Professional Documents

Culture Documents

Open Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10268 Aug-2005)

Open Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10268 Aug-2005)

Uploaded by

MHS salesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Open Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10268 Aug-2005)

Open Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10268 Aug-2005)

Uploaded by

MHS salesCopyright:

Available Formats

Open Circuit - Gear Product

Service Instruction Bulletin

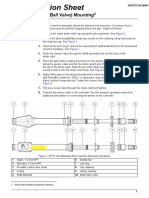

Shaft lip seal replacement

Snap

Tools needed; snap ring pliers, hammer, ring

awl, (2) sheet metal screws, (2) wire

cutting pliers, installation sleeve (PVC Support

tube approximately .02” smaller than washer

flange hole diameter), wide cellophane d Seal

p

packaging tape, and Parker Seal & O-ring

grease or Dow Triple III Lube.

b

i

Remove the shaft seal

1. Remove key from shaft (if equipped).

Remove snap ring and support

washer (if included with unit).

2. Clean shaft area of all rust, dirt and E101 262

grime.

3. Cover the shaft with a shaft cover or

cellophane tape. Punch holes

in seal

4. Use the following instructions to

carefully pry out the shaft seal.

5. Using a sharp punch or awl, punch

two holes in the shaft seal.

Do not drill holes, drilling holes produces

contamination. P101 386E

sheet metal

6. Turn two #8x2 in sheet metal screws screws

one or two turns into the seal.

P101 387E

1 BLN-10268 • August 2005

Open Circuit - Gear Product

Service Instruction Bulletin

Shaft lip seal replacement

7. Using side cutting wire pliers,

remove the seal by prying it

out as shown. Take care not to

damage the shaft.

8. Discard the seal.

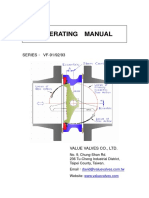

Inspect the components

Inspect the new seal, the unit

housing seal bore, and the sealing

area on the shaft for rust, wear, and

contamination. Polish the shaft and

clean the housing if necessary, being P104 388E

careful not to scratch the sealing

area on shaft or allow contamination

to fall into the unit.

Install the new shaft seal

1. Cover the shaft keyway, exposed Installation

threads, or shaft splines with a shaft sleeve

cover or packaging tape to protect

the shaft and seal during installation.

Snap

2. Lubricate the inside of the seal. ring

Support

3. Start the shaft seal and washer (if washer

included with unit) into the housing

with the cupped side of the seal d Seal

facing the unit.

b

4. Use the installation sleeve to press i

the seal, washer and snap ring slowly

in place.

5. Stop when the snap ring snaps into

the groove. Remove the installation

sleeve and packaging tape.

6. Re-install the key into the shaft. (if E101 321E

equipped)

2 BLN-10268 • August 2005

You might also like

- AT520JK Users ManualDocument15 pagesAT520JK Users ManualgerezairNo ratings yet

- Kayaba SuspensionDocument22 pagesKayaba SuspensionPhan LamNo ratings yet

- Yale FIGURE 500 & 500R Closure Operation and Maintenance InstructionsDocument12 pagesYale FIGURE 500 & 500R Closure Operation and Maintenance InstructionsShane CharltonNo ratings yet

- CyScan IV Engineers and Service Guide - v1Document11 pagesCyScan IV Engineers and Service Guide - v1Thang Pham100% (1)

- Panto Entanglement RDSO TCDocument4 pagesPanto Entanglement RDSO TCBrijendra SinghNo ratings yet

- Calculation CEMA 5 - Parte9Document5 pagesCalculation CEMA 5 - Parte9Angel AlvarezNo ratings yet

- 2006 2008 Cbf1000 A 8 Engine Removal InstallationDocument12 pages2006 2008 Cbf1000 A 8 Engine Removal InstallationdrkrassasNo ratings yet

- Current Flow Diagram Seats Heating VW Golf 5Document5 pagesCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguNo ratings yet

- Consumable Parts ScaniaDocument224 pagesConsumable Parts ScaniaAhmad HisyamNo ratings yet

- Open Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10269 Aug 2005)Document2 pagesOpen Circuit Gear Motors Shaft Seal Replacement Instructions (BLN-10269 Aug 2005)MHS salesNo ratings yet

- I & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDocument11 pagesI & M Mark Ed & Et Series 8-Inch: Ntroduction AintenanceDanel GonzalezNo ratings yet

- Extended Protection Tube Cap - Instructions v3Document2 pagesExtended Protection Tube Cap - Instructions v3Fuck YouNo ratings yet

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocument12 pagesValves S&S B Series 8-Inch Globe: Instruction ManualpedroNo ratings yet

- Wagner Hydraulic Cylinder Repair: SectionDocument4 pagesWagner Hydraulic Cylinder Repair: SectionLuis Silva NavarroNo ratings yet

- 2531Document5 pages2531sangkil05No ratings yet

- Tilt Cylinder: CylindersDocument6 pagesTilt Cylinder: CylindersCoque de LunaNo ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- material and hardware Lab report 02Document4 pagesmaterial and hardware Lab report 02ZORAIZ SHABBIRNo ratings yet

- MGentleLASE Focus Lens Replacement ProcedureDocument5 pagesMGentleLASE Focus Lens Replacement Proceduremuhanadelec44No ratings yet

- Valtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyDocument4 pagesValtek Pressure-Balanced Trim: General Instructions Disassembly and ReassemblyEduardo Landa GonzalezNo ratings yet

- Operating & Maintenance InstructionsDocument8 pagesOperating & Maintenance InstructionsVAN VIET NGONo ratings yet

- 6991 1252 01 - 1 - Gas SpringDocument18 pages6991 1252 01 - 1 - Gas SpringRaiza GabrielaNo ratings yet

- Conax MHM Series Assembly InstructionsDocument4 pagesConax MHM Series Assembly InstructionsColin ZhangNo ratings yet

- Sect 08 Plug CatchersDocument14 pagesSect 08 Plug CatcherspaimanNo ratings yet

- Instruction Sheet Is Jo1910: - Style Number Jo1910Ib:: Package ContentsDocument4 pagesInstruction Sheet Is Jo1910: - Style Number Jo1910Ib:: Package Contentsdayshift5No ratings yet

- Instruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package ContentsDocument3 pagesInstruction Sheet Is Tf878C - Style Number Tf878Cvb:: Package Contentsdayshift5No ratings yet

- Series 1200 - 7200 IomDocument6 pagesSeries 1200 - 7200 IomDEFRIZALNo ratings yet

- GXF147-FDT2103D V100R002C01 Quick Installation Guide 05Document20 pagesGXF147-FDT2103D V100R002C01 Quick Installation Guide 05Chua DavidNo ratings yet

- WheelHorse Snow Thrower Completing Package Manual 6-9111Document4 pagesWheelHorse Snow Thrower Completing Package Manual 6-9111Kevins Small Engine and Tractor ServiceNo ratings yet

- BDA EN Analog Digital DOC2735290031Document6 pagesBDA EN Analog Digital DOC2735290031Agustín narroNo ratings yet

- Yale Operation & Maintenance Rev1aDocument13 pagesYale Operation & Maintenance Rev1aAnonymous bHh1L1No ratings yet

- Fillup 200 - Powerpoint TemplateDocument11 pagesFillup 200 - Powerpoint Templatetafhim rashidNo ratings yet

- VE5C VE Commodore Hard Lid ManualDocument13 pagesVE5C VE Commodore Hard Lid ManualmathewNo ratings yet

- Orion ct80 56810 - 1 - Anleitung-ENDocument4 pagesOrion ct80 56810 - 1 - Anleitung-ENLam NguyenNo ratings yet

- Read Me First!: Resophonic and National Biscuit Installation GuideDocument3 pagesRead Me First!: Resophonic and National Biscuit Installation GuideJohn BrombaNo ratings yet

- 143367-Hyd Cylinder Repair GuideDocument3 pages143367-Hyd Cylinder Repair GuideheartofdixieNo ratings yet

- TL 800Document25 pagesTL 8003176985456No ratings yet

- Instruction Sheet Is-Pwl8307 Style Number: Pwl8307Wt: Package ContentsDocument4 pagesInstruction Sheet Is-Pwl8307 Style Number: Pwl8307Wt: Package Contentsdayshift5No ratings yet

- Instruction Sheet Is Fq9010 - Style Number Fq9010Mk, Fq9010AwDocument3 pagesInstruction Sheet Is Fq9010 - Style Number Fq9010Mk, Fq9010Awdayshift5No ratings yet

- Instruction Sheet Is-Cor8409 Style Number: Cor8409K: Package ContentsDocument5 pagesInstruction Sheet Is-Cor8409 Style Number: Cor8409K: Package Contentsdayshift5No ratings yet

- RL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Document2 pagesRL4 Series Relief Valve Adjustment and Seal Replacement Instructions (MS-CRD-0055 Rev - C en-US Maintenance)Tuan TranNo ratings yet

- Instr Montazu Filtra Stozkowego G60-1Document2 pagesInstr Montazu Filtra Stozkowego G60-1Lucas DomanskyNo ratings yet

- 25 K VInstall GuideDocument23 pages25 K VInstall GuideMarcelo ConchaNo ratings yet

- Impulse Poly Bag Sealers: TroubleshootingDocument6 pagesImpulse Poly Bag Sealers: Troubleshootingibss_mcmNo ratings yet

- Manual de Instalação 442 LargeDocument12 pagesManual de Instalação 442 LargeDanilo D'AmatoNo ratings yet

- VF-9 Operating ManualDocument17 pagesVF-9 Operating ManualMohamed MeeranNo ratings yet

- Alpha Repack Kit: Research&Development of America, IncDocument3 pagesAlpha Repack Kit: Research&Development of America, IncMandeep GillNo ratings yet

- Instruction Sheet Is Jo9010 - Style Number Jo9010Ib:: Package ContentsDocument3 pagesInstruction Sheet Is Jo9010 - Style Number Jo9010Ib:: Package Contentsdayshift5No ratings yet

- Coyote Aerial Fiber Drop Closure: OCTOBER 2006Document4 pagesCoyote Aerial Fiber Drop Closure: OCTOBER 2006kjnjk uijhNo ratings yet

- Fork Gold Valve Installation: DisassemblyDocument4 pagesFork Gold Valve Installation: DisassemblyTiyok HidrolikNo ratings yet

- SEPCO 14 Procedimiento para La InstalaciónDocument1 pageSEPCO 14 Procedimiento para La InstalaciónVictor Flores ResendizNo ratings yet

- Imo-030en 05-11Document4 pagesImo-030en 05-11HASBUL AZIZI BIN MAHMUNNo ratings yet

- Pro B Building InstructionDocument108 pagesPro B Building InstructionMatteo MiglioriniNo ratings yet

- AsDocument10 pagesAsAel ChNo ratings yet

- wp1148 IVDocument1 pagewp1148 IVaugustinhodjNo ratings yet

- Suspension KYB AOS manual finalDocument19 pagesSuspension KYB AOS manual finalmaciekkbilskiNo ratings yet

- 2013-07-24 001855 Sedona Trailer Wiring 2Document3 pages2013-07-24 001855 Sedona Trailer Wiring 2bibNo ratings yet

- Chapter 1 Manual SGT 100Document13 pagesChapter 1 Manual SGT 100uche ekeNo ratings yet

- Fiber Optical Splice Closure: Instruction ManualDocument6 pagesFiber Optical Splice Closure: Instruction ManualEric Huerta ArrañoNo ratings yet

- Lathe SherlineDocument2 pagesLathe SherlineDaron SchullerNo ratings yet

- Instruction Sheet Is Lss1814: - Style Number Lss1814Nr, Lss1814PsDocument3 pagesInstruction Sheet Is Lss1814: - Style Number Lss1814Nr, Lss1814Psdayshift5No ratings yet

- Type ValveDocument64 pagesType ValveJepri MarpaungNo ratings yet

- Design 461 Anti-Coke Valve Body (Fishebj: Fisher ControlsDocument16 pagesDesign 461 Anti-Coke Valve Body (Fishebj: Fisher ControlsDatt NguyenNo ratings yet

- Keep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareFrom EverandKeep Your Wrist Watch Clean and Ticking - A Guide to Wrist Watch Cleaning and CareNo ratings yet

- Ch7 G4010-R1Document140 pagesCh7 G4010-R1MoshNo ratings yet

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- KC 60335-2-5 - 수정Document23 pagesKC 60335-2-5 - 수정le duc huynhNo ratings yet

- Liebherr LTM 1060/2: Dimensions in Meters, Weights and Capacities in Metric Tonnes. For Reference OnlyDocument6 pagesLiebherr LTM 1060/2: Dimensions in Meters, Weights and Capacities in Metric Tonnes. For Reference OnlySvvgii SvvgiiNo ratings yet

- Roundo SF MachinesDocument4 pagesRoundo SF MachinesTan Chee MingNo ratings yet

- Rates For Major Works Materials/Equipments: Rates As Proposed For 2006-07 Amount in Rs LakhsDocument23 pagesRates For Major Works Materials/Equipments: Rates As Proposed For 2006-07 Amount in Rs Lakhsapi-25885200No ratings yet

- SSP 18 Octavia Manual Gearbox 02K 02JDocument30 pagesSSP 18 Octavia Manual Gearbox 02K 02Jcorona100% (1)

- Sant Valves CI-16B - Cast Iron Y Type StrainerDocument1 pageSant Valves CI-16B - Cast Iron Y Type StrainerBatsha PonnusamyNo ratings yet

- Bissell Little Green Carpet Cleaner 1400CDocument12 pagesBissell Little Green Carpet Cleaner 1400CmarabskyNo ratings yet

- XL250 (Double-Seat) : Service ManualDocument4 pagesXL250 (Double-Seat) : Service Manualloupapi330% (1)

- 9AKK107045A6911-RVC Manual Part 1 - Quick Start - REV CDocument2 pages9AKK107045A6911-RVC Manual Part 1 - Quick Start - REV CHpnoteNo ratings yet

- Grade 8 ICT Computer HardwareDocument23 pagesGrade 8 ICT Computer HardwareNelson PiconesNo ratings yet

- 07 k275 VaristorDocument27 pages07 k275 VaristorJorge Ugaz La RosaNo ratings yet

- VxStorageServer E-Series SpecSheet 031721Document4 pagesVxStorageServer E-Series SpecSheet 031721DP DiariesNo ratings yet

- 1ZSE 5492-152 en Rev 1Document30 pages1ZSE 5492-152 en Rev 1RAPRATSINNo ratings yet

- Lange Marine Cable (IEC)Document118 pagesLange Marine Cable (IEC)Eldar IsgenderovNo ratings yet

- FAP-IIA Series: Features Outline DrawingDocument2 pagesFAP-IIA Series: Features Outline Drawingbal3xNo ratings yet

- Mechanic CV TemplateDocument2 pagesMechanic CV Templateasmaa brkNo ratings yet

- ABB - Comutatoare Cu CameDocument60 pagesABB - Comutatoare Cu CameoscarilyesNo ratings yet

- LR3 (Eu)Document4 pagesLR3 (Eu)Đăng Điệp NguyễnNo ratings yet

- AVR Development Board (107010) : User's ManualDocument12 pagesAVR Development Board (107010) : User's ManualJibin Rajan VargheseNo ratings yet

- HP9116C Plus 1-20kvaDocument5 pagesHP9116C Plus 1-20kvaPaul Abi NajemNo ratings yet

- Janome 6260QCDocument20 pagesJanome 6260QCbianchifanNo ratings yet

- Design of Analog CMOS Integrated Circuits: (1st Edition)Document4 pagesDesign of Analog CMOS Integrated Circuits: (1st Edition)Himaja DasariNo ratings yet

- Power Electronics Lab Manual (2012-2013)Document84 pagesPower Electronics Lab Manual (2012-2013)srichanderNo ratings yet