Professional Documents

Culture Documents

Pump Seal - 1

Pump Seal - 1

Uploaded by

kapsarcCopyright:

Available Formats

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Used Cars in Saudi Arabia (EDA)Document33 pagesUsed Cars in Saudi Arabia (EDA)Abokhaled AL-ashmawiNo ratings yet

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- Manual Elevador 2 Columnas XG-3Document31 pagesManual Elevador 2 Columnas XG-3Juan SandyNo ratings yet

- NGK Catalogue 2013 14 LRDocument208 pagesNGK Catalogue 2013 14 LRjonathan220185No ratings yet

- Pages From API Standard 610 Centrifugal PumpsDocument1 pagePages From API Standard 610 Centrifugal PumpsAgustin A.100% (1)

- Pipe StrainDocument5 pagesPipe StrainJack WeaverNo ratings yet

- Pump Installation, Operation and MaintenanceDocument25 pagesPump Installation, Operation and Maintenancebayu kusumaNo ratings yet

- Centrifugal Pump API 686 Key RecommendationsDocument1 pageCentrifugal Pump API 686 Key RecommendationsAniekanNo ratings yet

- Commercial Pumps: Series 4030 Starnorm Base Mounted PumpsDocument8 pagesCommercial Pumps: Series 4030 Starnorm Base Mounted PumpsAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Commercial Pumps: Installation and Operating InstructionsDocument8 pagesCommercial Pumps: Installation and Operating InstructionsrakeshamechNo ratings yet

- Specifications Standards For Shafts Alignment PDFDocument18 pagesSpecifications Standards For Shafts Alignment PDFDelfinshNo ratings yet

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Document20 pagesVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNo ratings yet

- Industrial-Gutters-Installation-Instructions_all-modelsDocument12 pagesIndustrial-Gutters-Installation-Instructions_all-modelseNo ratings yet

- MHICA Axial SwageDocument42 pagesMHICA Axial SwageSwampfootNo ratings yet

- Control Unit InstructionsDocument1 pageControl Unit Instructionsmanoj_sitecNo ratings yet

- NEWCopy of Std's and SpecificationDocument90 pagesNEWCopy of Std's and SpecificationMichael Robinson100% (1)

- PDF 44201222333PMKPDSDocument63 pagesPDF 44201222333PMKPDSAnbarasan NagarajanNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Document24 pagesSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaNo ratings yet

- Chapter (4) Pump InstallationDocument21 pagesChapter (4) Pump Installationkarioke mohaNo ratings yet

- Sno 20010Document13 pagesSno 20010Alexander SharamiginNo ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- Technical Data Sheet & Part ListDocument24 pagesTechnical Data Sheet & Part ListM Farid Fakhrudduja100% (1)

- Technical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Document11 pagesTechnical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Naushad WadiaNo ratings yet

- HammerDocument20 pagesHammerdatnguyen789jNo ratings yet

- Pile Driving Guidelines: EquipmentDocument5 pagesPile Driving Guidelines: EquipmentSean CrossNo ratings yet

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengNo ratings yet

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- VO Model O & M ManualDocument17 pagesVO Model O & M ManualJigyesh SharmaNo ratings yet

- Power Tools: Operating and Maintenance InstructionsDocument16 pagesPower Tools: Operating and Maintenance InstructionsBill WidmerNo ratings yet

- Installation Guide Reciprocating Gas Compressors 1665249059Document21 pagesInstallation Guide Reciprocating Gas Compressors 1665249059ahmed meselhyNo ratings yet

- NuFlo EZ-In User Manual - PEDDocument32 pagesNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Industrial and General Purpose: Owners ManualDocument22 pagesIndustrial and General Purpose: Owners ManualoscarpabaNo ratings yet

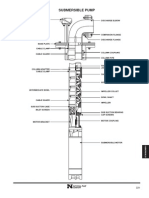

- Pumps: Suggested Specifications Submersible Sump Pump Type SMDocument4 pagesPumps: Suggested Specifications Submersible Sump Pump Type SMloveanbu24No ratings yet

- Cornell Vertical Close Coupled Solids Handling Pumps: (Choose)Document2 pagesCornell Vertical Close Coupled Solids Handling Pumps: (Choose)Alejandra Vega AvilezNo ratings yet

- ENTS 400 Rev5Document62 pagesENTS 400 Rev5Scherjeal Jangda100% (1)

- 2300 Series ManualDocument24 pages2300 Series ManualJuprayNo ratings yet

- ARI SpecDocument4 pagesARI SpecLinggar Setiawan NNo ratings yet

- Flo Fab Under Base Bid. Equivalent Units May Be Submitted As DeductDocument6 pagesFlo Fab Under Base Bid. Equivalent Units May Be Submitted As DeducttexmoNo ratings yet

- Acson AHU O&M ManualDocument13 pagesAcson AHU O&M ManualKamran AhmedNo ratings yet

- Trim Tab Installation InstructionsDocument2 pagesTrim Tab Installation InstructionsPaul CharltonNo ratings yet

- MR Num4-EnDocument14 pagesMR Num4-EnaminardakaniNo ratings yet

- Equipment LayoutDocument25 pagesEquipment LayoutCalNo ratings yet

- Manual Mtto Roper 3600HBDocument43 pagesManual Mtto Roper 3600HBjairoNo ratings yet

- Manual Bomba RoperDocument43 pagesManual Bomba RoperFranco Alejandro Olivares Alvarez100% (2)

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- Auger Boring MethodologyDocument5 pagesAuger Boring MethodologyVipin GuptaNo ratings yet

- Double Suction Split Case PumpsDocument27 pagesDouble Suction Split Case Pumpsgbogboiwe100% (1)

- Erection and Commissioning Procedure PDFDocument94 pagesErection and Commissioning Procedure PDFShankar JhaNo ratings yet

- Weld Spec 2Document3 pagesWeld Spec 2spstainless316No ratings yet

- Sewers For Adoption - PUMPSDocument25 pagesSewers For Adoption - PUMPSatiNo ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- SpecificationsDocument3 pagesSpecificationsajeesh_petrocilNo ratings yet

- ER-56-03 EN Packager Standards Skid Design and FabricationDocument4 pagesER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNo ratings yet

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- Kpds AllmodelsDocument39 pagesKpds AllmodelsSumit ChaurasiaNo ratings yet

- SJ Petro LGF-500 Mud Pump Operation ManualDocument52 pagesSJ Petro LGF-500 Mud Pump Operation ManualSEAZONE EXIM100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Vehicle Presentation Volkswagen FOX: Waldemar SteuerDocument39 pagesVehicle Presentation Volkswagen FOX: Waldemar SteuerMihai MocanuNo ratings yet

- Manual de Partes Compresor SANDEMDocument25 pagesManual de Partes Compresor SANDEMLuis Panti EkNo ratings yet

- Abdul MajeedDocument6 pagesAbdul MajeedUmar AbdullahNo ratings yet

- D3.2 Part1 Guidelines Dependability Hazard AnalysisDocument340 pagesD3.2 Part1 Guidelines Dependability Hazard Analysisnchandu306No ratings yet

- Tata Staff Bus Range Brochure BSVI 6march20Document2 pagesTata Staff Bus Range Brochure BSVI 6march20annaji annajiNo ratings yet

- Tugas Bahasa Inggris Faris FIXDocument4 pagesTugas Bahasa Inggris Faris FIXFarisRizki RamadhaniNo ratings yet

- Window-Type Air Conditioner Unit and Split-Type AirconditionerDocument4 pagesWindow-Type Air Conditioner Unit and Split-Type AirconditionerTempwell company Naga BranchNo ratings yet

- Nettra Ultimate Negative Keyword ListDocument19 pagesNettra Ultimate Negative Keyword ListPercyRojasNo ratings yet

- BE YK EngineeringGuide HDocument86 pagesBE YK EngineeringGuide Hahmad ReshadNo ratings yet

- Inspection Report For NarmulDocument3 pagesInspection Report For NarmulmelakuNo ratings yet

- PTO-HN.11.MX06.H.ISO CatalogueDocument1 pagePTO-HN.11.MX06.H.ISO CatalogueBrion Bara IndonesiaNo ratings yet

- RPT Operation ManualDocument36 pagesRPT Operation ManualKiều Văn TrungNo ratings yet

- 06D Compressor 2020Document2 pages06D Compressor 2020Syarif HidayatullahNo ratings yet

- Chairless Chair For Improved Ergonomics in Audi's Production PlantsDocument3 pagesChairless Chair For Improved Ergonomics in Audi's Production PlantsDeepak ChaurasiaNo ratings yet

- Arriel 2DDocument2 pagesArriel 2DMUKESH CHAKRAWARTINo ratings yet

- Royal Enfield Classic 350 Spare Parts Price ListDocument2 pagesRoyal Enfield Classic 350 Spare Parts Price ListDKNo ratings yet

- 01 Clutch Construction and OperationDocument32 pages01 Clutch Construction and Operationdawit abebualNo ratings yet

- Ece Lab Manual - MiteDocument44 pagesEce Lab Manual - MiteSubuddhi DamodarNo ratings yet

- Tower Lamp Multi YanmarDocument4 pagesTower Lamp Multi YanmararifauliaNo ratings yet

- Brief Study On Failed Products or Branding Campaigns in MarketingDocument41 pagesBrief Study On Failed Products or Branding Campaigns in Marketingpratiush07100% (2)

- Parts List EUPOLO150 (JC150T)Document44 pagesParts List EUPOLO150 (JC150T)GARAGE PREMIUMNo ratings yet

- Navitas AC TAC2 Error Code and TroubleshootingDocument8 pagesNavitas AC TAC2 Error Code and Troubleshootingelectronics malayalamNo ratings yet

- Toyota and Subaru Agree On New Business and Capital AllianceDocument2 pagesToyota and Subaru Agree On New Business and Capital AllianceAlfredo MedinaNo ratings yet

- Asme B5.8-2001 (2017)Document32 pagesAsme B5.8-2001 (2017)윤규섭No ratings yet

- Guía de Lubricación de Motos GileraDocument7 pagesGuía de Lubricación de Motos GileraDamian alejandroNo ratings yet

- Ilnas-En 50604-1:2016Document9 pagesIlnas-En 50604-1:2016kishore msnNo ratings yet

- Seicane No 32 Android 8 0 Upgrade User Manual Replacement InstructionDocument22 pagesSeicane No 32 Android 8 0 Upgrade User Manual Replacement Instructiondjdeeablo100% (1)

- Forbes Middle East July 2020Document84 pagesForbes Middle East July 2020Mohsin KhanNo ratings yet

Pump Seal - 1

Pump Seal - 1

Uploaded by

kapsarcOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Seal - 1

Pump Seal - 1

Uploaded by

kapsarcCopyright:

Available Formats

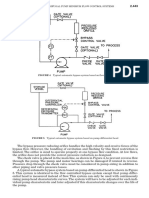

CENTRIFUGAL PUMPS FOR PETROLEUM, PETROCHEMICAL, AND NATURAL GAS INDUSTRIES 79

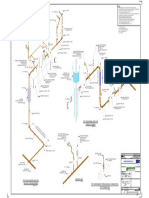

Baseplates for OH2 pumps shall have nothing (auxiliaries or seal flush plan) mounted beside or above

the coupling or bearing housing. If the seal flush plan and/or auxiliaries are specified to be mounted on the

baseplate, the increased length standard baseplate shall be used and the auxiliaries and/or seal flush plan

shall be mounted adjacent to the suction nozzle (see Figure 40).

Figure 40—Location for Seal Flush Plan or Auxiliaries Mounted on the Baseplate

The height of the pump-shaft centerline above the baseplate shall be minimized. Sufficient clearance

shall be provided between the casing drain connection and the baseplate for connecting piping by the

purchaser. For threaded drains, clearance shall allow the use of a nipple and elbow of the same size as the

connection. The use of a street (male-female) elbow is not allowed.

⚫ Mounting pads shall be provided for the pump and all drive-train components, such as motors and

gears. The pads shall be larger than the foot of the mounted equipment, including extra width of shims under

drive-train components, to allow levelling of the baseplate with a precision level, without removal of the

equipment. The minimum exposed area on the mounting pads for leveling purposes shall be 2 in. (50 mm) on

two sides of each foot. The pads shall be fully machined flat and parallel to each other. Corresponding surfaces

shall be in the same plane within 0.002 in./ft (150 µm/m) of distance between the pads.

If specified, the flatness requirement shall be demonstrated in the pump-vendor’s shop prior to mounting of

the equipment and with the baseplate supported at the foundation bolt holes only. This demonstration is to

be performed with the baseplate in the unclamped condition, after completion of machining.

NOTE Installed baseplate flatness can be affected by transportation, handling, and installation procedures beyond the

vendor’s scope. For information, see API 686.

⚫ Unless otherwise specified, pumps shall be mounted directly on mounting pads of the baseplate

without shims. Shims shall not be used under the pump. Mounting pads for drive-train components shall be

machined to allow for the installation of shims at least 0.12 in. (3 mm) thick under each component. If the

vendor mounts the drive train components, a set of stainless steel shims (shim packs) at least 0.12 in. (3 mm)

thick shall be furnished. Shim packs shall not be thicker than 0.5 in. (13 mm) nor contain more than 5 shims.

All shim packs shall straddle the hold-down bolts and vertical jackscrews and extend at least 1/4 in. (5 mm)

beyond the outer edges of the equipment feet. If the vendor does not mount the components, the pads shall

not be drilled and shims shall not be provided.

⚫ If specified, in addition to shims under drive train components, pumps shall be mounted on solid

stainless steel plates not less than 0.200 in. (5 mm) thick. Solid plates shall be machined parallel and flat on

both sides and shall be the same length and width as the specific pump mounting feet.

All joints, including deck plate to structural members, shall be continuously seal-welded on both sides,

or full penetration welded, to prevent crevice corrosion. Stitch welding anywhere, top or bottom, is

unacceptable.

Accessed

user: LUISbyA.account:

LOPEZNorth Carolina A & T State | Date: Fri Jan 29 11:58:28 2021 | IP address: 152.8.254.250

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Pre Qualified WPSDocument1 pagePre Qualified WPSkapsarcNo ratings yet

- Performance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallFrom EverandPerformance Exhaust Systems: How to Design, Fabricate, and Install: How to Design, Fabricate, and InstallRating: 4 out of 5 stars4/5 (8)

- Used Cars in Saudi Arabia (EDA)Document33 pagesUsed Cars in Saudi Arabia (EDA)Abokhaled AL-ashmawiNo ratings yet

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- Manual Elevador 2 Columnas XG-3Document31 pagesManual Elevador 2 Columnas XG-3Juan SandyNo ratings yet

- NGK Catalogue 2013 14 LRDocument208 pagesNGK Catalogue 2013 14 LRjonathan220185No ratings yet

- Pages From API Standard 610 Centrifugal PumpsDocument1 pagePages From API Standard 610 Centrifugal PumpsAgustin A.100% (1)

- Pipe StrainDocument5 pagesPipe StrainJack WeaverNo ratings yet

- Pump Installation, Operation and MaintenanceDocument25 pagesPump Installation, Operation and Maintenancebayu kusumaNo ratings yet

- Centrifugal Pump API 686 Key RecommendationsDocument1 pageCentrifugal Pump API 686 Key RecommendationsAniekanNo ratings yet

- Commercial Pumps: Series 4030 Starnorm Base Mounted PumpsDocument8 pagesCommercial Pumps: Series 4030 Starnorm Base Mounted PumpsAlhgasjsghjagjsdajlsd AsdalsdlkaksdNo ratings yet

- Commercial Pumps: Installation and Operating InstructionsDocument8 pagesCommercial Pumps: Installation and Operating InstructionsrakeshamechNo ratings yet

- Specifications Standards For Shafts Alignment PDFDocument18 pagesSpecifications Standards For Shafts Alignment PDFDelfinshNo ratings yet

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Document20 pagesVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNo ratings yet

- Industrial-Gutters-Installation-Instructions_all-modelsDocument12 pagesIndustrial-Gutters-Installation-Instructions_all-modelseNo ratings yet

- MHICA Axial SwageDocument42 pagesMHICA Axial SwageSwampfootNo ratings yet

- Control Unit InstructionsDocument1 pageControl Unit Instructionsmanoj_sitecNo ratings yet

- NEWCopy of Std's and SpecificationDocument90 pagesNEWCopy of Std's and SpecificationMichael Robinson100% (1)

- PDF 44201222333PMKPDSDocument63 pagesPDF 44201222333PMKPDSAnbarasan NagarajanNo ratings yet

- FIS113eng Hi Temp BellowsDocument8 pagesFIS113eng Hi Temp Bellowsmahesh_eilNo ratings yet

- SPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Document24 pagesSPANCO FR WSB Instmaint Manual 103 0011 Rev06 11Eduardo OchaitaNo ratings yet

- Chapter (4) Pump InstallationDocument21 pagesChapter (4) Pump Installationkarioke mohaNo ratings yet

- Sno 20010Document13 pagesSno 20010Alexander SharamiginNo ratings yet

- Tooling Standard (Die Casting)Document39 pagesTooling Standard (Die Casting)Kmilo GiraldoNo ratings yet

- Technical Data Sheet & Part ListDocument24 pagesTechnical Data Sheet & Part ListM Farid Fakhrudduja100% (1)

- Technical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Document11 pagesTechnical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Naushad WadiaNo ratings yet

- HammerDocument20 pagesHammerdatnguyen789jNo ratings yet

- Pile Driving Guidelines: EquipmentDocument5 pagesPile Driving Guidelines: EquipmentSean CrossNo ratings yet

- Blackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CDocument12 pagesBlackmer Power Pumps: Models: Xl2B, Xl3B, Xl4CKhoh Kai ShengNo ratings yet

- Piping Design Guide-Vertical DrumsDocument9 pagesPiping Design Guide-Vertical DrumsTejas PatelNo ratings yet

- VO Model O & M ManualDocument17 pagesVO Model O & M ManualJigyesh SharmaNo ratings yet

- Power Tools: Operating and Maintenance InstructionsDocument16 pagesPower Tools: Operating and Maintenance InstructionsBill WidmerNo ratings yet

- Installation Guide Reciprocating Gas Compressors 1665249059Document21 pagesInstallation Guide Reciprocating Gas Compressors 1665249059ahmed meselhyNo ratings yet

- NuFlo EZ-In User Manual - PEDDocument32 pagesNuFlo EZ-In User Manual - PEDsarkaft100% (1)

- Industrial and General Purpose: Owners ManualDocument22 pagesIndustrial and General Purpose: Owners ManualoscarpabaNo ratings yet

- Pumps: Suggested Specifications Submersible Sump Pump Type SMDocument4 pagesPumps: Suggested Specifications Submersible Sump Pump Type SMloveanbu24No ratings yet

- Cornell Vertical Close Coupled Solids Handling Pumps: (Choose)Document2 pagesCornell Vertical Close Coupled Solids Handling Pumps: (Choose)Alejandra Vega AvilezNo ratings yet

- ENTS 400 Rev5Document62 pagesENTS 400 Rev5Scherjeal Jangda100% (1)

- 2300 Series ManualDocument24 pages2300 Series ManualJuprayNo ratings yet

- ARI SpecDocument4 pagesARI SpecLinggar Setiawan NNo ratings yet

- Flo Fab Under Base Bid. Equivalent Units May Be Submitted As DeductDocument6 pagesFlo Fab Under Base Bid. Equivalent Units May Be Submitted As DeducttexmoNo ratings yet

- Acson AHU O&M ManualDocument13 pagesAcson AHU O&M ManualKamran AhmedNo ratings yet

- Trim Tab Installation InstructionsDocument2 pagesTrim Tab Installation InstructionsPaul CharltonNo ratings yet

- MR Num4-EnDocument14 pagesMR Num4-EnaminardakaniNo ratings yet

- Equipment LayoutDocument25 pagesEquipment LayoutCalNo ratings yet

- Manual Mtto Roper 3600HBDocument43 pagesManual Mtto Roper 3600HBjairoNo ratings yet

- Manual Bomba RoperDocument43 pagesManual Bomba RoperFranco Alejandro Olivares Alvarez100% (2)

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- Auger Boring MethodologyDocument5 pagesAuger Boring MethodologyVipin GuptaNo ratings yet

- Double Suction Split Case PumpsDocument27 pagesDouble Suction Split Case Pumpsgbogboiwe100% (1)

- Erection and Commissioning Procedure PDFDocument94 pagesErection and Commissioning Procedure PDFShankar JhaNo ratings yet

- Weld Spec 2Document3 pagesWeld Spec 2spstainless316No ratings yet

- Sewers For Adoption - PUMPSDocument25 pagesSewers For Adoption - PUMPSatiNo ratings yet

- Manual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)Document15 pagesManual de Zaranda Alta Frecuencia Sds38-6mv-5 (Sr4639)victoranticonajicaro100% (1)

- SpecificationsDocument3 pagesSpecificationsajeesh_petrocilNo ratings yet

- ER-56-03 EN Packager Standards Skid Design and FabricationDocument4 pagesER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNo ratings yet

- Dv300 STD MMDocument40 pagesDv300 STD MMjacklyn ade putraNo ratings yet

- Kpds AllmodelsDocument39 pagesKpds AllmodelsSumit ChaurasiaNo ratings yet

- SJ Petro LGF-500 Mud Pump Operation ManualDocument52 pagesSJ Petro LGF-500 Mud Pump Operation ManualSEAZONE EXIM100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 2Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 2kapsarcNo ratings yet

- Drum Screen - DesignDetailsDocument2 pagesDrum Screen - DesignDetailskapsarcNo ratings yet

- Boehler 2507 P100 Rutile E2594 16 Covered ElectrodeDocument1 pageBoehler 2507 P100 Rutile E2594 16 Covered ElectrodekapsarcNo ratings yet

- Guidelines For Welding Stainless Alloy Piping Part 1Document4 pagesGuidelines For Welding Stainless Alloy Piping Part 1kapsarcNo ratings yet

- PN 16 Flange EN1092Document2 pagesPN 16 Flange EN1092kapsarcNo ratings yet

- Viking Material SpecsDocument12 pagesViking Material SpecskapsarcNo ratings yet

- WQT - Aws D1.1Document3 pagesWQT - Aws D1.1kapsarc100% (1)

- Drum Screen Installation - GearsDocument2 pagesDrum Screen Installation - GearskapsarcNo ratings yet

- Piping IsoDocument1 pagePiping IsokapsarcNo ratings yet

- Horizontal Slurry PumpDocument1 pageHorizontal Slurry PumpkapsarcNo ratings yet

- Pump Back Pressure RegulatorDocument1 pagePump Back Pressure RegulatorkapsarcNo ratings yet

- One Week Look A Head PlanDocument1 pageOne Week Look A Head PlankapsarcNo ratings yet

- Inspection For TanksDocument1 pageInspection For TankskapsarcNo ratings yet

- Drive Unit For PumpDocument1 pageDrive Unit For PumpkapsarcNo ratings yet

- Instrumentation Control For Pumps - 1Document1 pageInstrumentation Control For Pumps - 1kapsarcNo ratings yet

- Delta Ferrite ContentDocument1 pageDelta Ferrite ContentkapsarcNo ratings yet

- Slurry PumpDocument1 pageSlurry PumpkapsarcNo ratings yet

- Chemical Compositiopn of FCAW ElectrodesDocument1 pageChemical Compositiopn of FCAW ElectrodeskapsarcNo ratings yet

- Double Suction ImpellerDocument1 pageDouble Suction ImpellerkapsarcNo ratings yet

- Construction Progress Report - 1Document2 pagesConstruction Progress Report - 1kapsarcNo ratings yet

- Construction Progress Report - 2Document2 pagesConstruction Progress Report - 2kapsarcNo ratings yet

- Weld Joint Location in Pressure VesselDocument1 pageWeld Joint Location in Pressure VesselkapsarcNo ratings yet

- Forces On BoltsDocument1 pageForces On BoltskapsarcNo ratings yet

- RT Acceptance Criteria For Pressure VesselDocument1 pageRT Acceptance Criteria For Pressure VesselkapsarcNo ratings yet

- Vertical Dry Pit PumpDocument1 pageVertical Dry Pit PumpkapsarcNo ratings yet

- Pump Alarm ControlDocument1 pagePump Alarm ControlkapsarcNo ratings yet

- Integral Flange FactorDocument1 pageIntegral Flange FactorkapsarcNo ratings yet

- Piping DWGDocument1 pagePiping DWGkapsarcNo ratings yet

- Flange ImperfectionDocument1 pageFlange ImperfectionkapsarcNo ratings yet

- Vehicle Presentation Volkswagen FOX: Waldemar SteuerDocument39 pagesVehicle Presentation Volkswagen FOX: Waldemar SteuerMihai MocanuNo ratings yet

- Manual de Partes Compresor SANDEMDocument25 pagesManual de Partes Compresor SANDEMLuis Panti EkNo ratings yet

- Abdul MajeedDocument6 pagesAbdul MajeedUmar AbdullahNo ratings yet

- D3.2 Part1 Guidelines Dependability Hazard AnalysisDocument340 pagesD3.2 Part1 Guidelines Dependability Hazard Analysisnchandu306No ratings yet

- Tata Staff Bus Range Brochure BSVI 6march20Document2 pagesTata Staff Bus Range Brochure BSVI 6march20annaji annajiNo ratings yet

- Tugas Bahasa Inggris Faris FIXDocument4 pagesTugas Bahasa Inggris Faris FIXFarisRizki RamadhaniNo ratings yet

- Window-Type Air Conditioner Unit and Split-Type AirconditionerDocument4 pagesWindow-Type Air Conditioner Unit and Split-Type AirconditionerTempwell company Naga BranchNo ratings yet

- Nettra Ultimate Negative Keyword ListDocument19 pagesNettra Ultimate Negative Keyword ListPercyRojasNo ratings yet

- BE YK EngineeringGuide HDocument86 pagesBE YK EngineeringGuide Hahmad ReshadNo ratings yet

- Inspection Report For NarmulDocument3 pagesInspection Report For NarmulmelakuNo ratings yet

- PTO-HN.11.MX06.H.ISO CatalogueDocument1 pagePTO-HN.11.MX06.H.ISO CatalogueBrion Bara IndonesiaNo ratings yet

- RPT Operation ManualDocument36 pagesRPT Operation ManualKiều Văn TrungNo ratings yet

- 06D Compressor 2020Document2 pages06D Compressor 2020Syarif HidayatullahNo ratings yet

- Chairless Chair For Improved Ergonomics in Audi's Production PlantsDocument3 pagesChairless Chair For Improved Ergonomics in Audi's Production PlantsDeepak ChaurasiaNo ratings yet

- Arriel 2DDocument2 pagesArriel 2DMUKESH CHAKRAWARTINo ratings yet

- Royal Enfield Classic 350 Spare Parts Price ListDocument2 pagesRoyal Enfield Classic 350 Spare Parts Price ListDKNo ratings yet

- 01 Clutch Construction and OperationDocument32 pages01 Clutch Construction and Operationdawit abebualNo ratings yet

- Ece Lab Manual - MiteDocument44 pagesEce Lab Manual - MiteSubuddhi DamodarNo ratings yet

- Tower Lamp Multi YanmarDocument4 pagesTower Lamp Multi YanmararifauliaNo ratings yet

- Brief Study On Failed Products or Branding Campaigns in MarketingDocument41 pagesBrief Study On Failed Products or Branding Campaigns in Marketingpratiush07100% (2)

- Parts List EUPOLO150 (JC150T)Document44 pagesParts List EUPOLO150 (JC150T)GARAGE PREMIUMNo ratings yet

- Navitas AC TAC2 Error Code and TroubleshootingDocument8 pagesNavitas AC TAC2 Error Code and Troubleshootingelectronics malayalamNo ratings yet

- Toyota and Subaru Agree On New Business and Capital AllianceDocument2 pagesToyota and Subaru Agree On New Business and Capital AllianceAlfredo MedinaNo ratings yet

- Asme B5.8-2001 (2017)Document32 pagesAsme B5.8-2001 (2017)윤규섭No ratings yet

- Guía de Lubricación de Motos GileraDocument7 pagesGuía de Lubricación de Motos GileraDamian alejandroNo ratings yet

- Ilnas-En 50604-1:2016Document9 pagesIlnas-En 50604-1:2016kishore msnNo ratings yet

- Seicane No 32 Android 8 0 Upgrade User Manual Replacement InstructionDocument22 pagesSeicane No 32 Android 8 0 Upgrade User Manual Replacement Instructiondjdeeablo100% (1)

- Forbes Middle East July 2020Document84 pagesForbes Middle East July 2020Mohsin KhanNo ratings yet