Professional Documents

Culture Documents

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Uploaded by

Rana Sabouni TabariCopyright:

Available Formats

You might also like

- Electrospinning of PMMADocument7 pagesElectrospinning of PMMAvetrixNo ratings yet

- Effect of Crosslinking On The MechanicalDocument8 pagesEffect of Crosslinking On The MechanicalThoại Nguyễn QuốcNo ratings yet

- MohemDocument19 pagesMohemRana Sabouni TabariNo ratings yet

- Influence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesDocument9 pagesInfluence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesBharathi PonrajNo ratings yet

- Structural and Dielectrical Study of PZT/PVDF Film CompositesDocument10 pagesStructural and Dielectrical Study of PZT/PVDF Film CompositesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- PVDFDocument9 pagesPVDFAnish KumarNo ratings yet

- Highly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon Fiber Supporting DataDocument12 pagesHighly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon Fiber Supporting DataTeddy KimNo ratings yet

- Effect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesDocument10 pagesEffect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesTamam AbymNo ratings yet

- KJ - Volume 4 - Issue 2 - Pages 201-208Document8 pagesKJ - Volume 4 - Issue 2 - Pages 201-208gamil2No ratings yet

- ScienceDocument3 pagesScienceDhirendra SinghNo ratings yet

- Effect of Surface Modification of Nanosilica On Crystallization, Thermal and Mechanical Properties of Poly (Vinylidene Fluoride)Document10 pagesEffect of Surface Modification of Nanosilica On Crystallization, Thermal and Mechanical Properties of Poly (Vinylidene Fluoride)Rana Sabouni TabariNo ratings yet

- Structural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioDocument7 pagesStructural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioRana Sabouni TabariNo ratings yet

- Ja8005918 BaozhenanDocument2 pagesJa8005918 BaozhenanYonggang ZhenNo ratings yet

- Artikel 2Document12 pagesArtikel 2Carolina TambaNo ratings yet

- Water Absorption by An Epoxy Resin and Its Effect On The Mechanical Properties and Infra-Red SpectraDocument7 pagesWater Absorption by An Epoxy Resin and Its Effect On The Mechanical Properties and Infra-Red SpectraNavid HoseiniNo ratings yet

- Fabrication and Morphological Control of Electrospun Ethyl Cellulose NanofibersDocument4 pagesFabrication and Morphological Control of Electrospun Ethyl Cellulose NanofibersMaría BorregoNo ratings yet

- Effect of Crystalline Phase, Orientation and Temperature On The Dielectric Properties of Poly (Vinylidene Fluoride) (PVDF)Document12 pagesEffect of Crystalline Phase, Orientation and Temperature On The Dielectric Properties of Poly (Vinylidene Fluoride) (PVDF)salmanNo ratings yet

- The Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesDocument12 pagesThe Effect of Processing Variables On The Morphology of Electrospun Nanofibers and Textilesالكترنيات قداحNo ratings yet

- Synthesis of Poly (3,4 Ethylenedioxythi ParadeeDocument8 pagesSynthesis of Poly (3,4 Ethylenedioxythi ParadeeZim ShahNo ratings yet

- Electro CoalescenciaDocument7 pagesElectro CoalescenciaiqubaldoNo ratings yet

- The Formation of Microporous Polyvinylidene Difluoride Membranes by Phase SeparationDocument20 pagesThe Formation of Microporous Polyvinylidene Difluoride Membranes by Phase SeparationAfrillia FahrinaNo ratings yet

- Relationship Between Different Mixing Conditions and DC Breakdown Strength of High Density Polyethylene CompoundDocument3 pagesRelationship Between Different Mixing Conditions and DC Breakdown Strength of High Density Polyethylene Compoundrogerio.salustianoNo ratings yet

- Study of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationDocument6 pagesStudy of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationKRUNAL ParmarNo ratings yet

- 2008 Effect of RH On Electrospun NanofibersDocument10 pages2008 Effect of RH On Electrospun NanofibersEliton Medeiros Candido de MacêdoNo ratings yet

- Structural and Electrical Properties of FerroelectDocument11 pagesStructural and Electrical Properties of FerroelectRavi KiranNo ratings yet

- FiltrationDocument16 pagesFiltrationYash PatelNo ratings yet

- Effect of PMMA AdditionDocument5 pagesEffect of PMMA Additiontripti060586No ratings yet

- The Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Document9 pagesThe Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Aji Candra ElNo ratings yet

- 10.1515 Epoly.2005.5.1.273Document11 pages10.1515 Epoly.2005.5.1.273Hoang BuiNo ratings yet

- Gradient Distribution of Pan Based CellsDocument19 pagesGradient Distribution of Pan Based Cellsbroneissalaso-3573No ratings yet

- Characterization of An Electrospinning Process Using Different PAN/DMF ConcentrationsDocument6 pagesCharacterization of An Electrospinning Process Using Different PAN/DMF ConcentrationsAsif Fareed QaisraniNo ratings yet

- Slimming World, Feb 2011Document5 pagesSlimming World, Feb 2011emediageNo ratings yet

- TFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyDocument10 pagesTFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyAlisya AlyaNo ratings yet

- Effect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersDocument5 pagesEffect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersMuhammad Shafiz DanialNo ratings yet

- A General Approach To High-Ef Ficiency Perovskite Solar Cells by Any AntisolventDocument11 pagesA General Approach To High-Ef Ficiency Perovskite Solar Cells by Any AntisolventBhabaniNo ratings yet

- Removal of Post-Etch Photoresist and Sidewall Residues Using Organic Solvent and Additive Combined With Physical ForcesDocument5 pagesRemoval of Post-Etch Photoresist and Sidewall Residues Using Organic Solvent and Additive Combined With Physical Forcesfreebee12345No ratings yet

- Preparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationDocument8 pagesPreparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationAyyaz ButtNo ratings yet

- Aqueous Solution-Gel Preparation of Ultrathin Zro Films For Gate Dielectric ApplicationDocument23 pagesAqueous Solution-Gel Preparation of Ultrathin Zro Films For Gate Dielectric Applicationvick ENo ratings yet

- Enhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmDocument8 pagesEnhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmMuhammad Bilal QadirNo ratings yet

- Calculation of The Rate Constant For The Ultrasonic Degradation of Aqueous Solutions of Polyvinyl Alcohol by ViscometryDocument5 pagesCalculation of The Rate Constant For The Ultrasonic Degradation of Aqueous Solutions of Polyvinyl Alcohol by ViscometryAdonilson FreitasNo ratings yet

- Exfoliation and Dispersion of Graphene in Ethanol-Water MixturesDocument7 pagesExfoliation and Dispersion of Graphene in Ethanol-Water MixturesHoang Anh NguyenNo ratings yet

- Preparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsDocument5 pagesPreparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsRana Sabouni TabariNo ratings yet

- Impact of Surfactants On The Electrical and Rheological Aspects of Silica Based Synthetic Ester NanofluidsDocument9 pagesImpact of Surfactants On The Electrical and Rheological Aspects of Silica Based Synthetic Ester NanofluidsSathu Yaduvamsee ee23e007No ratings yet

- Electrospun Poly Lactic Acid (PLA) Fibreseffect of Different Solvent Systems On Fibre Morphology and DiameterDocument10 pagesElectrospun Poly Lactic Acid (PLA) Fibreseffect of Different Solvent Systems On Fibre Morphology and DiameterMuhammad Mushtaq AliNo ratings yet

- 3Document8 pages3DeepikaNo ratings yet

- Corona PretreatmentDocument8 pagesCorona PretreatmentcehigueraNo ratings yet

- Drevet 2010Document10 pagesDrevet 2010hayet debbichNo ratings yet

- Highly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberDocument9 pagesHighly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberTeddy KimNo ratings yet

- Studies of Polyvinyl Alcohol: Under Temperature and Humidity Control Application NoteDocument3 pagesStudies of Polyvinyl Alcohol: Under Temperature and Humidity Control Application Notekishorkumarn8212No ratings yet

- Effect of NCO and OH Molar RatioDocument10 pagesEffect of NCO and OH Molar RatioUsama AwadNo ratings yet

- 2021-Muh. Ada-DSSC Nanocrystals - CompressedDocument12 pages2021-Muh. Ada-DSSC Nanocrystals - CompressedIrwan Ibn HasanNo ratings yet

- Effect of Salt Additives On The Fabrication of Poly (Vinylidene Fluoride-Co-Hexafluropropylene) (PVDF-HFP) Nanofiber Membranes For Air Gap Membrane DistillationDocument6 pagesEffect of Salt Additives On The Fabrication of Poly (Vinylidene Fluoride-Co-Hexafluropropylene) (PVDF-HFP) Nanofiber Membranes For Air Gap Membrane DistillationKanthan DevanNo ratings yet

- CG5082 Advanced Transport Processes - W.kwapinski Spring 2013Document11 pagesCG5082 Advanced Transport Processes - W.kwapinski Spring 2013WilliamLoobyNo ratings yet

- Ionic Conductivity Enhancement For Pva/ 20Wt.% Cuso Gel Polymer Electrolyte by Using GlycerinDocument9 pagesIonic Conductivity Enhancement For Pva/ 20Wt.% Cuso Gel Polymer Electrolyte by Using GlycerinFADHIL AGUNG NUGRAHANo ratings yet

- 2013-Enhanced Piezoelectric Properties of Electrospun Poly (Vinylidene Fluoride) Multiwalled Carbon Nanotube Composites Due to High β‑Phase Formation in Poly (Vinylidene Fluoride)Document9 pages2013-Enhanced Piezoelectric Properties of Electrospun Poly (Vinylidene Fluoride) Multiwalled Carbon Nanotube Composites Due to High β‑Phase Formation in Poly (Vinylidene Fluoride)AmirNo ratings yet

- Surface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZDocument5 pagesSurface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZArun Kumar ShresthaNo ratings yet

- POFT - EditDocument5 pagesPOFT - Editchuah kelvinNo ratings yet

- The Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesDocument13 pagesThe Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesTwinkle RanaNo ratings yet

- Magnetofluidics SpreadingDocument11 pagesMagnetofluidics SpreadingVijaykumar VarmaNo ratings yet

- Understanding Membrane Distillation and Osmotic DistillationFrom EverandUnderstanding Membrane Distillation and Osmotic DistillationNo ratings yet

- SU-8 Lithography UVDocument11 pagesSU-8 Lithography UVRana Sabouni TabariNo ratings yet

- MohemDocument19 pagesMohemRana Sabouni TabariNo ratings yet

- JMMpaperDocument13 pagesJMMpaperRana Sabouni TabariNo ratings yet

- Micromachines 10 00438 v3Document13 pagesMicromachines 10 00438 v3Rana Sabouni TabariNo ratings yet

- Fabrication, Integration and Study of Micropillars For Cell CultureDocument214 pagesFabrication, Integration and Study of Micropillars For Cell CultureRana Sabouni TabariNo ratings yet

- The Tensile Propertiesof Electrospun Nylon 6 Single NanofibersDocument14 pagesThe Tensile Propertiesof Electrospun Nylon 6 Single NanofibersRana Sabouni TabariNo ratings yet

- Kheili Mohem 18Document7 pagesKheili Mohem 18Rana Sabouni TabariNo ratings yet

- Srep 09093Document9 pagesSrep 09093Rana Sabouni TabariNo ratings yet

- Nano Material For Hearing AidDocument4 pagesNano Material For Hearing AidRana Sabouni TabariNo ratings yet

- Print 6Document11 pagesPrint 6Rana Sabouni TabariNo ratings yet

- Kheili Mohemtar 3Document19 pagesKheili Mohemtar 3Rana Sabouni TabariNo ratings yet

- Print 7Document6 pagesPrint 7Rana Sabouni TabariNo ratings yet

- Hydrogel 3Document11 pagesHydrogel 3Rana Sabouni TabariNo ratings yet

- Porous PVDF As Effective Sonic Wave Driven Nanogenerators: AbstractDocument6 pagesPorous PVDF As Effective Sonic Wave Driven Nanogenerators: AbstractRana Sabouni TabariNo ratings yet

- Nanoparticle Based Drug Delivery in The Inner Ear Current Challenges Limitations and OpportunitiesDocument10 pagesNanoparticle Based Drug Delivery in The Inner Ear Current Challenges Limitations and OpportunitiesRana Sabouni TabariNo ratings yet

- PVDF Sensor PaperDocument4 pagesPVDF Sensor PaperRana Sabouni TabariNo ratings yet

- Hydrogel 5Document17 pagesHydrogel 5Rana Sabouni TabariNo ratings yet

- Large-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsDocument9 pagesLarge-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsRana Sabouni TabariNo ratings yet

- Morphology and Phase Transition of High Melt Temperature Crystallized Poly (Vinylidene Fluoride)Document8 pagesMorphology and Phase Transition of High Melt Temperature Crystallized Poly (Vinylidene Fluoride)Rana Sabouni TabariNo ratings yet

- Polymers 13 00174Document23 pagesPolymers 13 00174Rana Sabouni TabariNo ratings yet

- Kheiliiiiiiiiiiiiiiiiiiiiiiii Mohem222Document41 pagesKheiliiiiiiiiiiiiiiiiiiiiiiii Mohem222Rana Sabouni TabariNo ratings yet

- Flexible Piezoelectric Transducer Based On Electrospun PVDF Nanofibers For Sensing ApplicationsDocument4 pagesFlexible Piezoelectric Transducer Based On Electrospun PVDF Nanofibers For Sensing ApplicationsRana Sabouni TabariNo ratings yet

- 5Document9 pages5Rana Sabouni TabariNo ratings yet

- Biomimetic Artificial Basilar Membranes For Next-Generation Cochlear ImplantsDocument16 pagesBiomimetic Artificial Basilar Membranes For Next-Generation Cochlear ImplantsRana Sabouni TabariNo ratings yet

- Structural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioDocument7 pagesStructural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioRana Sabouni TabariNo ratings yet

- Recent Advancements in The Regeneration of Auditory Hair Cells and Hearing RestorationDocument16 pagesRecent Advancements in The Regeneration of Auditory Hair Cells and Hearing RestorationRana Sabouni TabariNo ratings yet

- The Advantages and Disadvantages of ITC, ITE andDocument10 pagesThe Advantages and Disadvantages of ITC, ITE andRana Sabouni TabariNo ratings yet

- A Mouse Model For Human Deafness DFNB22 Reveals That Hearing Impairment Is Due To A Loss of Inner Hair Cell StimulationDocument6 pagesA Mouse Model For Human Deafness DFNB22 Reveals That Hearing Impairment Is Due To A Loss of Inner Hair Cell StimulationRana Sabouni TabariNo ratings yet

- Flow Through PipesDocument31 pagesFlow Through PipesShyam Pandey50% (2)

- 3 2 Creep PDFDocument7 pages3 2 Creep PDFtnchsgNo ratings yet

- Question Bank - HMTDocument5 pagesQuestion Bank - HMTSUNDARAMAHALINGAM ANo ratings yet

- ThermodynamicsDocument40 pagesThermodynamicsais3000No ratings yet

- Publication 3Document10 pagesPublication 3Engr Muhammad Zaheer SaleemNo ratings yet

- Lateral Earth PressureDocument15 pagesLateral Earth Pressuresreendd100% (1)

- Chap 8 LectureDocument27 pagesChap 8 LectureMuhammadAizatNo ratings yet

- Connection DesignDocument94 pagesConnection DesignAnand.5100% (1)

- 08chapters7 8Document26 pages08chapters7 8Bucket IdliNo ratings yet

- Column DesignDocument4 pagesColumn DesignArnel Dodong83% (6)

- Question Paper Concrete TechnologyDocument8 pagesQuestion Paper Concrete Technologyjsyadav.nithNo ratings yet

- Lecture 11 PDFDocument26 pagesLecture 11 PDFmariaNo ratings yet

- Midterm Es 404Document4 pagesMidterm Es 404Ian GaleonNo ratings yet

- Tolerancias de FundicionDocument15 pagesTolerancias de FundicionSalvadorNo ratings yet

- Tunneling-Assisted Poole-Frenkel Conduction Mechanism in HfO2 Thin FilmsDocument7 pagesTunneling-Assisted Poole-Frenkel Conduction Mechanism in HfO2 Thin FilmsDiego Carranza CelisNo ratings yet

- 3.mass Transfer Coefficients PDFDocument13 pages3.mass Transfer Coefficients PDFMohit SathwaraNo ratings yet

- Neutral Grounding Resistor (NGR)Document14 pagesNeutral Grounding Resistor (NGR)vennapusa VenkateshNo ratings yet

- Full PaperDocument34 pagesFull PaperCarrieann Stocks100% (1)

- Plasticity Models For Soils PDFDocument74 pagesPlasticity Models For Soils PDFJianfeng XueNo ratings yet

- HandoutChemical EquilibriumDocument10 pagesHandoutChemical EquilibriumPankaj KumarNo ratings yet

- Strain Gauge Installation Examples PDFDocument5 pagesStrain Gauge Installation Examples PDFWandyy GonçalvesNo ratings yet

- Structural Analysis Problems For PracticeDocument10 pagesStructural Analysis Problems For PracticePradyumnaSadgir100% (1)

- Datasheet en AW-6063Document1 pageDatasheet en AW-6063Erick De La RoSaNo ratings yet

- Atomic Structure - IiDocument9 pagesAtomic Structure - IiSUMITH K SNo ratings yet

- ContentsDocument19 pagesContentsClaims JoseNo ratings yet

- 9 SteelDocument14 pages9 SteelSteven KuaNo ratings yet

- Studies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsDocument24 pagesStudies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsTirupati TulasiNo ratings yet

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- Analysis of Rotational Constant of HBRDocument4 pagesAnalysis of Rotational Constant of HBRRock MaheshNo ratings yet

- Product Technical Specification: Power CableDocument6 pagesProduct Technical Specification: Power CableGanabathi NadarajooNo ratings yet

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Uploaded by

Rana Sabouni TabariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Effect of Solution Concentration On The Electrospray/Electrospinning Transition and On The Crystalline Phase of PVDF

Uploaded by

Rana Sabouni TabariCopyright:

Available Formats

Materials Sciences and Applications, 2010, 1, 247-252

doi:10.4236/msa.2010.14036 Published Online October 2010 (http://www.SciRP.org/journal/msa)

Effect of Solution Concentration on the

Electrospray/Electrospinning Transition and

on the Crystalline Phase of PVDF

Lígia Maria Manzine Costa, Rosário Elida Suman Bretas, Rinaldo Gregorio, Jr.

Department of Materials Engineering, Federal University of São Carlos, Rod. Washington Luís, São Carlos-SP, Brazil.

Email: gregorio@ufscar.br

Received March 19th, 2010; revised June 17th, 2010; accepted June 21st, 2010.

ABSTRACT

A study was conducted regarding the effect of concentration of poly (vinylidene fluoride) (PVDF)/N,N-dimethylformamide

(DMF) and PVDF/DMF/acetone solutions on the transition between electrospray and electrospinning and on the for-

mation of the and crystalline phases of PVDF. The crystalline phases present in the samples, crystallinity and

morphology were determined by Fourier transform infrared spectroscopy (FTIR), differential scanning calorimetry

(DSC) and scanning electron microscopy (SEM), respectively. Low concentration solutions resulted in films consisting

of small droplets (electrospray) containing predominantly the phase. High concentration solutions resulted in a

non-woven mesh of nano-to-micron diameter fibers (electrospinning) containing exclusively the phase. These results

showed that, the formation of this phase in the electrospinning is related mainly to the solvent evaporation rate, and not

to drawing experienced by the polymer during the process. Solvent type affected the amount of crystalline phase present,

the boundary concentration between the two processes and the average diameter of fibers. Meshes processed by elec-

trospinning display a degree of crystallinity higher than the films obtained by electrospray.

Keywords: Poly(Vinylidene Fluoride) (PVDF), Electrospinning, Electrospray, Crystalline Phase, Fibers, Morphology

1. Introduction dominantly the phase [12-18]. In this technique the

polymer solution is added to a capillary (which can be a

PVDF, poly(vinylidene fluoride), is a widely investigated syringe with needle). The solution forms a droplet at the

polymer due to its excellent mechanical properties, tip of the needle due to surface tension. If a sufficiently

chemical stability and ferroelectricity. This polymer has high electric voltage (5-30 kV) is applied to the solution

a simple chemical formula, -CH2-CF2-, and may crystal- electric charges accumulate in the droplet. When the

lize in at least four crystalline phases known as α, β, γ electrostatic repulsion between the charges overcomes

and δ. The structure and property of these phases are well the surface tension and viscoelasticity of the droplet this

documented in the literature [1]. Each crystalline phase assumes the shape of a cone. When the force exerted by

confers characteristic properties to the polymer and the electric field, formed between the droplet and a

therefore distinct applications. The β phase is that which grounded collector, overcomes the surface tension, a thin

displays the strongest pyro and piezoelectric activities jet is formed. The jet of the charged solution is acceler-

and is therefore technologically more interesting. Many ated towards the collector under the action of the electric

techniques have been used to obtain this phase, being the field. If the concentration of the solution is sufficiently

most common uni or biaxial drawing of originally α high (viscous) to stabilize the jet, the polymer solution is

phase films [2-6]. Crystallization of PVDF from solution severely stretched and the solvent evaporates to form

(casting) may also result in the phase, depending on the ultrathin fibers which solidify and are deposited on the

evaporation rate of the solvent [7-9]. Low rates result collector forming a non-woven mesh of fibers. Some

predominantly in the phase, whereas high rates favor authors [13-17] attribute the formation of β phase in

the phase. Electrospinning [10,11] also produces pre- electrospun PVDF meshes to this severe drawing ex-

Copyright © 2010 SciRes. MSA

248 Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF

perienced by the polymer jet solution. This elongation Table 1. Properties of the solvents used (20℃).

process would be similar to the well known transi- Boiling

Density Viscosity

tion caused by mechanical drawing at T 90℃ [2-6]. Solvent Formula

(g/mL) point (℃) (mPa.s)

A variant of electrospinning is electrospray [19]. The

Acetone C3H6O 0.786 56.5 0.326

basic difference between these two processes lies in the

concentration of the solution. In electrospray the concen- DMF C3H7NO 0.944 153 0.820

tration is sufficiently low to destabilize the charged jet

which then breaks down into small spherical droplets that

solidify during the course and are deposited on the col-

lector. In this case the polymer solution does not experi-

ence severe drawing and the formed film consists of

small droplets instead of fibers.

The objectives of the current investigation were: 1)

determine the solution concentration at which the transi-

tion between electrospray and electrospinning of PVDF

occurs and 2) verify through the electrospray technique,

where no stretching occurs, that the formation of the

phase depends fundamentally on the solvent evaporation

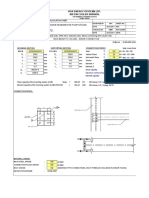

rate. The effect of the type of solvent in the process was Figure 1. Scheme of the setup used in the Electrospinning/

also verified. Electrospray process.

2. Experimental Methods

brated with In, using samples of 8 mg and heating rate

2.1. Materials of 10℃/min. Degree of crystallinity was determined by

The PVDF used was Foraflon® 4000HD, from Elf Ato- comparing the enthalpy of fusion of the sample obtained

chem. The solvents used were N,N-dimethylformamide by DSC with that of 100% crystalline PVDF- (104.5 J/g)

(DMF, Merck 99.5%) and acetone (Merck, 99.7%). So- [20]. Sample surface morphology was observed by using

lutions were prepared at concentrations of 5, 7, 10 and 15 a scanning electron microscope (Philips 30 FEG Model

wt% PVDF using as solvent pure DMF and a 3:1 v/v XL, operating at 15 kV) after gold coating. Size distribu-

mixture of DMF with acetone. The ratio of mixture DMF tion of the fibers diameters was determined by the soft-

and acetone was selected because they produce thinner ware “image J” developed by the National Institute of

and more homogeneous nanofibers in the electrospinning Health.

process [13]. Solubilization was carried out at 70℃ un- 3. Results and Discussions

der stirring for one hour. Table 1 shows some properties

of the solvents used. The micrographs in Figures 2(a) to (d) and 3(a) to (d)

present the morphology of the samples processed with

2.2. Electrospray/Electrospinning PVDF/DMF and PVDF/DMF/acetone solutions at dif-

A scheme of the system used in the electrospray/electro- ferent concentrations, respectively.

spinning process is shown in Figure 1. A 20-mL glass One can observe in Figures 2(a)-(b) (5 and 7 wt% in

syringe was used with a steel needle with internal di- DMF) and 3(a) (5 wt% in DMF/acetone) the formation

ameter of 0.7 mm. The distance between needle and col- of a film consisting of small droplets, characteristic of

lector was 3 cm and the electric voltage applied was 10 the electrospray process. The morphology of this film

kV, using a Bertan 210 30R (0-30 kV) high voltage source. depends among other things on droplet volume at impact

The collector used was an aluminum disk with diameter and on evaporation rate of the solvent [21]. In Figures

of 15 cm and width of 5 cm, at an angular velocity of 60 2(c)-(d) (10, 15 wt% in DMF) and 3(b)-(d) (7, 10 and 15

rpm. The process was carried out at 25℃ and RH 55%. wt% in DMF/acetone) fibers predominate, characteristic

of electrospinning. In micrographs 2(c) (10 wt% in DMF)

2.3. Characterizations and 3(b) (7 wt% in DMF/acetone) the electrospun sheets

The crystalline phases present in the samples were char- present some small droplets, demonstrating that concen-

acterized by transmission infrared spectroscopy (FTIR, tration was not yet ideal for the formation of homogene-

Perkin Elmer Spectrum 1000) in the range between 400 ous fibers. These results show that the boundary concen-

and 1000 cm-1 and with resolution of 2 cm-1. Calorimetric tration between electrospray and electrospinning ranges

analyses were conducted in a Perkin Elmer DSC-7, cali- from 7 to10 wt% PVDF in DMF and from 5 to 7 wt% in

Copyright © 2010 SciRes. MSA

Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF 249

(a) (b)

(c) (d)

Figure 2. Micrographs of the samples processed from PVDF/

DMF solution at the following concentrations (wt%): (a) 5; Figure 4. Size distribution of the fibers diameters processed

(b) 7; (c) 10 and (d) 15. from 15 wt% PVDF/DMF solution.

(a) (b)

(c) (d)

Figure 3. Micrographs of samples processed from solution

of PVDF with DMF/acetone (3:1 v/v) at the following con-

centrations (wt%): (a) 5; (b) 7; (c) 10 and (d) 15. Figure 5. Size distribution of the fibers diameters processed

from 15 wt% PVDF/DMF/acetone.

DMF/acetone mixture, at the conditions used of voltage

Average diameter of the nanofibers prepared from

and distance between needle and collector. The solution

DMF solution (514 nm) were superior to that obtained

containing acetone is less viscous than that of pure DMF

from DMF/acetone solution (330 nm), at the same con-

and therefore the electrospinning process should be initi-

centration. This has been caused by the lower viscosity

ated at a higher concentration. However, the high volatil-

of the acetone solution, since average fiber diameter in-

ity of acetone increased the jet concentration rapidly creases with solution viscosity [12]. That effect can be

during its course towards the collector, impeding forma- observed in Figures 2(c)-(d) and 3(b)-(d).

tion of droplets and resulting in electrospinning at a The phases present in the samples were analyzed by

lower initial concentration. Micrographs 2(d) (15 wt% in FTIR and results are presented in Figures 6 and 7 for

DMF) and 3(c)-(d) (10 and 15 wt% in DMF/acetone) DMF and DMF/acetone solutions at different concentra-

show fibers with improved homogeneity and no droplets, tions, respectively.

indicating that these concentrations are the optimum for All samples presented bands at 445, 510 and 840 cm-1,

obtaining electrospun meshes. characteristic of the phase of PVDF [22,23]. Therefore,

Figures 4 and 5 contain the size distribution of fibers the β phase predominated both in the electrosprayed

diameters prepared with 15 wt% PVDF in DMF and films and the electrospun meshes. Since no stretching

DMF/acetone, respectively. occurred during electrospray, we may conclude that for

Copyright © 2010 SciRes. MSA

250 Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF

ration temperature, and this resulted in the formation of a

small amount of in almost all concentrations. Thus, the

formation of the β phase in the electrospinning/electro-

spray process is related mainly to the solvent evaporation

rate, as verified in cast films [8,9], and not to drawing

experienced by the polymer during the electro-spinning

process, as suggested by some authors [13-17]. Low

evaporation rates result predominantly in the phase,

thermodynamically more favorable, intermediate rates in

a mixture of and and high rates in the phase, ki-

netically more favorable.

Figure 8 shows DSC curves for samples prepared with

5 and 10 wt% PVDF in DMF and DMF/acetone. The

DSC measurements give the melting point (Tm) (endo-

therm peak), enthalpy of fusion (H), and degree of

crystallinity (%C) of samples. These values are summa-

Figure 6. FTIR spectra of the samples with different wt% rized in Table 2.

PVDF in DMF solution. The characteristic bands of the α It is easy to observe that meshes produced by electro-

and β phase are pointed out in the figure. spinning display a degree of crystallinity higher when

compared to films obtained by electrospray. This result

probably happens due to the preferential orientation of

the chains in the direction of the nanofibers, caused by

the drawing experienced by the polymer during the elec-

trospinning and that facilitates the crystallization. In this

process the addition of acetone promoted a small in-

crease in the degree of the mesh crystallinity. The melt-

ing points, in all cases correspond to the temperature

range related to the PVDF α and β phases [7,23], which

confirm FTIR results.

4. Conclusions

The current investigation showed that formation of the β

crystalline phase of PVDF in the electrospun meshes is

Figure 7. FTIR spectra of the samples with different wt%

PVDF in 3:1 DMF/acetone solution. The characteristic

bands of the α and β phase are pointed out in the figure.

mation of this phase can not be attributed to drawing

experienced by the polymer during the process. The oc-

currence of weak bands at 614, 764 and 976 cm-1 indicate

the presence of a small amount of the phase [22,23],

observed at concentrations of 5 to 10 wt% in DMF/ace-

tone solution. In the solution containing pure DMF the

presence of the phase was only observed for 5 wt%.

Since solvent evaporation rate increases with decreasing

concentration of the solution, appearance of this phase

may be related to the higher solvent evaporation rate in

low-concentration solutions. The evaporation rate of the Figure 8. DSC curves for samples prepared with 5 wt%

solutions containing acetone increased in relation to those PVDF in DMF (a) and DMF/acetone (b); with 10 wt%

containing pure DMF, since acetone has a lower evapo- PVDF in DMF (c) and DMF/acetone (d).

Copyright © 2010 SciRes. MSA

Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF 251

Table 2. Melting point (Tm), enthalpy of fusion (H) and degree of cristallinity (%C) of the samples processed with

PVDF/DMF and PVDF/DMF/acetone solutions at different concentrations.

Sample Process Tm (℃) H (J/g) %C

5 wt% PVDF/DMF 166 46.2 44.6

Electrospray

5 wt% PVDF/DMF/acetone 167 46.8 45.2

10 wt% PVDF/DMF 168 53.4 51.1

Electrospinning

10 wt% PVDF/DMF/acetone 167 55.0 53.1

not related to drawing experienced by the polymer during Oriented Poly(Vinylidene Fluoride) Films Exclusively in

the process, as suggested by some authors. Formation of the Phase,” Journal of Polymer Science Part B: Poly-

mer Physics, Vol. 45, 2007, pp. 2793-2801.

the and phase is related primarily to the evaporation

rate of the solvent. High rates favor formation of the [7] R. Gregorio, Jr., and M. Cestari, “Effect of Crystallization

Temperature on the Crystalline Phase Content and Mor-

phase, whereas low rates favor the phase. Under the

phology of Poly(Vinylidene Fluoride),” Journal of Poly-

same conditions of voltage and needle-collector distance, mer Science Part B: Polymer Physics, Vol. 32, No. 5, pp.

the boundary concentration between electrospray and 859-870.

electrospinning depends on the solvent used. For PVDF [8] R. Gregorio, Jr. and D. S. Borges, “Effect of Crystalliza-

this concentration lies between 7 and 10 wt% with DMF tion Rate on the Formation of the Polymorphs of Solution

as solvent and between 5 and 7 wt% for the 3:1 DMF/ Cast Poly(Vinylidene Fluoride),” Polymer, Vol. 49, No.

acetone mixture. Moreover, addition of acetone to the 18, 2008, pp. 4009-4016.

solution reduced average fiber diameter. Meshes pro- [9] D. L. Chinaglia, R. Gregorio, Jr., J. C. Stefanello, R. A. P.

duced by electrospinning present degree of crystallinity Altafin, W. Wirges, F. Wang and R. Gerhard, “Influence

higher than the films obtained by electrospray, for both of the Solvent Evaporation Rate on the Crystalline Phases

of Solution-Cast Poly(Vinylidene Fluoride) Films,” Jour-

used solvents.

nal of Applied Polymer Science, Vol. 116, No. 2, 2010,

5. Acknowledgements pp. 785-791.

[10] A. Formhals, “Process and Apparatus for Preparing

The following agencies are acknowledged for financial Artificial Threads,” U.S. Patent 1,975,504, 1934.

support: CAPES, CNPq and FAPESP. [11] J. Doshi and D. H. Reneker, “Electrospinning Process and

Application of Electrospun Fibers,” Journal of Electro-

REFERENCES statics, Vol. 35, No. 2-3, 1995, pp. 151-160.

[12] M. Nasir, H. Matsumoto, T. Danno, M. Minagawa, T.

[1] K. Tashiro, “Crystal Structure and Phase Transition of

Irisawa, M. Shioya and A. Tanioka, “Control of Diameter,

PVDF and Related Copolymers,” In: H. S. Nalwa, Ed.,

Morphology, and Structure of PVDF Nanofiber Fabri-

Ferroelectric Polymers: Chemistry, Physics and Applica-

cated by Electrospray Deposition,” Journal of Polymer

ons, Marcel Dekker, New York, 1995, pp. 63-180.

Science Part B: Polymer Physics, Vol. 44, No. 5, pp. 779-

[2] R. Gregorio, Jr. and E. M. Ueno, “Effect of Crystalline 786.

Phase, Orientation and Temperature on the Dielectric [13] W. A. Yee, M. Kotaki, Y. Liu and X. Lu, “Morphology,

Properties of Poly(Vinylidene Fluoride) (PVDF),” Jour- Polymorphism Behavior and Molecular Orientation of

nal of Materials Science, Vol. 34, 1999, pp. 4489-4500. Electrospun Poly(Vinylidene Fluoride) Fibers,” Polymer,

[3] V. Sencadas, V. M. Moreira, S. Lanceros-Mendez, A. S. Vol. 48, No. 2, 2007, pp. 512-521.

Pouzada and R. Gregorio, Jr., “Alpha-to-Beta Transfor- [14] E. Ogut, O. S. Yordem, Y. Z. Menceloglu and M. Papila,

mation on PVDF Films Obtained by Uniaxial Stretch,” “Poly(Vinylidene Fluoride)/Zinc Oxid Smart Composite

Advanced Materials Forum III, Vol. 514-516, 2006, 872- Material,” Proceeding of SPIE, Vol. 6526, 2007, p.

876. 65260Q-1-10

[4] P. Sajkiewicz, A. Wasiak and Z. Goclowski, “Phase Tran- [15] J. Zheng, A. He, J. Li and C. C. Han, “Polymorphism

sitions during Stretching of Poly(Vinylidene Fluoride),” Control of Poly(Vinylidene Fluoride) through Electro-

European Polymer Journal, Vol. 35, No. 3, pp. 423-429. spinning,” Macromolecular Rapid Communications, Vol.

[5] D. T. Grubb and F. R. Kearney, “Phase Transitions dur- 28, No. 22, 2007, pp. 2159-2162.

ing Stretching of Poly(Vinylidene Fluoride),” Journal of [16] W. A. Yee, A. C. Nguyen, P. S. Lee, M. Kotaki, Y. Liu, B.

Polymer Science Part B: Polymer Physics, Vol. 28, No. T. Tan, S. Mhaisalkar and X. Lu, “Stress-Induced Struc-

11, 1990, pp. 2071-2078. tural Changes in Electrospun Polyvinylidene Difluoride

[6] M. C. Branciforti, V. Sencadas, S. Lanceros-Mendez and Nanofibers Colleted Using a Modified Rotating Disk,”

R. Gregorio, Jr., “New Technique of Processing Highly Polymer, Vol. 49, No. 19, 2008, pp. 4196-4203.

Copyright © 2010 SciRes. MSA

252 Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF

[17] J. S. Andrew and D. R. Clarke, “Effect of Electrospin- Polymer Physics, Vol. 11, No. 8, pp. 1503-1533.

ning on the Ferroelectric Phase Content of Polyvinylidene [21] I. B. Rietveld, K. Kobayashi, H. Yamada and K. Matsu-

Difluoride Fibers,” Langmuir, Vol. 24, No. 3, 2008, pp. shige, “Model Supported Morphology Control of Elec-

670-672. trospray Deposited Poly(Vinylidene Fluoride) Film,”

[18] H. Na, Y. Zhao, C. Zhao, C. Zhao and X. Yuan, (2008) Macromolecular Symposium, 2007, pp. 249-250, 322-

Effect of Hot-Press on Electrospun Poly(Vinylidene Fluo- 329.

ride) Membranes,” Polymer Engineering and Science, Vol. [22] M. Kobayashi, K. Tashiro and H. Tadokoro, “Molecular

48, No. 5, pp. 934-940. Vibrations of Three Crystal Forms of Poly(Vilidene Fluo-

[19] G. Taylor, “Electrospray,” Proceedings of Royal Society ride),” Macromolecules, Vol. 8, No. 2, 1975, pp. 158-170.

of London, London, Vol. A280, 1964, pp. 383-387. [23] R. Gregorio, Jr., “Determination of the , and Crys-

[20] K. Nakagawa and Y. Ishida, “Dielectric Relaxations and talline Phases of Poly(Vinylidene Fluoride) Films Pre-

Molecular Motions in Poly(Vinylidene Fluoride) with pared at Different Conditions,” Journal of Applied Poly-

Crystal Form II,” Journal of Polymer Science Part B: mer Science, Vol. 100, No. 4, 2006, pp. 3272-3279.

Copyright © 2010 SciRes. MSA

You might also like

- Electrospinning of PMMADocument7 pagesElectrospinning of PMMAvetrixNo ratings yet

- Effect of Crosslinking On The MechanicalDocument8 pagesEffect of Crosslinking On The MechanicalThoại Nguyễn QuốcNo ratings yet

- MohemDocument19 pagesMohemRana Sabouni TabariNo ratings yet

- Influence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesDocument9 pagesInfluence of Nanoscale Nio On Magnetic and Electrochemical Behavior of Pvdf-Based Polymer NanocompositesBharathi PonrajNo ratings yet

- Structural and Dielectrical Study of PZT/PVDF Film CompositesDocument10 pagesStructural and Dielectrical Study of PZT/PVDF Film CompositesInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- PVDFDocument9 pagesPVDFAnish KumarNo ratings yet

- Highly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon Fiber Supporting DataDocument12 pagesHighly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon Fiber Supporting DataTeddy KimNo ratings yet

- Effect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesDocument10 pagesEffect of Oxide Nanoparticles On Thermal and Mechanical Properties Ofelectrospun Separators For Lithium-Ion BatteriesTamam AbymNo ratings yet

- KJ - Volume 4 - Issue 2 - Pages 201-208Document8 pagesKJ - Volume 4 - Issue 2 - Pages 201-208gamil2No ratings yet

- ScienceDocument3 pagesScienceDhirendra SinghNo ratings yet

- Effect of Surface Modification of Nanosilica On Crystallization, Thermal and Mechanical Properties of Poly (Vinylidene Fluoride)Document10 pagesEffect of Surface Modification of Nanosilica On Crystallization, Thermal and Mechanical Properties of Poly (Vinylidene Fluoride)Rana Sabouni TabariNo ratings yet

- Structural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioDocument7 pagesStructural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioRana Sabouni TabariNo ratings yet

- Ja8005918 BaozhenanDocument2 pagesJa8005918 BaozhenanYonggang ZhenNo ratings yet

- Artikel 2Document12 pagesArtikel 2Carolina TambaNo ratings yet

- Water Absorption by An Epoxy Resin and Its Effect On The Mechanical Properties and Infra-Red SpectraDocument7 pagesWater Absorption by An Epoxy Resin and Its Effect On The Mechanical Properties and Infra-Red SpectraNavid HoseiniNo ratings yet

- Fabrication and Morphological Control of Electrospun Ethyl Cellulose NanofibersDocument4 pagesFabrication and Morphological Control of Electrospun Ethyl Cellulose NanofibersMaría BorregoNo ratings yet

- Effect of Crystalline Phase, Orientation and Temperature On The Dielectric Properties of Poly (Vinylidene Fluoride) (PVDF)Document12 pagesEffect of Crystalline Phase, Orientation and Temperature On The Dielectric Properties of Poly (Vinylidene Fluoride) (PVDF)salmanNo ratings yet

- The Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesDocument12 pagesThe Effect of Processing Variables On The Morphology of Electrospun Nanofibers and Textilesالكترنيات قداحNo ratings yet

- Synthesis of Poly (3,4 Ethylenedioxythi ParadeeDocument8 pagesSynthesis of Poly (3,4 Ethylenedioxythi ParadeeZim ShahNo ratings yet

- Electro CoalescenciaDocument7 pagesElectro CoalescenciaiqubaldoNo ratings yet

- The Formation of Microporous Polyvinylidene Difluoride Membranes by Phase SeparationDocument20 pagesThe Formation of Microporous Polyvinylidene Difluoride Membranes by Phase SeparationAfrillia FahrinaNo ratings yet

- Relationship Between Different Mixing Conditions and DC Breakdown Strength of High Density Polyethylene CompoundDocument3 pagesRelationship Between Different Mixing Conditions and DC Breakdown Strength of High Density Polyethylene Compoundrogerio.salustianoNo ratings yet

- Study of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationDocument6 pagesStudy of A New Polymer Electrolyte Poly (Ethylene Oxide) : Naclo With Several Plasticizers For Battery ApplicationKRUNAL ParmarNo ratings yet

- 2008 Effect of RH On Electrospun NanofibersDocument10 pages2008 Effect of RH On Electrospun NanofibersEliton Medeiros Candido de MacêdoNo ratings yet

- Structural and Electrical Properties of FerroelectDocument11 pagesStructural and Electrical Properties of FerroelectRavi KiranNo ratings yet

- FiltrationDocument16 pagesFiltrationYash PatelNo ratings yet

- Effect of PMMA AdditionDocument5 pagesEffect of PMMA Additiontripti060586No ratings yet

- The Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Document9 pagesThe Prediction of Cone-Jet Formation in Electrospray Method Using Computational Fluid Dynamics (CFD)Aji Candra ElNo ratings yet

- 10.1515 Epoly.2005.5.1.273Document11 pages10.1515 Epoly.2005.5.1.273Hoang BuiNo ratings yet

- Gradient Distribution of Pan Based CellsDocument19 pagesGradient Distribution of Pan Based Cellsbroneissalaso-3573No ratings yet

- Characterization of An Electrospinning Process Using Different PAN/DMF ConcentrationsDocument6 pagesCharacterization of An Electrospinning Process Using Different PAN/DMF ConcentrationsAsif Fareed QaisraniNo ratings yet

- Slimming World, Feb 2011Document5 pagesSlimming World, Feb 2011emediageNo ratings yet

- TFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyDocument10 pagesTFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyAlisya AlyaNo ratings yet

- Effect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersDocument5 pagesEffect of Concentration and Nozzle-Collector Distance On The Morphology of NanofibersMuhammad Shafiz DanialNo ratings yet

- A General Approach To High-Ef Ficiency Perovskite Solar Cells by Any AntisolventDocument11 pagesA General Approach To High-Ef Ficiency Perovskite Solar Cells by Any AntisolventBhabaniNo ratings yet

- Removal of Post-Etch Photoresist and Sidewall Residues Using Organic Solvent and Additive Combined With Physical ForcesDocument5 pagesRemoval of Post-Etch Photoresist and Sidewall Residues Using Organic Solvent and Additive Combined With Physical Forcesfreebee12345No ratings yet

- Preparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationDocument8 pagesPreparation of Polyvinylchloride Membranes From Solvent Mixture by Immersion PrecipitationAyyaz ButtNo ratings yet

- Aqueous Solution-Gel Preparation of Ultrathin Zro Films For Gate Dielectric ApplicationDocument23 pagesAqueous Solution-Gel Preparation of Ultrathin Zro Films For Gate Dielectric Applicationvick ENo ratings yet

- Enhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmDocument8 pagesEnhancing The Performance of Dye-Sensitized Solar Cells Based On An Organic Dye by Incorporating TiO2 Nanotube in A TiO2 Nanoparticle FilmMuhammad Bilal QadirNo ratings yet

- Calculation of The Rate Constant For The Ultrasonic Degradation of Aqueous Solutions of Polyvinyl Alcohol by ViscometryDocument5 pagesCalculation of The Rate Constant For The Ultrasonic Degradation of Aqueous Solutions of Polyvinyl Alcohol by ViscometryAdonilson FreitasNo ratings yet

- Exfoliation and Dispersion of Graphene in Ethanol-Water MixturesDocument7 pagesExfoliation and Dispersion of Graphene in Ethanol-Water MixturesHoang Anh NguyenNo ratings yet

- Preparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsDocument5 pagesPreparation of Pvdf-Based Electrospun Membranes and Their Application As SeparatorsRana Sabouni TabariNo ratings yet

- Impact of Surfactants On The Electrical and Rheological Aspects of Silica Based Synthetic Ester NanofluidsDocument9 pagesImpact of Surfactants On The Electrical and Rheological Aspects of Silica Based Synthetic Ester NanofluidsSathu Yaduvamsee ee23e007No ratings yet

- Electrospun Poly Lactic Acid (PLA) Fibreseffect of Different Solvent Systems On Fibre Morphology and DiameterDocument10 pagesElectrospun Poly Lactic Acid (PLA) Fibreseffect of Different Solvent Systems On Fibre Morphology and DiameterMuhammad Mushtaq AliNo ratings yet

- 3Document8 pages3DeepikaNo ratings yet

- Corona PretreatmentDocument8 pagesCorona PretreatmentcehigueraNo ratings yet

- Drevet 2010Document10 pagesDrevet 2010hayet debbichNo ratings yet

- Highly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberDocument9 pagesHighly Porous Electrospun Polyvinylidene Fluoride (PVDF) - Based Carbon FiberTeddy KimNo ratings yet

- Studies of Polyvinyl Alcohol: Under Temperature and Humidity Control Application NoteDocument3 pagesStudies of Polyvinyl Alcohol: Under Temperature and Humidity Control Application Notekishorkumarn8212No ratings yet

- Effect of NCO and OH Molar RatioDocument10 pagesEffect of NCO and OH Molar RatioUsama AwadNo ratings yet

- 2021-Muh. Ada-DSSC Nanocrystals - CompressedDocument12 pages2021-Muh. Ada-DSSC Nanocrystals - CompressedIrwan Ibn HasanNo ratings yet

- Effect of Salt Additives On The Fabrication of Poly (Vinylidene Fluoride-Co-Hexafluropropylene) (PVDF-HFP) Nanofiber Membranes For Air Gap Membrane DistillationDocument6 pagesEffect of Salt Additives On The Fabrication of Poly (Vinylidene Fluoride-Co-Hexafluropropylene) (PVDF-HFP) Nanofiber Membranes For Air Gap Membrane DistillationKanthan DevanNo ratings yet

- CG5082 Advanced Transport Processes - W.kwapinski Spring 2013Document11 pagesCG5082 Advanced Transport Processes - W.kwapinski Spring 2013WilliamLoobyNo ratings yet

- Ionic Conductivity Enhancement For Pva/ 20Wt.% Cuso Gel Polymer Electrolyte by Using GlycerinDocument9 pagesIonic Conductivity Enhancement For Pva/ 20Wt.% Cuso Gel Polymer Electrolyte by Using GlycerinFADHIL AGUNG NUGRAHANo ratings yet

- 2013-Enhanced Piezoelectric Properties of Electrospun Poly (Vinylidene Fluoride) Multiwalled Carbon Nanotube Composites Due to High β‑Phase Formation in Poly (Vinylidene Fluoride)Document9 pages2013-Enhanced Piezoelectric Properties of Electrospun Poly (Vinylidene Fluoride) Multiwalled Carbon Nanotube Composites Due to High β‑Phase Formation in Poly (Vinylidene Fluoride)AmirNo ratings yet

- Surface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZDocument5 pagesSurface Modification of Polycarbonate Using Mesh Electrode at Atmospheric Pressure Discharge at 50 HZArun Kumar ShresthaNo ratings yet

- POFT - EditDocument5 pagesPOFT - Editchuah kelvinNo ratings yet

- The Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesDocument13 pagesThe Effect of Processing Variables On The Morphology of Electrospun Nanofibers and TextilesTwinkle RanaNo ratings yet

- Magnetofluidics SpreadingDocument11 pagesMagnetofluidics SpreadingVijaykumar VarmaNo ratings yet

- Understanding Membrane Distillation and Osmotic DistillationFrom EverandUnderstanding Membrane Distillation and Osmotic DistillationNo ratings yet

- SU-8 Lithography UVDocument11 pagesSU-8 Lithography UVRana Sabouni TabariNo ratings yet

- MohemDocument19 pagesMohemRana Sabouni TabariNo ratings yet

- JMMpaperDocument13 pagesJMMpaperRana Sabouni TabariNo ratings yet

- Micromachines 10 00438 v3Document13 pagesMicromachines 10 00438 v3Rana Sabouni TabariNo ratings yet

- Fabrication, Integration and Study of Micropillars For Cell CultureDocument214 pagesFabrication, Integration and Study of Micropillars For Cell CultureRana Sabouni TabariNo ratings yet

- The Tensile Propertiesof Electrospun Nylon 6 Single NanofibersDocument14 pagesThe Tensile Propertiesof Electrospun Nylon 6 Single NanofibersRana Sabouni TabariNo ratings yet

- Kheili Mohem 18Document7 pagesKheili Mohem 18Rana Sabouni TabariNo ratings yet

- Srep 09093Document9 pagesSrep 09093Rana Sabouni TabariNo ratings yet

- Nano Material For Hearing AidDocument4 pagesNano Material For Hearing AidRana Sabouni TabariNo ratings yet

- Print 6Document11 pagesPrint 6Rana Sabouni TabariNo ratings yet

- Kheili Mohemtar 3Document19 pagesKheili Mohemtar 3Rana Sabouni TabariNo ratings yet

- Print 7Document6 pagesPrint 7Rana Sabouni TabariNo ratings yet

- Hydrogel 3Document11 pagesHydrogel 3Rana Sabouni TabariNo ratings yet

- Porous PVDF As Effective Sonic Wave Driven Nanogenerators: AbstractDocument6 pagesPorous PVDF As Effective Sonic Wave Driven Nanogenerators: AbstractRana Sabouni TabariNo ratings yet

- Nanoparticle Based Drug Delivery in The Inner Ear Current Challenges Limitations and OpportunitiesDocument10 pagesNanoparticle Based Drug Delivery in The Inner Ear Current Challenges Limitations and OpportunitiesRana Sabouni TabariNo ratings yet

- PVDF Sensor PaperDocument4 pagesPVDF Sensor PaperRana Sabouni TabariNo ratings yet

- Hydrogel 5Document17 pagesHydrogel 5Rana Sabouni TabariNo ratings yet

- Large-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsDocument9 pagesLarge-Scale Fabrication of Robust Textile Triboelectric NanogeneratorsRana Sabouni TabariNo ratings yet

- Morphology and Phase Transition of High Melt Temperature Crystallized Poly (Vinylidene Fluoride)Document8 pagesMorphology and Phase Transition of High Melt Temperature Crystallized Poly (Vinylidene Fluoride)Rana Sabouni TabariNo ratings yet

- Polymers 13 00174Document23 pagesPolymers 13 00174Rana Sabouni TabariNo ratings yet

- Kheiliiiiiiiiiiiiiiiiiiiiiiii Mohem222Document41 pagesKheiliiiiiiiiiiiiiiiiiiiiiiii Mohem222Rana Sabouni TabariNo ratings yet

- Flexible Piezoelectric Transducer Based On Electrospun PVDF Nanofibers For Sensing ApplicationsDocument4 pagesFlexible Piezoelectric Transducer Based On Electrospun PVDF Nanofibers For Sensing ApplicationsRana Sabouni TabariNo ratings yet

- 5Document9 pages5Rana Sabouni TabariNo ratings yet

- Biomimetic Artificial Basilar Membranes For Next-Generation Cochlear ImplantsDocument16 pagesBiomimetic Artificial Basilar Membranes For Next-Generation Cochlear ImplantsRana Sabouni TabariNo ratings yet

- Structural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioDocument7 pagesStructural Deformation of PVDF Nanoweb Due To Electrospinning Behavior Affected by Solvent RatioRana Sabouni TabariNo ratings yet

- Recent Advancements in The Regeneration of Auditory Hair Cells and Hearing RestorationDocument16 pagesRecent Advancements in The Regeneration of Auditory Hair Cells and Hearing RestorationRana Sabouni TabariNo ratings yet

- The Advantages and Disadvantages of ITC, ITE andDocument10 pagesThe Advantages and Disadvantages of ITC, ITE andRana Sabouni TabariNo ratings yet

- A Mouse Model For Human Deafness DFNB22 Reveals That Hearing Impairment Is Due To A Loss of Inner Hair Cell StimulationDocument6 pagesA Mouse Model For Human Deafness DFNB22 Reveals That Hearing Impairment Is Due To A Loss of Inner Hair Cell StimulationRana Sabouni TabariNo ratings yet

- Flow Through PipesDocument31 pagesFlow Through PipesShyam Pandey50% (2)

- 3 2 Creep PDFDocument7 pages3 2 Creep PDFtnchsgNo ratings yet

- Question Bank - HMTDocument5 pagesQuestion Bank - HMTSUNDARAMAHALINGAM ANo ratings yet

- ThermodynamicsDocument40 pagesThermodynamicsais3000No ratings yet

- Publication 3Document10 pagesPublication 3Engr Muhammad Zaheer SaleemNo ratings yet

- Lateral Earth PressureDocument15 pagesLateral Earth Pressuresreendd100% (1)

- Chap 8 LectureDocument27 pagesChap 8 LectureMuhammadAizatNo ratings yet

- Connection DesignDocument94 pagesConnection DesignAnand.5100% (1)

- 08chapters7 8Document26 pages08chapters7 8Bucket IdliNo ratings yet

- Column DesignDocument4 pagesColumn DesignArnel Dodong83% (6)

- Question Paper Concrete TechnologyDocument8 pagesQuestion Paper Concrete Technologyjsyadav.nithNo ratings yet

- Lecture 11 PDFDocument26 pagesLecture 11 PDFmariaNo ratings yet

- Midterm Es 404Document4 pagesMidterm Es 404Ian GaleonNo ratings yet

- Tolerancias de FundicionDocument15 pagesTolerancias de FundicionSalvadorNo ratings yet

- Tunneling-Assisted Poole-Frenkel Conduction Mechanism in HfO2 Thin FilmsDocument7 pagesTunneling-Assisted Poole-Frenkel Conduction Mechanism in HfO2 Thin FilmsDiego Carranza CelisNo ratings yet

- 3.mass Transfer Coefficients PDFDocument13 pages3.mass Transfer Coefficients PDFMohit SathwaraNo ratings yet

- Neutral Grounding Resistor (NGR)Document14 pagesNeutral Grounding Resistor (NGR)vennapusa VenkateshNo ratings yet

- Full PaperDocument34 pagesFull PaperCarrieann Stocks100% (1)

- Plasticity Models For Soils PDFDocument74 pagesPlasticity Models For Soils PDFJianfeng XueNo ratings yet

- HandoutChemical EquilibriumDocument10 pagesHandoutChemical EquilibriumPankaj KumarNo ratings yet

- Strain Gauge Installation Examples PDFDocument5 pagesStrain Gauge Installation Examples PDFWandyy GonçalvesNo ratings yet

- Structural Analysis Problems For PracticeDocument10 pagesStructural Analysis Problems For PracticePradyumnaSadgir100% (1)

- Datasheet en AW-6063Document1 pageDatasheet en AW-6063Erick De La RoSaNo ratings yet

- Atomic Structure - IiDocument9 pagesAtomic Structure - IiSUMITH K SNo ratings yet

- ContentsDocument19 pagesContentsClaims JoseNo ratings yet

- 9 SteelDocument14 pages9 SteelSteven KuaNo ratings yet

- Studies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsDocument24 pagesStudies On Creep Crack Growth Using The F - Integral: Enyineering Frarrurr MechanicsTirupati TulasiNo ratings yet

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- Analysis of Rotational Constant of HBRDocument4 pagesAnalysis of Rotational Constant of HBRRock MaheshNo ratings yet

- Product Technical Specification: Power CableDocument6 pagesProduct Technical Specification: Power CableGanabathi NadarajooNo ratings yet