Professional Documents

Culture Documents

CH 1 Introduction

CH 1 Introduction

Uploaded by

Ala HijaziOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 1 Introduction

CH 1 Introduction

Uploaded by

Ala HijaziCopyright:

Available Formats

CH 1: Introduction

Science explains what is; Engineering creates what never was.

To find From Laws of nature

Science Laws System, Input, Output

Engineering System Input, Output, Laws System

Analysis Output System, Input, Laws Input Output

or

Inverse Analysis Input System, Output, Laws

Component

The designed product must be: functional, safe, reliable, usable, competitive,

manufacturable, and marketable.

Codes and Standards

Codes and standards are made to organize and unify the engineering work.

Imagine; what if there was no standard for bolts?

A code is a set of specifications for the analysis, design, manufacture, and

construction of something.

A standard is a set of specifications for parts, materials, or processes intended

to achieve uniformity, efficiency and specific quality.

Examples of organizations that establish standards and design codes: AISI, AGMA,

SAE, ASTM, ISO.

Stress and Strength

When designing a component, the designer needs to make sure that the maximum

stress is less than the strength of the material used for making that component.

Stress () depends on geometry and load.

Strength (S) is a material property; strength is the stress level at which

something occurs (such as yield strength or ultimate strength).

When designing mechanical components, the stress in the component should never

reach the yield strength of the material.

Yielding is considered failure; why?

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 1 of 15

According to AISC, the maximum allowable stress (all, all) is a reduced value of the

yield strength:

Tension: 0.45 S y all 0.6 S y

Shear: all 0.4 S y

Bending: 0.6 S y all 0.75 S y

Bearing: all 0.9 S y

Design Factor and Factor of Safety

A design factor is used to:

Account for uncertainty (material properties, load variability, validity of

mathematical models, etc.).

Ensure safety.

𝐿𝑜𝑠𝑠 𝑜𝑓 𝑓𝑢𝑛𝑐𝑡𝑖𝑜𝑛 𝑙𝑜𝑎𝑑

By definition: 𝑛𝑑 =

𝑀𝑎𝑥𝑖𝑚𝑢𝑚 𝑙𝑎𝑜𝑑

Example: The maximum load on a structure is known with an uncertainty of ±20%,

and the load causing failure is known with an uncertainty of ±15%. Find the value of

the design factor to account for the uncertainty.

Solution:

1 + 0.2 1 - 0.15

Critical situation when: Load is maximum & Loss-of-function load is minimum

0.85

0.708 To make them equal, we take the inverse

1.2

1

nd 1.41

0.708

Using the stress notation, the design factor is defined as:

𝑆𝑡𝑟𝑒𝑛𝑔𝑡ℎ

𝑛𝑑 =

𝑆𝑡𝑟𝑒𝑠𝑠

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 2 of 15

However, when the load is not linearly related to stress, the design factor can be

defined as:

2

Strength

nd for cylinders in contact

Stress

3

Strength

nd for spheres in contact

Stress

The factor of safety (𝑛𝑠 ) has the same definition as the design factor, but it is

numerically different due to the rounding (usually up) caused by using standard sizes.

Reliability

Reliability of a component is the probability that the component will not fail during

use (i.e., the probability of survival).

The reliability (R) can be expressed numerically in the range: 0 ≤ R < 1

If R = 0.9, it means that there is a chance of 90% that the component will

perform its function without failure.

4

If 4 parts fail out of each 1000, then the reliability is: R 1 0.996

1000

In the reliability method of design, the distributions of stresses and strengths need to

be known. Then the designer makes the design decisions in order to meet a reliability

goal.

Statistical Considerations (CH 20 - 9th Ed.)

Statistics provide the designer with a method for dealing with characteristics whose

values are variable (such as life of a product).

Random Variables

The total number of elements (or the entire group of anything) is called the

population, while a sample is a part of the population.

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 3 of 15

When studying the mechanical properties and the characteristics of mechanical

elements, we cannot study the entire population, thus we have to take a sample.

A sample chosen randomly out of a large population is called a random sample.

Consider that we choose a random sample of steel pieces (say 20), out of a truck load

of pieces, and use those to make tensile-test specimens and test them for ultimate

strength. Such experiment is called a random experiment and the outcome of the

random experiment (the ultimate strength in this case) is called a random variable.

There are two types of random variables:

- Discrete random variable (can take discrete values only, such as when tossing

a die)

- Continuous random variable (can take any value, such as the ultimate strength

of a specimen)

When two dice are tossed (knowing that each can display any number from 1 to 6),

there are 36 possible outcomes. Thus the probability of each outcome is 1/36.

If we define a random variable 𝑥 as the sum of the numbers obtained on

the two dice, the probability of any value of 𝑥, termed as 𝑝 = 𝑓(𝑥), is

obtained by summing the probabilities of individual events.

For example 𝑥 = 4 can be obtained from: (2, 2), (1, 3) & (3, 1); therefore

𝑓(4) = 3/36

The function 𝑓(𝑥) is usually called the probability or frequency function.

If we plot the frequency function 𝑝 = 𝑓(𝑥)

against 𝑥, we obtain the frequency

distribution diagram which is usually called

the Histogram.

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 4 of 15

The probability that 𝑥 is less than or equal to a certain value 𝑥𝑖 is called the

Cumulative probability, and it is obtained by summing the probabilities of all 𝑥’s up

to and including 𝑥𝑖 .

𝐹(𝑥𝑖 ) = ∑ 𝑓(𝑥𝑗 )

𝑥𝑗 ≤𝑥𝑖

Example:

1 2 3 6

The probability that 𝑥 ≤ 4 is: 𝐹(4) = 𝑓(2) + 𝑓(3) + 𝑓(4) = + + =

36 36 36 36

For continuous random variables, the probability of obtaining

an observation less than or equal to a certain value is found as:

𝑥

𝐹(𝑥) = ∫−∞ 𝑓(𝑥) 𝑑𝑥

Median, Mean, Variance and Standard Deviation

The Median is the middle element among a group of elements listed in an increasing

(or decreasing) order.

Example: 10, 13, 14, 18, 20, 25, 26 Median = 18

Note: median is not affected by out-layers.

The Mean (average) of a sample consisting of 𝑁 elements is defined as:

𝑁

𝑥1 + 𝑥2 + 𝑥3 + ⋯ + 𝑥𝑁 1

𝑥̅ = = ∑ 𝑥𝑖

𝑁 𝑁

𝑖=1

Note: - Median and mean should have reasonably close values (unless

the data has some irregular distribution).

- The mean is sensitive to out-layers.

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 5 of 15

Besides the mean, we need another kind of measure to tell us about the spread of

the data.

The variation of an observation 𝑥𝑖 from the mean is (𝑥𝑖 − 𝑥̅ ); however, if we

sum the variations of all observations we get zero. Thus, we square them.

This is defined as the Sample Variance

𝑁

2

(𝑥1 − 𝑥̅ )2 + (𝑥2 − 𝑥̅ )2 + ⋯ + (𝑥𝑁 − 𝑥̅ )2 1

𝑆𝑥 = = ∑(𝑥𝑖 − 𝑥̅ )2

𝑁−1 𝑁−1

𝑖=1

The square root of the variance is called the Standard Deviation

𝑁

1 (∑𝑁 2

𝑖=1 𝑥𝑖 ) − 𝑁𝑥̅

2 Easier for

𝑆𝑥 = √ 2

∑(𝑥𝑖 − 𝑥̅ ) = √

𝑁−1 𝑁−1 calculation

𝑖=1

Note: - (𝑁 − 1) is used rather than (𝑁) because it gives better estimate

of the variance especially when the sample size is small.

- When dealing with the entire population, the mean and standard

deviation are found using the same equation, but (𝑁) is used

instead of (𝑁 − 1) in the standard deviation equation. Also, 𝑥̅

and 𝑆𝑥 are replaced with 𝜇𝑥 and 𝜎̂𝑥 .

For continuous variables, the distribution is obtained by plotting a discrete frequency

histogram.

- The data is divided into ranges

or classes and plotted against

the frequency (the number of

occurrences within each class)

For example, the ultimate strengths

of a number of samples are plotted

as:

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 6 of 15

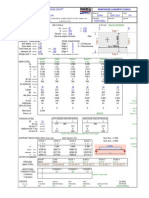

Example: Nine rods were chosen randomly out of a truck load

of 1030 hot-rolled steel rods. The rods were machined into

standard tensile-test specimens and tested for ultimate

strength. The ultimate strength values obtained from the

tests are given in the table in an increasing order.

a) Median

b) Mean

c) Standard deviation

d) Plot the histogram of the data with a class

width of 3 and the first class centered at 62 ksi

Solution:

a) Median = 68.1 𝑘𝑠𝑖

1 1

b) Mean: 𝑥̅ = ∑𝑁 𝑥 = (611.8) = 67.98 𝑘𝑠𝑖

𝑁 𝑖=1 𝑖 9

c) Standard deviation:

(∑𝑁 2

𝑖=1 𝑥𝑖 ) − 𝑁𝑥̅

2 41689 − 9 (67.98)2

𝑆𝑥 = √ =√ = 3.54 𝑘𝑠𝑖

𝑁−1 8

d)

Probability Distributions

There are a number of standard discrete and continuous probability distributions that

are applicable to engineering problems.

The most important continuous distributions are:

- The Gaussian (or normal) distribution

- The Lognormal distribution

- The Uniform distribution

- The Weibull distribution

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 7 of 15

The Gaussian (Normal) Distribution

The normal distribution is symmetrical, bell-shaped, and is centered at the mean (𝜇𝑥 ).

The probability density function is expressed in terms of the mean (𝜇𝑥 ) and standard

deviation (𝜎̂𝑥 ) as:

1 1 𝑥 − 𝜇𝑥

𝑓(𝑥) = 𝑒𝑥𝑝 [− ( )]

𝜎̂𝑥 √2𝜋 2 𝜎̂𝑥

Same as for all distribution curves, the total area under the curve (total

probability) is equal to one.

The curve gets taller and

narrower for small values of

𝜎̂𝑥 , and gets shorter and

wider for large 𝜎̂𝑥

For a normally distributed random variable:

* 68% of the data is bounded between 𝜇𝑥 − 𝜎̂𝑥 and 𝜇𝑥 + 𝜎̂𝑥

* 95% of the data is bounded between 𝜇𝑥 − 2𝜎̂𝑥 and 𝜇𝑥 + 2𝜎̂𝑥

* 99.7% of the data is bounded between 𝜇𝑥 − 3𝜎̂𝑥 and 𝜇𝑥 + 3𝜎̂𝑥

The normal distribution is usually applicable to sizes and dimensions.

The Lognormal Distribution

If a random variable have the following two characteristics;

- The distribution is asymmetrical about the mean

- The variables have only positive values

Then, the distribution could be lognormal.

The distribution is called lognormal because the logarithms of the variable have a

normal distribution.

The lognormal distribution is applicable to things as fatigue life.

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 8 of 15

The Uniform Distribution

The uniform distribution is a closed interval distribution where the chance of an

observation is the same as that of any other observation.

The probability density function is given as:

1⁄(𝑏 − 𝑎) 𝑎≤𝑥≤𝑏

𝑓(𝑥) =

0 𝑥 < 𝑎 ,𝑥 > 𝑏

This distribution is applicable to the dimensions of parts manufactured in mass-

quantities using an automated operation, where the size gradually increases due to

tool wear.

The Weibull Distribution

The Weibull distribution is a non-classical distribution and it is especially applicable

to experimental results (life of rolling-contact bearings for example).

The Weibull is a three parameter distribution that can take many different shapes.

The probability density function is expressed as:

𝑏 𝑥−𝑥0 𝑏−1 𝑥−𝑥0 𝑏

( ) 𝑒𝑥𝑝 [− ( ) ] 𝑥 ≥ 𝑥0 ≥ 0

𝜃−𝑥0 𝜃−𝑥0 𝜃−𝑥0

𝑓(𝑥) =

0 𝑥 < 𝑥0

The three parameters are:

𝑥0 : minimum guaranteed value of 𝑥

𝑏 : shape parameter (𝑏 > 1)

𝜃 : scale value (𝜃 ≥ 𝑥0 )

*63.2% of the observations are smaller than 𝜃 *

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 9 of 15

To find the Reliability of any given 𝑥 value; knowing that the reliability is the

complement of the cumulative probability 𝑅(𝑥) = 1 − 𝐹(𝑥)

𝑥−𝑥0 𝑏

The reliability at any

Thus, 𝑅(𝑥) = 𝑒𝑥𝑝 [− ( ) ] 𝑥 ≥ 𝑥0 ≥ 0 given value of 𝑥

𝜃−𝑥0

- If a specific required reliability is given, solving for 𝑥 gives:

1⁄

1 𝑏 Value of 𝑥 at

𝑥 = 𝑥0 + (𝜃 − 𝑥0 ) [ln ]

𝑅 certain reliability

The mean and standard deviation for the Weibull distribution are given by:

𝜇𝑥 = 𝑥0 + (𝜃 − 𝑥0 ) Γ(1 + 1⁄b)

𝜎̂𝑥 = (𝜃 − 𝑥0 ) √Γ(1 + 2⁄b) − Γ 2 (1 + 1⁄b)

Where Γ is called the "Gama function", and its value is found from Table A-34

Table A-25 gives the Weibull parameters for yield & ultimate strengths for some

metallic alloys (in kPsi units).

Example: If the life of rolling-contact bearings (under a fixed radial load) follows a

Weibull distribution having the parameters (𝑥0 = 0.02, 𝜃 = 4.459, 𝑏 = 1.483)

where the unit of 𝑥 (life) is one million revolution.

Find:

a) Life at a reliability of 𝑅 = 0.9

b) Life at a reliability of 𝑅 = 0.1

c) The median life

d) The average (mean) life

e) The reliability that a bearing will survive five million revolutions

Solution:

1⁄

1 𝑏 90% of bearings

a) 𝐿 = 𝑥 = 𝑥0 + (𝜃 − 𝑥0 ) [ln ]

𝑅 will live this long

1⁄

1 1.483

𝐿(𝑅 = 0.9) = 0.02 + (4.459 − 0.02) [ln ] = 1 × 106 𝑟𝑒𝑣.

0.9

1⁄

1 1.483

b) 𝐿(𝑅 = 0.1) = 0.02 + (4.459 − 0.02) [ln ] = 7.81 × 106 𝑟𝑒𝑣.

0.1

10% of bearings

will live this long

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 10 of 15

c) Median life means 𝑅 = 0.5

1⁄

1 1.483

𝐿(𝑅 = 0.5) = 0.02 + (4.459 − 0.02) [ln ] = 3.49 × 106 𝑟𝑒𝑣.

0.5

d) 𝜇𝑥 = 𝑥0 + (𝜃 − 𝑥0 ) Γ(1 + 1⁄b)

→ 𝜇𝑥 = 0.02 + (4.459 − 0.02) Γ(1 + 1⁄1.483) = 4.03 × 106 𝑟𝑒𝑣.

from Table A-34

𝑥−𝑥0 𝑏

e) 𝑅(𝑥) = 𝑒𝑥𝑝 [− ( ) ]

𝜃−𝑥0

5−0.02 1.483

𝑅(𝐿 = 5) = 𝑒𝑥𝑝 [− ( ) ] = 0.33

4.459−0.02

Dimensions and Tolerances (Sec. 1 - 14)

Tolerance is the maximum allowable variation in the size of a part.

- Nominal size: the size we use in speaking of an element.

- Basic size: the exact desired theoretical size.

There are two ways for specifying tolerance:

Bilateral tolerance: the variation in both directions from the basic size.

Example: 100 ± 0.2 𝑚𝑚

Basic size Limits

- Usually used for parts that fit besides each other

Unilateral tolerance: the basic size is taken as one of the limits and the variation

is only in one direction.

Example: 40+0

−0.1 𝑚𝑚 𝑜𝑟 40+0.1

−0 𝑚𝑚

Basic size Limits

- Usually used for parts that fit inside each other

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 11 of 15

Why do we specify a tolerance?

Because parts cannot be manufactured at exact sizes, so we specify the

acceptable range of variation.

The tighter the tolerances, the higher the cost.

Variations in dimensions of manufactured parts occur at random (usually they

follow a normal distribution).

When several parts are assembled, the gap (or

interference) depends on both the dimensions and

tolerances of the individual parts.

Consider the shown assembly:

𝐺𝑎𝑝 = 𝑎 − 𝑏 + 𝑐 − 𝑑 + 𝑒 − 𝑓

Using 𝑥 for ( → ) and 𝑦 for ( ← ) we can write;

𝑤 = (𝑥1 + 𝑥2 + ⋯ ) − (𝑦1 + 𝑦2 + ⋯ )

𝑤 = ∑ 𝑥𝑖 − ∑ 𝑦𝑗

- The largest gap 𝑤𝑚𝑎𝑥 occurs when the 𝑥 values are the largest possible & the

𝑦 values are the smallest possible.

If we call the bilateral tolerance as “ ” we get,

𝑤𝑚𝑎𝑥 = ∑(𝑥𝑖 + 𝑡𝑖 ) − ∑(𝑦𝑗 − 𝑡𝑗 ) = ∑ 𝑥𝑖 − ∑ 𝑦𝑗 + ∑𝑎𝑙𝑙 𝑡

- The smallest gap 𝑤𝑚𝑖𝑛 occurs when the 𝑥 values are the smallest possible &

the 𝑦 values are the largest possible.

𝑤𝑚𝑖𝑛 = ∑(𝑥𝑖 − 𝑡𝑖 ) − ∑(𝑦𝑗 + 𝑡𝑗 ) = ∑ 𝑥𝑖 − ∑ 𝑦𝑗 − ∑𝑎𝑙𝑙 𝑡

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 12 of 15

Example: Find the maximum and minimum gap then give

the size of the gap using bilateral tolerance.

𝑎 = 500 ± 1 𝑚𝑚

𝑏 = 200 ± 0.4 𝑚𝑚

𝑐 = 150 ± 0.1 𝑚𝑚

Solution:

𝑤𝑚𝑎𝑥 = 500 − 200 − 150 + (1 + 0.4 + 0.1) = 151.5 𝑚𝑚

𝑤𝑚𝑖𝑛 = 500 − 200 − 150 − (1 + 0.4 + 0.1) = 148.5 𝑚𝑚

𝑤 = 150 ± 1.5 𝑚𝑚

Limits & Fits (Sec. 7 - 8)

When a shaft or pin needs to be inserted into a hole, the type of fit is decided based

on the intended application.

- For example, if the shaft and the hole are to make a pin-joint or a journal

bearing, then a clearance fit is needed to allow the shaft to rotate inside the

hole.

- Another example, when the shaft is inserted into a rolling-contact bearing, an

interference fit is used to prevent any slipping between the shaft and the inner-

ring of the bearing.

Limits and fits are standardized. Here we will use the ANSI metric standard.

- Capital letters refer to the hole and lower case letters refer to the shaft.

- The Basic size (or nominal size) is the size to which limits are assigned and it is

the same for both members of the fit.

There are two methods for assigning the fits:

- Hole Basis: the size of the hole is kept unchanged and the different fits are

obtained by varying the size of the shaft.

- Shaft Basis: the size of the shaft is kept unchanged and the different fits are

obtained by varying the size of the hole.

Hole Basis is more commonly used, Why?

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 13 of 15

The ANSI preferred fits are:

Type of Fit Sub-type ISO symbol

(Hole Basis)

Lose running fit H11/c11

Free running fit H9/d9

Clearance Close running fit H8/f7

Sliding fit Full descriptions

H7/g6

for each type are

Locational clearance fit H7/h6 given in Table 7-9

in the text

Transition Locational transition fit H7/k6, H7/n6

Locational interference fit H7/p6

Interference Medium drive fit H7/s6

Force fit H7/u6

Once the fit is decided according to the intended use, the fit is described by the basic

size and the fit symbol.

Example: A joint with basic size of 40 mm having a sliding fit 40 H7/g6

The hole 40 H 7 International tolerance

The shaft 40 g 6 grade number (IT#)

Fundamental deviation

The maximum and minimum diameters for the hole and shaft are found as follows:

Hole: 𝐷𝑚𝑎𝑥 = 𝐷 + ∆𝐷 & 𝐷𝑚𝑖𝑛 = 𝐷

Shaft:

- For clearance fits: c, d, f, g, & h

𝑑𝑚𝑎𝑥 = 𝑑 + 𝛿𝐹 & 𝑑𝑚𝑖𝑛 = 𝑑 + 𝛿𝐹 − ∆𝑑

- For interference fits: k, n, p, s, & u

𝑑𝑚𝑎𝑥 = 𝑑 + 𝛿𝐹 + ∆𝑑 & 𝑑𝑚𝑖𝑛 = 𝑑 + 𝛿𝐹

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 14 of 15

Where,

𝐷 : basic size of the hole the same

𝑑 : basic size of the shaft

found from Table A-12 according

𝛿𝐹 : fundamental deviation to the fundamental deviation letter

∆𝐷: tolerance grade for the hole

found from Table A-11

∆𝑑: tolerance grade for the shaft according to the IT#

Example: Find the shaft and hole dimensions for a sliding fit with 25mm basic size,

then specify the dimensions of both elements using unilateral tolerance.

Solution:

ISO symbol: 25 H7/g6

Hole: 25 H 7 𝐷 = 25

IT 7 (from Table A-11) ∆𝐷 = 0.021

𝐷𝑚𝑎𝑥 = 𝐷 + ∆𝐷 = 25.021 𝑚𝑚

𝐷𝑚𝑖𝑛 = 𝐷 = 25 𝑚𝑚

Shaft: 25 g 6 𝑑 = 25

IT 6: (from Table A-11) ∆𝑑 = 0.013

(from Table A-12) 𝛿𝐹 = −0.007

𝑑𝑚𝑎𝑥 = 𝑑 + 𝛿𝐹 = 25 + (−0.007) = 24.993 𝑚𝑚

Sliding fit: g

𝑑𝑚𝑖𝑛 = 𝑑 + 𝛿𝐹 − ∆𝑑 = 25 + (−0.007) − 0.013 = 24.98 𝑚𝑚

Hole: 25+0.021

−0 𝑚𝑚

Shaft: 24.993+0

−0.013 𝑚𝑚

Shigley’s Mechanical Engineering Design, 10th Ed. Class Notes by: Dr. Ala Hijazi

CH 1 – Introduction (R2) Page 15 of 15

You might also like

- CMPE 287&187 Homework 1 Spring 2012Document3 pagesCMPE 287&187 Homework 1 Spring 2012whoisnullNo ratings yet

- A Neo-Riemannian Approach To Jazz AnalysisDocument33 pagesA Neo-Riemannian Approach To Jazz AnalysisBrook Brooke100% (1)

- Distance Time Velocity SemDocument12 pagesDistance Time Velocity SemFernando Gonzalez0% (2)

- CH 1-IntroductionDocument15 pagesCH 1-IntroductionOmar AbdullahNo ratings yet

- MEE 3001 Design of Machine Element (Module 1 Introduction To Design Process)Document40 pagesMEE 3001 Design of Machine Element (Module 1 Introduction To Design Process)Ponnam KarthikNo ratings yet

- An Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingDocument11 pagesAn Investigation of The Effect of Shot Peening On The Properties of Lm25 Aluminium Alloy and Statistical ModellingInternational Journal of computational Engineering research (IJCER)No ratings yet

- Ch2 Basic StatisticDocument46 pagesCh2 Basic StatisticNget KhitNo ratings yet

- 19 Robust Design, Sensitivity Analysis, and Tolerance SettingDocument13 pages19 Robust Design, Sensitivity Analysis, and Tolerance SettingrogeriojuruaiaNo ratings yet

- DataminingDocument16 pagesDataminingPinky InsaNo ratings yet

- CH 5Document10 pagesCH 5Ala HijaziNo ratings yet

- Probabilistic Safety Factor For The Weibull Distribution (05!04!2019) FinalDocument8 pagesProbabilistic Safety Factor For The Weibull Distribution (05!04!2019) Finalbaro4518No ratings yet

- Applied Statistics II-SLRDocument23 pagesApplied Statistics II-SLRMagnifico FangaWoro100% (1)

- 9 15Document7 pages9 15IWNESTNo ratings yet

- Univariate and Bivariate Data Analysis + ProbabilityDocument5 pagesUnivariate and Bivariate Data Analysis + ProbabilityBasoko_Leaks100% (1)

- Reliability Analysis of Hydraulic FractureingDocument13 pagesReliability Analysis of Hydraulic FractureingVasav DubeyNo ratings yet

- Tutorial On Probability Concepts For Power EngineeringDocument24 pagesTutorial On Probability Concepts For Power Engineeringمحمد سلامNo ratings yet

- Harimanojsimha2020-A Note On A Plastic Work-Based Parameter For Correlating Constraint and ToughnessDocument9 pagesHarimanojsimha2020-A Note On A Plastic Work-Based Parameter For Correlating Constraint and ToughnessP. R. SREENIVASANNo ratings yet

- KD6031 2023 Generalised Model Section 2 (Wk3)Document27 pagesKD6031 2023 Generalised Model Section 2 (Wk3)mohamed redaNo ratings yet

- Dinh 2021Document45 pagesDinh 2021Gabriel CorrêaNo ratings yet

- CH 3Document29 pagesCH 3Ala HijaziNo ratings yet

- Lecture 2 - Tension Members - Part 1Document10 pagesLecture 2 - Tension Members - Part 1Dad MeNo ratings yet

- 1029 4777 1 PBDocument15 pages1029 4777 1 PBNguyen Tran HieuNo ratings yet

- Ductile Fracture SimulationDocument6 pagesDuctile Fracture SimulationPunit ShresthaNo ratings yet

- Prediction of Behavior From The Past Data Well-Understood ProcessesDocument23 pagesPrediction of Behavior From The Past Data Well-Understood ProcessesAshish George RoyNo ratings yet

- Basic Concepts of Inference: Corresponds To Chapter 6 of Tamhane and DunlopDocument40 pagesBasic Concepts of Inference: Corresponds To Chapter 6 of Tamhane and Dunlopakirank1No ratings yet

- SD 666 Home Work01Document9 pagesSD 666 Home Work01simon maaaklaNo ratings yet

- 1 s2.0 S0888327021005847 MainDocument19 pages1 s2.0 S0888327021005847 Mainranim najibNo ratings yet

- ESci132 Module 1.2Document16 pagesESci132 Module 1.2bbyybeasttNo ratings yet

- Validation of Stresses With Numerical Method and Analytical MethodDocument12 pagesValidation of Stresses With Numerical Method and Analytical MethodOMUNG GARG 14BME0154No ratings yet

- Shigley's SLecture Notes - Chapter 1-20-2Document68 pagesShigley's SLecture Notes - Chapter 1-20-2huyev2000No ratings yet

- WQU - Econometrics - Module2 - Compiled ContentDocument73 pagesWQU - Econometrics - Module2 - Compiled ContentYumiko Huang100% (1)

- WQU Econometrics M3 Compiled Content PDFDocument44 pagesWQU Econometrics M3 Compiled Content PDFNarayani PandeyNo ratings yet

- Logrank Tests in A Cluster-Randomized DesignDocument8 pagesLogrank Tests in A Cluster-Randomized DesignscjofyWFawlroa2r06YFVabfbajNo ratings yet

- CH 3 PDFDocument30 pagesCH 3 PDFsalahuddin khanNo ratings yet

- CH 3Document30 pagesCH 3dhanya1995No ratings yet

- 1 s2.0 S0898122110001951 Main PDFDocument5 pages1 s2.0 S0898122110001951 Main PDFSantiago UrgilesNo ratings yet

- Chapter 11Document35 pagesChapter 11derbew2112No ratings yet

- Mechanical Behaviour of MaterialsDocument48 pagesMechanical Behaviour of Materialsedua777ytNo ratings yet

- ASD Lab ScaleUpDocument13 pagesASD Lab ScaleUpwhyareugayNo ratings yet

- LKNLBK 4 TNNDocument19 pagesLKNLBK 4 TNNbilkheer driveNo ratings yet

- The Foundations of Logic and Proof in Discrete MathematicsDocument38 pagesThe Foundations of Logic and Proof in Discrete MathematicsAlFayedArnobNo ratings yet

- VanPaepegem 2003 Composites Science TechnologyDocument13 pagesVanPaepegem 2003 Composites Science TechnologymiladNo ratings yet

- UTM - Lab ReportDocument5 pagesUTM - Lab Reportshubhradiproy2003No ratings yet

- Linearization SsDocument29 pagesLinearization SsMY PRACTICENo ratings yet

- CAE TheoryDocument30 pagesCAE TheorySuhas ShindeNo ratings yet

- 1.stress and Strain BasicsDocument14 pages1.stress and Strain BasicsAmr El SaeedNo ratings yet

- Mane-4040 Mechanical Systems Laboratory (MSL) Lab Report Cover SheetDocument13 pagesMane-4040 Mechanical Systems Laboratory (MSL) Lab Report Cover Sheetjack ryanNo ratings yet

- Gkab255 Supplemental FileDocument29 pagesGkab255 Supplemental FileSharanappa ANo ratings yet

- Week 3Document2 pagesWeek 3Nisal KarunathilakeNo ratings yet

- Unit 5Document104 pagesUnit 5downloadjain123No ratings yet

- Regression and Multiple Regression AnalysisDocument21 pagesRegression and Multiple Regression AnalysisRaghu NayakNo ratings yet

- ABE 463 Main-2Document41 pagesABE 463 Main-2Taiwo SubairNo ratings yet

- Statistics Concepts: An Overview of Upper-Division Statistics With RDocument69 pagesStatistics Concepts: An Overview of Upper-Division Statistics With RmukeshNo ratings yet

- Data Analysis ExamDocument9 pagesData Analysis Examayushi sarafNo ratings yet

- Reliability Design Based On Dynamic Factorial Experimental ModelDocument7 pagesReliability Design Based On Dynamic Factorial Experimental ModelnaturaretNo ratings yet

- Formula SheetDocument7 pagesFormula SheetMohit RakyanNo ratings yet

- Metal FormingDocument18 pagesMetal FormingMohamed AbdelrazekNo ratings yet

- Slope Stability Back Analysis Methods Using Rocscience SoftwareDocument10 pagesSlope Stability Back Analysis Methods Using Rocscience SoftwareMiguel CadenaNo ratings yet

- Finite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaFrom EverandFinite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaNo ratings yet

- Pointers To Review Jhs Grade 8Document2 pagesPointers To Review Jhs Grade 8Maria Jocosa33% (3)

- Naca 3615Document5 pagesNaca 3615Adib GaniNo ratings yet

- Iti Interview QesDocument3 pagesIti Interview QesMahmoud AbdallahNo ratings yet

- 1-RC DesignDocument4 pages1-RC DesignOSCARTAWNNo ratings yet

- 1 PDFDocument6 pages1 PDFMohamed MansourNo ratings yet

- 3613 s05 PDFDocument8 pages3613 s05 PDFBabasrinivas GuduruNo ratings yet

- BEE4413 Digital Signal ProcessingDocument3 pagesBEE4413 Digital Signal Processingdinie90No ratings yet

- Chapter 2 Quadratic FunctionsDocument2 pagesChapter 2 Quadratic FunctionsWan HasliraNo ratings yet

- MOT 1 JEE 2022 Paper VMC PDFDocument10 pagesMOT 1 JEE 2022 Paper VMC PDFBiswadeep GiriNo ratings yet

- Attachment DSummary Sheet - Time Value of Money PDFDocument12 pagesAttachment DSummary Sheet - Time Value of Money PDFUnmesh MitraNo ratings yet

- Decision-Making Under Risk and Uncertainty: OutcomesDocument21 pagesDecision-Making Under Risk and Uncertainty: OutcomesprabodhNo ratings yet

- Creating Lithology Plan-View MapsDocument4 pagesCreating Lithology Plan-View MapsRenda RachmanNo ratings yet

- FIELD STUDY 2 Learning Episode 2: Embedding Action Research For Reflective TeachingDocument4 pagesFIELD STUDY 2 Learning Episode 2: Embedding Action Research For Reflective Teachingshenna100% (1)

- EppDM5eMetric 10 04Document31 pagesEppDM5eMetric 10 04Hitesh NaikNo ratings yet

- Unit Plan Inclined PlaneDocument67 pagesUnit Plan Inclined Planeapi-232523393No ratings yet

- Lab Manual 02Document5 pagesLab Manual 02Muhammad AmirNo ratings yet

- Electrical Power Systems - C. L. WadhwaDocument120 pagesElectrical Power Systems - C. L. WadhwaMayank Rawal0% (1)

- The Mathematics of FinanceDocument30 pagesThe Mathematics of FinancezahidacaNo ratings yet

- RF Power Amplifier FundamentalsDocument36 pagesRF Power Amplifier Fundamentalsi_spyder5388100% (1)

- Cape Pure Mathematics Unit 1Document32 pagesCape Pure Mathematics Unit 1kesna50% (2)

- Two-Layer Obstacle Collision Avoidance With Machine Learning For More Energy-Efficient Unmanned Aircraft TrajectoriesDocument16 pagesTwo-Layer Obstacle Collision Avoidance With Machine Learning For More Energy-Efficient Unmanned Aircraft TrajectoriesMarcelo RodriguesNo ratings yet

- University of Ghana (2nd Semester 2016/2017) Final ExamsDocument40 pagesUniversity of Ghana (2nd Semester 2016/2017) Final ExamsKwabena A. KoomsonNo ratings yet

- 2022 Prediction of Blasting Induced Air-Overpressure Using A Radial Basis Function Network With An Additional Hidden LayerDocument14 pages2022 Prediction of Blasting Induced Air-Overpressure Using A Radial Basis Function Network With An Additional Hidden Layer周牮No ratings yet

- Summary of TransformationsDocument1 pageSummary of TransformationsNgonidzashe ChirevaNo ratings yet

- Name: Teacher: Date: Score:: Properties of EllipsesDocument2 pagesName: Teacher: Date: Score:: Properties of EllipsesBEAL1519No ratings yet

- Counting and Patterns 1. Counting by Twos: M7 Class 6 NotesDocument6 pagesCounting and Patterns 1. Counting by Twos: M7 Class 6 NotesnaNo ratings yet