Professional Documents

Culture Documents

As dc11 001

As dc11 001

Uploaded by

Tua TambaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

As dc11 001

As dc11 001

Uploaded by

Tua TambaCopyright:

Available Formats

SERVICE NEWS MITSUBISHI DECK CRANE

subject Ref

type CHECK OF TIGHTNESS OF FIXING BOLT AS- DC11-0 01

HDC Date

FOR DECK CRANE’S WINCHES March 4, 2011

We would express our sincere appreciation for your patronage for MITSUBISHI deck cranes.

On the one of our deck crane, the trouble had been occurred that fixing bolts for hoisting and luffing winch have

been broken and abnormal noise occurred.

Estimated cause of this problem was loose of fixing bolts, due to insufficient tightening torque at the time of

manufactured. As the bolts get looser, internal stress of bolts rises, and it leads to break of bolt.

The detailed location of the bolts is shown as below. This bolts are provided for shaft fixing structure, located inside

of side frame for winches. This bolts are located at blind area, therefore, it is difficult to find loose of bolts, unless

they are checked consciously.

To prevent occurrence of trouble in advance, please check tightness of the bolts as soon as possible, and fasten

the bolts if they are loosen.

In general, loose of bolts can be the cause of serious trouble, therefore, please carry out periodical check of

tightness of bolts entirely (for all machinery of deck crane), not only around winch area, as instructed in the

instruction manual. (As for winch area, please check bolts for both of side frame-side and hyd. motor-side.)

【Detailed location of broken bolt】

Winch area

Hoisting/Luffing Winch

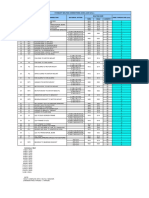

Hyd. motor -side Side frame-side Bolt specification (for 30T crane)

Size : M24

Material : SCM435

Tightening torque: 628N-m

Broken bolt

[Contact address]

PIC: Mr. Tanabe/ Mr. Ushirogochi

Power Systems Business Group (Marine Machinery Team)

Mitsubishi Heavy Industries, Ltd. / Shimonoseki Shipyard and Machinery Works

TEL +81-83-67-7094 FAX +81-83-266-8173

MITSUBISHI HEAVY INDUSTRIES,LTD .Shimonoseki Shipyard & Machinery works

You might also like

- Travers o V47Document32 pagesTravers o V47Jorge Espinoza100% (1)

- TSB1503G 9 P 1 PDFDocument18 pagesTSB1503G 9 P 1 PDFHatada Felipe100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- The Division 2 - Gear Attribute SheetDocument36 pagesThe Division 2 - Gear Attribute SheetgaliNo ratings yet

- Xtreet 140R 2015 Parts Catalogue 2014 11 20Document33 pagesXtreet 140R 2015 Parts Catalogue 2014 11 20Gloria Ramirez100% (1)

- Breakage of The Tightening Stud of Cyl - CoverDocument5 pagesBreakage of The Tightening Stud of Cyl - Coverstergios meletisNo ratings yet

- Toge TDSDocument4 pagesToge TDSSaif Ur RahmanNo ratings yet

- Elite Magna-Range Bridge PlugDocument2 pagesElite Magna-Range Bridge PlugJohanes GigihNo ratings yet

- HSV-R2 Stud Anchor: Concrete (Non-Cracked)Document8 pagesHSV-R2 Stud Anchor: Concrete (Non-Cracked)Ambreen FatimaNo ratings yet

- Equipment ListDocument11 pagesEquipment ListTunaNo ratings yet

- Bollhoff Kobsert (Press In) Insert Catalog PDFDocument16 pagesBollhoff Kobsert (Press In) Insert Catalog PDFClifford BernardNo ratings yet

- USI-24506E Measures Against Worn Piston RodDocument1 pageUSI-24506E Measures Against Worn Piston RodSantosh KumarNo ratings yet

- +696wxgdqfkru: HSV Stud AnchorDocument9 pages+696wxgdqfkru: HSV Stud AnchorThang VoNo ratings yet

- MTP-X: Product InformationDocument14 pagesMTP-X: Product Informationabhishek yadavNo ratings yet

- SKF Bearings - Trouble-Free Operation PDFDocument19 pagesSKF Bearings - Trouble-Free Operation PDFOwenNo ratings yet

- pmBR777eng 211Document20 pagespmBR777eng 211victorhugodiaz20085603No ratings yet

- Data Sheet: Kris Chen Ben Chang Ben ChangDocument7 pagesData Sheet: Kris Chen Ben Chang Ben ChangBriggitte OrtizNo ratings yet

- SKF Bearing Fitting Tool Kit TMFT 36: Helps Prevent Premature Bearing FailuresDocument2 pagesSKF Bearing Fitting Tool Kit TMFT 36: Helps Prevent Premature Bearing FailuresFebriyantoNo ratings yet

- Parts Manual: Serial No. 222A0005-UPDocument16 pagesParts Manual: Serial No. 222A0005-UPOrhanNo ratings yet

- Kit de Ferramentas Retirar RolamentoDocument2 pagesKit de Ferramentas Retirar RolamentoANDERSON WINTHERNo ratings yet

- SKF Bearing Fitting ToolDocument2 pagesSKF Bearing Fitting ToolTOKO CAHAYA PERMATANo ratings yet

- 0901d1968008a1ff PDF Preview MediumDocument2 pages0901d1968008a1ff PDF Preview Mediump.karthick05No ratings yet

- Item # SAF22517X2.15/1, Split Pillow Blocks, Cast Iron Housing, SAF TypeDocument3 pagesItem # SAF22517X2.15/1, Split Pillow Blocks, Cast Iron Housing, SAF TypenadipallsrirajNo ratings yet

- Evr Instruction Manual enDocument8 pagesEvr Instruction Manual enKjsNo ratings yet

- SL2016 627Document15 pagesSL2016 627lavkeshNo ratings yet

- DEB020ENDocument4 pagesDEB020ENNahum LBNo ratings yet

- TurningDocument766 pagesTurningDavid BahenaNo ratings yet

- Camloc KeensertsDocument9 pagesCamloc KeensertsJai BhandariNo ratings yet

- 14 Spline NutDocument24 pages14 Spline NutCAT MINING SHOVELNo ratings yet

- Records: Big End Bearing BoreDocument1 pageRecords: Big End Bearing BoreDomenicoNo ratings yet

- Rompedor (Hammer E66 - Sandvik BR2266)Document28 pagesRompedor (Hammer E66 - Sandvik BR2266)Gledison MartinsNo ratings yet

- FTA MTPA4 enDocument14 pagesFTA MTPA4 enFALwilliamsNo ratings yet

- DCMT11T0304-FV NX3035Document1 pageDCMT11T0304-FV NX3035sdhgwdNo ratings yet

- 3210Q011 - Cylinder Liner Maintenance - ExternalDocument6 pages3210Q011 - Cylinder Liner Maintenance - Externaloska150No ratings yet

- MSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023Document4 pagesMSB-TPL-REW-BV-HYD-8705-FIR 003 Dated 16-02-2023pl_arunachalam79No ratings yet

- Makita Torque Shear Bolt For TighteningDocument2 pagesMakita Torque Shear Bolt For TighteningMeriam DacunesNo ratings yet

- TATA Quick Reference Guide For Use With Steel RoofDek S220 Technical Information ASSET DOC LOC 951182Document2 pagesTATA Quick Reference Guide For Use With Steel RoofDek S220 Technical Information ASSET DOC LOC 951182Shane ConnellyNo ratings yet

- Terminal BlocksDocument6 pagesTerminal Blockshasanah1108aNo ratings yet

- VNMG160404-MP Ue6105Document1 pageVNMG160404-MP Ue6105sdhgwdNo ratings yet

- M60es44 NX449L Man 001Document24 pagesM60es44 NX449L Man 001Riski KurniawanNo ratings yet

- Cylinder Liner MaintenanceDocument3 pagesCylinder Liner MaintenanceMuhammad Arslaan100% (1)

- Anchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in ConcreteDocument10 pagesAnchor Fastening Technology Manual: HSV M8 HSV M10 HSV M12 HSV M16 Application in Concreteraju9991No ratings yet

- Calculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35Document6 pagesCalculation Sheet For Spit Anchors: TAPCON XTREM HFL Min. Anchorage 10x120/65-35abdallah badrNo ratings yet

- FTRS Threaded Rod AnchorDocument2 pagesFTRS Threaded Rod AnchorariefNo ratings yet

- Type TR60 Flyer LR 732Document2 pagesType TR60 Flyer LR 732ELUSIVE S M JAFRINo ratings yet

- Torrent: Frame Assembly & Service Parts ReferenceDocument3 pagesTorrent: Frame Assembly & Service Parts ReferencebenssjNo ratings yet

- Connection Design ReportDocument97 pagesConnection Design ReportTrungNguyenNo ratings yet

- Repair SpecDocument4 pagesRepair SpecShridhar AmatiNo ratings yet

- 3345 PartsDocument28 pages3345 Partschaky212No ratings yet

- PEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoDocument20 pagesPEBJ0011 Cutter Bit Reference Guide Puntas Cat Micro FresadoHECTOR ESCALLONNo ratings yet

- Technical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Document2 pagesTechnical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Yusfian TurnerNo ratings yet

- KHK Bevel GearsDocument34 pagesKHK Bevel GearsBurak KoyuncuogluNo ratings yet

- Hilti CatalogDocument13 pagesHilti CatalogYongHan KwongNo ratings yet

- SL1991 289Document21 pagesSL1991 289edmamiosNo ratings yet

- Frame Fi Xing SXS: AccessoriesDocument2 pagesFrame Fi Xing SXS: AccessoriesMNo ratings yet

- S160 43 001Document1 pageS160 43 001PHÁT NGUYỄN THẾNo ratings yet

- Balde Cargador 992KDocument52 pagesBalde Cargador 992KPablo Rojas BernalNo ratings yet

- RTA-45 - Tightening Instructions For Screws and Wasted StudsDocument4 pagesRTA-45 - Tightening Instructions For Screws and Wasted Studsdhilip87No ratings yet

- Compact Cylinder, Double-Acting ADN-SDocument31 pagesCompact Cylinder, Double-Acting ADN-SMuhammad HaidiNo ratings yet

- STPC520 - Viti A Testa Cilindrica Con Esagono IncassatoDocument18 pagesSTPC520 - Viti A Testa Cilindrica Con Esagono IncassatoLucaNo ratings yet

- MN 01005Document20 pagesMN 01005Ali AliNo ratings yet

- Unprotected-006criteria of Parts Replacement of NA TurbochargersDocument7 pagesUnprotected-006criteria of Parts Replacement of NA Turbochargersstergios meletisNo ratings yet

- Chicc 2014 6896887Document6 pagesChicc 2014 6896887Tua TambaNo ratings yet

- Consensus Analysis ZDH ZHBDocument28 pagesConsensus Analysis ZDH ZHBTua TambaNo ratings yet

- Jamp 2020101915233010Document12 pagesJamp 2020101915233010Tua TambaNo ratings yet

- JRNL 1 - Ieee Caa Aut SNCDocument1 pageJRNL 1 - Ieee Caa Aut SNCTua TambaNo ratings yet

- Supra Wittur Door Operator ManualDocument3 pagesSupra Wittur Door Operator ManualclaudioNo ratings yet

- Prepositions of Place CLASSWORKDocument4 pagesPrepositions of Place CLASSWORKLuis Benitez0% (1)

- Parker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualDocument48 pagesParker Dual-Bed Nitrogen Generation Systems: Installation, Operation, and Maintenance ManualgokulNo ratings yet

- Manual Test Pump 50bar - 262015 VIRAX - Hamiz ShopDocument5 pagesManual Test Pump 50bar - 262015 VIRAX - Hamiz ShopHamza BounezraNo ratings yet

- User Manual: 4-Axis GPS DroneDocument24 pagesUser Manual: 4-Axis GPS DroneJaime Núññez SotomayorNo ratings yet

- WelchAllyn Aneroid Sphygmomanometer - Service ManualDocument67 pagesWelchAllyn Aneroid Sphygmomanometer - Service ManualPablo Millaquén GNo ratings yet

- Cat Scale Model CatalogDocument11 pagesCat Scale Model CatalogJose Vicente Olguin Rodriguez100% (1)

- USTAR ACM 4U InstalacionDocument34 pagesUSTAR ACM 4U InstalacionEder Guerra SerpaNo ratings yet

- Siemens: A PCD-3Psx Laptop, Released in 1989Document2 pagesSiemens: A PCD-3Psx Laptop, Released in 1989RamelNo ratings yet

- Propane Dryness Test (Cobalt Bromide Method) : The Indieator. /B inDocument3 pagesPropane Dryness Test (Cobalt Bromide Method) : The Indieator. /B indiego echagarayNo ratings yet

- A ProcessDocument41 pagesA ProcessjulioNo ratings yet

- GE Lighting Systems M-250A Powr-Door Series Roadway Cobrahead Spec Sheet 9-75Document2 pagesGE Lighting Systems M-250A Powr-Door Series Roadway Cobrahead Spec Sheet 9-75Alan Masters100% (1)

- Thermostat 57X113220000Document5 pagesThermostat 57X113220000SADIQUE AHMADNo ratings yet

- Perfect Home For Your MCCB: Suitable To Accommodate 185 Sq. Mm. 3 / Core Aluminum Armoured CableDocument1 pagePerfect Home For Your MCCB: Suitable To Accommodate 185 Sq. Mm. 3 / Core Aluminum Armoured Cable4usangeetNo ratings yet

- ACS Screw Water Chiller R-134aDocument52 pagesACS Screw Water Chiller R-134aسہمہو الامہيرNo ratings yet

- Feed 304 M12 - M13, Feed 484 M12 - M13 R 0459 161 990 PDFDocument22 pagesFeed 304 M12 - M13, Feed 484 M12 - M13 R 0459 161 990 PDFMadalina LazarNo ratings yet

- IM MultiV Ducted IDUDocument83 pagesIM MultiV Ducted IDUashoreNo ratings yet

- Cooper Fuse Dual Sensing 24046Document4 pagesCooper Fuse Dual Sensing 24046heri fauziNo ratings yet

- PISO TECHO Manual Control RemotoDocument7 pagesPISO TECHO Manual Control RemotoTeo GonzalezNo ratings yet

- Unbrako New Price List Jan 2021-3 PDFDocument1 pageUnbrako New Price List Jan 2021-3 PDFManoj Doshi67% (3)

- ION 900 Series Owners ManualDocument24 pagesION 900 Series Owners ManualParosanu IonelNo ratings yet

- 3 Way and 4 Way Switches WorksheetDocument2 pages3 Way and 4 Way Switches WorksheetMinor100% (1)

- Everyday Electronics 1972-02Document60 pagesEveryday Electronics 1972-02Toni TursićNo ratings yet

- AB Catalog FDCLP2 v100 ProlificDocument4 pagesAB Catalog FDCLP2 v100 ProlificRJ GevenNo ratings yet

- DP G4 ManualDocument30 pagesDP G4 ManualEdnelson DanielNo ratings yet

- 100 Kva Isb CPG Parts CatlugeDocument62 pages100 Kva Isb CPG Parts CatlugeNikkikumar MaisuriyaNo ratings yet

- 2.21 5.12Document3 pages2.21 5.12hoiyen92100% (1)

- Standart Connection Bolting AcheDocument1 pageStandart Connection Bolting Achebayu kusumaNo ratings yet