Professional Documents

Culture Documents

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

Uploaded by

Mohammed MujahidCopyright:

Available Formats

You might also like

- Construction AuditDocument5 pagesConstruction AuditMohammed Mujahid100% (1)

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- French Cleat Tool WallDocument6 pagesFrench Cleat Tool WallKeith WilliamsNo ratings yet

- Site Inspection and Test Plan For Architectural Work Rev-1Document23 pagesSite Inspection and Test Plan For Architectural Work Rev-1Mohammed Mujahid100% (1)

- ITP For ASPHALT CONCRETE PAVINGDocument4 pagesITP For ASPHALT CONCRETE PAVINGMohammed Mujahid100% (1)

- Apple Watch Series 7Document1 pageApple Watch Series 7Mohammed MujahidNo ratings yet

- Advanced Building Construction Technology Rqs2s1g2 PPT SlideDocument90 pagesAdvanced Building Construction Technology Rqs2s1g2 PPT Slideyh50% (2)

- Inspection Checklist Earthworks: (Project Number) (Client Name) (Date) (Client Representative Name) (Contractor Name)Document1 pageInspection Checklist Earthworks: (Project Number) (Client Name) (Date) (Client Representative Name) (Contractor Name)Lazar Andonov100% (1)

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Document4 pagesWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIAN100% (1)

- MS For Blockwork - 01Document33 pagesMS For Blockwork - 01scarlett3232100% (2)

- Pour CardDocument1 pagePour CardJohn DoeNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- Curing Compound ApplicationDocument3 pagesCuring Compound Applicationmoytabura96No ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- Guide To Designing For Mine SubsidenceDocument4 pagesGuide To Designing For Mine SubsidenceScooby DooNo ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- ITP-CONCRETE Blinding WorkDocument2 pagesITP-CONCRETE Blinding WorkYash Sharma100% (1)

- 045 ITP For MASONRY PLASTERING WORKS Buildings PDFDocument10 pages045 ITP For MASONRY PLASTERING WORKS Buildings PDFBenjamin ChavezNo ratings yet

- 3 Checklist For Structural Work (Post-Pour)Document2 pages3 Checklist For Structural Work (Post-Pour)alfieNo ratings yet

- ITP - Plaster WorkDocument1 pageITP - Plaster Workmahmoud ghanemNo ratings yet

- SPEC BrickworkDocument4 pagesSPEC BrickworkyantieschumiNo ratings yet

- Checklist For External Painting R1Document1 pageChecklist For External Painting R1hkshyla89No ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanMadison ChanNo ratings yet

- 4.method Statement Blinding and Concrete WorksDocument5 pages4.method Statement Blinding and Concrete Worksشاز إياسNo ratings yet

- During Concreting Check ListDocument1 pageDuring Concreting Check ListFaiz RahmatNo ratings yet

- Itp For Installation of FormworksDocument1 pageItp For Installation of FormworksImho TepNo ratings yet

- Approval of - Concurewb309-As Concrete Curing CompoundDocument4 pagesApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqNo ratings yet

- MS 1 Concrete Quality ControlDocument30 pagesMS 1 Concrete Quality ControlMarwa FaroukNo ratings yet

- Checklist For Window M.S GrillDocument2 pagesChecklist For Window M.S GrillAh RashedNo ratings yet

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDocument19 pagesIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinNo ratings yet

- Inspection and Test Plan - Wooden Wall Panel InstallationDocument2 pagesInspection and Test Plan - Wooden Wall Panel Installationexia1992No ratings yet

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimNo ratings yet

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsNo ratings yet

- SECTION 09220 Portland Cement Plaster Rev 0Document30 pagesSECTION 09220 Portland Cement Plaster Rev 0sk mukhtarNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Concrete Post Pour Check ListDocument1 pageConcrete Post Pour Check ListKamal FitriNo ratings yet

- Paver Blocks FixingDocument1 pagePaver Blocks FixingBharathraj RajNo ratings yet

- CL-QA-07D Retaining Wall, RCC Wall & Others ReinforcementDocument1 pageCL-QA-07D Retaining Wall, RCC Wall & Others Reinforcementthangamani gNo ratings yet

- ITP - IrrigationDocument5 pagesITP - IrrigationashwinNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- Table A - Cement Content and W/C Ratio For ConcreteDocument1 pageTable A - Cement Content and W/C Ratio For ConcreteIbrahim NaguibNo ratings yet

- False Celling Check ListDocument2 pagesFalse Celling Check Listjohn paul100% (1)

- FPM 221 Checklist Earth WorkDocument2 pagesFPM 221 Checklist Earth WorkPrabaharan K100% (1)

- Checklist For External PlasterDocument3 pagesChecklist For External PlasterSantosh YadavNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Surface Preparation: Afras Inspection Chek List - Sar ProjectDocument2 pagesSurface Preparation: Afras Inspection Chek List - Sar ProjecteslamNo ratings yet

- 02-Pre-Concreting Inspection RequestDocument2 pages02-Pre-Concreting Inspection RequestJohn Oliver GuiangNo ratings yet

- ITP For Blinding Concrete WorksDocument3 pagesITP For Blinding Concrete WorksMohammed Ghareib NasrNo ratings yet

- Method Statement For Aac BlockworkDocument10 pagesMethod Statement For Aac BlockworkobieNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- 1 MS - Pouring of ConcreteDocument8 pages1 MS - Pouring of ConcreteFauzi MastamNo ratings yet

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocument9 pages017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- ملف ممتاز عن الرشاشاتDocument13 pagesملف ممتاز عن الرشاشاتakram husseinNo ratings yet

- Installation of LV Cables: Inspection and Test Plan ForDocument1 pageInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNo ratings yet

- Field Tests of Common Building MaterialsDocument4 pagesField Tests of Common Building Materialsjkligvk. jukjNo ratings yet

- Inspection & Test Plan (Itp) : Road WorkDocument1 pageInspection & Test Plan (Itp) : Road WorkLOPA THANDARNo ratings yet

- Block Masonary Work: Method StatementDocument5 pagesBlock Masonary Work: Method StatementAneel KumarNo ratings yet

- Inspection Checklist: Concrete Screed PlacementDocument2 pagesInspection Checklist: Concrete Screed PlacementZiaul HaqNo ratings yet

- Electrical Inspections ChecklistDocument6 pagesElectrical Inspections Checklistasyraf azaharyNo ratings yet

- Masonry: Name of Contractor: Ref. Drwg. No.Document2 pagesMasonry: Name of Contractor: Ref. Drwg. No.yash shah100% (1)

- Method Statement For Granite FrameDocument7 pagesMethod Statement For Granite FrameMonali Varpe100% (1)

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호No ratings yet

- C8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksDocument2 pagesC8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksJabinNo ratings yet

- Non Conformance Report: Refer Attached PhotographsDocument8 pagesNon Conformance Report: Refer Attached PhotographsJitender Tanwar100% (1)

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Document10 pagesFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- ASP-CSP 14 Noise Study Solutions Rev009Document4 pagesASP-CSP 14 Noise Study Solutions Rev009Mohammed MujahidNo ratings yet

- Mujahid CVDocument8 pagesMujahid CVMohammed MujahidNo ratings yet

- ون مليون ONE MILLION - FLOWER FACTORYDocument1 pageون مليون ONE MILLION - FLOWER FACTORYMohammed MujahidNo ratings yet

- M6UMTYDocument3 pagesM6UMTYMohammed MujahidNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed Mujahid0% (1)

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Document10 pagesFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- Span Vol2 2015 Part1Document150 pagesSpan Vol2 2015 Part1Mohammed MujahidNo ratings yet

- International Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFDocument2 pagesInternational Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFMohammed Mujahid0% (1)

- Guide To Inspecting and Maintaining CranesDocument8 pagesGuide To Inspecting and Maintaining CranesMohammed MujahidNo ratings yet

- Cooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiDocument2 pagesCooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiMohammed MujahidNo ratings yet

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- QP Cutting JSADocument6 pagesQP Cutting JSAMohammed MujahidNo ratings yet

- History With DetailsDocument10 pagesHistory With DetailsSuha FathimaNo ratings yet

- Aavarna 2Document13 pagesAavarna 2SNEHA DEVARAJU100% (1)

- Chapter 5 Post-Tensioned SlabDocument19 pagesChapter 5 Post-Tensioned SlabSharan BvpNo ratings yet

- 700 BMC QuestionDocument72 pages700 BMC QuestionrpsirNo ratings yet

- Wa0000Document35 pagesWa0000gauthami pjNo ratings yet

- BS5628-3 2005 PDFDocument136 pagesBS5628-3 2005 PDFJoãoNo ratings yet

- Wallscanner D Tect 150 Professional - Manual PDFDocument351 pagesWallscanner D Tect 150 Professional - Manual PDFVladimír KřížNo ratings yet

- Seminar ReportDocument34 pagesSeminar ReportShreyas M CNo ratings yet

- British Residency 2Document16 pagesBritish Residency 2Syeda Sameeha MaryamNo ratings yet

- 155 BRCDocument2 pages155 BRCRaajeev Neela75% (4)

- Dep-34.17.10.33-Portable Blast-Resistant ModulesDocument36 pagesDep-34.17.10.33-Portable Blast-Resistant ModulesStephen MalobaNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- Obstructions in SprinklerDocument28 pagesObstructions in SprinklerMd Rafat ArefinNo ratings yet

- Piping Spec: CS150 TFS 1021: Engineering StandardDocument4 pagesPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16No ratings yet

- General Specifications: Scope of WorkDocument10 pagesGeneral Specifications: Scope of WorkChy GomezNo ratings yet

- Rate Analysis Excel MetricDocument7 pagesRate Analysis Excel MetricAltaf NiaziNo ratings yet

- Building Design and Erection Using Prefabricated Concrete Code of PracticeDocument56 pagesBuilding Design and Erection Using Prefabricated Concrete Code of Practicemadhukannan.mohanNo ratings yet

- 58 Deadly TrapsDocument9 pages58 Deadly Trapsthe_doom_dudeNo ratings yet

- Single Storey Extension SMMDocument13 pagesSingle Storey Extension SMMFlokrida SherifiNo ratings yet

- MASONRY HandoutDocument20 pagesMASONRY HandoutJoshua Andrei A. DelacruzNo ratings yet

- Real Life Projects Report Onyango Alfred Ndijo. 21.1.224.D.510Document6 pagesReal Life Projects Report Onyango Alfred Ndijo. 21.1.224.D.510Bweks LeBron MVPNo ratings yet

- O'Skea - Dramatics Magazine - Painting The SceneDocument7 pagesO'Skea - Dramatics Magazine - Painting The SceneMerabo SimonishviliNo ratings yet

- DR Horton Homeowners ManualDocument80 pagesDR Horton Homeowners ManualLynn RaisesNo ratings yet

- PPC Ebrochure Bricks & Blocks 2011 1Document2 pagesPPC Ebrochure Bricks & Blocks 2011 1Ryan MalyonNo ratings yet

- Construction MaterialsDocument20 pagesConstruction MaterialsmariyaNo ratings yet

- Hotel Public Area GuidelinesDocument10 pagesHotel Public Area GuidelinesamyraeuhjNo ratings yet

- Lafarge Ceilings Solutions BrochureDocument48 pagesLafarge Ceilings Solutions BrochurericNo ratings yet

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

Uploaded by

Mohammed MujahidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

FINAL-ITP For Concreting Work Rev.2 25-Oct-2014

Uploaded by

Mohammed MujahidCopyright:

Available Formats

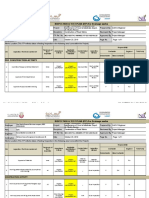

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25Oct. 2014

Rev. No.: 2 Concreting Work Page: 1 of 12

SITE INSPECTION AND TEST PLAN FOR

CONCRETING WORK

2 Issued for Construction 25 Oct 2014 Isrhael Khan S.H Ahn

1A Issued for Construction 21 Oct 2014 Isrhael Khan S.H Ahn

1 Issued for Construction 13 Sept 2014 Isrhael Khan S.H. Ahn

0A Issued for Approval 08 Sept. 2014 Isrhael Khan S.H. Ahn

0 Issued for Construction 04 Dec. 2013 Isrhael Rene Keun Park

A Issued for Approval 01 Dec. 2013 Isrhael Rene Keun Park

Rev. Description Date Prepared By Checked By Approved By

REHABILITATION AND EXPANSION OF SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Date of Issue: 25Oct. 2014

Rev. No.: 2

Site Inspection and Test Plan for Concreting Work Page: 2 of 12

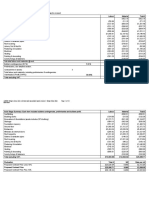

Project Name: Rehabilitation & Expansion of I.T.P. No.: ITP-CE-002

SWTP - Yanbu

INSPECTION AND TEST PLAN FOR CONCRETING WORK Page: 1 of 3

Contract No.:

Discipline: Civil Date:

Acceptance Criteria Inspection for

No. Description of Inspection or Test Verifying Doc. Remarks

Reference(Code/Std/Spec/Proc/Dwg.) Subcontractor Contractor QC Owner/PMC

1 CONCRETING WORK

Material

1.1 Cement Mat’l Test Cert../MRR

1.2 Fine Aggregate

1.3 Coarse Aggregate

Section 03310 Third Party Lab. Report

1.4 Combined Aggregate H W/R W/R

1.5 Water

1.6 Mineral Admixtures Mat’l Test Cert./MRR

1.7 Reinforcement

a) Regular Reinforcement(un-coated

reinforcing steel)

MILL Cert.

b) Epoxy-Coated Reinforcement Section 03205 2.02

Mat’l Test Cert./MRR H W/R W/R

c) High Strength Polymer Grids

d)Reinforcement Accessories

e) Repair of Epoxy-coated Bars Section 03205 3.04

1.8 Joint Material Section 03310 2.a

Rubber-CEO C513, Polyvinyl-COE CRD

a) Waterstops

C572

b) Preformed Expansion Joint Filler Section 07910

c) Joint Sealing Compound Section 07920 H W/R W/R

Mat’l Test Cert/MRR

1.9 Curing Material Section 03310 3.07

1.10 Water Proofing Material Section 07100

1.11 Concrete Repair Material Section 03930 2.02

2 INSTALLATION ACTIVITY

H W (W)

2.2 Polyethylene Sheet Section 03310 3.10 B

2.3 Blinding Concrete Section 03310 Third Party Lab. Report

ITP-CE-F009, ITP-CE-F007, ITP-

a) Slump Test ASTM C143

ORGANIZATION NAME/POSITION SIGNATURE DATE

WE CERTIFY THAT WORK HAS BEEN CONTRACTOR (POSCO E&C)

COMPLETED ACCORDING TO THE

PMC (JACOBS)

REQUIREMENTS OF INSPECTION TEST PLAN.

CONTRACT No.: 7200018704 CLIENT (MARAFIQ)

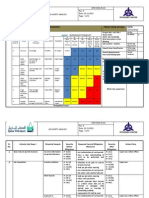

REHABILITATION AND EXPANSION OF SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Date of Issue: 25Oct. 2014

Rev. No.: 2

Site Inspection and Test Plan for Concreting Work Page: 3 of 12

b)Temperature

c) Cylinder Mould Sampling

CE-F008, ITP-CE-F012

d) Compressive Strength Test

2.4 Water Proofing ITP-CE-F010

2.5 Steel Reinforcement ITP-CE-F008

I : Inspection R : Review (W) : Random Witness W: Witness H: Hold

Project Name: Rehabilitation & Expansion of SWTP I.T.P. No.: ITP-CE-002

- Yanbu

INSPECTION AND TEST PLAN FOR CONCRETING WORK Page: 2 of 2

Contract No.:

Discipline: Civil Date:

Acceptance Criteria Inspection for

No. Description of Inspection or Test Verifying Doc. Remarks

Reference(Code/Std/Spec/Proc/Dwg.) Subcontractor Contractor QC Owner/PMC

CONCRETING WORK

2.6 Formworks Installation Approved Dwg./MS

a) Form Tiles Section 03105 2.05 A

b) Form Coating Section 03105 2.05 B

c) Form Release Agent Section 03105 2.05 C ITP-CE-F007, ITP-CE-F008,

d) Metal Inserts Section 03105 2.05 D ITP-CE-F003,ITP-CE-F012

H W W

e) Corners Section 03105 2.05 E

f) Formwork Tolerance Section 03105 3.07

2.7 Embedded Item/Steel Inserts

Approved Dwg./MS ITP-CE-F008, ITP-CE-F012

2.8 Elect./Mech. Embedded Item

2.9 Concreting Section 03310. Part 3.3.04

2.9.1 Testing

a) Slump ASTM C143

b) Air Test ASTM C231

Third Party Lab. Test

c) Temperature Report H W (W)/R

Blinding 20MPa SRC

d) Cylinder Mould and Curing ITP-CE-F009

Screed 30MPa OPC

e) Compressive Strength Test Structure 30MPa+MS OPC

ORGANIZATION NAME/POSITION SIGNATURE DATE

WE CERTIFY THAT WORK HAS BEEN CONTRACTOR (POSCO E&C)

COMPLETED ACCORDING TO THE

PMC (JACOBS)

REQUIREMENTS OF INSPECTION TEST PLAN.

CONTRACT No.: 7200018704 CLIENT (MARAFIQ)

REHABILITATION AND EXPANSION OF SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Date of Issue: 25Oct. 2014

Rev. No.: 2

Site Inspection and Test Plan for Concreting Work Page: 4 of 12

2.10 Curing

1. Curing Material

a) Impervious Sheeting ASTM 171

H W (W)

b) Burlap AASHTO M 182. Class 3

c) Membrane Curing Compound ASTM C 309 Type 2.

d) Water Section 0333-18 paragraph. 2.1 E

I : Inspection R : Review (W) : Random Witness W : Witness H : Hold

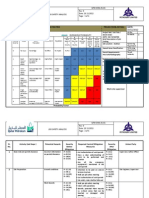

Project Name: Rehabilitation & Expansion of SWTP I.T.P. No.: ITP-CE-002

- Yanbu

INSPECTION AND TEST PLAN FOR CONCRETING WORK Page: 3 of 3

Contract No.: 720018704

Discipline: Civil Date:

Acceptance Criteria Inspection for

No. Description of Inspection or Test Verifying Doc. Remarks

Reference(Code/Std/Spec/Proc) Subcontractor Contractor QC Owner/PMC

3 CONCRETE REHABILITATION Section 03930

3.1 Material Section 03930 2.02

a) Portland Cement Concrete Type I Cement Third Party Lab. Report H W/R (W)/R

b) Reinforcement Section 03205

Mat’l Test Cert./MRR

c) Latex Modified Concrete

ASTM C 109 M, ASTM C 1107,

d) Grout

ASTM C 157M

e) Aggregate Section 03310 Third Party Lab. Report

ASTM C 109 M, ASTM C 1107,

f) Patching Mortars

ASTM C 157M

g) Plugging Compound ASTM C 109M, ASTM C 191 Mat’l Test Cert./MRR

h) Bonding Agent

i) Coating for Reinforcing Steel BS 4652

j) Injection Compound

k) Concrete Crack Sealer

ORGANIZATION NAME/POSITION SIGNATURE DATE

WE CERTIFY THAT WORK HAS BEEN CONTRACTOR (POSCO E&C)

COMPLETED ACCORDING TO THE

PMC (JACOBS)

REQUIREMENTS OF INSPECTION TEST PLAN.

CONTRACT No.: 7200018704 CLIENT (MARAFIQ)

REHABILITATION AND EXPANSION OF SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Date of Issue: 25Oct. 2014

Rev. No.: 2

Site Inspection and Test Plan for Concreting Work Page: 5 of 12

l) Joint Sealant

m) Back Material & Preformed Joint Fillers

n) Form Materials, Curing Compounds & Other

Section 03105,03310

Material

o) Concrete Surface Protection Material

3.2 Concrete Repairing Works

a) Surface Preparation Section 03930

b) Concrete Repairing

c)Surface Cleaning Section 03930 Part 3 3.03

d)Site Investigation and Location Defects Section 03930 Part 3 3.04

e)Removal and Repairing of Unsound Concrete Section 03930 Part 3 3.06

ITP-CE-F011 H W W

f)Treatment of Exposed Reinforcing Bars Section 03930 Part 3 3.07

g)Surface Preparation of Existing Concrete Section 03930 Part 3 3.08

h)Usage and Placement of Repair Material Section 03930 Part 3 3.09

i)Repair of Cracks Section 03930 Part 3 3.11

j)Concrete Surface Protection System Section 03930 Part 3 3.12

k)Concrete Protective Coating Section 03930 Part 3 3.09

I : Inspection R : Review (W) : Random Witness W : Witness H : Hold

ORGANIZATION NAME/POSITION SIGNATURE DATE

WE CERTIFY THAT WORK HAS BEEN CONTRACTOR (POSCO E&C)

COMPLETED ACCORDING TO THE

PMC (JACOBS)

REQUIREMENTS OF INSPECTION TEST PLAN.

CONTRACT No.: 7200018704 CLIENT (MARAFIQ)

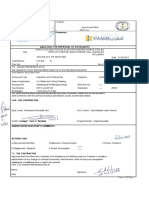

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:6 of 12

PRE-CONCRETING CHECK LIST PAGE 1 OF 1

Project Name: Rehabilitation & Expansion of SWTP-Yanbu Contract No.: 720018705

Ref. No.:

Work Area/Location:

Sub-con Name:

Co-Signature by :

(Before RFI to QC)

Construction of :

Civil Mechanical Electrical

Inspection Result

No. Description SUB-CON. QA/QC POSCO QA/QC

Accepted Rejected Accepted Rejected

Construction/Expansion Joint

a) Dowel Bar

1 b) Join Filler

c) Chamfer

d) Water Stop

Form Work

a) Position

b) Dimension

- Horizontal

- Vertical

2 c) Elevation

d) Adequate Bracing

e) Sealing Gaps

f) Applying Oil Coating

g) Chamfer

g) Survey Report

3 Cleaning Condition

REMARKS:

Inspected by: Witnessed by: Reviewed/Verified by:

SUBCONTRACTOR QA/QC POSCO QA/QC JACOBS/MARAFIQ

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:7 of 12

NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE:

DATE: DATE: DATE:

Form No.: ITP-CE-F007(Rev.2)

Steel Reinforcement Embedded Items/ PAGE 1 OF 1

Electrical & Mechanical Inserts Checklist

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:8 of 12

Project Name: Rehabilitation & Expansion of SWTP-Yanbu Contract No.: 720018705

Ref. No.:

Work Area/Location:

Sub-con Name:

Co-Signature by :

(Before RFI to QC)

Construction of :

Civil Mechanical Electrical

Inspection Result

No. Description SUB-CON. QA/QC POSCO QA/QC

Accepted Rejected Accepted Rejected

Re-bar Work

a) Size Number

b) Length of Lapping

1CIVIL

c) Bending Position/Type(as per IFC Bar Bending Schedule)

d) Removing of Laitance

e) Over-all Cleaning at Base

Embedded Item

Mechanical

a) Anchor Bolts, Plates: Size, Length

b) Pipes : Length, Diameter

c) Sleeves & Openings : Position

2 d)Location

a) Conduit Pipes: Size & Length

Electrical

b) Sleeve & Opening Sizes

c) Location

d) Spacing

Remarks:

Inspected by: Witnessed by: Reviewed /Verified by:

SUB-CONTRACTOR QA/QC POSCO QA/QC JACOBS/MARAFIQ

NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE:

DATE: DATE: DATE:

Form No.: ITP-CE-F008(Rev.2)

Pouring Report PAGE 1 OF 4

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:9 of 12

Project Name: Rehabilitation & Expansion of SWTP-Yanbu Contract No.: 720018705

Ref. No.:

Work Area/Location

Sub-con Name:

Concrete Supplier: Pouring Date:

Concrete Class: Weather Condition:

Time

Delivery Volume Off site On Site Concrete Cylinder

Truck Concrete

S. No Ticket Concrete Departure Slump Sample Remarks

Number Temp. oC

Number (cu. m) at Batch Arrival Departure (mm) No.

Plant

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Third Party Laboratory :

Technician

Checked by: Noted by:

QA/QC Inspector QA/QC Manager

Form No.: ITP-CE-F009(Rev.2)

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:10 of 12

PROTECTIVE COATING AND LINING CHECK LIST PAGE 1 OF 1

Project Name: Rehabilitation & Expansion of SWTP-Yanbu Contract No.: 720018705

Ref. No.:

Work Area/Location: Date:

Sub-con Name:

Inspection Result

No. Description SUB-CON. QA/QC POSCO QA/QC

Accepted Rejected Accepted Rejected

1. Surface Preparation

2. Primer Application (Prior of Waterproofing Membrane/Lining/Painting)

3. Waterproofing Membrane Installation/Application

4. Liquid Waterproofing

5. Protection Board Installation

REMARKS:

Inspected by: Witnessed by: Reviewed/Verified

SUBCONTRACTOR QA/QC POSCO QA/QC JACOBS/MARAFIQ

NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE:

DATE: DATE: DATE:

Form No.: ITP-CE-F010 (Rev.2)

REHABILITATION AND EXPANSION OF

SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Date of Issue: 25 Oct. 2014

Rev. No.: 2 Concreting Work Page:11 of 12

CONCRETE REPAIR CHECK LIST PAGE 1 OF 1

Project Name: Rehabilitation & Expansion of SWTP-Yanbu Contract No.: 720018705

Ref. No.: 5697

Work Area/Location: BESB-floor Date:

Sub-con Name:

Inspection Result

SUB-CON. QA/QC POSCO QA/QC

No. Description

Accepted Rejected Accepted Rejected

1. Surface Preparation Prior to Repair

2. Treatment of Re-bar Corrosion (if required)

3 Repair Condition

4 Final Surface

5. Cleaning Condition

Remarks:

Inspected by: Witnessed by: Reviewed/Verified by;

SUBCONTRACTOR QA/QC POSCO QA/QC JACOBS/MARAFIQ

NAME: NAME: NAME:

SIGNATURE: SIGNATURE: SIGNATURE:

DATE: DATE: DATE:

Form No.: ITP-CE-F011(Rev.2)

REHABILITATION AND EXPANSION OF SWTP-YANBU

Doc. No.: 03-A20-CE-ITP-002 Site Inspection and Test Plan for Concreting Date of Issue: 25 Oct. 2014

Rev. No.: 2 Work Page: 12 of 12

REHABILITATION AND EXPANSION OF SWTP-YANBU

CLEARANCE REPORT PRIOR TO CONCRETE PLACEMENT

DATE: LOCATION:

DESCRIPTION:

RFI NO :

DISCIPLINE CHECKLIST RFI ISSUED POSCO E&C

Anchor Bolts, RFI No: CONSTRUCTION JACOBS/MARAFIQ REMARKS

QA/QC

Plates, Pipe

Mechanical: Sleeves, Mech. App

Openings, Size, AWC

Length REJ

RFI No:

Conduit Pipes,

APP:

Electrical /C &I : Sleeves, Openings,

AWC:

Size, Length

REJ :

Related Site Change Documents Verified : Y N

If Yes provide Site Change Document/Sketch No:

POSCO CONSTRUCTION MANAGER POSCO QC INSPECTOR POSCO QA/QC MANAGER

Name: Name: Name:

Sign: Sign: Sign:

Date: Date: Date:

Form No.: ITP-CE-F012(Rev.2)

You might also like

- Construction AuditDocument5 pagesConstruction AuditMohammed Mujahid100% (1)

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- J910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)Document13 pagesJ910-DH02-P10ZEN-040004 Field ITP For Shotcrete Work For Ash Handling Facilities - Rev. 0 (AFC)rudi sarifudinNo ratings yet

- French Cleat Tool WallDocument6 pagesFrench Cleat Tool WallKeith WilliamsNo ratings yet

- Site Inspection and Test Plan For Architectural Work Rev-1Document23 pagesSite Inspection and Test Plan For Architectural Work Rev-1Mohammed Mujahid100% (1)

- ITP For ASPHALT CONCRETE PAVINGDocument4 pagesITP For ASPHALT CONCRETE PAVINGMohammed Mujahid100% (1)

- Apple Watch Series 7Document1 pageApple Watch Series 7Mohammed MujahidNo ratings yet

- Advanced Building Construction Technology Rqs2s1g2 PPT SlideDocument90 pagesAdvanced Building Construction Technology Rqs2s1g2 PPT Slideyh50% (2)

- Inspection Checklist Earthworks: (Project Number) (Client Name) (Date) (Client Representative Name) (Contractor Name)Document1 pageInspection Checklist Earthworks: (Project Number) (Client Name) (Date) (Client Representative Name) (Contractor Name)Lazar Andonov100% (1)

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Document4 pagesWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIAN100% (1)

- MS For Blockwork - 01Document33 pagesMS For Blockwork - 01scarlett3232100% (2)

- Pour CardDocument1 pagePour CardJohn DoeNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- Curing Compound ApplicationDocument3 pagesCuring Compound Applicationmoytabura96No ratings yet

- QP Painting JSADocument6 pagesQP Painting JSAMohammed Mujahid100% (2)

- Guide To Designing For Mine SubsidenceDocument4 pagesGuide To Designing For Mine SubsidenceScooby DooNo ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Check List For Backfilling WorksDocument2 pagesCheck List For Backfilling WorksYash SharmaNo ratings yet

- ITP-CONCRETE Blinding WorkDocument2 pagesITP-CONCRETE Blinding WorkYash Sharma100% (1)

- 045 ITP For MASONRY PLASTERING WORKS Buildings PDFDocument10 pages045 ITP For MASONRY PLASTERING WORKS Buildings PDFBenjamin ChavezNo ratings yet

- 3 Checklist For Structural Work (Post-Pour)Document2 pages3 Checklist For Structural Work (Post-Pour)alfieNo ratings yet

- ITP - Plaster WorkDocument1 pageITP - Plaster Workmahmoud ghanemNo ratings yet

- SPEC BrickworkDocument4 pagesSPEC BrickworkyantieschumiNo ratings yet

- Checklist For External Painting R1Document1 pageChecklist For External Painting R1hkshyla89No ratings yet

- Inspection and Test PlanDocument6 pagesInspection and Test PlanMadison ChanNo ratings yet

- 4.method Statement Blinding and Concrete WorksDocument5 pages4.method Statement Blinding and Concrete Worksشاز إياسNo ratings yet

- During Concreting Check ListDocument1 pageDuring Concreting Check ListFaiz RahmatNo ratings yet

- Itp For Installation of FormworksDocument1 pageItp For Installation of FormworksImho TepNo ratings yet

- Approval of - Concurewb309-As Concrete Curing CompoundDocument4 pagesApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqNo ratings yet

- MS 1 Concrete Quality ControlDocument30 pagesMS 1 Concrete Quality ControlMarwa FaroukNo ratings yet

- Checklist For Window M.S GrillDocument2 pagesChecklist For Window M.S GrillAh RashedNo ratings yet

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDocument19 pagesIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinNo ratings yet

- Inspection and Test Plan - Wooden Wall Panel InstallationDocument2 pagesInspection and Test Plan - Wooden Wall Panel Installationexia1992No ratings yet

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimNo ratings yet

- FM-16 Material Verification RecordDocument1 pageFM-16 Material Verification RecordBleep NewsNo ratings yet

- SECTION 09220 Portland Cement Plaster Rev 0Document30 pagesSECTION 09220 Portland Cement Plaster Rev 0sk mukhtarNo ratings yet

- QES PEVC-ENG237 - Checklist For PSS Fencing DetailsDocument2 pagesQES PEVC-ENG237 - Checklist For PSS Fencing DetailsRupesh Khandekar100% (1)

- Concrete Post Pour Check ListDocument1 pageConcrete Post Pour Check ListKamal FitriNo ratings yet

- Paver Blocks FixingDocument1 pagePaver Blocks FixingBharathraj RajNo ratings yet

- CL-QA-07D Retaining Wall, RCC Wall & Others ReinforcementDocument1 pageCL-QA-07D Retaining Wall, RCC Wall & Others Reinforcementthangamani gNo ratings yet

- ITP - IrrigationDocument5 pagesITP - IrrigationashwinNo ratings yet

- Method Statement & Itp For Waterproofing WorkDocument7 pagesMethod Statement & Itp For Waterproofing WorkRumi ZamNo ratings yet

- Table A - Cement Content and W/C Ratio For ConcreteDocument1 pageTable A - Cement Content and W/C Ratio For ConcreteIbrahim NaguibNo ratings yet

- False Celling Check ListDocument2 pagesFalse Celling Check Listjohn paul100% (1)

- FPM 221 Checklist Earth WorkDocument2 pagesFPM 221 Checklist Earth WorkPrabaharan K100% (1)

- Checklist For External PlasterDocument3 pagesChecklist For External PlasterSantosh YadavNo ratings yet

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNo ratings yet

- Surface Preparation: Afras Inspection Chek List - Sar ProjectDocument2 pagesSurface Preparation: Afras Inspection Chek List - Sar ProjecteslamNo ratings yet

- 02-Pre-Concreting Inspection RequestDocument2 pages02-Pre-Concreting Inspection RequestJohn Oliver GuiangNo ratings yet

- ITP For Blinding Concrete WorksDocument3 pagesITP For Blinding Concrete WorksMohammed Ghareib NasrNo ratings yet

- Method Statement For Aac BlockworkDocument10 pagesMethod Statement For Aac BlockworkobieNo ratings yet

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- 1 MS - Pouring of ConcreteDocument8 pages1 MS - Pouring of ConcreteFauzi MastamNo ratings yet

- 017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFDocument9 pages017-W009-2667 - ITP - Precast & Prestressed Concrete - Revc0 PDFMohammad Hadoumi Saldan100% (1)

- ملف ممتاز عن الرشاشاتDocument13 pagesملف ممتاز عن الرشاشاتakram husseinNo ratings yet

- Installation of LV Cables: Inspection and Test Plan ForDocument1 pageInstallation of LV Cables: Inspection and Test Plan ForHussainShabbirNo ratings yet

- Field Tests of Common Building MaterialsDocument4 pagesField Tests of Common Building Materialsjkligvk. jukjNo ratings yet

- Inspection & Test Plan (Itp) : Road WorkDocument1 pageInspection & Test Plan (Itp) : Road WorkLOPA THANDARNo ratings yet

- Block Masonary Work: Method StatementDocument5 pagesBlock Masonary Work: Method StatementAneel KumarNo ratings yet

- Inspection Checklist: Concrete Screed PlacementDocument2 pagesInspection Checklist: Concrete Screed PlacementZiaul HaqNo ratings yet

- Electrical Inspections ChecklistDocument6 pagesElectrical Inspections Checklistasyraf azaharyNo ratings yet

- Masonry: Name of Contractor: Ref. Drwg. No.Document2 pagesMasonry: Name of Contractor: Ref. Drwg. No.yash shah100% (1)

- Method Statement For Granite FrameDocument7 pagesMethod Statement For Granite FrameMonali Varpe100% (1)

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호No ratings yet

- C8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksDocument2 pagesC8516-CLT-QMT-0003 Rev.00Inspection Checklist For Concreting WorksJabinNo ratings yet

- Non Conformance Report: Refer Attached PhotographsDocument8 pagesNon Conformance Report: Refer Attached PhotographsJitender Tanwar100% (1)

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Document10 pagesFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- ASP-CSP 14 Noise Study Solutions Rev009Document4 pagesASP-CSP 14 Noise Study Solutions Rev009Mohammed MujahidNo ratings yet

- Mujahid CVDocument8 pagesMujahid CVMohammed MujahidNo ratings yet

- ون مليون ONE MILLION - FLOWER FACTORYDocument1 pageون مليون ONE MILLION - FLOWER FACTORYMohammed MujahidNo ratings yet

- M6UMTYDocument3 pagesM6UMTYMohammed MujahidNo ratings yet

- ITP For Structural Work-1Document5 pagesITP For Structural Work-1Mohammed Mujahid0% (1)

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Document10 pagesFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- Span Vol2 2015 Part1Document150 pagesSpan Vol2 2015 Part1Mohammed MujahidNo ratings yet

- International Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFDocument2 pagesInternational Health and Safety at Work The Handbook For The NEBOSH International General Certificate 2nd Edition Paperback Routledge PDFMohammed Mujahid0% (1)

- Guide To Inspecting and Maintaining CranesDocument8 pagesGuide To Inspecting and Maintaining CranesMohammed MujahidNo ratings yet

- Cooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiDocument2 pagesCooking Time: 15-20 Minutes Servings: 4: Sprouted Moong KhichdiMohammed MujahidNo ratings yet

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- QP Cutting JSADocument6 pagesQP Cutting JSAMohammed MujahidNo ratings yet

- History With DetailsDocument10 pagesHistory With DetailsSuha FathimaNo ratings yet

- Aavarna 2Document13 pagesAavarna 2SNEHA DEVARAJU100% (1)

- Chapter 5 Post-Tensioned SlabDocument19 pagesChapter 5 Post-Tensioned SlabSharan BvpNo ratings yet

- 700 BMC QuestionDocument72 pages700 BMC QuestionrpsirNo ratings yet

- Wa0000Document35 pagesWa0000gauthami pjNo ratings yet

- BS5628-3 2005 PDFDocument136 pagesBS5628-3 2005 PDFJoãoNo ratings yet

- Wallscanner D Tect 150 Professional - Manual PDFDocument351 pagesWallscanner D Tect 150 Professional - Manual PDFVladimír KřížNo ratings yet

- Seminar ReportDocument34 pagesSeminar ReportShreyas M CNo ratings yet

- British Residency 2Document16 pagesBritish Residency 2Syeda Sameeha MaryamNo ratings yet

- 155 BRCDocument2 pages155 BRCRaajeev Neela75% (4)

- Dep-34.17.10.33-Portable Blast-Resistant ModulesDocument36 pagesDep-34.17.10.33-Portable Blast-Resistant ModulesStephen MalobaNo ratings yet

- Part B 1000 Bedded HostelDocument128 pagesPart B 1000 Bedded Hosteldhirajagarwal1989No ratings yet

- Obstructions in SprinklerDocument28 pagesObstructions in SprinklerMd Rafat ArefinNo ratings yet

- Piping Spec: CS150 TFS 1021: Engineering StandardDocument4 pagesPiping Spec: CS150 TFS 1021: Engineering Standardbmanojkumar16No ratings yet

- General Specifications: Scope of WorkDocument10 pagesGeneral Specifications: Scope of WorkChy GomezNo ratings yet

- Rate Analysis Excel MetricDocument7 pagesRate Analysis Excel MetricAltaf NiaziNo ratings yet

- Building Design and Erection Using Prefabricated Concrete Code of PracticeDocument56 pagesBuilding Design and Erection Using Prefabricated Concrete Code of Practicemadhukannan.mohanNo ratings yet

- 58 Deadly TrapsDocument9 pages58 Deadly Trapsthe_doom_dudeNo ratings yet

- Single Storey Extension SMMDocument13 pagesSingle Storey Extension SMMFlokrida SherifiNo ratings yet

- MASONRY HandoutDocument20 pagesMASONRY HandoutJoshua Andrei A. DelacruzNo ratings yet

- Real Life Projects Report Onyango Alfred Ndijo. 21.1.224.D.510Document6 pagesReal Life Projects Report Onyango Alfred Ndijo. 21.1.224.D.510Bweks LeBron MVPNo ratings yet

- O'Skea - Dramatics Magazine - Painting The SceneDocument7 pagesO'Skea - Dramatics Magazine - Painting The SceneMerabo SimonishviliNo ratings yet

- DR Horton Homeowners ManualDocument80 pagesDR Horton Homeowners ManualLynn RaisesNo ratings yet

- PPC Ebrochure Bricks & Blocks 2011 1Document2 pagesPPC Ebrochure Bricks & Blocks 2011 1Ryan MalyonNo ratings yet

- Construction MaterialsDocument20 pagesConstruction MaterialsmariyaNo ratings yet

- Hotel Public Area GuidelinesDocument10 pagesHotel Public Area GuidelinesamyraeuhjNo ratings yet

- Lafarge Ceilings Solutions BrochureDocument48 pagesLafarge Ceilings Solutions BrochurericNo ratings yet