Professional Documents

Culture Documents

Pto - Threading Machine Rev 2

Pto - Threading Machine Rev 2

Uploaded by

grantOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pto - Threading Machine Rev 2

Pto - Threading Machine Rev 2

Uploaded by

grantCopyright:

Available Formats

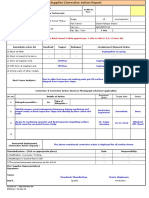

Document: PTO –

Threading machine

PLANED TASK OBSERVATION Rev 2

Next Revision date:

THREADING MACHINE 29/7/16

Date Issued 20/7/15

Date Department

Work Area Section

Employee Being Observed

How often is Task performed Company Name

Machine/Equipment No being used Observers Name

Task being observed ID Number/ Coy No

Reason for observation Change Management Legal Compliance

New Worker Unplanned Task

New Task Ergonomic Factor

Known Risk Taker Incident Repeater

Poor Performer Good Performer

New/Unfamiliar Equipment Complicated Task

1. Task Steps being observed

Was an continues risk assessment/DSTI conducted by all team members and signed by them?

Is the mini risk assessment/DSTI relevant to the current activities performed?

Pre use check carried out by whom? Name and signed off by relevant Supervisor

Is the operator competent to work with the machine?

Does the operator have an assistant to assist whilst performing task?

Is there good communication between the operator and his team members?

If the length of the pipe exceeds 3 meters are trestles being used for support?

Is the machine placed in a sufficient work space?

Prior to inserting the pipe, does the operator engage the E Stop and depress foot switch to ensure that the machine is not

operational?

Is the chuck opened completely when the pipe is inserted into or removed from the machine?

Is the electrical extension completely un routed and out of the walk ways?

How does the operator treat/prevent any spillage from the cutting fluid?

Page 1 of 3 Printed: 22 October 2022

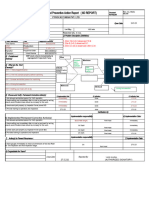

Document: PTO –

Threading machine

PLANED TASK OBSERVATION Rev 2

Next Revision date:

THREADING MACHINE 29/7/16

Date Issued 20/7/15

Can the operator hurt someone else while performing the task?

Can any member of the team slip, trip or fall over anything whilst performing the task?

Is the operator’s position correct to eliminate reaching over the machine to reach controls?

What PPE is the operator wearing whilst performing the task and is it to standard?

Does the operator ensure that his assistants (s) are complying with the PPE Requirements?

Does the operator allow the machine to come to a complete stop before handling the pipe or machine parts?

When leaving the machine un attendant what does the operator do?

After completion of the task, are all steel shavings and cut offs removed from the area.

5. Suggested Improvements (TO BE COMPLETED BY THE SUPERVISOR )

Revise SOP? Yes Use different PPE? Yes Engineering change Yes Re-Train Yes Placement of Yes

required? employee? employee?

No No No No No

Employee Task Observation

Employee Name: ______________________________________ I.D. No.: ______________

Job Title: _________

Date Assigned to Job: __

Operating Procedures Checked

Number Title Date Reviewed

SOP

RA

Page 2 of 3 Printed: 22 October 2022

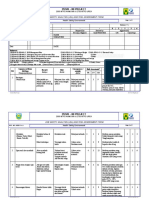

Document: PTO –

Threading machine

PLANED TASK OBSERVATION Rev 2

Next Revision date:

THREADING MACHINE 29/7/16

Date Issued 20/7/15

6. Feedback by observer to employee

1. TASK STEPS

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

2. PPE

DEVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

3. EQUIPMENT CONDITION

DIVIATION CORRECTION/COACHING EMPLOYEE SIGNATURE

7. Acknowledgement and agreement on feedback received

Observation conducted by: Signature Date

Reviewed with Employee: Signature Date

Reviewed by Site Manager: Signature Date

Page 3 of 3 Printed: 22 October 2022

You might also like

- The Psychology of Ethical Leadership in Organisations Implications of Group Processes 1St Ed Edition Catarina Morais Ebook Full ChapterDocument52 pagesThe Psychology of Ethical Leadership in Organisations Implications of Group Processes 1St Ed Edition Catarina Morais Ebook Full Chapterharold.young447100% (20)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Stoichiometry Worksheet6-1Document6 pagesStoichiometry Worksheet6-1Von AmoresNo ratings yet

- Disciplinary ProcedureDocument11 pagesDisciplinary ProcedureSURESH NAIRNo ratings yet

- Husserl, Edmund - The Idea of PhenomenologyDocument75 pagesHusserl, Edmund - The Idea of PhenomenologyFelipeMgr100% (7)

- Sintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFDocument143 pagesSintef A17034 Organisational Accidents and Resilience Organisations Six Perspectives. Revision 2 PDFAparupa KarNo ratings yet

- SheetingDocument2 pagesSheetinggrantNo ratings yet

- SupervisorDocument2 pagesSupervisorgrantNo ratings yet

- Plastering Rev 2Document2 pagesPlastering Rev 2grantNo ratings yet

- PTO - Plumbing Rev 2Document2 pagesPTO - Plumbing Rev 2grantNo ratings yet

- PTO - Shuttering and de Shuttering Rev 2Document2 pagesPTO - Shuttering and de Shuttering Rev 2grantNo ratings yet

- PTO Manual Handling Rev 2Document2 pagesPTO Manual Handling Rev 2grantNo ratings yet

- PTO TilingDocument2 pagesPTO TilinggrantNo ratings yet

- PTO - Cutting and Grinding Rev 2Document3 pagesPTO - Cutting and Grinding Rev 2grantNo ratings yet

- Operating Jig SawDocument2 pagesOperating Jig SawgrantNo ratings yet

- Operate A Hand Drill Rev 2Document3 pagesOperate A Hand Drill Rev 2grantNo ratings yet

- PTO - BrickworkDocument2 pagesPTO - BrickworkgrantNo ratings yet

- Operating Skill SawDocument2 pagesOperating Skill SawgrantNo ratings yet

- PTO - Pre Mix Concrete TruckDocument2 pagesPTO - Pre Mix Concrete TruckgrantNo ratings yet

- Operate A Pencil Grinder Rev 2Document3 pagesOperate A Pencil Grinder Rev 2grantNo ratings yet

- PTO - Pouring of Concrete Rev 2Document2 pagesPTO - Pouring of Concrete Rev 2grantNo ratings yet

- PTO - Use of Hand ToolsDocument2 pagesPTO - Use of Hand ToolsgrantNo ratings yet

- Operate An Impact Wrench Rev 2Document3 pagesOperate An Impact Wrench Rev 2grantNo ratings yet

- Gas Cutting Rev 2Document3 pagesGas Cutting Rev 2grantNo ratings yet

- PTO - SteelfixingDocument2 pagesPTO - SteelfixinggrantNo ratings yet

- Operate A Magnetic Base Drill Rev 2Document3 pagesOperate A Magnetic Base Drill Rev 2grantNo ratings yet

- Cm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)Document3 pagesCm-Mech - (49 To 50) - Send To MGPS at (13-08-2020)ali morisyNo ratings yet

- Cm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)Document1 pageCm-Hvac - (03 To 03) - Send To MGPS at (27-07-2020)ali morisyNo ratings yet

- PTO PaintingDocument2 pagesPTO Paintinggrant100% (1)

- Cm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)Document1 pageCm-Inst - (25 To 25) - Send To MGPS at ( 03-08-2020)ali morisyNo ratings yet

- Waiko International Sdn. BHD.: Daily Site ReportDocument1 pageWaiko International Sdn. BHD.: Daily Site ReportnidduzziNo ratings yet

- 03-Contoh JSA-OKEDocument2 pages03-Contoh JSA-OKEMaster AssassiNNo ratings yet

- Cm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)Document1 pageCm-Elec - (47 To 47) - Send To MGPS at (03-08-2020)ali morisyNo ratings yet

- Cm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)Document1 pageCm-Elec - (50 To 50) - Send To MGPS at (10-08-2020)ali morisyNo ratings yet

- Cm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)Document1 pageCm-Mech - (42 To 42) - Send To MGPS at ( 21-07-2020)ali morisyNo ratings yet

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Cm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)Document1 pageCm-Elec - (51 To 51) - Send To MGPS at (12-08-2020)ali morisyNo ratings yet

- Cm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)Document3 pagesCm-Elec - (53 To 55) - Send To MGPS at (23-08-2020)ali morisyNo ratings yet

- Cm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)Document2 pagesCm-Mech - (73 To 74) - Send To MGPS at (03-11-2020)ali morisyNo ratings yet

- WMS.14 - JIT.CAP - Install tubing Rev.1_NADocument23 pagesWMS.14 - JIT.CAP - Install tubing Rev.1_NAOny CiboNo ratings yet

- Indra: Vendor's Name Company's NameDocument14 pagesIndra: Vendor's Name Company's NameHuy Thieu BuiNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Cm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)Document2 pagesCm-Mech - (42 To 43) - Send To MGPS at ( 27-07-2020)ali morisyNo ratings yet

- SWMS Bored PilingDocument17 pagesSWMS Bored PilingnaraNo ratings yet

- JSA Box UpDocument7 pagesJSA Box Upimam dianiNo ratings yet

- Form Izin Kerja - LiftingDocument3 pagesForm Izin Kerja - Liftingsafetyofficer752No ratings yet

- Grout Release FormDocument2 pagesGrout Release FormThulani MasheleNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- CM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) ReprintDocument2 pagesCM-ELEC - (61 and 73) - SEND TO MGPS AT (04-11-2020) Reprintali morisyNo ratings yet

- JSA SC Area KariangauDocument20 pagesJSA SC Area KariangauSiti AminahNo ratings yet

- FORM-HSE-001-028 Checklist Forklift - Id.enDocument6 pagesFORM-HSE-001-028 Checklist Forklift - Id.enroni jasonNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- JSA-Tie-In WeldingDocument7 pagesJSA-Tie-In WeldingR Sahadeo ReddyNo ratings yet

- BINDERDocument17 pagesBINDERprakashNo ratings yet

- Permit To Work ProcedureDocument18 pagesPermit To Work ProcedureRaghavendra Kiran100% (1)

- Permit Lifting Kota MinyakDocument3 pagesPermit Lifting Kota MinyakYogi OktabertoNo ratings yet

- SWMS For Hoarding GateDocument9 pagesSWMS For Hoarding GateSam LimNo ratings yet

- 6163 3M PPP005B Mech StopDocument4 pages6163 3M PPP005B Mech StopEdward MenaNo ratings yet

- Standard Work Combination Sheet: Part Number: Part Name: Operationtime (Inseconds)Document8 pagesStandard Work Combination Sheet: Part Number: Part Name: Operationtime (Inseconds)Bhupinder Singh MakanNo ratings yet

- Outside Work Request (OWS)Document8 pagesOutside Work Request (OWS)Edo FedricoNo ratings yet

- 6163 3M Eva180e MTR Elec StopDocument4 pages6163 3M Eva180e MTR Elec StopEdward MenaNo ratings yet

- IMS-SOP-001-VER 02 - PPM of Electrical Panel (Upto 415V)Document16 pagesIMS-SOP-001-VER 02 - PPM of Electrical Panel (Upto 415V)Dinesh ThalaNo ratings yet

- 6163 3M Eva180f MTR Elec StopDocument4 pages6163 3M Eva180f MTR Elec StopEdward MenaNo ratings yet

- Anant Corr. MOM 7-08-18Document4 pagesAnant Corr. MOM 7-08-18Abhimanyu Singh ChundawatNo ratings yet

- 217 Confined Space LaminatingDocument11 pages217 Confined Space LaminatinggrantNo ratings yet

- ISO Training List - ConstructionDocument2 pagesISO Training List - ConstructiongrantNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)grantNo ratings yet

- 218 Site EstablishmentDocument14 pages218 Site EstablishmentgrantNo ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- BSA - Safe Working at Height On SteelworkDocument95 pagesBSA - Safe Working at Height On SteelworkgrantNo ratings yet

- Prj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundDocument2 pagesPrj-She-Mst-001 Emergency Procedure For Returning Cradle Occupants To The GroundgrantNo ratings yet

- 216 Fire PreventionDocument12 pages216 Fire PreventiongrantNo ratings yet

- 1 Osha 2Document19 pages1 Osha 2grantNo ratings yet

- 1 PM Proj 06 - Major Design Change Report - Revised JHLDocument4 pages1 PM Proj 06 - Major Design Change Report - Revised JHLgrantNo ratings yet

- Handtool Safe UsageDocument42 pagesHandtool Safe UsagegrantNo ratings yet

- PM Site 07a - Revised JHLDocument1 pagePM Site 07a - Revised JHLgrantNo ratings yet

- Accident Investigation 3Document33 pagesAccident Investigation 3grantNo ratings yet

- PM Proj 01 Wi-Method Statement - Revised JHLDocument11 pagesPM Proj 01 Wi-Method Statement - Revised JHLgrantNo ratings yet

- PM Site 15b - Site Materials Control - REVISED JHLDocument2 pagesPM Site 15b - Site Materials Control - REVISED JHLgrantNo ratings yet

- PM Site 02a - Quality Man System - Proc Summary Page RevisedjhlDocument1 pagePM Site 02a - Quality Man System - Proc Summary Page RevisedjhlgrantNo ratings yet

- 6 PM PROJ 06 - Change of Scope FormDocument2 pages6 PM PROJ 06 - Change of Scope FormgrantNo ratings yet

- PM Site 02b - Revised JHL #Document1 pagePM Site 02b - Revised JHL #grantNo ratings yet

- 2 PM PROJ 06 - Major Design Change Register - REVISED JHLDocument2 pages2 PM PROJ 06 - Major Design Change Register - REVISED JHLgrantNo ratings yet

- PM PROJ 01-Project Execution Procedure - REVISED JHL XXDocument1 pagePM PROJ 01-Project Execution Procedure - REVISED JHL XXgrantNo ratings yet

- Section 6 - Index - Revised JHLDocument1 pageSection 6 - Index - Revised JHLgrantNo ratings yet

- Section 9 - Check Out - Test & Acceptance Certificates - REVISED JHLDocument3 pagesSection 9 - Check Out - Test & Acceptance Certificates - REVISED JHLgrantNo ratings yet

- Section 7 - Index - Revised JHLDocument1 pageSection 7 - Index - Revised JHLgrantNo ratings yet

- Section 4 - Index - Revised JHLDocument1 pageSection 4 - Index - Revised JHLgrantNo ratings yet

- Section 2 - Execution Plan - REVISED JHLDocument1 pageSection 2 - Execution Plan - REVISED JHLgrantNo ratings yet

- Section 1 Index - Revised JHLDocument1 pageSection 1 Index - Revised JHLgrantNo ratings yet

- Sectiion 8 - Index - Quality Forms - Revised JHLDocument1 pageSectiion 8 - Index - Quality Forms - Revised JHLgrantNo ratings yet

- Section 2 - Index - Revised JHLDocument1 pageSection 2 - Index - Revised JHLgrantNo ratings yet

- 1.conveyors Risk AssessmentDocument19 pages1.conveyors Risk AssessmentgrantNo ratings yet

- 4.RAMS Machine Installations 2023Document14 pages4.RAMS Machine Installations 2023grantNo ratings yet

- Cantilever Slab (Unlocked)Document3 pagesCantilever Slab (Unlocked)WRay TanNo ratings yet

- Rollarc 400Document48 pagesRollarc 400m khNo ratings yet

- Physics Lab Heat and HumidityDocument3 pagesPhysics Lab Heat and HumidityLAUREN YAPNo ratings yet

- ContractionsDocument2 pagesContractionsAlexander Vargas TorresNo ratings yet

- Planificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-ADocument6 pagesPlanificare Calendaristică Anuală Pentru Limba Modernă 1 - Studiu Intensiv. Engleză. Clasa A Vi-Acatalina marinoiuNo ratings yet

- 1st Quarter ToolkitDocument6 pages1st Quarter ToolkitDimple BolotaoloNo ratings yet

- Sharp Edge OrificeDocument2 pagesSharp Edge Orificeleo.caguimbal6433No ratings yet

- MBB and DR PG Data2kDocument143 pagesMBB and DR PG Data2kYogesh PalNo ratings yet

- International Strategic Alliances 1Document21 pagesInternational Strategic Alliances 1mukesh93567No ratings yet

- 3126E Engine: Electrical Circuit DiagramDocument10 pages3126E Engine: Electrical Circuit DiagramPhil B.No ratings yet

- Heater: Hydrate PreventionDocument12 pagesHeater: Hydrate PreventionMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Exercise Oracle Forms 6i TrainingDocument5 pagesExercise Oracle Forms 6i TrainingFarooq Shahid100% (1)

- CBRDocument3 pagesCBRJunita PasaribuNo ratings yet

- Proces CostingDocument14 pagesProces CostingKenDedesNo ratings yet

- 134.4902.06 - DM4170 - DatasheetDocument7 pages134.4902.06 - DM4170 - DatasheetVinicius MollNo ratings yet

- Month + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)Document65 pagesMonth + Teaching Days Unit Total Teaching Periods: Vibgyor High Grade - 2 English Literature Year Plan (AY 2020 - 2021)TAPASsenguptaNo ratings yet

- rx330 Gasoline 106Document2 pagesrx330 Gasoline 106Андрей СилаевNo ratings yet

- UPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Document6 pagesUPS Technical Data Sheet (MS-DD-SAP01-ELE-DS-0015 - Rev2)Muhammad YusufNo ratings yet

- 4 Quarter Performance Task in Statistics and ProbabilityDocument5 pages4 Quarter Performance Task in Statistics and ProbabilitySHS Panaguiton Emma Marimel HUMSS12-ANo ratings yet

- Flood Precast - Super Wideslab Load Span TablesDocument1 pageFlood Precast - Super Wideslab Load Span TablesRaymond KinnairdNo ratings yet

- Detailed Lesson Plan in ICT ExcelDocument5 pagesDetailed Lesson Plan in ICT ExcelColleen Vender100% (3)

- Catálogo Bombas K3V y K5VDocument15 pagesCatálogo Bombas K3V y K5VRamón Rivera100% (2)

- Ieee 1205-2014Document77 pagesIeee 1205-2014master9137100% (1)

- All About DVIDocument4 pagesAll About DVIperex_cuteNo ratings yet

- 11th English BE Confident 5 Test Questions With Answer PDF DownloadDocument57 pages11th English BE Confident 5 Test Questions With Answer PDF Downloadbsai2749No ratings yet