Professional Documents

Culture Documents

Series 27100 28000 Vertical Detect A Fire Units

Series 27100 28000 Vertical Detect A Fire Units

Uploaded by

Marcelo LeguizamonCopyright:

Available Formats

You might also like

- Nursing Informatics Lecture OutlineDocument17 pagesNursing Informatics Lecture OutlineAdriane Villanueva100% (1)

- Yanan: PowerDocument6 pagesYanan: Powergreenbest777No ratings yet

- Electrical Plan-ModelDocument1 pageElectrical Plan-ModelMaria CincoNo ratings yet

- Evacuate LampDocument2 pagesEvacuate LampYosses Sang NahkodaNo ratings yet

- Detect A Fire Installation Manual VerticalDocument2 pagesDetect A Fire Installation Manual VerticalhcalderonmarinNo ratings yet

- Series 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionDocument2 pagesSeries 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionAli AlSowaidiNo ratings yet

- Detect-A-Fire Detection and Release DevicesDocument6 pagesDetect-A-Fire Detection and Release DevicesAli HadiNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesGustavo Alejandro Flores GarriNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesFirman TopNo ratings yet

- DS - F-12-0-001 Fenwal Heat DetectorDocument6 pagesDS - F-12-0-001 Fenwal Heat DetectorElia Nugraha AdiNo ratings yet

- Detection and Release Devices: FeaturesDocument6 pagesDetection and Release Devices: FeaturesMarcelo LeguizamonNo ratings yet

- DETECTOR TERMICO Detec-a-FireDocument2 pagesDETECTOR TERMICO Detec-a-FirefranciscoNo ratings yet

- Vertical Detect A Fire & Ultraviolet Fire DetectorDocument10 pagesVertical Detect A Fire & Ultraviolet Fire Detectoryouceflebni26No ratings yet

- 15N60Document6 pages15N60Alejandra SeguraNo ratings yet

- Branch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Document2 pagesBranch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Rober BlanquitoNo ratings yet

- Is Now Part ofDocument15 pagesIs Now Part ofSaikumarNo ratings yet

- Datasheet Fike Control Module 55-042Document2 pagesDatasheet Fike Control Module 55-042roni kurniawanNo ratings yet

- FDPA Programing1231Document10 pagesFDPA Programing1231Engr. Syed Ghulam Mustafa ShahNo ratings yet

- ASD10H: Isolated and Regulated 10 WATT Open Frame DC/DC ConverterDocument3 pagesASD10H: Isolated and Regulated 10 WATT Open Frame DC/DC ConverterRoger Mamani OrcconNo ratings yet

- Fdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MDocument11 pagesFdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MSukandar TeaNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- P55NF06 ThinkiSemiconductorDocument6 pagesP55NF06 ThinkiSemiconductorAlex MotNo ratings yet

- Taiwan Semiconductor: Features Key ParametersDocument5 pagesTaiwan Semiconductor: Features Key ParametersspotNo ratings yet

- PBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410Document3 pagesPBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410alexnder gallegoNo ratings yet

- Unisonic Technologies Co., LTD: 15A, 600V N-CHANNEL Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 15A, 600V N-CHANNEL Power MosfetCode Main ProjectNo ratings yet

- FDP20N50 184794Document11 pagesFDP20N50 184794Paulo NogueiraNo ratings yet

- lm310 PDFDocument16 pageslm310 PDFrumralkarNo ratings yet

- PM175 QuickStartDocument13 pagesPM175 QuickStartKasirNo ratings yet

- SV 1-10/210 Aluminium Servo ValveDocument3 pagesSV 1-10/210 Aluminium Servo ValveAlphaNo ratings yet

- 300W Modified Sine Wave DC-AC Power InverterDocument2 pages300W Modified Sine Wave DC-AC Power InverterFlorin DoruNo ratings yet

- Unisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDarush RjNo ratings yet

- FDP20N50FDocument10 pagesFDP20N50Ftplink.gtzrojasNo ratings yet

- 12N50 PDFDocument6 pages12N50 PDFhectorsevillaNo ratings yet

- LTW C230DSDocument12 pagesLTW C230DSSławomir ChargotNo ratings yet

- PAF-F280 Series: 200V To 400VDC Input Full Brick DC-DC ConvertersDocument3 pagesPAF-F280 Series: 200V To 400VDC Input Full Brick DC-DC ConvertersJunaid RafiqueNo ratings yet

- Rfm12N08, Rfm12N10, Rfp12N08, Rfp12N10: 'L.E.'Iis.U Tsztnl-Conduetoi Product ., DNCDocument2 pagesRfm12N08, Rfm12N10, Rfp12N08, Rfp12N10: 'L.E.'Iis.U Tsztnl-Conduetoi Product ., DNCOscarVargasNo ratings yet

- SX310 WTE Diode PDFDocument4 pagesSX310 WTE Diode PDFHưng HQNo ratings yet

- FDB13AN06A0Document11 pagesFDB13AN06A0kamil.smolinski.1980No ratings yet

- 30n06L InterfaceDocument8 pages30n06L Interfacepre freedaNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument5 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZsyahril boonieNo ratings yet

- Shakiso Relay Setting Calculations For 25 MVA 132 - 33kV Trafo - Rev00 - FiqDocument12 pagesShakiso Relay Setting Calculations For 25 MVA 132 - 33kV Trafo - Rev00 - FiqEyasu YemataNo ratings yet

- DatasheetDocument5 pagesDatasheetEdgarNo ratings yet

- SolenoidesDocument3 pagesSolenoidesMarcosNo ratings yet

- 2N5950 PDFDocument3 pages2N5950 PDFnanodocl5099No ratings yet

- Installation Manualime72470v Ds80Document85 pagesInstallation Manualime72470v Ds80ZawYeLinNo ratings yet

- Unisonic Technologies Co., LTD: 11A, 900V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 11A, 900V N-CHANNEL Power MosfetShahzad NazirNo ratings yet

- P19401 Control ModuleDocument2 pagesP19401 Control ModulerkssNo ratings yet

- Lambda PAF600F280-12 - TDocument2 pagesLambda PAF600F280-12 - TLuizNo ratings yet

- Utc 571 NDocument4 pagesUtc 571 Ndang minh khaNo ratings yet

- GRT8 AB ManualDocument2 pagesGRT8 AB ManualSanny HamdaniNo ratings yet

- Fcp190N60 / Fcpf190N60: N-Channel Superfet Ii MosfetDocument10 pagesFcp190N60 / Fcpf190N60: N-Channel Superfet Ii Mosfetarness22No ratings yet

- 4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionDocument2 pages4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionVinod Kumar PatelNo ratings yet

- 1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Document4 pages1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Nando AguilarNo ratings yet

- Unisonic Technologies Co., LTD: 12A, 500V N-CHANNEL Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 12A, 500V N-CHANNEL Power MosfetMoez MizouNo ratings yet

- 600W Modified Sine Wave DC-AC Power Inverter: SeriesDocument2 pages600W Modified Sine Wave DC-AC Power Inverter: SeriesvkNo ratings yet

- CatalogDocument5 pagesCatalogdevy andiniNo ratings yet

- Surge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDocument2 pagesSurge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDuy ChuNo ratings yet

- Takedo - 3VF: Instruction ManualDocument19 pagesTakedo - 3VF: Instruction ManualMohd Abu AjajNo ratings yet

- Excelitas VTB6061UVJH DatasheetDocument1 pageExcelitas VTB6061UVJH DatasheetJosé FariaNo ratings yet

- Siemens Thermal Overload Relay CatalogueDocument16 pagesSiemens Thermal Overload Relay CatalogueRajendran RNo ratings yet

- FCP104N60 D-2312015Document11 pagesFCP104N60 D-2312015Electronica Analogica Y DigitalNo ratings yet

- D-CFL Balasto DimableDocument4 pagesD-CFL Balasto Dimabledlinares07No ratings yet

- NOSP 17668-03a-OM-DGi TT7 E - DGi TT7 O - DG TT7 S - Type D-EnDocument72 pagesNOSP 17668-03a-OM-DGi TT7 E - DGi TT7 O - DG TT7 S - Type D-EnMarcelo LeguizamonNo ratings yet

- Simtronics LT15 UserManualDocument16 pagesSimtronics LT15 UserManualMarcelo LeguizamonNo ratings yet

- Simtronics TLU600Document1 pageSimtronics TLU600Marcelo LeguizamonNo ratings yet

- NOSP 14540-12-OM-TLU600-EnDocument32 pagesNOSP 14540-12-OM-TLU600-EnMarcelo LeguizamonNo ratings yet

- MX 62Document84 pagesMX 62Marcelo LeguizamonNo ratings yet

- MX62 Manual GBDocument84 pagesMX62 Manual GBMarcelo LeguizamonNo ratings yet

- Interface WB Rev A.0 Eng 0Document24 pagesInterface WB Rev A.0 Eng 0Marcelo LeguizamonNo ratings yet

- TA DAF Test Procedures F 12 1001Document1 pageTA DAF Test Procedures F 12 1001Marcelo LeguizamonNo ratings yet

- MX 62 Rev H.0 EnglishDocument76 pagesMX 62 Rev H.0 EnglishMarcelo LeguizamonNo ratings yet

- Detection and Release Devices: FeaturesDocument6 pagesDetection and Release Devices: FeaturesMarcelo LeguizamonNo ratings yet

- GF-30048E-EN - MX 62 - BroA4Document8 pagesGF-30048E-EN - MX 62 - BroA4Marcelo LeguizamonNo ratings yet

- Fenwal - Controls TA DAF - Principles - F 12 1001Document4 pagesFenwal - Controls TA DAF - Principles - F 12 1001Marcelo LeguizamonNo ratings yet

- Avr Atmega 8 UcDocument14 pagesAvr Atmega 8 UcmalhiavtarsinghNo ratings yet

- Uninterrupted Power Supply To A Load Using Auto-Selection Between Four Different SourceDocument3 pagesUninterrupted Power Supply To A Load Using Auto-Selection Between Four Different SourceTahir Abubakar SadiqNo ratings yet

- Controls For Information SecurityDocument26 pagesControls For Information SecurityFaris FarabiNo ratings yet

- Ppadb Codes Prosperous ZoneDocument3 pagesPpadb Codes Prosperous ZoneGaone Lydia SetlhodiNo ratings yet

- BUCK - What Is CyberspaceDocument3 pagesBUCK - What Is CyberspaceAtikah Adila Bt AzizNo ratings yet

- Voxengo SPAN Plus User Guide enDocument8 pagesVoxengo SPAN Plus User Guide enMarin GanciuNo ratings yet

- Construction of Fred's Shed: Project ActivityDocument4 pagesConstruction of Fred's Shed: Project ActivityTanmay JhulkaNo ratings yet

- URA Circular - Temporary Revision To Guidelines For Temporary Workers' DormitoriesDocument23 pagesURA Circular - Temporary Revision To Guidelines For Temporary Workers' DormitoriesKahHoe ChongNo ratings yet

- Math Works Web in Ar Power Train Full VehiclesDocument46 pagesMath Works Web in Ar Power Train Full VehiclesAtharva Joshi.No ratings yet

- 02-Data Mining Functionalities-2Document23 pages02-Data Mining Functionalities-2Lakshmi Priya BNo ratings yet

- KONE Escalator and Autowalk SolutionsDocument8 pagesKONE Escalator and Autowalk Solutionsselthunath abdullahNo ratings yet

- Resume - Sandeep PatelDocument1 pageResume - Sandeep Pateljainvaibhav2006No ratings yet

- CHAPTER 3. Disk Management RevDocument44 pagesCHAPTER 3. Disk Management Revfidelekamsu12No ratings yet

- SAP EWM Lessons Learned Case Studies From The Warehouse FloorDocument41 pagesSAP EWM Lessons Learned Case Studies From The Warehouse FloorAdnan Babu100% (1)

- Corporate Case StudiesDocument68 pagesCorporate Case StudiesAnand RajNo ratings yet

- Csit101 Midterm CollabDocument5 pagesCsit101 Midterm Collabapi-266897183No ratings yet

- Facial Emotion and Object Detection For Visually Impaired Blind Persons IJERTV10IS090108Document4 pagesFacial Emotion and Object Detection For Visually Impaired Blind Persons IJERTV10IS090108Aayush SachdevaNo ratings yet

- Lab 3 Field Speed Control of DC Motors: 1. ObjectiveDocument7 pagesLab 3 Field Speed Control of DC Motors: 1. ObjectiveErgin ÖzdikicioğluNo ratings yet

- CV Aadya SaraswatDocument2 pagesCV Aadya SaraswatAadyaNo ratings yet

- Cool Tech Parameters AMF 20Document8 pagesCool Tech Parameters AMF 20Butch ArroyoNo ratings yet

- Snowflake - Certforall.snowpro Core - free.PDF.2023 Oct 02.by - Levi.182q.vceDocument26 pagesSnowflake - Certforall.snowpro Core - free.PDF.2023 Oct 02.by - Levi.182q.vcesaipriyacooolNo ratings yet

- 75LC 10Document12 pages75LC 10royvindasNo ratings yet

- Tab 4-Mechanical DataDocument54 pagesTab 4-Mechanical DataJocelyn Ambar Gallardo ArismendiNo ratings yet

- HTTTKT Bài 10.1 DangDocument1 pageHTTTKT Bài 10.1 DangDANG PHAM HAINo ratings yet

- Project Charter TemplateDocument2 pagesProject Charter Templateعلی احمدNo ratings yet

- Audit:: The Tipping Point Is NowDocument14 pagesAudit:: The Tipping Point Is NowjonaNo ratings yet

- Comm W Other Hams-Tech Band Chart BackDocument2 pagesComm W Other Hams-Tech Band Chart BackCelaphe ArinataNo ratings yet

Series 27100 28000 Vertical Detect A Fire Units

Series 27100 28000 Vertical Detect A Fire Units

Uploaded by

Marcelo LeguizamonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Series 27100 28000 Vertical Detect A Fire Units

Series 27100 28000 Vertical Detect A Fire Units

Uploaded by

Marcelo LeguizamonCopyright:

Available Formats

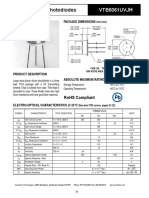

SERIES 27100, 28000

Vertical DETECT-A-FIRE® Units

Installation Instructions

12.01.G

DESCRIPTION MOUNTING

DETECT-A-FIRE® (D-A-F) thermal detectors are UL Listed (UL of Canada D-A-F units are not position sensitive. Horizontal and vertical detectors

available upon request), and FM Approved detection and release devices refer to the most common mounting configuration for that unit.

for use with fire detection systems to activate alarms and extinguishing However, each type can be mounted either horizontally or vertically

systems. This Rate Compensated device combines the best features of depending on the application and installation requirements.

both fixed temperature and rate-of-rise detectors.

TABLE 2: MODEL NUMBER 12-X28020*, 12-X28021

Electrical Rating Spacings

°F °F Color

Contact X (in feet) RTI

Model Electrical Rating* Setting Tolerance Coding

Operation on UL ULc FM

Number (Resistive Only)

Temperature Rise 140 +7/-8 50 50 30 V-Fast Black

160 +7/-8 25 25 30 V-Fast Black

12-X27120 5.0 amps 125 VAC

Opens (450°F Max) E 190 +7/-8 50 50 30 V-Fast White

12-X28020 0.5 Amps 125 VDC 210 +7/-8 25 50 30 V-Fast White

225 +7/-8 25 50 30 V-Fast White

12-X27121 5.0 Amps 125 VAC

0.5 Amps 125 VDC 275 ±10 25 50 30 V-Fast Blue

Closes

2.0 Amps 24 VDC F 325 ±10 50 50 30 V-Fast Red

12-X28021

1.0 Amps 48 VDC 360 ±10 25 50 30 V-Fast Red

450 ±15 25 50 30 V-Fast Green

Note: *Although incandescent lamps are considered resistive, G

their inrush current is 10-15 times their steady 500 ±15 50 50 30 V-Fast Orange

current. Do not exceed ratings. 600 ±20 N/A 50 30 V-Fast Orange

H

725 ±20 N/A 50 30 V-Fast Orange

LOCATION

Notes:

D-A-F detectors are precision temperature sensors. They must be • For clean agents and CO2 suppression systems, ceiling spacing is 20 ft. apart

mounted in an area (normally a ceiling) so that: unless otherwise specified.

• 28020 is a 2-wire device and RTI is not applicable.

1. The detector spacing complies with both system requirements • 28020 is a normally closed device and does not meet the requirements of

and requirements of the agency having local jurisdiction. NFPA-72 for use as an initiating device.

2. The thermal air path to the shell is not obstructed.

Spacing per UL, FM, and UL of Canada is shown in Table 1. Distances

given are for between units on smooth ceilings. Distances from partitions Fitting Required For

or walls are half that shown. To assure that all spacing requirements are Model UL, ULC

Hazardous Location

met, consult the authority having local jurisdiction. Number Listings and FM

Approvals

TABLE 1: MODEL NUMBER 12-X27120*, 12-X27121 27120-22 Mount detector to a

Spacings Class 1*, Groups A, B, C and D; 27121-20

°F °F Color suitably listed

X (in feet) RTI Class II*, Groups E, F and G 28020-3 fitting in

Setting Tolerance Coding

UL ULc FM 28021-5 accordance with

140 +7/-8 50 50 20 Quick Black 27120-0 National Electric Code

Class 1*, Groups B, C and D; and/or local authority

160 +7/-8 25 25 20 Quick Black 27121-0

Class II*, Groups E, F and G having jurisdiction.

E 190 +7/-8 50 50 25 Fast White 28021-0

210 +7/-8 25 50 25 Fast White Note: * Division 1 and 2.

225 +7/-8 25 50 25 Fast White

275 ±10 25 50 25 Fast Blue INSTALLATION

F 325 ±10 50 50 25 Fast Red Note: Kidde-Fenwal recommends that standard 4-inch octagonal

360 ±10 25 50 30 V-Fast Red outlet boxes be used to mount detectors.

450 ±15 25 50 30 V-Fast Green 1. Attach detector to outlet box cover through a 0.875 inch diameter

G

500 ±15 50 50 30 V-Fast Orange hole and using two 1/2-14NPT retainer nuts as indicated.

600 ±20 N/A 50 30 V-Fast Orange 2. Connect system wiring to detector per Figure 1 and applicable

H

725 ±20 N/A 50 30 V-Fast Orange electrical codes.

Notes: • Ordinary Locations: The D-A-F Units are to be installed in

• For clean agents and CO2 suppression systems, ceiling spacing is 20 ft. apart grounded metallic junction boxes only. They are to be secured to

unless otherwise specified. the boxes using two lock nuts, one on either side of the mounting

• 27120 is a 2-wire device and RTI is not applicable. plate. D-A-F Units are not to be installed in non-metallic junction

• 27120 is a normally closed device and does not meet the requirements of

boxes.

NFPA-72 for use as an initiating device.

06-L04103-000 Effective: June 2018

• Hazardous Locations: For Class I, Division 1 and 2 locations install DETECT-A-FIRE MOUNTING

the D-A-F Unit in a listed explosion-proof enclosure with a minimum

thread engagement of five full turns. No non-conductive material is

to be placed on the threaded joint of the D-A-F Unit or in the listed

explosion-proof enclosure. For Division 2 locations assure that a

protective ground terminal is provided in the listed explosion-proof

enclosure when flexible metal conduit is used.

• Non-Hazardous Outdoor Locations: Mount the D-A-F in a Listed

NEMA Type 3 outlet box, cover and conduit, with 1/2- 14 NPT

TABLE 3

threads and a minimum thread engagement of 5 full turns. Use pipe

plugs with RTV silicone rubber sealant, a rubber gasket and self- Non-Hazardous Outdoor Locations

sealing screws to attach the cover, and PTFE thread sealtape on the °

Model F Fitting Required for UL

D-A-F threads. For additional requirements consult the local fire

Number Temperature Listing and FM Approval

department, the National Electric Code and/or the local authority

Setting

having jurisdiction in the area.

12-X27120-0 Mount detector to a fitting suitable for

Note: Do not exceed a maximum torque without thread lubricant of 20

12-X27120-22 140, 160, outside use, (NEMA Type 3), in accor-

foot-pounds (27.1 Newton Meters).

12-X27121-0 190, 225 dance with National Electric Code and/

Series 28000 units are similar to Series 27100 units except they have two 12-X27121-20 or local authority having jurisdiction.

1/2-14 NPT threads for mounting.

FM requires the use of a Killark Oulet Box P/N VLJK-1, with P/N VJH-1

The unit may be mounted as described above or may be threaded into cover, and P/N VBNB Gasket to satisfy Outdoor NEMA 3 rated installa-

a 1/2-14 NPT tapped hole in the vessel wall or threaded into a coupling tion requirements.

brazed or welded to the vessel wall.

FUNCTIONAL TEST

When used with automatic fire extinguishing systems first disconnect

the initiator/solenoid leads from the panel and connect a 24 VDC bulb to

initiator terminals in the control unit. Gently heat the D-A-F units with a

heat lamp or other convenient source (see WARNING below). When the

bulb in the control unit changes state, remove heat source and allow D-

A-F unit to cool. Reset control unit. Test lamp must change state and

stay changed after system is reset. Do not reconnect initiator/ solenoid

leads until all D-A-F units have cooled below set point as indicated by

test lamp. When D-A-F units are used in other types of systems,

disconnect them from the system, connect a 24 VDC lamp and power

source in series with the D-A-F units and test with heat source as above.

Make sure that contacts have reset to normal condition before

reconnecting to system circuit.

1. DO NOT overshoot the setpoint of the unit by more

Field Wiring Requirement than 100F (55C). DO NOT contact the sensing shell

with a heating device. Either action could result in a

Field wiring must be capable of withstanding the maximum anticipated shift of the set point temperature or damage the unit.

ambient temperature in the application. For Type G and H Detectors, 2. Keep the sensing shell of the unit free from paint,

field wiring should be capable for continuous operation at the maximum grease, oil, etc. If a buildup occurs, do not attempt to

remove the buildup. Replace the unit.

rated ambient temperature of 250°C.

3. Detectors mounted in an area subject to physical

abuse or damage must be suitably protected without

SYSTEM WIRING obstructing the thermal airpath to the unit.

Typical Fire Alarm System Method 4. Do not install the unit where the shell would be

physically damaged by sand, grain, rocks, etc.

2 WIRE 4 WIRE 5. Any detector that has been involved in a fire or

damaged must be replaced.

6. Do not over torque the unit when installing.

END-OF-LINE

DEVICE

TO ALARM AND TO ALARM AND WARNING Recommended practice is to hand tighten the unit.

(Current

MONITORING

PANEL

MONITORING

PANEL

Then using a suitable sized wrench, turn 1 1/2

Limiting)

additional turns without damaging the hex surfaces.

7. Consult the factory for special precautions necessary

for outdoor use or moist environments.

Typical Security System Method ANY OF THE ABOVE COULD CHANGE THE FACTORY TEM-

PERATURE SETTING, WHICH MAY RESULT IN PROPERTY

2 WIRE

DAMAGE AND/OR PERSONAL INJURY OR DEATH.

IT IS POSSIBLE FOR A UNIT TO HAVE BEEN ABUSED OR

TO ALARM AND

MONITORING DAMAGED AND NOT DISPLAY ANY OUTWARD INDICA-

PANEL TION OF THE DAMAGE. ALL UNITS SHOULD BE TESTED

PERIODICALLY IN ACCORDANCE WITH NATIONAL FIRE

PROTECTION ASSOCIATION REQUIREMENTS (72e) OR

THE AGENCY HAVING LOCAL JURISDICTION.

DETECT-A-FIRE is a registered trademark of Kidde-Fenwal, Inc., or its parents, subsidiaries, or affiliates.

Kidde is a registered trademark of Kidde-Fenwal, Inc., or its parents, subsidiaries, or affiliates.

Specifications are subject to change without notice.This literature is provided for informational purposes only. KIDDE-FENWAL, INC. assumes no responsibility for

the product’s suitability for a particular application. The product must be properly applied to work correctly. If you need more information on this product, or have a

particular problem or question, contact KIDDE-FENWAL, INC.

2 Fenwal Controls, Kidde-Fenwal Inc.

400 Main Street

EXPORT INFORMATION (USA) Ashland, MA 01721

Jurisdiction: EAR Tel: 800-FENWAL-1 Fax: 508-881-7619

Classification: EAR99 www.fenwal.com

06-L04103-000 Rev. AC This document contains technical data subject to the EAR.

©2018 Kidde-Fenwal, Inc.

You might also like

- Nursing Informatics Lecture OutlineDocument17 pagesNursing Informatics Lecture OutlineAdriane Villanueva100% (1)

- Yanan: PowerDocument6 pagesYanan: Powergreenbest777No ratings yet

- Electrical Plan-ModelDocument1 pageElectrical Plan-ModelMaria CincoNo ratings yet

- Evacuate LampDocument2 pagesEvacuate LampYosses Sang NahkodaNo ratings yet

- Detect A Fire Installation Manual VerticalDocument2 pagesDetect A Fire Installation Manual VerticalhcalderonmarinNo ratings yet

- Series 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionDocument2 pagesSeries 27100, 28000: 12.01.F Table 2: Model Number 28021 DescriptionAli AlSowaidiNo ratings yet

- Detect-A-Fire Detection and Release DevicesDocument6 pagesDetect-A-Fire Detection and Release DevicesAli HadiNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesGustavo Alejandro Flores GarriNo ratings yet

- Detect-A-Fire: Detection and Release DevicesDocument6 pagesDetect-A-Fire: Detection and Release DevicesFirman TopNo ratings yet

- DS - F-12-0-001 Fenwal Heat DetectorDocument6 pagesDS - F-12-0-001 Fenwal Heat DetectorElia Nugraha AdiNo ratings yet

- Detection and Release Devices: FeaturesDocument6 pagesDetection and Release Devices: FeaturesMarcelo LeguizamonNo ratings yet

- DETECTOR TERMICO Detec-a-FireDocument2 pagesDETECTOR TERMICO Detec-a-FirefranciscoNo ratings yet

- Vertical Detect A Fire & Ultraviolet Fire DetectorDocument10 pagesVertical Detect A Fire & Ultraviolet Fire Detectoryouceflebni26No ratings yet

- 15N60Document6 pages15N60Alejandra SeguraNo ratings yet

- Branch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Document2 pagesBranch Panel Mounted Surge Protective Device (SPD) : Cat. Nos. 51120-1 & 51120-3Rober BlanquitoNo ratings yet

- Is Now Part ofDocument15 pagesIs Now Part ofSaikumarNo ratings yet

- Datasheet Fike Control Module 55-042Document2 pagesDatasheet Fike Control Module 55-042roni kurniawanNo ratings yet

- FDPA Programing1231Document10 pagesFDPA Programing1231Engr. Syed Ghulam Mustafa ShahNo ratings yet

- ASD10H: Isolated and Regulated 10 WATT Open Frame DC/DC ConverterDocument3 pagesASD10H: Isolated and Regulated 10 WATT Open Frame DC/DC ConverterRoger Mamani OrcconNo ratings yet

- Fdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MDocument11 pagesFdb2532 - F085: N-Channel Powertrench Mosfet 150V, 79A, 16MSukandar TeaNo ratings yet

- Eaton 269471 Emt6 KDB en GBDocument4 pagesEaton 269471 Emt6 KDB en GBAriel TorresNo ratings yet

- P55NF06 ThinkiSemiconductorDocument6 pagesP55NF06 ThinkiSemiconductorAlex MotNo ratings yet

- Taiwan Semiconductor: Features Key ParametersDocument5 pagesTaiwan Semiconductor: Features Key ParametersspotNo ratings yet

- PBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410Document3 pagesPBL401 - PBL407: Not Recommended For New Design USE GBU4005 - GBU410alexnder gallegoNo ratings yet

- Unisonic Technologies Co., LTD: 15A, 600V N-CHANNEL Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 15A, 600V N-CHANNEL Power MosfetCode Main ProjectNo ratings yet

- FDP20N50 184794Document11 pagesFDP20N50 184794Paulo NogueiraNo ratings yet

- lm310 PDFDocument16 pageslm310 PDFrumralkarNo ratings yet

- PM175 QuickStartDocument13 pagesPM175 QuickStartKasirNo ratings yet

- SV 1-10/210 Aluminium Servo ValveDocument3 pagesSV 1-10/210 Aluminium Servo ValveAlphaNo ratings yet

- 300W Modified Sine Wave DC-AC Power InverterDocument2 pages300W Modified Sine Wave DC-AC Power InverterFlorin DoruNo ratings yet

- Unisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 4.0A, 600V N-CHANNEL Power MosfetDarush RjNo ratings yet

- FDP20N50FDocument10 pagesFDP20N50Ftplink.gtzrojasNo ratings yet

- 12N50 PDFDocument6 pages12N50 PDFhectorsevillaNo ratings yet

- LTW C230DSDocument12 pagesLTW C230DSSławomir ChargotNo ratings yet

- PAF-F280 Series: 200V To 400VDC Input Full Brick DC-DC ConvertersDocument3 pagesPAF-F280 Series: 200V To 400VDC Input Full Brick DC-DC ConvertersJunaid RafiqueNo ratings yet

- Rfm12N08, Rfm12N10, Rfp12N08, Rfp12N10: 'L.E.'Iis.U Tsztnl-Conduetoi Product ., DNCDocument2 pagesRfm12N08, Rfm12N10, Rfp12N08, Rfp12N10: 'L.E.'Iis.U Tsztnl-Conduetoi Product ., DNCOscarVargasNo ratings yet

- SX310 WTE Diode PDFDocument4 pagesSX310 WTE Diode PDFHưng HQNo ratings yet

- FDB13AN06A0Document11 pagesFDB13AN06A0kamil.smolinski.1980No ratings yet

- 30n06L InterfaceDocument8 pages30n06L Interfacepre freedaNo ratings yet

- Similar To Illustration: Motor Rating AC-23A, 50 - 60 HZDocument5 pagesSimilar To Illustration: Motor Rating AC-23A, 50 - 60 HZsyahril boonieNo ratings yet

- Shakiso Relay Setting Calculations For 25 MVA 132 - 33kV Trafo - Rev00 - FiqDocument12 pagesShakiso Relay Setting Calculations For 25 MVA 132 - 33kV Trafo - Rev00 - FiqEyasu YemataNo ratings yet

- DatasheetDocument5 pagesDatasheetEdgarNo ratings yet

- SolenoidesDocument3 pagesSolenoidesMarcosNo ratings yet

- 2N5950 PDFDocument3 pages2N5950 PDFnanodocl5099No ratings yet

- Installation Manualime72470v Ds80Document85 pagesInstallation Manualime72470v Ds80ZawYeLinNo ratings yet

- Unisonic Technologies Co., LTD: 11A, 900V N-CHANNEL Power MosfetDocument7 pagesUnisonic Technologies Co., LTD: 11A, 900V N-CHANNEL Power MosfetShahzad NazirNo ratings yet

- P19401 Control ModuleDocument2 pagesP19401 Control ModulerkssNo ratings yet

- Lambda PAF600F280-12 - TDocument2 pagesLambda PAF600F280-12 - TLuizNo ratings yet

- Utc 571 NDocument4 pagesUtc 571 Ndang minh khaNo ratings yet

- GRT8 AB ManualDocument2 pagesGRT8 AB ManualSanny HamdaniNo ratings yet

- Fcp190N60 / Fcpf190N60: N-Channel Superfet Ii MosfetDocument10 pagesFcp190N60 / Fcpf190N60: N-Channel Superfet Ii Mosfetarness22No ratings yet

- 4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionDocument2 pages4026 Frequency To Analog Converter Mag & Digital Type: 4026-xx Drop-In Type For Y3 Product DescriptionVinod Kumar PatelNo ratings yet

- 1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Document4 pages1.0A Surface Mount Schottky Barrier Diode: Add "-LF" Suffix To Part Number, See Page 4Nando AguilarNo ratings yet

- Unisonic Technologies Co., LTD: 12A, 500V N-CHANNEL Power MosfetDocument6 pagesUnisonic Technologies Co., LTD: 12A, 500V N-CHANNEL Power MosfetMoez MizouNo ratings yet

- 600W Modified Sine Wave DC-AC Power Inverter: SeriesDocument2 pages600W Modified Sine Wave DC-AC Power Inverter: SeriesvkNo ratings yet

- CatalogDocument5 pagesCatalogdevy andiniNo ratings yet

- Surge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDocument2 pagesSurge Arrester-Class I+ Class II MG25/275-S/PN50: Power Supply SystemDuy ChuNo ratings yet

- Takedo - 3VF: Instruction ManualDocument19 pagesTakedo - 3VF: Instruction ManualMohd Abu AjajNo ratings yet

- Excelitas VTB6061UVJH DatasheetDocument1 pageExcelitas VTB6061UVJH DatasheetJosé FariaNo ratings yet

- Siemens Thermal Overload Relay CatalogueDocument16 pagesSiemens Thermal Overload Relay CatalogueRajendran RNo ratings yet

- FCP104N60 D-2312015Document11 pagesFCP104N60 D-2312015Electronica Analogica Y DigitalNo ratings yet

- D-CFL Balasto DimableDocument4 pagesD-CFL Balasto Dimabledlinares07No ratings yet

- NOSP 17668-03a-OM-DGi TT7 E - DGi TT7 O - DG TT7 S - Type D-EnDocument72 pagesNOSP 17668-03a-OM-DGi TT7 E - DGi TT7 O - DG TT7 S - Type D-EnMarcelo LeguizamonNo ratings yet

- Simtronics LT15 UserManualDocument16 pagesSimtronics LT15 UserManualMarcelo LeguizamonNo ratings yet

- Simtronics TLU600Document1 pageSimtronics TLU600Marcelo LeguizamonNo ratings yet

- NOSP 14540-12-OM-TLU600-EnDocument32 pagesNOSP 14540-12-OM-TLU600-EnMarcelo LeguizamonNo ratings yet

- MX 62Document84 pagesMX 62Marcelo LeguizamonNo ratings yet

- MX62 Manual GBDocument84 pagesMX62 Manual GBMarcelo LeguizamonNo ratings yet

- Interface WB Rev A.0 Eng 0Document24 pagesInterface WB Rev A.0 Eng 0Marcelo LeguizamonNo ratings yet

- TA DAF Test Procedures F 12 1001Document1 pageTA DAF Test Procedures F 12 1001Marcelo LeguizamonNo ratings yet

- MX 62 Rev H.0 EnglishDocument76 pagesMX 62 Rev H.0 EnglishMarcelo LeguizamonNo ratings yet

- Detection and Release Devices: FeaturesDocument6 pagesDetection and Release Devices: FeaturesMarcelo LeguizamonNo ratings yet

- GF-30048E-EN - MX 62 - BroA4Document8 pagesGF-30048E-EN - MX 62 - BroA4Marcelo LeguizamonNo ratings yet

- Fenwal - Controls TA DAF - Principles - F 12 1001Document4 pagesFenwal - Controls TA DAF - Principles - F 12 1001Marcelo LeguizamonNo ratings yet

- Avr Atmega 8 UcDocument14 pagesAvr Atmega 8 UcmalhiavtarsinghNo ratings yet

- Uninterrupted Power Supply To A Load Using Auto-Selection Between Four Different SourceDocument3 pagesUninterrupted Power Supply To A Load Using Auto-Selection Between Four Different SourceTahir Abubakar SadiqNo ratings yet

- Controls For Information SecurityDocument26 pagesControls For Information SecurityFaris FarabiNo ratings yet

- Ppadb Codes Prosperous ZoneDocument3 pagesPpadb Codes Prosperous ZoneGaone Lydia SetlhodiNo ratings yet

- BUCK - What Is CyberspaceDocument3 pagesBUCK - What Is CyberspaceAtikah Adila Bt AzizNo ratings yet

- Voxengo SPAN Plus User Guide enDocument8 pagesVoxengo SPAN Plus User Guide enMarin GanciuNo ratings yet

- Construction of Fred's Shed: Project ActivityDocument4 pagesConstruction of Fred's Shed: Project ActivityTanmay JhulkaNo ratings yet

- URA Circular - Temporary Revision To Guidelines For Temporary Workers' DormitoriesDocument23 pagesURA Circular - Temporary Revision To Guidelines For Temporary Workers' DormitoriesKahHoe ChongNo ratings yet

- Math Works Web in Ar Power Train Full VehiclesDocument46 pagesMath Works Web in Ar Power Train Full VehiclesAtharva Joshi.No ratings yet

- 02-Data Mining Functionalities-2Document23 pages02-Data Mining Functionalities-2Lakshmi Priya BNo ratings yet

- KONE Escalator and Autowalk SolutionsDocument8 pagesKONE Escalator and Autowalk Solutionsselthunath abdullahNo ratings yet

- Resume - Sandeep PatelDocument1 pageResume - Sandeep Pateljainvaibhav2006No ratings yet

- CHAPTER 3. Disk Management RevDocument44 pagesCHAPTER 3. Disk Management Revfidelekamsu12No ratings yet

- SAP EWM Lessons Learned Case Studies From The Warehouse FloorDocument41 pagesSAP EWM Lessons Learned Case Studies From The Warehouse FloorAdnan Babu100% (1)

- Corporate Case StudiesDocument68 pagesCorporate Case StudiesAnand RajNo ratings yet

- Csit101 Midterm CollabDocument5 pagesCsit101 Midterm Collabapi-266897183No ratings yet

- Facial Emotion and Object Detection For Visually Impaired Blind Persons IJERTV10IS090108Document4 pagesFacial Emotion and Object Detection For Visually Impaired Blind Persons IJERTV10IS090108Aayush SachdevaNo ratings yet

- Lab 3 Field Speed Control of DC Motors: 1. ObjectiveDocument7 pagesLab 3 Field Speed Control of DC Motors: 1. ObjectiveErgin ÖzdikicioğluNo ratings yet

- CV Aadya SaraswatDocument2 pagesCV Aadya SaraswatAadyaNo ratings yet

- Cool Tech Parameters AMF 20Document8 pagesCool Tech Parameters AMF 20Butch ArroyoNo ratings yet

- Snowflake - Certforall.snowpro Core - free.PDF.2023 Oct 02.by - Levi.182q.vceDocument26 pagesSnowflake - Certforall.snowpro Core - free.PDF.2023 Oct 02.by - Levi.182q.vcesaipriyacooolNo ratings yet

- 75LC 10Document12 pages75LC 10royvindasNo ratings yet

- Tab 4-Mechanical DataDocument54 pagesTab 4-Mechanical DataJocelyn Ambar Gallardo ArismendiNo ratings yet

- HTTTKT Bài 10.1 DangDocument1 pageHTTTKT Bài 10.1 DangDANG PHAM HAINo ratings yet

- Project Charter TemplateDocument2 pagesProject Charter Templateعلی احمدNo ratings yet

- Audit:: The Tipping Point Is NowDocument14 pagesAudit:: The Tipping Point Is NowjonaNo ratings yet

- Comm W Other Hams-Tech Band Chart BackDocument2 pagesComm W Other Hams-Tech Band Chart BackCelaphe ArinataNo ratings yet