Professional Documents

Culture Documents

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Uploaded by

anishCopyright:

Available Formats

You might also like

- Sa 278Document5 pagesSa 278AnilNo ratings yet

- Astm A759 PDFDocument3 pagesAstm A759 PDFCristian OtivoNo ratings yet

- TANGAZO Madeni Ya Ada - 13march2015Document27 pagesTANGAZO Madeni Ya Ada - 13march2015Othman MichuziNo ratings yet

- Abstract of ASTM A574 2000Document8 pagesAbstract of ASTM A574 2000Jesse ChenNo ratings yet

- Asme 2a - Sa-350 PDFDocument12 pagesAsme 2a - Sa-350 PDFEswaran100% (1)

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 pagesAustenitic Gray Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Asme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater TubesDocument10 pagesAsme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater Tubeslucecita1902No ratings yet

- Astm A439-83-2004Document6 pagesAstm A439-83-2004NadhiraNo ratings yet

- 042 - Sa-278Document6 pages042 - Sa-278javierNo ratings yet

- Astm A 563 2014Document9 pagesAstm A 563 2014Marlonnog100% (2)

- Sa 278Document5 pagesSa 278ismaelarchilacastilloNo ratings yet

- Sa 194Document14 pagesSa 194Raju SkNo ratings yet

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 pagesAustenitic Gray Iron Castings: Standard Specification ForTushar RanpiseNo ratings yet

- 09-01 - Heat Exchangers Using Special Materials or Thick WalDocument14 pages09-01 - Heat Exchangers Using Special Materials or Thick WalFolayemiNo ratings yet

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsDocument5 pagesA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.No ratings yet

- Is 210 PDFDocument13 pagesIs 210 PDFJagdeep DhillonNo ratings yet

- Abstract of ASTM A449 2000Document7 pagesAbstract of ASTM A449 2000Jesse ChenNo ratings yet

- Asme Sa268Document10 pagesAsme Sa268jimmysteelpipeNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Facturer For The Hot Rolling Operation and The Processor For TheDocument1 pageFacturer For The Hot Rolling Operation and The Processor For TheDipesh PatelNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument6 pagesAustenitic Ductile Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Astm A 729Document6 pagesAstm A 729Jamil SalmanNo ratings yet

- Sa 350Document12 pagesSa 350ismaelarchilacastilloNo ratings yet

- A 563 - 00 - Qtu2my1sruqDocument10 pagesA 563 - 00 - Qtu2my1sruqAnderson VelandiaNo ratings yet

- Specification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceDocument10 pagesSpecification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceAnilNo ratings yet

- Asme Sa214Document3 pagesAsme Sa214MargaritaNo ratings yet

- Sa 351Document6 pagesSa 351Anil0% (1)

- Astm A278Document4 pagesAstm A278dneradNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument7 pagesAustenitic Ductile Iron Castings: Standard Specification Forist93993No ratings yet

- Sa 106 PDFDocument16 pagesSa 106 PDFRaju SkNo ratings yet

- Asme Section II A-2 Sa-688 Sa-688mDocument10 pagesAsme Section II A-2 Sa-688 Sa-688mAnonymous GhPzn1xNo ratings yet

- Sa 335 PDFDocument12 pagesSa 335 PDFAnilNo ratings yet

- Astm F 835 PDFDocument6 pagesAstm F 835 PDFDan Dela Peña100% (1)

- H99sec2asa 335Document4 pagesH99sec2asa 335Fermín VallejoNo ratings yet

- A516A516M-17 Standard Specification Pressure Vessel PlatesDocument2 pagesA516A516M-17 Standard Specification Pressure Vessel PlatesYilia Wang100% (2)

- Gray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)Document4 pagesGray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)sharon blushteinNo ratings yet

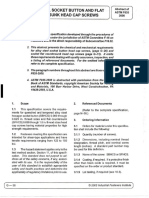

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument6 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDeen ewNo ratings yet

- M150Document9 pagesM150Ajit ChauhanNo ratings yet

- Astm A439 (2004)Document6 pagesAstm A439 (2004)Kundan SinghNo ratings yet

- Sa 369Document5 pagesSa 369ismaelarchilacastilloNo ratings yet

- Specification For Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesDocument6 pagesSpecification For Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesMauricio FernándezNo ratings yet

- Specification For Carbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceDocument5 pagesSpecification For Carbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceAnilNo ratings yet

- Sa 320 PDFDocument13 pagesSa 320 PDFRaju SkNo ratings yet

- Is 210 PDFDocument12 pagesIs 210 PDFmaheshkbandari100% (4)

- Astm F 2329Document5 pagesAstm F 2329Renan SouzaNo ratings yet

- Zinc Coat ASTM F 2329Document5 pagesZinc Coat ASTM F 2329Nassim SabriNo ratings yet

- Specification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument19 pagesSpecification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature Servicekranthi kumarNo ratings yet

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanNo ratings yet

- Specification For Centrifugally Cast Austenitic Steel Cold-Wrought Pipe For High-Temperature ServiceDocument6 pagesSpecification For Centrifugally Cast Austenitic Steel Cold-Wrought Pipe For High-Temperature Serviceabbaz ajiNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument6 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsMohammed EldakhakhnyNo ratings yet

- Sec 2 A Sa 696Document4 pagesSec 2 A Sa 696byom18No ratings yet

- Astm A574m 1998Document7 pagesAstm A574m 1998Jesse ChenNo ratings yet

- Astm A532 PDFDocument4 pagesAstm A532 PDFJuan Leon100% (1)

- ASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceDocument5 pagesASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceWagner Renato AraújoNo ratings yet

- Norma Astm A532Document6 pagesNorma Astm A532mipo.scl.clNo ratings yet

- Sec 2 A Sa 695Document4 pagesSec 2 A Sa 695byom18No ratings yet

- A 574 - 00 - Qtu3naDocument8 pagesA 574 - 00 - Qtu3naOswaldo Leyva RNo ratings yet

- Sa 226Document4 pagesSa 226Raju SkNo ratings yet

- Asme 1461Document12 pagesAsme 1461HAITHAM ATEFNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- TABLE 2 Chemical Requirements For Classes 8S3 and 10S3 Nuts: 6. Mechanical Properties 7. DimensionsDocument1 pageTABLE 2 Chemical Requirements For Classes 8S3 and 10S3 Nuts: 6. Mechanical Properties 7. DimensionsanishNo ratings yet

- TABLE 4 Nut Proof Load Values, KN: OTE OTEDocument1 pageTABLE 4 Nut Proof Load Values, KN: OTE OTEanishNo ratings yet

- Carbon and Alloy Steel Nuts (Metric) : Standard Specification ForDocument1 pageCarbon and Alloy Steel Nuts (Metric) : Standard Specification ForanishNo ratings yet

- TABLE 3 Mechanical Requirements of NutsDocument1 pageTABLE 3 Mechanical Requirements of NutsanishNo ratings yet

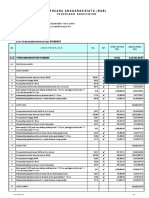

- Rencana Anggaran Biaya (Rab) : Pekerjaan ArsitekturDocument10 pagesRencana Anggaran Biaya (Rab) : Pekerjaan ArsitekturRifqi Fairuz ZuhdiNo ratings yet

- Intertherm 79: Temporary Protective PrimerDocument4 pagesIntertherm 79: Temporary Protective PrimerNassim Ben AbdeddayemNo ratings yet

- Hilti Rebar 2Document69 pagesHilti Rebar 2Jeevan ShendreNo ratings yet

- Making A Camembert Box: MaterialsDocument6 pagesMaking A Camembert Box: MaterialsSara RodriguezNo ratings yet

- Ceramic FibresDocument18 pagesCeramic Fibressuhaib_abdurahmanNo ratings yet

- Draftsman CivilDocument2 pagesDraftsman CivilSooraj S KollamNo ratings yet

- WYN032Document13 pagesWYN032marvinNo ratings yet

- Relative Plugging IndexDocument10 pagesRelative Plugging Indexspurwito46No ratings yet

- CONSTANT OY K Oils EN enDocument4 pagesCONSTANT OY K Oils EN enSiska JozefNo ratings yet

- Boq 1-8 - PR - Irq - Nin - 2020 - 247Document35 pagesBoq 1-8 - PR - Irq - Nin - 2020 - 247Ahmad IbrahimNo ratings yet

- Hexagonal Woven Gabion: (Bronjong Kawat Anyaman Mesin)Document8 pagesHexagonal Woven Gabion: (Bronjong Kawat Anyaman Mesin)Fikri HarisNo ratings yet

- Types of ReactionsDocument22 pagesTypes of ReactionsSalina SalujaNo ratings yet

- Final JBCC Priceindex June 2022Document7 pagesFinal JBCC Priceindex June 2022maltus5454No ratings yet

- D095 PDFDocument5 pagesD095 PDFwalterNo ratings yet

- Materials Science and Engineering ADocument7 pagesMaterials Science and Engineering ALuan CaetanoNo ratings yet

- How To Select Spider Fittings in Point Supported GlassDocument3 pagesHow To Select Spider Fittings in Point Supported GlassHan JoeNo ratings yet

- Concrete Hollow Block LayeringDocument7 pagesConcrete Hollow Block LayeringMichael Adrian Magbanua100% (1)

- RougingDocument6 pagesRougingmarcmanichNo ratings yet

- Viscosity-Classifications Astm d2422Document8 pagesViscosity-Classifications Astm d2422Francisco TipanNo ratings yet

- BS 3396-1 GF Fabric For Plastic RF PDFDocument13 pagesBS 3396-1 GF Fabric For Plastic RF PDFPD AWSSIESPNo ratings yet

- Wood Composite SeminarDocument25 pagesWood Composite SeminarsriNo ratings yet

- Chemistry Nov 07 Paper 2 Mark SchemeDocument7 pagesChemistry Nov 07 Paper 2 Mark SchemePhoolee0% (1)

- Production of Urea Formaldehyde UF85-947312 - 2Document66 pagesProduction of Urea Formaldehyde UF85-947312 - 2Sanzar Rahman 1621555030No ratings yet

- Iso 21068 2 2008 en PDFDocument11 pagesIso 21068 2 2008 en PDFmuhammad abidinNo ratings yet

- 1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceDocument13 pages1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceandhucaosNo ratings yet

- Comparison of Asme Specifications - 4Document1 pageComparison of Asme Specifications - 4MechanicalNo ratings yet

- Technological University of The PhilippinesDocument2 pagesTechnological University of The PhilippinesJohn Richard MalongNo ratings yet

- Pressure Ratings Stainless Steel PipeDocument4 pagesPressure Ratings Stainless Steel PipeduncmcleodNo ratings yet

- Mpa 2000XDocument2 pagesMpa 2000Xtep365No ratings yet

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Uploaded by

anishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Ordering Information: 3 3 3 Heavy Hex 3 1.5 Hex Flange Nuts, Class 10, ASTM A 563M-XX

Uploaded by

anishCopyright:

Available Formats

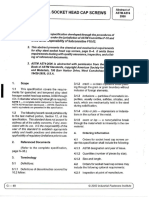

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 563M

With Specified Proof Loads hot-dip, mechanically deposited, or no preference.

ISO 4775 Hexagon Nuts for High-Strength Structural Bolt- 4.7.2 When hot-dip is specified, the fasteners shall be

ing with Large Width Across Flats—Product Grade zinc-coated by the hot-dip process in accordance with the

B—Property Classes 8 and 10 requirements of Class C of Specification A 153.

3. Ordering Information 4.7.3 When mechanically deposited is specified, the fasten-

ers shall be zinc-coated by the mechanical-deposition process

3.1 Orders for nuts under this specification shall include the in accordance with the requirements of Class 50 of Specifica-

following: tion B 695.

3.1.1 Quantity (number of nuts); 4.7.4 When no preference is specified, the supplier may

3.1.2 Nominal diameter and thread pitch; furnish either a hot-dip zinc coating in accordance with

3.1.3 Dimensional style of nut (for example, hex, heavy Specification A 153, Class C, or a mechanically deposited zinc

hex, or hex flange); coating in accordance with Specification B 695, Class 50. All

3.1.4 Property class of nut; components of mating fasteners (bolts, nuts, and washers) shall

3.1.5 Zinc Coating—Specify the zinc coating process re- be coated by the same zinc coating process and the supplier’s

quired, hot-dip, mechanically deposited, or no preference (see option is limited to one process per item with no mixed

4.7); processes in a lot.

3.1.6 Other Finishes—Specify other protective finish if 4.7.5 Hot-dip zinc coated nuts shall be tapped after zinc

required; coating in accordance with the thread limits in 7.8.

3.1.7 ASTM designation and year of issue; and 4.7.6 Mechanically deposited zinc-coated nuts for assembly

3.1.8 Any special requirements. with mechanically deposited zinc-coated bolts shall be tapped

3.2 The strength requirements for any class of nut may be oversize in accordance with the thread limits in 7.8 prior to

satisfied by substituting a nut of a higher class provided that the zinc coating and need not be retapped afterwards.

nut width across flats is the same. With the written approval of

the purchaser, the supplier may substitute as follows: Class 12 NOTE 6—It is the intent of 4.7 and 4.8 together with the requirements

nuts for Classes 10, 9, and 5; Class 10 nuts for Classes 9 and specified in 7.8 that galvanized bolts and nuts will assemble freely,

regardless of source of supply.

5; Class 9 nuts for Class 5; Class 10S for Class 8S; Class 8S3

for Class 8S; and Class 10S3 for Classes 10S, 8S, and 8S3. 4.8 Hot-dip and mechanically deposited zinc-coated Class

10S nuts shall be provided with an additional lubricant that

NOTE 4—Purchasers are cautioned that different classes of nuts have

shall be clean and dry to the touch.

different nut thickness (see 7.2 through 7.5). Dimensional suitability of the

nut for the intended application should be considered before approving 5. Chemical Composition

substitution of a higher class.

NOTE 5—Examples of ordering descriptions are: (a) 10 000 M12 3 5.1 Classes 5, 9, 8S, 10, 10S, and 12 shall conform to the

1.75 hex nuts, Class 9, ASTM A 563M–XX; (b) 2500 M24 3 3 heavy hex chemical composition specified in Table 1.

nuts, Class 10S, hot-dip zinc-coated, ASTM A 563M–XX; and (c) 5000 5.2 Classes 8S3 and 10S3 shall conform to the chemical

M10 3 1.5 hex flange nuts, Class 10, ASTM A 563M–XX. composition specified in Table 2. See Guide G 101 for methods

4. Materials and Manufacture of estimating corrosion resistance of low alloy steels.

5.3 Resulfurized or rephosphorized steel, or both, are not

4.1 Steel for nuts shall be made by the open-hearth, basic-

subject to rejection based on product analysis for sulfur or

oxygen, or electric-furnace process.

phosphorus unless misapplication is clearly indicated.

4.2 Nuts may be made cold or hot by forming, pressing, or

5.4 Application of heats of steel to which bismuth, sele-

punching, or may be machined from bar stock.

nium, tellurium, or lead has been intentionally added shall not

4.3 Classes 10, 12, 10S, and 10S3 nuts shall be heat treated

be permitted for Classes 10, 12, 10S, and 10S3.

by quenching in a liquid medium from a temperature above the

transformation temperature and tempering at a temperature of TABLE 1 Chemical Requirements

at least 425°C.

Property Composition, %

4.4 Classes 8S and 8S3 nuts made of any steel permitted for Class of

these classes may be heat treated by quenching in a liquid Nut

medium from a temperature above the transformation tempera- Analysis Carbon Manga- Phos- Sulfur,

ture and tempering at a temperature of at least 425°C. nese, phorus, max

min max

4.5 Class 8S nuts made of steel having a carbon content not

exceeding 0.20 %, phosphorus not exceeding 0.04 %, and 5, 9, 8S heat 0.55 max ... 0.04 0.15A

product 0.58 max ... 0.048 ...

sulfur not exceeding 0.05 % by heat analysis may be heat

treated by quenching in a liquid medium from a temperature 10B, 10S heat 0.55 max 0.30 0.04 0.05

product 0.58 max 0.27 0.048 0.058

above the transformation temperature and need not be tem-

pered. When this heat treatment is used, particular attention 12B heat 0.20–0.55 0.60 0.04 0.05

shall be paid to the requirements in 6.1. product 0.18–0.58 0.57 0.048 0.058

8S3, 10S3 See Table 2

4.6 Threads shall be formed, tapped, or machined.

A

4.7 Zinc Coatings, Hot-Dip and Mechanically Deposited: For Classes 5 and 9, a sulfur content of 0.23 % max. is acceptable with the

purchasers approval.

4.7.1 When zinc-coated fasteners are required, the pur- B

For Classes 10 and 12, a sulfur content of 0.15 % max. is acceptable provided

chaser shall specify the zinc coating process, for example, the manganese is 1.35 % min.

You might also like

- Sa 278Document5 pagesSa 278AnilNo ratings yet

- Astm A759 PDFDocument3 pagesAstm A759 PDFCristian OtivoNo ratings yet

- TANGAZO Madeni Ya Ada - 13march2015Document27 pagesTANGAZO Madeni Ya Ada - 13march2015Othman MichuziNo ratings yet

- Abstract of ASTM A574 2000Document8 pagesAbstract of ASTM A574 2000Jesse ChenNo ratings yet

- Asme 2a - Sa-350 PDFDocument12 pagesAsme 2a - Sa-350 PDFEswaran100% (1)

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 pagesAustenitic Gray Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Asme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater TubesDocument10 pagesAsme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater Tubeslucecita1902No ratings yet

- Astm A439-83-2004Document6 pagesAstm A439-83-2004NadhiraNo ratings yet

- 042 - Sa-278Document6 pages042 - Sa-278javierNo ratings yet

- Astm A 563 2014Document9 pagesAstm A 563 2014Marlonnog100% (2)

- Sa 278Document5 pagesSa 278ismaelarchilacastilloNo ratings yet

- Sa 194Document14 pagesSa 194Raju SkNo ratings yet

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 pagesAustenitic Gray Iron Castings: Standard Specification ForTushar RanpiseNo ratings yet

- 09-01 - Heat Exchangers Using Special Materials or Thick WalDocument14 pages09-01 - Heat Exchangers Using Special Materials or Thick WalFolayemiNo ratings yet

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsDocument5 pagesA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.No ratings yet

- Is 210 PDFDocument13 pagesIs 210 PDFJagdeep DhillonNo ratings yet

- Abstract of ASTM A449 2000Document7 pagesAbstract of ASTM A449 2000Jesse ChenNo ratings yet

- Asme Sa268Document10 pagesAsme Sa268jimmysteelpipeNo ratings yet

- Abstract of ASTM F835 2000Document7 pagesAbstract of ASTM F835 2000Jesse ChenNo ratings yet

- Facturer For The Hot Rolling Operation and The Processor For TheDocument1 pageFacturer For The Hot Rolling Operation and The Processor For TheDipesh PatelNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument6 pagesAustenitic Ductile Iron Castings: Standard Specification ForDarwin DarmawanNo ratings yet

- Astm A 729Document6 pagesAstm A 729Jamil SalmanNo ratings yet

- Sa 350Document12 pagesSa 350ismaelarchilacastilloNo ratings yet

- A 563 - 00 - Qtu2my1sruqDocument10 pagesA 563 - 00 - Qtu2my1sruqAnderson VelandiaNo ratings yet

- Specification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceDocument10 pagesSpecification For Welded Large Diameter Austenitic Steel Pipe For Corrosive or High-Temperature ServiceAnilNo ratings yet

- Asme Sa214Document3 pagesAsme Sa214MargaritaNo ratings yet

- Sa 351Document6 pagesSa 351Anil0% (1)

- Astm A278Document4 pagesAstm A278dneradNo ratings yet

- Austenitic Ductile Iron Castings: Standard Specification ForDocument7 pagesAustenitic Ductile Iron Castings: Standard Specification Forist93993No ratings yet

- Sa 106 PDFDocument16 pagesSa 106 PDFRaju SkNo ratings yet

- Asme Section II A-2 Sa-688 Sa-688mDocument10 pagesAsme Section II A-2 Sa-688 Sa-688mAnonymous GhPzn1xNo ratings yet

- Sa 335 PDFDocument12 pagesSa 335 PDFAnilNo ratings yet

- Astm F 835 PDFDocument6 pagesAstm F 835 PDFDan Dela Peña100% (1)

- H99sec2asa 335Document4 pagesH99sec2asa 335Fermín VallejoNo ratings yet

- A516A516M-17 Standard Specification Pressure Vessel PlatesDocument2 pagesA516A516M-17 Standard Specification Pressure Vessel PlatesYilia Wang100% (2)

- Gray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)Document4 pagesGray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)sharon blushteinNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument6 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDeen ewNo ratings yet

- M150Document9 pagesM150Ajit ChauhanNo ratings yet

- Astm A439 (2004)Document6 pagesAstm A439 (2004)Kundan SinghNo ratings yet

- Sa 369Document5 pagesSa 369ismaelarchilacastilloNo ratings yet

- Specification For Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesDocument6 pagesSpecification For Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesMauricio FernándezNo ratings yet

- Specification For Carbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceDocument5 pagesSpecification For Carbon and Ferritic Alloy Steel Forged and Bored Pipe For High-Temperature ServiceAnilNo ratings yet

- Sa 320 PDFDocument13 pagesSa 320 PDFRaju SkNo ratings yet

- Is 210 PDFDocument12 pagesIs 210 PDFmaheshkbandari100% (4)

- Astm F 2329Document5 pagesAstm F 2329Renan SouzaNo ratings yet

- Zinc Coat ASTM F 2329Document5 pagesZinc Coat ASTM F 2329Nassim SabriNo ratings yet

- Specification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument19 pagesSpecification For Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature Servicekranthi kumarNo ratings yet

- Sec. II A - SA - 209Document6 pagesSec. II A - SA - 209RamuAlagappanNo ratings yet

- Specification For Centrifugally Cast Austenitic Steel Cold-Wrought Pipe For High-Temperature ServiceDocument6 pagesSpecification For Centrifugally Cast Austenitic Steel Cold-Wrought Pipe For High-Temperature Serviceabbaz ajiNo ratings yet

- Alloy Steel Socket Button and Flat Countersunk Head Cap ScrewsDocument6 pagesAlloy Steel Socket Button and Flat Countersunk Head Cap ScrewsMohammed EldakhakhnyNo ratings yet

- Sec 2 A Sa 696Document4 pagesSec 2 A Sa 696byom18No ratings yet

- Astm A574m 1998Document7 pagesAstm A574m 1998Jesse ChenNo ratings yet

- Astm A532 PDFDocument4 pagesAstm A532 PDFJuan Leon100% (1)

- ASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceDocument5 pagesASME SA-437-SA-437M Specification For Alloy-Steel Turbine Type Bolting Material Specially Heat Treated For High-Temperature ServiceWagner Renato AraújoNo ratings yet

- Norma Astm A532Document6 pagesNorma Astm A532mipo.scl.clNo ratings yet

- Sec 2 A Sa 695Document4 pagesSec 2 A Sa 695byom18No ratings yet

- A 574 - 00 - Qtu3naDocument8 pagesA 574 - 00 - Qtu3naOswaldo Leyva RNo ratings yet

- Sa 226Document4 pagesSa 226Raju SkNo ratings yet

- Asme 1461Document12 pagesAsme 1461HAITHAM ATEFNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- TABLE 2 Chemical Requirements For Classes 8S3 and 10S3 Nuts: 6. Mechanical Properties 7. DimensionsDocument1 pageTABLE 2 Chemical Requirements For Classes 8S3 and 10S3 Nuts: 6. Mechanical Properties 7. DimensionsanishNo ratings yet

- TABLE 4 Nut Proof Load Values, KN: OTE OTEDocument1 pageTABLE 4 Nut Proof Load Values, KN: OTE OTEanishNo ratings yet

- Carbon and Alloy Steel Nuts (Metric) : Standard Specification ForDocument1 pageCarbon and Alloy Steel Nuts (Metric) : Standard Specification ForanishNo ratings yet

- TABLE 3 Mechanical Requirements of NutsDocument1 pageTABLE 3 Mechanical Requirements of NutsanishNo ratings yet

- Rencana Anggaran Biaya (Rab) : Pekerjaan ArsitekturDocument10 pagesRencana Anggaran Biaya (Rab) : Pekerjaan ArsitekturRifqi Fairuz ZuhdiNo ratings yet

- Intertherm 79: Temporary Protective PrimerDocument4 pagesIntertherm 79: Temporary Protective PrimerNassim Ben AbdeddayemNo ratings yet

- Hilti Rebar 2Document69 pagesHilti Rebar 2Jeevan ShendreNo ratings yet

- Making A Camembert Box: MaterialsDocument6 pagesMaking A Camembert Box: MaterialsSara RodriguezNo ratings yet

- Ceramic FibresDocument18 pagesCeramic Fibressuhaib_abdurahmanNo ratings yet

- Draftsman CivilDocument2 pagesDraftsman CivilSooraj S KollamNo ratings yet

- WYN032Document13 pagesWYN032marvinNo ratings yet

- Relative Plugging IndexDocument10 pagesRelative Plugging Indexspurwito46No ratings yet

- CONSTANT OY K Oils EN enDocument4 pagesCONSTANT OY K Oils EN enSiska JozefNo ratings yet

- Boq 1-8 - PR - Irq - Nin - 2020 - 247Document35 pagesBoq 1-8 - PR - Irq - Nin - 2020 - 247Ahmad IbrahimNo ratings yet

- Hexagonal Woven Gabion: (Bronjong Kawat Anyaman Mesin)Document8 pagesHexagonal Woven Gabion: (Bronjong Kawat Anyaman Mesin)Fikri HarisNo ratings yet

- Types of ReactionsDocument22 pagesTypes of ReactionsSalina SalujaNo ratings yet

- Final JBCC Priceindex June 2022Document7 pagesFinal JBCC Priceindex June 2022maltus5454No ratings yet

- D095 PDFDocument5 pagesD095 PDFwalterNo ratings yet

- Materials Science and Engineering ADocument7 pagesMaterials Science and Engineering ALuan CaetanoNo ratings yet

- How To Select Spider Fittings in Point Supported GlassDocument3 pagesHow To Select Spider Fittings in Point Supported GlassHan JoeNo ratings yet

- Concrete Hollow Block LayeringDocument7 pagesConcrete Hollow Block LayeringMichael Adrian Magbanua100% (1)

- RougingDocument6 pagesRougingmarcmanichNo ratings yet

- Viscosity-Classifications Astm d2422Document8 pagesViscosity-Classifications Astm d2422Francisco TipanNo ratings yet

- BS 3396-1 GF Fabric For Plastic RF PDFDocument13 pagesBS 3396-1 GF Fabric For Plastic RF PDFPD AWSSIESPNo ratings yet

- Wood Composite SeminarDocument25 pagesWood Composite SeminarsriNo ratings yet

- Chemistry Nov 07 Paper 2 Mark SchemeDocument7 pagesChemistry Nov 07 Paper 2 Mark SchemePhoolee0% (1)

- Production of Urea Formaldehyde UF85-947312 - 2Document66 pagesProduction of Urea Formaldehyde UF85-947312 - 2Sanzar Rahman 1621555030No ratings yet

- Iso 21068 2 2008 en PDFDocument11 pagesIso 21068 2 2008 en PDFmuhammad abidinNo ratings yet

- 1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceDocument13 pages1.0 Scope: Special Requirements For Equipment Purchased For Gaseous Oxygen ServiceandhucaosNo ratings yet

- Comparison of Asme Specifications - 4Document1 pageComparison of Asme Specifications - 4MechanicalNo ratings yet

- Technological University of The PhilippinesDocument2 pagesTechnological University of The PhilippinesJohn Richard MalongNo ratings yet

- Pressure Ratings Stainless Steel PipeDocument4 pagesPressure Ratings Stainless Steel PipeduncmcleodNo ratings yet

- Mpa 2000XDocument2 pagesMpa 2000Xtep365No ratings yet