Professional Documents

Culture Documents

SLL 693 Questioneries

SLL 693 Questioneries

Uploaded by

Ali Baig0 ratings0% found this document useful (0 votes)

10 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views1 pageSLL 693 Questioneries

SLL 693 Questioneries

Uploaded by

Ali BaigCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

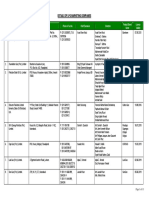

Information To Be Provided By The Manufacturer Within 48 Hrs of Receiving PO FOR

TENDER SLL 693, 11.8 Kg LPG Cylinders Date:

1. Company Name

2. Responsible Person NAME:_ DESIGNATION: Mo:

3. Delivery Schedule Committed OCT: , NOV: DEC:

4, Parallel PO (other comp) Dec 22:

5. Number of Shifts :ONE: Two: » THREE: _

6. Cylinder Fabrication Capacity PER/DAY: PER/WEEK: , PER/MONTH:

7. Additional manpower hiring: Trades:_ ary: DATE:

8, Sub-contracting (S/C) task, if any: YES: NO:

9. Sub Contract if any. Activities(s) to be S/C:

10,5/C resource to support output due to:

11, Submit Work Plan/Schedule to be provided on separate sheet consisting of:

a) Week-wise Production Schedule til final delivery date including activities: Cutting, Pressing, Welding, Heat

‘Treatment, Hydrotest, Painting, Valve Fixing, Pneumatic Test with TPIA inspection stages.

b) Material Procurement: Item list, Qty, Expected PO issuance date, tentative work shop delivery dates. Separate list

7 plan for both local/foreign items.

) Tools/Equipment Procurement (if any): Items, Qty, expected PO issuance, tentative work shop delivery dates.

12, Detail of Material Resources To Be Deployed for SSGC-LPG Tender SLL 693:

's#| Material Description | Specification Detail | Unit ‘Manuf. /Supplier [aty Available [aty To Orded Order Date

1 | Stee!

Compact vale

[manuf on CNC m/e)

3 | Hlectrodes T

| Zine wire .

Paint

Detail of Equipment Resources To Be Deployed for SSGC-LPG Tender SLL 693:

Equipment Detail/Specs | Gty Available | capacity/shin |

Press - ——

Press?

cutting mad

Cutting machine 2

‘Welding set up 1

‘Welding set up 2

‘Welding set up 3

Zinc metalizing

Heat treatment

Paintshop set up

Hydrotest set up

“Ee

T

Pneumatic test set up

Page 1061

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Blackmer BV Bypass Valves - : Precise, On-Line Pressure ProtectionDocument2 pagesBlackmer BV Bypass Valves - : Precise, On-Line Pressure ProtectionAli BaigNo ratings yet

- SPB 800 LPG Reels-1Document1 pageSPB 800 LPG Reels-1Ali BaigNo ratings yet

- Charakterystyka NHVe.32-160-CA (Diesel)Document1 pageCharakterystyka NHVe.32-160-CA (Diesel)Ali BaigNo ratings yet

- Isuzu FVR Brochure 2017Document2 pagesIsuzu FVR Brochure 2017Ali BaigNo ratings yet

- Detail of LPG Marketing Companies Dated February 28 2018Document13 pagesDetail of LPG Marketing Companies Dated February 28 2018Ali BaigNo ratings yet

- 6300Document2 pages6300Ali BaigNo ratings yet

- For PDF Alco Valves 2016Document44 pagesFor PDF Alco Valves 2016Ali BaigNo ratings yet

- Pit Mistry Abhishek ChavanDocument18 pagesPit Mistry Abhishek ChavanAli BaigNo ratings yet

- Linkon CatalogDocument715 pagesLinkon CatalogAli BaigNo ratings yet

- S No. Description Qty Unit Price GST Total Price: Scope of ServicesDocument1 pageS No. Description Qty Unit Price GST Total Price: Scope of ServicesAli BaigNo ratings yet

- Em-Tek (PVT) LTD: Hemi Head LPG Pressure Vessels Elliptical Dish LPG Pressure VesselsDocument6 pagesEm-Tek (PVT) LTD: Hemi Head LPG Pressure Vessels Elliptical Dish LPG Pressure VesselsAli BaigNo ratings yet