

- Artificial Intelligence Research AT Carnegie-Mellon UniversityDocument6 pagesArtificial Intelligence Research AT Carnegie-Mellon UniversityMo EmadNo ratings yet

- PUMPSDocument3 pagesPUMPSMo EmadNo ratings yet

- Chiller Plant ExplainedDocument3 pagesChiller Plant ExplainedMo EmadNo ratings yet

- Autocad MepDocument3 pagesAutocad MepMo EmadNo ratings yet

- Carrier Corporation: Limited Warranty For Condensing Gas Furnace With Clamshell Secondary Heat ExchangerDocument2 pagesCarrier Corporation: Limited Warranty For Condensing Gas Furnace With Clamshell Secondary Heat ExchangerMo EmadNo ratings yet

- Roadstone: Thermal Liteblock SystemDocument24 pagesRoadstone: Thermal Liteblock SystemMo EmadNo ratings yet

- BODR For HVACDocument3 pagesBODR For HVACMo EmadNo ratings yet

- Optimization of A Battery Manufacturing Line Using Computer SimulationDocument107 pagesOptimization of A Battery Manufacturing Line Using Computer SimulationMo EmadNo ratings yet

- Precast Products - Declaration of Performance: Hallowcore FlooringDocument2 pagesPrecast Products - Declaration of Performance: Hallowcore FlooringMo EmadNo ratings yet

- Oman - Ophiolite Hollow Block U-ValueDocument32 pagesOman - Ophiolite Hollow Block U-ValueMo EmadNo ratings yet

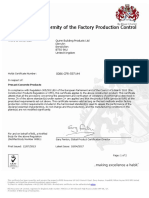

- Certificate of Conformity of The Factory Production ControlDocument2 pagesCertificate of Conformity of The Factory Production ControlMo EmadNo ratings yet

- Precast Concrete: Custom Built Solutions From Design To InstallationDocument6 pagesPrecast Concrete: Custom Built Solutions From Design To InstallationMo EmadNo ratings yet

- Handbook 2016 2017Document59 pagesHandbook 2016 2017Mo EmadNo ratings yet

- HandbookDocument206 pagesHandbookMo EmadNo ratings yet

- BUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Document48 pagesBUILDING SERVICES-I Sanitary Fixtures, Fittings & Wellness-1Vidya Hitti100% (2)

- GA 1 1MeasuringPracticeDocument3 pagesGA 1 1MeasuringPracticeVincent Garcia0% (1)

- Project: Hunfalvy János Bilingual Secondary Vocational School of Economics and Trade of BGSZCDocument3 pagesProject: Hunfalvy János Bilingual Secondary Vocational School of Economics and Trade of BGSZCVilmos BudinszkyNo ratings yet

- Tle Cookery 9 Week 3 & 4 Summative Test Name: - Date: - Grade/ Section: - ScoreDocument2 pagesTle Cookery 9 Week 3 & 4 Summative Test Name: - Date: - Grade/ Section: - ScoreMirasol SegundoNo ratings yet

- Unit 2: Rebel Without A CauseDocument62 pagesUnit 2: Rebel Without A CauseEnglish TimeNo ratings yet

- ASKODocument33 pagesASKOlauraNo ratings yet

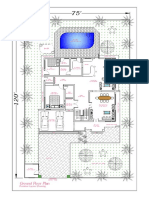

- Ground Floor Plan: Furniture Layout DrawingDocument1 pageGround Floor Plan: Furniture Layout DrawingZaid AliNo ratings yet

- Ground Floor Plan Second Floor Plan Roof Plan: T&B Laundry Laundry T&BDocument1 pageGround Floor Plan Second Floor Plan Roof Plan: T&B Laundry Laundry T&BFELICITY MONTEFALCONo ratings yet

- Uputstvo Za UpotrebuDocument44 pagesUputstvo Za UpotrebuBranko AndricNo ratings yet

- G/F Cleanwater Line Layout Scale: 1: 1 0 0 A 2/F Cleanwater Line Layout Scale: 1: 1 0 0 BDocument1 pageG/F Cleanwater Line Layout Scale: 1: 1 0 0 A 2/F Cleanwater Line Layout Scale: 1: 1 0 0 BMiguel EllaNo ratings yet

- Plumbers Finchley CentralDocument2 pagesPlumbers Finchley CentralSusan joesNo ratings yet

- GODREJ SKIDO UniversalDocument44 pagesGODREJ SKIDO UniversalTeenager MarsNo ratings yet

- Iso 1964 1987Document11 pagesIso 1964 1987Dina ANDRIAMAHEFAHERYNo ratings yet

- Inventory Report CNB 190722Document303 pagesInventory Report CNB 190722nikhil soniNo ratings yet

- 3 - PDFsam - 13 Elements BrochureDocument2 pages3 - PDFsam - 13 Elements BrochureSundar Shankar NarayananNo ratings yet

- 5 - Vocabulary - Towns and BuildingsDocument9 pages5 - Vocabulary - Towns and BuildingsaismelNo ratings yet

- Advance Food Production Operations - II May 15Document2 pagesAdvance Food Production Operations - II May 15Kumar SatyamNo ratings yet

- Schedule MEPDocument36 pagesSchedule MEPReysa Hermanda SariNo ratings yet

- Listening Listen and Match. /5 Marks: NameDocument3 pagesListening Listen and Match. /5 Marks: NamelibrosileNo ratings yet

- Inside The Rooms of A HouseDocument3 pagesInside The Rooms of A HouseSebastián PosadaNo ratings yet

- 2bhk Premium Unit Upper PlanDocument1 page2bhk Premium Unit Upper PlannahkbceNo ratings yet

- 2.10.1.8 Ground-Fault Circuit-Interrupter Protection For PersonnelDocument1 page2.10.1.8 Ground-Fault Circuit-Interrupter Protection For PersonnelLevy CanaletaNo ratings yet

- Perfect Roast Chicken Recipe - Ina Garten - Food NetworkDocument2 pagesPerfect Roast Chicken Recipe - Ina Garten - Food NetworkDarminton Yordanus SinulinggaNo ratings yet

- Validity: 1 August - 31 December 2021 Product Code Barcode Product Name Price/pc Qty (PC) TotalDocument3 pagesValidity: 1 August - 31 December 2021 Product Code Barcode Product Name Price/pc Qty (PC) TotalfreteerNo ratings yet

- Spek InteriorDocument20 pagesSpek InteriorCv MatahariNo ratings yet

- Expansion Valves PDFDocument36 pagesExpansion Valves PDFlarafernandoNo ratings yet

- Steelhead Community Hall Hall LayoutDocument2 pagesSteelhead Community Hall Hall Layoutshubham kumarNo ratings yet

- WWW Nakodadcs Com Services House Cleaning Services in BhopalDocument9 pagesWWW Nakodadcs Com Services House Cleaning Services in Bhopalpreet singhNo ratings yet

- Vegetable Peeler: Is Commonly Used To Shave The Skin Off Fruits and VegetablesDocument61 pagesVegetable Peeler: Is Commonly Used To Shave The Skin Off Fruits and Vegetablesnichole azusanoNo ratings yet