Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

53 viewsPositive Material Identification Procedure

Positive Material Identification Procedure

Uploaded by

Koya ThangalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1-Vision Ability WQCDocument1 page1-Vision Ability WQCKoya ThangalNo ratings yet

- Active Doc ListDocument675 pagesActive Doc ListKoya ThangalNo ratings yet

- Aramco Tank Projects Study ReferenceDocument19 pagesAramco Tank Projects Study ReferenceKoya ThangalNo ratings yet

- Cswip 3.1 Practice QuestionDocument22 pagesCswip 3.1 Practice QuestionKoya ThangalNo ratings yet

- Saudi Aramco Interview QuestionsDocument4 pagesSaudi Aramco Interview QuestionsKoya ThangalNo ratings yet

- Cswip Qa 3 2Document8 pagesCswip Qa 3 2Koya ThangalNo ratings yet

- Stainless Steel Cast FittingsDocument7 pagesStainless Steel Cast FittingsKoya ThangalNo ratings yet

- Pressure Vessel Shop Fabrication & InspectionDocument80 pagesPressure Vessel Shop Fabrication & InspectionKoya Thangal100% (1)

- QA10-G-5058 G03 Project Execution Rev.0Document26 pagesQA10-G-5058 G03 Project Execution Rev.0Koya ThangalNo ratings yet

- Fitup Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument2 pagesFitup Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Valve Basic Interview Questions & AnswersDocument6 pagesValve Basic Interview Questions & AnswersKoya Thangal100% (1)

- Editable List of Industrial ReportDocument3 pagesEditable List of Industrial ReportKoya ThangalNo ratings yet

- Pickling Passivation ProcedureDocument5 pagesPickling Passivation ProcedureKoya Thangal100% (1)

- Procedure For FabricationDocument10 pagesProcedure For FabricationKoya ThangalNo ratings yet

- Project Weld Status Report - (Rev.01) : Saudi Aramco Test ReportDocument1 pageProject Weld Status Report - (Rev.01) : Saudi Aramco Test ReportKoya ThangalNo ratings yet

- Post Weld Visual Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument2 pagesPost Weld Visual Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Editable List of Procedure+Document5 pagesEditable List of Procedure+Koya ThangalNo ratings yet

- FAT - 59 Fixed Asset Transfer - Construction For WO# 2038-121Document1 pageFAT - 59 Fixed Asset Transfer - Construction For WO# 2038-121Koya ThangalNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Storage TANK - WELD MAPDocument2 pagesStorage TANK - WELD MAPKoya Thangal100% (1)

- Dimensional Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument1 pageDimensional Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Hydro Test Package For The Tank No.#: Khobar To Dammam / Jamiah Water Transmission SystemDocument2 pagesHydro Test Package For The Tank No.#: Khobar To Dammam / Jamiah Water Transmission SystemKoya ThangalNo ratings yet

Positive Material Identification Procedure

Positive Material Identification Procedure

Uploaded by

Koya Thangal100%(1)100% found this document useful (1 vote)

53 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

100%(1)100% found this document useful (1 vote)

53 views10 pagesPositive Material Identification Procedure

Positive Material Identification Procedure

Uploaded by

Koya ThangalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 10

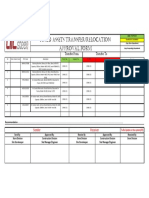

Transmittal No. Date

DOCUMENT TRANSMITTAL

TO: FROM:

Contract Name: Project Title:

Contract No. Location:

Saudi Aramco Approval Status Code:

*Approved *Correct & Resubmit *For information _—_*Other as Noted

*Approved with Comments “Not Approved * No Comments

*For Action

PSAL Reference N

Document No | Rev Subject Status | Qty | Remarks

02 | ALLOY VERIFICATION PROCEDURE (POSITIVE Approved 1

MATERIAL IDENTIFICATION) COOPERHEAT with

Comments

“Accepted w/ comments.”

Transmitted by: Received By: Received Dater

sna Name and Signature

Positive Material Identification Procedure

CONTENTS

DESCRIPTION PAGE

COVER SHEET 1

CONTENTS 2

4.0 AIM/SCOPE 3

20 DEFINITIONS 3

8.0 REFERENCES 3

40 SAFETY 3

6.0 PERSONNEL 4

60 EQUIPMENT 4

7.0 EQUIPMENT CALIBRATION AND VALIDATION 5

8.0 VERIFICATION COVERAGE 5

9.0 PREPARATION 6

10.0 PROCEDURE 7

11.0 EVALUATION 7

120 ACCEPTANCE CRITERIA 7

13.0 REJECTION PROCEDURE 8

14.0 MARKING 9

180 REPORTING 10

PMI REPORT FORMAT SAMPLE 10

I Identification Procedure

1.0 AIM/ SCOPE

20

44 This procedure establishes the minimum requirements for Kdentification of metaltic materials,

also referred to as Alloy Verification (Positive Material Identication - PMI).

4.2 The aim of the identification of material shall be to ensure that the nominal material

‘composition is as supplied and complies with purchase order and / or design requirements.

4.3. This procedure shall be used to perform Positive Material Identification (PMI) for SAUDI

ARAMCO FADHILI PROJECT in KSA.

4.4 Considering safety issues involved in placing the OES PM equipment at elevated locations,

the usage of the same wil be limited to ground level work or limited to those elevations

where it can be safely lifted and placed.

DEFINITIONS

a) Material Verification - Verifying the composition of metalic elements against known data.

b) Material Identification - investigating unknown or unidentified metallic materials,

©) Material Sorting - Comparing and soring material against a reference sample analysis for

which analyser is programmed.

d)_ AV- Alloy Verification

)_PMI- Positive material identification is the determination / verification whether the nominal

‘material composition is as specified.

f) _ OES- Opiical Emission Spectrometer

9) Client - with whom Cooperheat has a direct contractual agreement - NSH

hy

Company ~ Owner — Saudi Aramco

50

60

Positive Material Identification Procedure

+175-320300, Saudi Aramco Inspection & Testing Requirements form 176 for PMI, 2013,

Equipment Operations Manual

‘SAFETY

Only trained personnel shall use this equipment.

As this procedure Involves the use of an electrically operated / x-ay producing portable

equipments care should be exercised due to the possible hazards of using them in humid and

other adverse operating conditions. Safe operation and emergency requirement shall be carried

‘out in accordance with the respective equipment operations manual,

Direct viewing of the arc or x-ray should be avoided to protect the eyes from damaging ultraviolet

rays and x-ray radiation.

PERSONNEL

PMI technician shall have been trained to use the equipment in accordance with this procedure,

Personnel training shall include Radiation Safely (as per equipment manufacturer's instructions),

Instrument operation, instrument limitations, basic knowledge in metallurgy and standards related

to steel manufacture.

Only trained, qualtied and experienced personnel shall undertake the operation and intorpretation

of recorded results to ensure that both the procedure and the work are implemented correctly in

‘order to identify / very the nominal material compositions. Operator records meeting the minimum

requirements of training, qualification and experience shall be submitted for Company approval.

In case of specific request fram Saudi ARAMCO inspector, the PM technician shall demonstrate

his working knowledge to operate the PMI equipment on a representative sample of the aloy

‘material and PMI technicians training record shall be offered to review. The PMI technician shall

have knowledge about all aspects of PMl test mefhods and the operation of PMI test equipment

used on the job.

EQUIPMENT

6.1 OES - Optical Emission Spectrometer equipment shall be used when Carbon has to be

verified as per the inspection request from the client / owner.

‘XRF - X-Ray Fluorescence equipment shall be used when element lighter than Sulphur has

NOT to be verified as per the inspection request from the client / owner.

62 The following equipment or similar equipment shall be used, as may be available:

6.2.1 Optical Emission Spectrometer (OES)

a) Spectro Analytical ‘Spectroport’ Alloy Analyser works on the principle of Optical

Emission Spectrograph (OES).

b) —_Belec Optical Emission Spectrometer (OES) works on the principle of Spark Emission

Spectroscopy.

Note: OES equipment may be used to check for the required elements including

carbon, A hot work permit may be required before using this equipment. Any bum

damage resulting from the usage of emission spectrograph shall be removed by

grinding.

Positive Material Identification Procedure

6.2.2 X-Ray Fluoresoence (XRF)

a) Niton Corporation ‘XLt 800" Alloy Analyser works on the principle of X-Ray

Fluorescence (XRF).

b) Innov-X Systems ‘Alpha 2000' Alloy Analyser works on the principle of X-Ray

Fluorescence (XRF) or similar equipment.

Note: Because of inherent limitation of XRF, it is not possible to detect all elements.

Elements lighter than Sulphur cannot be detected using portable XRF equipment.

‘Therefore, this technique shall nat be used to deteat Carbon.

7.0 EQUIPMENT CALIBRATION AND VALIDATION

80

a

»)

°

‘The equipment shall be calibrated or veriied as specified in the equipment operation

manual. The equipment shall be calibrated orce in a year.

‘The equipment shall be set up with the standard samples in accordance with procedure

given by the manufacturer.

Verification of calibration shall be carried out on_a standard callbration sample,

representalive of the base metal / weld being tested. The calibration verification shall be

done at the beginning of each shift or whenever there is change in material to be tested.

VERIFICATION COVERAGE

8a

a2

83

a4

‘The PMI programme shall cover alloy materials and materials as per the project ITP and as,

given in the written PMI request by the Client and SAES-A-206. Client shall follow the NDT

Matrix and line class list for PMI.

PMI of weld material shall be performed in the same manner as for the adjacent base metal.

PMI testing of welds shall be done after remeval of slag and/or oxide from the weld surface.

In cases where PMI testing of the competed weld is not possible because of geometry (e.9..

‘small fillet welds and narrow root beads), PMI testing of filler metal lots and visual inspection

of electrodes may be acceptable.

‘The required number of PMI tests shall be in accordance with SAES-A-206 sec 7.4 and

Table-1.

@) One sample for each pipe spool component.

b) One sample for any component that makes up part of the pressure boundary.

©) Fornon-pressure components, ten (16) samples or 10% of total, whichever is greater,

from each heat or lot.

4) One sample for each pressure boundery weld and for all welds between non-pressure

paris and pressure parts,

2) When welding of alloy materials is conducted, one electrode or wire sample from each

{ot of filler metal shall be positively identified.

‘The elements of the basic alloy materials to be verified shall be in accordance with the Table

shown below;

8s

86

aT

Positive Material Identification Procedure

TABLE

Basic Alioy Elements to be verified

Carbon-Molyodenum, Manganese- | Chromium, Molybdenum and Vanadium

Molybdenum, and Chromium

Molybdenum-Vanadium steels

Regular Carbon grade Stainless Stesis | Chromium, Nickel and Molybdenum

Low and High Carbon Stainless Steels _| Chromium, Nickel, Molyodenum and Carbon

Stabiised Stainiess Steel Chromium, Nickel, Molybdenum, Tianium and

Nicbium

Nicker-based alloys ‘Nickel, iron, Copper, Chromium, Molybdenum,

‘Tungsten, Vanadium and Copper as applicable

Note: Nickel base alloys also include “Hastelloys",“Inoonels", “Alloy20", Monel etc,

For Copper alloys PMI verification is not required.

For alloys not covered in the Table, the Client shall obtain written instructions from the owner

(GA). Dissimilar Metal Weld PMI resulis from base and weld metals shall be submitted by

Client to the Materials Engineering Unit of ME&CCD/CSD foe evaluation and approval.

PMI Testing of Welding Consumables

PMItesting of welding consumables shall be cone as per Client's requirement as follows;

(As recommended in SAES- A- 206)

One consumable from each lot shall be PMi-tested. The remainder of

the lot shall be commared to the idextified consumable to verify that the

auarkings of the electrodes/twires are comect.

PMI testing of weld metal (¢.z,, deposited or undiluted weld "buttons") is

an acceptable alternative fo PMI testing of an electrode or wire sample

provided it is conducted immediately prior to welding or during the

welding process.

PMI Testing of Weld Overlay and Clad Materials (Ref. SAES-W-014)

‘The final weld overlay surface shall have the chemical composition checking prior to final

PWHT or Hydrolest. The chemistry may be tested using portable Xray fluorescence

equipment (XRF equipment) instead of Spectrograph equipment.

All elements specified for the deposit chemistry shall be analyzed and reported, except for

‘Catbon when Using the X-ray fluorescence method. The analysis method and acouraay limits

for each element shall be submitted to Owner inspector for review and approval

“The frequency of Chemical composition analysis shal be as follows:

‘@) Automatic Welding - One analysis for each overlay area or Clad joint. Separate

analysis shall be made for each heatbatch of Filler metal or Electrode.

b) Manual Welding — One analysis for each 1 meter square of area or one analysis at

interval of 2 meter or less for overlay restoration of clad joints.

Positive Material Identification Procedure

9.0 PREPARATION

100

‘The metalic surface to be tested shall be free from all extraneous materials such as scale, welding

fiux, slag, grease, rust, drt, etc, which may interfere with the testing.

If necessary, light filing shall be done to ensure good suriace contact of the electrode of the

Spectroport equipment.

Only stainless steel brasses, ceramic (glass) beads, iron-free grit or stainless steo! grit shall be

used to mechanically clean the overlay surfaces.

PROCEDURE

10.4

10.2

Optical Emission Spectrometer (OES)

‘The Spectroport Equipment shall be set, veriled and operated in accordance with the

‘manufacturer's instructions.

a) The Spectroport equipment shall be connected to power source after ensuring

‘compatible voltage. The electrode shall be checked for cleanliness and having sharp

tip, otherwise the electrode shall be property cleaned or replaced. The basic electrode

is copper, which is suitable for most analysis; however for identification of copper in

metalic material, a silver electrode shall replace the copper electrode.

b) Inthe case of Spectroport the electrode shall make contact with the metallic material to

strike an arc and then the readings obtaired shall be stored; the print out shall give the

permanent record of the readings.

©) Programme options as per Client requiement, such as identification, verification or

sorting shall be selected

X-Ray Fluorescence (XRF)

‘The XRF equipment shall be set, verified and operated in accordance with the

‘manufacturer's instructions.

a) In the case of the battery powered Nion or similar equipment, the measurement

window shall be placed against the sample to be analysed and the trigger pulled to get

the analysis of the sample. The chemical composition obtained shall be noted dawn in

the appropriate report format.

b) Programme options as per Client requirement, such as identification, verification or

sorting shall be selected.

©) Display Requirement: On start-up, the soreen will be replaced by the restart screen

which will count down from 9 to 0 in increments of 1 second. When restart is complete

the screen will be replaced by Logon screen. The operator needs to enter the 4 digit

securily code followed by enter key to access the main menu.

d) Once in the main menu by selecting the utiles menu one can select the auto calibrate

‘option. Once auto calibration is complete one can go to the Mode menu to select one

ILis recommended to use the Trigger + Interlock + Proxi

Positive Material Identification Procedure

of the test mode ~ Alloy, PB paint, Thin Sample, Buk sample and User definable

modes. The Alloy mode is normally used and under this the chemistry mode is

selected and the verification sample is tested to ensure proper identification.

©) From the main menu Test icon is selected to proceed with the test in the selected

measurement mode. Now the instrument is ready to take a measurement and there

are five (6) diferent methods of operation to take a sample measurement. These

methods are given below in increasing order of secure operation:

Trigger Only method

Trigger and Proximity Sensor method

Momentary Trigger Touch and Proximity Sensor method

Trigger and Interlock method

Trigger + Interlock + Proximity sensar method.

gasp

ily sensor method. When the proximity sensor

is enabled, the shutter will open only when the window is pressed against the sample. The X-Ray tube

will operate only when both the Trigger and the Interlock are pressed simultaneously and even if one is,

not pressed or released the X-Ray gels switched off.

For Further information on the measurement modes refer fo the Instruction manual of the Equipment.

11.0 EVALUATION

120

13.0

a4

92

Sort mode may be used whenever different grades of the same material are mixed and the

aim shall be to separate one grade from other in a quick manner. This mode is helpful in

reclaiming valuable metals from scrap material.

Material verification made shall be selected whenever the chemical composition of the job is

to be verified. The chemical composition of the job shall be programmed into the equipment

and the result shall be verified.

ACCEPTANCE CRITERIA (Ref. SAES-A-208)

a)

»)

2

For acceptance, it shall be demonstrated that materials contain the amount of alloying

elements shown in the material speciicatn. Alloys shall be deemed acceptable if the

alloying elements are each within ten percent (10%) of the specified values.

Welds having consumable material content that matches, or nearly matches, the base metal

‘composition within approximately twelve and half percent ( 12.5%) of the ranges allowed in

ASME Section II, Part C for each element.

‘Acceptance eriteria for dissimilar metal alloy welds shal be in accordance with the welding

‘consumable material specified in the approved welding procedure. The effects of dilution

between the different base metals and the filer metal shall be taken into account when

determining the nominal as-deposited weld metal composition.

REJECTION PROCEDURE (Ret. SAES-A-206)

4

If the PMI testing results fall outside the azceptable range, the Client has the option to

‘conduct a more accurate analysis to determine the component acceptance such as obtaining

‘a chemical analysis performed by an indeperdent testing laboratory. The results of the more

Positive Material Identification Procedure

‘accurate test method or independent chemicel analysis shali govern. PMI test results which

{all outside the acceptance range shall be informed to the Company PID.

b) If any component or weld falls outside the acceptable range, it shall be replaced and the

replacement shall be alloy verified.

©) Client shall ensure that rejected components are segregated and properly identified to

prevent reuse.

d) Where one of the selected items falls outside the acceptable range, all remaining materials

represented by such selected items shall be tested,

14.0 MARKING (Ref. SAES-A-206)

‘All components and / or welds that are examined by PMl shall be marked by the Client (NSH)

14.1. Verification Marking

4141.1 Paint marking shall be done with water-insoluble material that contains no substances that

harmiully afect the metal at ambient or elevated temperatures. in particular, the marking material

shall be free of lead, sulfur, zinc, cadmium, mercury, chlorine, or other halogens.

14.1.2 All components and welds that are found unacceptzble shall be marked immediately with a circled

red *X" pending resolution in accordance with Section 11.

14.1.3 All verified materials with an acceptable analysis shall be marked with the letiers "PMI" using a

certified low-stress stamp (these use a series of rcunded dots or a rounded indenter to form the

letters).

Alternatively, a vibrating "pencil" may be used. The marking shall be placed as follows:

Pipe: One mark, 75 mm from one end on the outer surface of the pipe. This marking shall be in

addition to the requirements of PFI ES-22 and Attachment 3 of 00-SAIP-07.

Welds: Adjacent to the welder’s mark on the weld (Welds on tubes for heat transfer equipment

shall be marked by either stenclling or vibro-etching on the tubeshee!).

Fittings and Forgings: Adjacent to the manufacturer's markings.

\Valves: Adjacent to the valve manufacturer's markings on bodies and other pressure parts.

Castings: Adjacent to the casting manufacturer's merkings and heat numbers.

Plates: 75 mm from one edge, adjacent to manufacturer's markings.

‘Tubes: Stenciled, 300 mm from each end.

For 300-serles stainless steel operating above 900°F (482°C), consult with the Materials

Engineering Unit Supervisor of CSD (to guard against “strain aging” - unlikely to be encountered in

refinery processes).

14.4.4 When heat treating is performed after PMI, the identification marking must be recognizable after

heat treatment. PMI markings shall be transferred to retain material identification when a plate or

pipe is cut, The transfer of PMI markings shall be carried cut prior to material cuting/separaton. If

this is not possible, then transfer shall be perormec immediately after material cutting/separation.

Positive Material Identification Procedure

14.2 Color Coding

14.2.1 The color coding system for material identiication described herein is intended to help prevent

fabricators from using incorrect alloy material. The principal purpose of color coding Is visual

identification during storage and after the componerts have been cut for fabrication.

14.2.2 Color coding is not a substitute for PMI testing or other, permanent manufacturers’ markings

required by ASTM or other specifications. Permanent manufacturers’ markings shall not be

obscured by cotor coding.

15.0 REPORTING

15.1. PMLis to be integrated with the Weld ID system and data base as an element as per SAEP

1160 and the results shall be logged / reported / tracked accordingly by the Client.

15.2. The repor if required by Client (NSH) shall be teken directly from the ‘Spectroport’ Alloy

‘Analyser.

15.3. For X-Ray fluorescence equipment, the PMI Feport shall have the following information;

Client Name

Cooperheat Job Number

Technician Name

Site/ Location

Project

Line / Heat Number

Weld Size

Element Percentage

Element Range

Grade identiication

Results

PMI Report Format (Sample!

‘PM Ropont

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1-Vision Ability WQCDocument1 page1-Vision Ability WQCKoya ThangalNo ratings yet

- Active Doc ListDocument675 pagesActive Doc ListKoya ThangalNo ratings yet

- Aramco Tank Projects Study ReferenceDocument19 pagesAramco Tank Projects Study ReferenceKoya ThangalNo ratings yet

- Cswip 3.1 Practice QuestionDocument22 pagesCswip 3.1 Practice QuestionKoya ThangalNo ratings yet

- Saudi Aramco Interview QuestionsDocument4 pagesSaudi Aramco Interview QuestionsKoya ThangalNo ratings yet

- Cswip Qa 3 2Document8 pagesCswip Qa 3 2Koya ThangalNo ratings yet

- Stainless Steel Cast FittingsDocument7 pagesStainless Steel Cast FittingsKoya ThangalNo ratings yet

- Pressure Vessel Shop Fabrication & InspectionDocument80 pagesPressure Vessel Shop Fabrication & InspectionKoya Thangal100% (1)

- QA10-G-5058 G03 Project Execution Rev.0Document26 pagesQA10-G-5058 G03 Project Execution Rev.0Koya ThangalNo ratings yet

- Fitup Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument2 pagesFitup Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Valve Basic Interview Questions & AnswersDocument6 pagesValve Basic Interview Questions & AnswersKoya Thangal100% (1)

- Editable List of Industrial ReportDocument3 pagesEditable List of Industrial ReportKoya ThangalNo ratings yet

- Pickling Passivation ProcedureDocument5 pagesPickling Passivation ProcedureKoya Thangal100% (1)

- Procedure For FabricationDocument10 pagesProcedure For FabricationKoya ThangalNo ratings yet

- Project Weld Status Report - (Rev.01) : Saudi Aramco Test ReportDocument1 pageProject Weld Status Report - (Rev.01) : Saudi Aramco Test ReportKoya ThangalNo ratings yet

- Post Weld Visual Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument2 pagesPost Weld Visual Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Editable List of Procedure+Document5 pagesEditable List of Procedure+Koya ThangalNo ratings yet

- FAT - 59 Fixed Asset Transfer - Construction For WO# 2038-121Document1 pageFAT - 59 Fixed Asset Transfer - Construction For WO# 2038-121Koya ThangalNo ratings yet

- Inspection Test PlanDocument141 pagesInspection Test PlanKoya ThangalNo ratings yet

- Storage TANK - WELD MAPDocument2 pagesStorage TANK - WELD MAPKoya Thangal100% (1)

- Dimensional Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejDocument1 pageDimensional Inspection Register: S.No Report No Description ITP Status Remarks Item No AIC Ssem Fitchner Acc / RejKoya ThangalNo ratings yet

- Hydro Test Package For The Tank No.#: Khobar To Dammam / Jamiah Water Transmission SystemDocument2 pagesHydro Test Package For The Tank No.#: Khobar To Dammam / Jamiah Water Transmission SystemKoya ThangalNo ratings yet