Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

60 viewsWeapons4 Gound 1010

Weapons4 Gound 1010

Uploaded by

ThallezThe Program Executive Office Ground Combat Systems (PEO GCS) oversees ground combat vehicle programs for the armed forces, including the Abrams tank, Bradley fighting vehicle, and others. The Project Manager for the Heavy Brigade Combat Team manages major combat vehicles like the Abrams, which comes in M1A1, M1A1 AIM, and M1A2 SEP variants. The Abrams Integrated Management program refurbishes older M1A1 tanks to extend their service life. PEO GCS also oversees recovery vehicles like the M88A2 Hercules and assault bridges like the M104 Wolverine to support combat operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Amap BDocument6 pagesAmap Ba19952083100% (1)

- Merkava 4 Heavy TanksDocument3 pagesMerkava 4 Heavy TanksBồ Câu ThưNo ratings yet

- MortarsDocument12 pagesMortarsAji Wijanarko100% (1)

- Leopard 2 A4 EvolutionDocument6 pagesLeopard 2 A4 EvolutionAlexjohn2009100% (3)

- AMX 56 LeclercDocument10 pagesAMX 56 LeclercAlexandru StroeNo ratings yet

- Three Sisters Full PacketDocument16 pagesThree Sisters Full PacketRinny FischerNo ratings yet

- The ScarDocument12 pagesThe ScarMacmillan Publishers27% (15)

- Artillery 05Document11 pagesArtillery 05Jet Vissanu100% (1)

- Abrams Upgrade: Investment ComponentDocument2 pagesAbrams Upgrade: Investment ComponentAlexanderPetrovNo ratings yet

- Abrams Tank Upgrade (M1A2) : Investment ComponentDocument2 pagesAbrams Tank Upgrade (M1A2) : Investment ComponentSuzuki ImproNo ratings yet

- Ground VehiclesDocument18 pagesGround Vehicleswlamiller100% (2)

- General Dynamics - MACS M231/M232A1 Modular Artillery Charge SystemDocument1 pageGeneral Dynamics - MACS M231/M232A1 Modular Artillery Charge SystemYamvea100% (1)

- U.S. Army Weapon Systems Handbook 2012Document2 pagesU.S. Army Weapon Systems Handbook 2012joaoguilhermealbertoNo ratings yet

- Ada 323152Document6 pagesAda 323152TenshiJibril100% (1)

- 06 Weapons AmmunitionDocument6 pages06 Weapons AmmunitionChonk LeeNo ratings yet

- This We'll Defend: The Weapons & Equipment of the U.S. ArmyFrom EverandThis We'll Defend: The Weapons & Equipment of the U.S. ArmyRating: 3.5 out of 5 stars3.5/5 (2)

- Army - Mil-Army Rolls Out Latest Version of Iconic Abrams Main Battle TankDocument3 pagesArmy - Mil-Army Rolls Out Latest Version of Iconic Abrams Main Battle TankOsorio LuisNo ratings yet

- BAE - Digital - USL - Landscape - AMPV - Mortar CarrierDocument2 pagesBAE - Digital - USL - Landscape - AMPV - Mortar CarrierLuciano PinheiroNo ratings yet

- General Dynamics Awarded $34 Million For M1A1 Abrams Tank Upgrades - General Dynamics PDFDocument2 pagesGeneral Dynamics Awarded $34 Million For M1A1 Abrams Tank Upgrades - General Dynamics PDFOsorio LuisNo ratings yet

- 2020,年m1a2sepv3Document4 pages2020,年m1a2sepv3龙成No ratings yet

- 2015 M 270 A 1 MlrsDocument2 pages2015 M 270 A 1 MlrsBee AscenzoNo ratings yet

- MILTEC KPZDocument15 pagesMILTEC KPZWolfgang SchneiderNo ratings yet

- 4 Agds 96Document6 pages4 Agds 96Michael CummingsNo ratings yet

- Multiple Launch Rocket System (MLRS) M270A1: Investment ComponentDocument2 pagesMultiple Launch Rocket System (MLRS) M270A1: Investment ComponentBee AscenzoNo ratings yet

- Tank Employment in Expeditionary Operations Submitted by Rummler, P. MDocument16 pagesTank Employment in Expeditionary Operations Submitted by Rummler, P. MChris BeckmanNo ratings yet

- 121 Ground Combat ElementDocument5 pages121 Ground Combat ElementCody JacksonNo ratings yet

- MRAP Family of VehiclesDocument8 pagesMRAP Family of Vehiclessudhavel100% (1)

- High Mobility Artillery Rocket System (HIMARS)Document2 pagesHigh Mobility Artillery Rocket System (HIMARS)Zoran Vulovic100% (3)

- Gicat Brochure-Capacites Mrav Uk Exe-150Document28 pagesGicat Brochure-Capacites Mrav Uk Exe-150malaoui44No ratings yet

- TOE 05337F1000 or L000 - 5 - Company - Engineer Co Heavy Division XXI (FAS - Org) - ToE 05337F1000 or L000 - BDocument5 pagesTOE 05337F1000 or L000 - 5 - Company - Engineer Co Heavy Division XXI (FAS - Org) - ToE 05337F1000 or L000 - BMartin WhitenerNo ratings yet

- WiSENT 2Document8 pagesWiSENT 2jrigorighiNo ratings yet

- Amx-56 Leclerc Main Battle TankDocument5 pagesAmx-56 Leclerc Main Battle TankTimia TalashekNo ratings yet

- Abrams Brochure ModernizationDocument2 pagesAbrams Brochure ModernizationLavi1889100% (1)

- FM 11-24 Signal Tactical Satellite CompanyDocument64 pagesFM 11-24 Signal Tactical Satellite CompanyMark CheneyNo ratings yet

- Anti-Tank Missile Systems: Missiles and ArtilleryDocument5 pagesAnti-Tank Missile Systems: Missiles and ArtilleryDeez34PNo ratings yet

- JSC Research and Production Corporation UralVagonZavod EngDocument27 pagesJSC Research and Production Corporation UralVagonZavod EngAlex Cerneavschi100% (1)

- M1A2: One Year Later: by Captain John BassoDocument4 pagesM1A2: One Year Later: by Captain John BassoMuhammad FerialNo ratings yet

- Rheinmetall DSEI LANCE enDocument2 pagesRheinmetall DSEI LANCE enJulien Beleno AranetaNo ratings yet

- MK41 VLS Product CardDocument2 pagesMK41 VLS Product Cardpvssrh9929100% (1)

- Global Mortar Systems: Market UpdateDocument31 pagesGlobal Mortar Systems: Market UpdateejgarciacabralNo ratings yet

- M1A1 A2 AbramsDocument50 pagesM1A1 A2 AbramsHandrey Zoz100% (2)

- ASBFY20 BF2040 Ex SumDocument58 pagesASBFY20 BF2040 Ex Sumdebrah heatonNo ratings yet

- Body mm07761 Mirach 100 5 LQDocument2 pagesBody mm07761 Mirach 100 5 LQultrapampersNo ratings yet

- FM7 7Document399 pagesFM7 7Babrak BabrakovicNo ratings yet

- ADA329084Document18 pagesADA329084mahanramtin100% (1)

- PositionedDocument9 pagesPositionedMohamad HaizarNo ratings yet

- 44 Armoured VehiclesDocument15 pages44 Armoured Vehiclespieffepi03No ratings yet

- Amx Leclerc Main Battle Tank For The Year 2000Document6 pagesAmx Leclerc Main Battle Tank For The Year 2000Timia TalashekNo ratings yet

- Light Mine Resistant VehiclesDocument4 pagesLight Mine Resistant Vehiclestaktik(z), Inc.100% (2)

- S 300VDocument49 pagesS 300VSohail SafeerNo ratings yet

- Army Aviation Digest - May 1991Document68 pagesArmy Aviation Digest - May 1991Aviation/Space History LibraryNo ratings yet

- M1 AbramsDocument30 pagesM1 AbramsrameshNo ratings yet

- Catalog Artillery Ammunition 13 WebDocument6 pagesCatalog Artillery Ammunition 13 WebDavid Alarcon Ulloa100% (1)

- Breaking The Tether of Fuel 2007Document5 pagesBreaking The Tether of Fuel 2007j_s_fuchsNo ratings yet

- UTMT-30-6pgs 3 PRINTDocument6 pagesUTMT-30-6pgs 3 PRINTFranco LuceroNo ratings yet

- MCRP 3-12.1 Tank PlatoonDocument380 pagesMCRP 3-12.1 Tank PlatoonBenjamin David Spaeth100% (1)

- 20x102mm Fact SheetDocument2 pages20x102mm Fact SheetHossam AliNo ratings yet

- 120-mm Advanced Multi-Purpose (AMP), XM1147: Fy20 Army ProgramsDocument2 pages120-mm Advanced Multi-Purpose (AMP), XM1147: Fy20 Army ProgramsmattNo ratings yet

- Mgm-166 Losat - WikipediaDocument3 pagesMgm-166 Losat - WikipediasorinartistuNo ratings yet

- War Emergency Power: Unleashing Tactical Dominance in Critical Combat ScenariosFrom EverandWar Emergency Power: Unleashing Tactical Dominance in Critical Combat ScenariosNo ratings yet

- Training Strategies For The M1 Abrams Tank Driver TrainerDocument100 pagesTraining Strategies For The M1 Abrams Tank Driver TrainerThallezNo ratings yet

- TURMS D LQ mm07939Document4 pagesTURMS D LQ mm07939ThallezNo ratings yet

- Lothar LQ mm07836Document2 pagesLothar LQ mm07836ThallezNo ratings yet

- C-27J Next Gen - Datasheet - ENGDocument2 pagesC-27J Next Gen - Datasheet - ENGThallez0% (2)

- 93doc04 0Document85 pages93doc04 0ThallezNo ratings yet

- C-27J Next Gen - Brochure - ENGDocument11 pagesC-27J Next Gen - Brochure - ENGThallezNo ratings yet

- WEB DATA SHEET - M345 Pattuglia - CANADADocument2 pagesWEB DATA SHEET - M345 Pattuglia - CANADAThallezNo ratings yet

- VBM Freccia Amc: Dimensions (Approx.) Driveline / Suspension ArmamentDocument1 pageVBM Freccia Amc: Dimensions (Approx.) Driveline / Suspension ArmamentThallezNo ratings yet

- Aermacchi M-346 Brochure ENG NewDocument11 pagesAermacchi M-346 Brochure ENG NewThallez100% (1)

- Dardo FamilyDocument1 pageDardo FamilyThallezNo ratings yet

- VBM Freccia Land Tactical Command PostDocument1 pageVBM Freccia Land Tactical Command PostThallezNo ratings yet

- Aermacchi M-346 AJT - Datasheet - ENG - NewDocument2 pagesAermacchi M-346 AJT - Datasheet - ENG - NewThallezNo ratings yet

- Aermacchi M-345: The Next Generation TrainerDocument2 pagesAermacchi M-345: The Next Generation TrainerThallezNo ratings yet

- Amphibious Armoured Vehicle: Dimensions Wheels Firing Direction SystemDocument1 pageAmphibious Armoured Vehicle: Dimensions Wheels Firing Direction SystemThallezNo ratings yet

- Puma 4x4 Puma 6x6Document1 pagePuma 4x4 Puma 6x6ThallezNo ratings yet

- Aermacchi M-345: The Next Generation TrainerDocument7 pagesAermacchi M-345: The Next Generation TrainerThallez0% (1)

- VBM Freccia Arv: Dimensions Driveline / SuspensionDocument1 pageVBM Freccia Arv: Dimensions Driveline / SuspensionThallezNo ratings yet

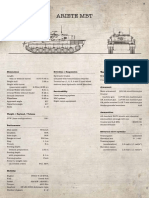

- Ariete MBTDocument1 pageAriete MBTThallezNo ratings yet

- Freccia OWSDocument1 pageFreccia OWSThallezNo ratings yet

- VBM Freccia Aifv/Atgm: Driveline / Suspension Crew DimensionsDocument1 pageVBM Freccia Aifv/Atgm: Driveline / Suspension Crew DimensionsThallezNo ratings yet

- Textron Lycoming AGT1500 Engine - Transitioning For Future ApplicationsDocument11 pagesTextron Lycoming AGT1500 Engine - Transitioning For Future ApplicationsThallez100% (1)

- Centauro I: 105 MM /120 MMDocument1 pageCentauro I: 105 MM /120 MMThallezNo ratings yet

- Testing Battle Tank Gas TurbinesDocument2 pagesTesting Battle Tank Gas TurbinesThallezNo ratings yet

- Dardo Aifv/Atgm: Dimensions Driveline / Suspension CrewDocument1 pageDardo Aifv/Atgm: Dimensions Driveline / Suspension CrewThallezNo ratings yet

- InterSKY 4MDocument4 pagesInterSKY 4Mvsatdog100% (1)

- G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - &Document44 pagesG 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - &sreekrishna9No ratings yet

- S.J.Lurje - Arhimed (1952) PDFDocument274 pagesS.J.Lurje - Arhimed (1952) PDFIvana PaunovicNo ratings yet

- Seven Ages Collector Edition RulesDocument37 pagesSeven Ages Collector Edition RulesRaulonescribdNo ratings yet

- Candidly, One Friend To Another Pub1022Document2 pagesCandidly, One Friend To Another Pub1022scparcoNo ratings yet

- Data Produksi Machining Bulan Juli 2022Document301 pagesData Produksi Machining Bulan Juli 2022yuli dwi atmokoNo ratings yet

- Fomrhi Q135Document42 pagesFomrhi Q135Gaetano PreviteraNo ratings yet

- Hot Toys Iron Man Action Figures ChecklistDocument8 pagesHot Toys Iron Man Action Figures ChecklistmarcotuliocNo ratings yet

- Notice: Meetings: Defense Language Institute Foreign Language Center Board of VisitorsDocument1 pageNotice: Meetings: Defense Language Institute Foreign Language Center Board of VisitorsJustia.comNo ratings yet

- New Flight Plan Bonus ScenariosDocument12 pagesNew Flight Plan Bonus ScenariosHistorylover88No ratings yet

- KriegsspielDevelopments Mouat ODocument34 pagesKriegsspielDevelopments Mouat OFabio RiggiNo ratings yet

- How To Read A Nautical Chart Course PresentationDocument80 pagesHow To Read A Nautical Chart Course PresentationVirgil Titimeaua100% (2)

- My Infinity Army List - PanOceaniaDocument1 pageMy Infinity Army List - PanOceaniaDražen BičanićNo ratings yet

- Establishment of MadrasDocument16 pagesEstablishment of MadrasWilliam StainsNo ratings yet

- Compare and Contrast Italian and German UnificationDocument2 pagesCompare and Contrast Italian and German UnificationCameron CampbellNo ratings yet

- Data - STR 191018 192025Document68 pagesData - STR 191018 192025hainh036188No ratings yet

- Take Five Brubeck - 3 Tons - EbmDocument3 pagesTake Five Brubeck - 3 Tons - EbmEduardoSantosNo ratings yet

- Velasco, Lino Paul History Activity Semi FinalsDocument3 pagesVelasco, Lino Paul History Activity Semi FinalsGlitchedBoiiNo ratings yet

- Zimmerman - Origins of A Catastrophe - Yugoslavia and Its Destroyers (1999)Document287 pagesZimmerman - Origins of A Catastrophe - Yugoslavia and Its Destroyers (1999)milosdimic83% (6)

- Imp Wars TN1643762536457Document4 pagesImp Wars TN1643762536457monica lallichettiNo ratings yet

- FM 90-13 - River Crossing OperationsDocument152 pagesFM 90-13 - River Crossing OperationsSurvivIt100% (1)

- The Dangerous of Nuclear WarDocument12 pagesThe Dangerous of Nuclear WarAhmed KhanNo ratings yet

- Gun Swell DataDocument4 pagesGun Swell DataMcSOLA ONo ratings yet

- Lobster 15Document58 pagesLobster 15belga197100% (1)

- Combat Commander Europe RulesDocument24 pagesCombat Commander Europe Ruless_hager100% (3)

- Consti2Digest - People vs. de Gracia, 233 SCRA 716, GR 102009 (6 July 1994)Document2 pagesConsti2Digest - People vs. de Gracia, 233 SCRA 716, GR 102009 (6 July 1994)Lu Cas100% (1)

- (Birol Başkan (Auth.) ) Turkey and Qatar in The Ta (B-Ok - Xyz)Document153 pages(Birol Başkan (Auth.) ) Turkey and Qatar in The Ta (B-Ok - Xyz)jojoNo ratings yet

- Understanding Hadrians WallDocument5 pagesUnderstanding Hadrians WallBernardo Milazzo0% (1)

Weapons4 Gound 1010

Weapons4 Gound 1010

Uploaded by

Thallez0 ratings0% found this document useful (0 votes)

60 views8 pagesThe Program Executive Office Ground Combat Systems (PEO GCS) oversees ground combat vehicle programs for the armed forces, including the Abrams tank, Bradley fighting vehicle, and others. The Project Manager for the Heavy Brigade Combat Team manages major combat vehicles like the Abrams, which comes in M1A1, M1A1 AIM, and M1A2 SEP variants. The Abrams Integrated Management program refurbishes older M1A1 tanks to extend their service life. PEO GCS also oversees recovery vehicles like the M88A2 Hercules and assault bridges like the M104 Wolverine to support combat operations.

Original Description:

Original Title

Weapons4_Gound_1010

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Program Executive Office Ground Combat Systems (PEO GCS) oversees ground combat vehicle programs for the armed forces, including the Abrams tank, Bradley fighting vehicle, and others. The Project Manager for the Heavy Brigade Combat Team manages major combat vehicles like the Abrams, which comes in M1A1, M1A1 AIM, and M1A2 SEP variants. The Abrams Integrated Management program refurbishes older M1A1 tanks to extend their service life. PEO GCS also oversees recovery vehicles like the M88A2 Hercules and assault bridges like the M104 Wolverine to support combat operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

60 views8 pagesWeapons4 Gound 1010

Weapons4 Gound 1010

Uploaded by

ThallezThe Program Executive Office Ground Combat Systems (PEO GCS) oversees ground combat vehicle programs for the armed forces, including the Abrams tank, Bradley fighting vehicle, and others. The Project Manager for the Heavy Brigade Combat Team manages major combat vehicles like the Abrams, which comes in M1A1, M1A1 AIM, and M1A2 SEP variants. The Abrams Integrated Management program refurbishes older M1A1 tanks to extend their service life. PEO GCS also oversees recovery vehicles like the M88A2 Hercules and assault bridges like the M104 Wolverine to support combat operations.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 8

GRO U N D C O M B AT S Y S T E M S

The Program Executive Office Ground

Combat Systems (PEO GCS) serves as the

“system of systems integrator” of the

ground combat systems for the armed

forces and leads Army transformation ef-

forts toward future systems while main-

taining a current combat-ready force. GCS

is a command partner in the Tank-automo-

tive and Armaments Command (TACOM)

Life Cycle Management Command. The M1A2 Abrams tank

PEO encompasses a number of project

management offices.

For example, the Project Manager for

the Heavy Brigade Combat Team (PM

HBCT) serves as the life-cycle manager for

the major combat vehicles in the Army’s

heavy forces, including the Abrams, M88,

Bradley, M113, M109 and Knight family of

vehicles. Combined, these fleets total

32,682 platforms in various stages of their

life cycles under PM HBCT’s management

purview, and total program funding

through fiscal year (FY) 2013 of approxi- The M1A2 has a digital command-and- handing full spectrum operations.

mately $36.8 billion. PM HBCT’s responsi- control system that provides situational The Army must sustain the readiness

bilities include the design, development, awareness updates to all the other tanks in and reduce the operations and support

production, fielding and sustainment (re- a unit. Vetronics architecture ties all elec- costs of approximately 4,300 older M1A1

set, recap and upgrade) of safe, reliable tronic components in the tank together Abrams main battle tanks in its active and

and lethal ground combat systems. Prod- and provides increased survivability and reserve component units.

uct Manager Abrams manages approxi- supportability. The commander’s indepen- The Abrams Integrated Management

mately 8,325 platforms within the Abrams dent thermal viewer (CITV) gives it a (AIM) Program is the recapitalization pro-

family of vehicles, including M1A1, M1A1 hunter-killer capacity, allowing the M1A2 gram for the M1A1 tank. Under AIM,

AIM and M1A2 SEP tanks, M88A1/A2 re- to engage one target while simultaneously M1A1 tanks are completely disassembled at

covery vehicles and M104 Wolverine As- tracking another. The M1A2 also has im- Anniston Army Depot, Ala. The depot re-

sault Bridge. proved onboard diagnostics that allow the furbishes many of the tank’s components.

tank to self-diagnose faults without any The assemblies are then shipped to the

M1A1, M1A1 AIM and M1A2 SEP additional special tools or equipment. Joint Systems Manufacturing Center (JSMC)

Tanks Further M1A2 improvements, through in Ohio, where General Dynamics Land

The M1 Series Abrams Tank provides the SEP, are under way. The M1A2 SEP is Systems reassembles the tanks to a zero

the Army with mobile, protected fire- the backbone of the Army’s first digitized time/zero miles standard.

power and will remain the cornerstone of division and the counterattack corps of the The AIM program has fielded tanks to

the Army’s counterattack and containment Army’s current force. It is the only weapon units at Fort Hood, Texas, and in Germany.

forces as the Army transforms to the Fu- system that can withstand the impact of Annual production now stands at 135

ture Force. The Abrams tank provides sol- high-energy warheads and remain lethal tanks per year and will continue until

diers with the lethality, survivability and in full spectrum operations. It has inte- 2012.

staying power to successfully close with grated combat command and control (IC3), In addition, AIM serves as the venue to

and destroy enemy forces on the inte- which incorporates Force XXI Battle Com- apply modifications and upgrades to the

grated battlefield. The 120 mm main gun mand Brigade and Below (FBCB2) to pro- tank, including embedded diagnostics. AIM

on the M1A1 and M1A2, combined with vide real-time command and control and also serves as a means to combat electronic

the powerful 1,500-hp turbine engine and situational awareness. obsolescence by introducing improved line-

special armor, make the Abrams tank par- Its sights use the latest thermal-imaging replaceable units for those that face techni-

ticularly suitable for attacking or defend- system (second-generation forward-look- cal obsolescence. The AIM process also

ing against large concentrations of heavy ing infrared [FLIR]) for increased lethality incorporates redesigned hull and turret

armor forces on a highly lethal battlefield and survivability. The M1A2 SEP tank network boxes.

and for other roles that require shock effect takes advantage of computer/electronic The M88A2 Heavy Equipment Recov-

and mobile direct firepower to support industry advances by including improved ery Combat Utility Lift and Evacuation

Army mission requirements. electronics developed since the introduc- System (HERCULES) is a full-tracked,

Two major programs maintain and re- tion of the M1A2. heavy armored vehicle developed to ac-

capitalize the Abrams fleet: the M1A2 sys- The SEP package includes a new com- complish safe, effective and independent

tems enhancement program (SEP) and the puterized mass-memory unit and color battlefield recovery operations.

M1A1 Abrams integrated management maps and displays. A thermal manage- It implements swift and effective com-

(AIM) program. ment system increases electronic reliability bat evacuations through the battlefield re-

The M1A2 program provides the Abrams and decreases crew fatigue. covery operations of towing, winching

with advanced improvements in lethality, Production deliveries of the M1A2 SEP and lifting. The Hercules uses the M88A1

survivability and fighting ability required to tank began in September 1999. These vehi- chassis modified to significantly improve

defeat future threats. It is the Army’s first cles were used extensively during OIF, in towing, winching, lifting and braking

digitized, direct-fire combat vehicle. which they were proven to be capable of characteristics.

October 2010 ■ ARMY 343

Bradley M2A3

It is the primary recovery support for

the 70-ton M1 Abrams tank, the Wolverine

and other heavy combat vehicles.

The M88A2 includes a 1,050-hp engine;

a 35-ton boom; overlay armor; a 140,000-

pound, single-line, constant-pull main

winch; and a 3-ton auxiliary winch for de-

ploying the main winch cable. When com-

pared to the M88A1, these upgrades im-

prove towing power by 25 percent, lifting

capability by 40 percent and winching

ability by 55 percent.

The system is in full-rate production

and deployment. Fielding began in July

1997, and it achieved first unit equipped in and to suppress and defeat enemy tanks, re- The Bradley Operation Desert Storm-

July 1997. connaissance vehicles, infantry fighting ve- Situational Awareness (ODS-SA) M2/M3

The M104 Wolverine Heavy Assault hicles (IFVs), armored personnel carriers, A2 conversion implements a digital archi-

Bridge (HAB) is an M1A2 Abrams SEP bunkers, dismounted infantry and attack tecture and will benefit the fleet by mitigat-

variant and is operated by a two-man helicopters. The infantry version (M2) of the ing obsolescence and providing commonal-

crew. The 26-meter bridge can span gaps A3 Bradley fighting vehicle is used most of- ity. The M2/M3 A2 ODS-SA system consists

of up to 24 meters to support heavy ma- ten to close with the enemy by means of fire of a modified BFVS A2 ODS turret and chas-

neuver operations at 16 kph. and maneuver. The primary tasks per- sis. The two-man turret consists of a

The bridge is computer-controlled and formed by the cavalry version (M3) as part gun/turret stabilization system, a 25 mm

automatically compensates for minor devi- of a troop and/or squadron are reconnais- gun, a coaxial 7.62 mm machine gun, am-

ations in launch-site elevation and terrain sance, security and flank guard missions. munition feed/storage systems, a dual-tube

rack and cant. The crew can launch the The A3 is the consummate digitized TOW missile launcher with a launcher erec-

bridge under armor in five minutes and re- platform, with a core electronics architec- tion mechanism/drive and a TOW launcher

trieve it in less than 10 minutes. ture on a 1553 data bus and an improved elevation drive, gunner’s and commander’s

The M104 Wolverine enables decisive target acquisition system that includes a stations, gunner’s and commander’s sight

maneuver by allowing units to span tank full ballistic fire-control package with systems, and a turret processor with associ-

ditches, road craters and partially dam- hunter-killer functionality via a comman- ated subsystems and sensors. The chassis

aged bridge sections up to 24 meters wide der’s independent viewer (CIV). Optical contains the power train, suspension sys-

at combat speeds. improvements also include two second- tem, the driver’s station and the squad com-

generation FLIRs and day television cam- partment. The A2 ODS SA electronics archi-

Product Manager Bradley eras, which can be displayed to the squad tecture is based on a dual redundant

Product Manager Bradley manages ap- members in the back of the vehicle via the MIL-STD-1553B serial data bus. All major

proximately 6,452 M2/3A2, M2/3A2 ODS rear-mounted squad leader’s display. This turret system units are linked through this

and M2/3A3 Bradleys, approximately feature significantly improves the real- bus for signal and data transfer. Sight im-

13,943 M113 series platforms, as well as time situational awareness for the entire agery and graphics data are routed as RS-

the M7/A3 Bradley fire-support team dismounted or mounted crew. 170 video signals to the operators.

(BFIST) vehicles and the M707/M1200 The A3 integrated combat command- The A2 ODS SA system has the Improved

Knight family of vehicles. and-control (IC3) package incorporates the Bradley Acquisition Subsystem (IBAS) for

The Bradley M2A3 Infantry/M3A3 Army’s digital command-and-control suite the gunner that replaces the Bradley Eyesafe

Cavalry Fighting Vehicle (IFV/CFV) facil- of automated messages, overlays and Laser Rangefinder (BELRF) integrated sight

itates enhanced command-and-control ca- friend-or-foe graphics that meet the unit (ISU) in the A2 ODS. The sight has a

pabilities, provides mobile protected trans- Army’s objectives for a fully digitized day TV and a forward looking infrared

port of an infantry squad to critical points force. This same digital command-and- (FLIR) channel, both with a narrow and

on the battlefield, and performs cavalry control capability was incorporated into wide field of view. The sight images are dis-

scout and other essential missions in the the A2 Operation Desert Storm (ODS), in- played as video images to the gunner and

21st century. Upgrades in this program in- cluding a squad leader’s display for mes- commander on cathode ray tube (CRT)-

clude advanced technology in the areas of sages and graphics. based biocular virtual image displays. The

command and control, lethality, surviv- The A3 variants reflect the latest itera- IBAS also has a gunner’s monocular direct-

ability, mobility and sustainability, re- tions of a fighting vehicle family that in- view optics port for the day view channel

quired to defeat current and future threat cludes the Bradley M2/M3A0, A1, A2, A2 and a laser rangefinder for target ranging.

forces while remaining operationally com- ODS, IFV/cavalry fighting vehicle (CFV), The line of sight is inertially stabilized. The

patible with the main battle tank. The Bradley fire-support team (BFIST) vehicle M7 BFIST SA vehicle is the fire-support

M2/M3 vehicle armament includes the 25 and M2A2 ODS engineer vehicle. Addi- team (FIST) version of the Bradley ODS SA,

mm M242 Bushmaster cannon, the TOW II tional Bradley variants, based on the asso- and is scheduled for first unit equipped to

missile system and a 7.62 mm M240C ma- ciated tracked M270 multiple-launch the 81st BCT, Washington National Guard,

chine gun. rocket system (MLRS) chassis, range from in October 2010.

The M2A3/M3A3 provides overwatch- command-and-control systems to armored The M113 Family of Vehicles (FOV) pro-

ing fires to support dismounted infantry medical treatment vehicles. vides a highly mobile, survivable and reli-

344 ARMY ■ October 2010

M113

other systems demands full compatibility

with the newest C4ISR equipment and pro-

cedures.

The M7 BFIST is one of the two models

that replaces all the M981s (FISTVs) in the

active force at the company FIST opera-

tional facility. The M7 BFIST integrates

both existing and improved FIST mission

equipment packages onto an M3A2 Oper-

ation Desert Storm (ODS) chassis. Some of

the mission equipment, such as the

G/VLLD, will be taken directly from dis-

placed FISTVs and stowed. Features incor-

porated from the M3A2 ODS chassis in-

able tracked-vehicle platform that, with up- vided by this and other upgrade packages clude the 25 mm gun, 7.62 coaxial machine

grades, is able to keep pace with Abrams- permits a range of enhanced survivability gun, precision lightweight global position-

and Bradley-equipped units and is adapt- options. ing system (GPS) receiver (PLGR) and the

able to a wide range of current and future M7/A3 Bradley Fire Support Team Bradley eyesafe laser rangefinder. The cur-

battlefield tasks through the integration of (BFIST). The BFIST program is executing rent M7 BFIST uses the integrated sight

specialized mission modules. Although not to the Army campaign plan and will com- unit, which is also used as the gun sight

presently in new production, the 13,943 plete modularization of the force in FY for self-defense. The M7 BFIST uses the

M113 FOV systems now in Army vehicle 2013 with 20 heavy brigades of A3 BFISTs stand-alone computer unit (SCU), the

inventories constitute a significant percent- and 11 heavy brigades of M7 BFISTs. BFIST ruggedized handheld computer and the

age of present and future heavy division as- vehicles are required to conduct various forward observer system with full interop-

sets. Recent activities within the M113 FOV mission scenarios including reconnaissance erability with advanced field artillery tacti-

focused on upgrading several models of the and surveillance, reporting of enemy activ- cal data system (AFTADS) fire-support

vehicles to meet or exceed the mobility ity in the area of operations, reporting of networks. The inertial navigation system

characteristics of the supported maneuver hazards and obstacles to movement, and (INS) provides navigational capability

force. The most recent upgrade to see wide the coordination of indirect fire support. based on a blended inertial/GPS solution.

fielding is the A3 reliability improvement Both versions have equivalent mobility, The mission processor unit (MPU) calcu-

for selected equipment (RISE). RISE pro- survivability, signature and night-vision lates target grid location by processing in-

vides various derivatives within the FOV capability and consume common repair formation received from the INS, and mis-

with major performance improvements in parts with the maneuver force they sup- sion information from the targeting station

mobility, reliability and survivability port. Target designation for all available control panel (TSCP) serves as the primary

through installation of a 275-hp 6V53T en- laser-guided munitions is required, includ- operator interface. The TSCP functions are

gine with an X-200-4A transmission. Cou- ing those delivered by mortars and air- controlled through a series of menus. The

pled with reconfiguration of the driver’s borne platforms. Dismount operations are TSCP controls the 1553B data bus. The

station and several other vehicle subsys- required under some conditions. Extensive MPU sends processed information back to

tems, these improvements provide battle- and real-time communications with other the TSCP and SCU for display and routing

field mobility commensurate with the sup- members of the force and rear-area com- over the single-channel ground and the

ported Abrams/Bradley maneuver force. mand posts is required for mission success. airborne radio system to external fire-sup-

Moreover, the increased performance pro- Interoperability in the netcentric array of port elements. The first unit equipped

with the M7 BFIST was the 3rd Infantry

Division in FY 2000.

The second model BFIST is the A3

BFIST. The A3 BFIST incorporates the FIST

mission equipment package (MEP) with a

digitized M3A3 chassis. Features incorpo-

rated from the M3A3 chassis include: the

commander ’s independent viewer with

360-degree traverse and the improved

Bradley acquisition system (IBAS), both

second-generation FLIRs, to improve tar-

M7/A3 Bradley fire support team (BFIST)

October 2010 ■ ARMY 345

155 mm self-propelled howitzer provides

the primary indirect fire support to modu-

lar HBCTs and armored cavalry regiments.

Like the earlier M109 models, the M109A6

Paladin is a fully tracked, armored vehicle.

The enhanced Paladin configuration is

achieved through extensive modifications

to existing M109A2/A3 vehicle hulls and

the subsequent introduction of an entirely

M1200 Armored new turret structure. The Paladin includes

Knight an onboard Paladin Digital Fire-Control

System (PDFCS) that provides ballistic

computation, weapon control, a vehicle lo-

cation/navigation system, secure radio

communications systems, an improved

M284 cannon and M182A1 gun mount, au-

tomotive improvements, improved ballis-

tic and nuclear-biological-chemical protec-

tion, driver’s night-vision capability, and

built-in test equipment. Additional chassis

upgrades include a remotely actuated

get acquisition and target engagement; the projectiles such as Excalibur. travel lock (for quicker site occupation and

25 mm gun; 7.62 coaxial machine gun; First fielded in 2008, the M1200 Armored displacement), longer torsion bars (to help

PLGR; and digital command-and-control Knight provides improved survivability for support the new turret) and a low-heat re-

enhancements. The first unit equipped for the COLTs. Integrating the M707 mission jection engine with an improved cooling

the M3A3 BFIST was the 4th Infantry Divi- equipment package onto the more surviv- system. Described as the first digitized

sion. able M1117 armored security vehicle chas- combat vehicle in the Army’s inventory,

An effort is under way to incorporate sis, the M1200 Armored Knight adds 360- the Paladin has improved responsiveness,

the fire-support sensor system (FS3) onto degree continuous cupola rotation, CREW survivability, lethality and reliability com-

the A3 digitized BFIST. In addition to the II, high-frequency radio capability, and pared to the earlier M109s.

improved features of the M3A3, the A3 M2HB .50-caliber capability. To date, more A parallel U.S. Army recapitalization ef-

BFIST with FS3 will allow the fire-support than 200 M1200 Armored Knights have fort was seen in the M992A2 Field Artillery

team to detect, identify and designate tar- been fielded to support operations in Iraq Ammunition Supply Vehicle (FAASV).

gets for precision munitions at greater and Afghanistan. In addition, 45 systems are The basic M992A0 FAASV emerged from

ranges while remaining “buttoned up”— scheduled to be fielded to IBCTs and HBCTs an industry research and development pro-

protected by the vehicle’s armor. The new through the remainder of fiscal year FY ject designed to provide self-propelled

ranges will meet Office of Research and 2010, and additional Armored Knights will field artillery units with a ballistically pro-

Development requirements and will also continue to be fielded via new production tected vehicle capable of performing criti-

allow for laser-guided smart munitions, or reset in FY 2011. cal resupply and support functions. The

laser-guided bombs, and missiles for ro- The last year of procurement to meet the FAASV system was type classified and en-

tary- and fixed-wing aircraft. The first unit authorized acquisition objective of 465 is tered production in 1983. It was based on

equipped with the M3A3 BFIST with FS3 is FY 2011, and product improvements are an M109 howitzer chassis that provided

scheduled to be the 3rd Infantry Division currently under way to incorporate target- the resupply asset with mobility and sur-

in March 2011. ing under armor (TUA) onto the M1200 vivability characteristics commensurate

M707 Knight/M1200 Armored Knight. Armored Knight. The program will ac- with the supported cannon element. The

The M707 Knight was developed and complish this by incorporating a common system is paired on a one-for-one basis

fielded during the late 1990s. Based on the remotely operated weapons system II with the Army’s M109A6 Paladin self-pro-

M1025A2 Humvee chassis, the M707 fea- (CROWS II) and a common remote stabi- pelled howitzer.

tures a mission equipment package fully lized sensor system (CRS3) onto the Ar- Paladin/FAASV Integrated Manage-

adapted to support the U.S. Army Field mored Knight. This capability will put the ment (PIM/CAT). The PIM program is a

Artillery Combat Observation Lasing soldier under armor for operations, with sustainment program engineered to im-

Team (COLT) mission with G/VLLD and no degradation in capability, and add an prove readiness, avoid components’ obso-

ANTAS-4 sensors. In 2003, the M707 was optional fourth crew-member station. Ad- lescence and increase sustainability of the

enhanced with an FS3 second-generation ditional efforts are under way to upgrade M109A6 Paladin and the M992A2 FAASV

FLIR based on the LRAS3. the MEP and software to a more open ar- platforms out to the year 2050. PIM will

Fielded to both Infantry and heavy chitecture. The program is currently funded leverage fleet commonality for key compo-

brigade combat teams (IBCTs/HBCTs), for 416 upgraded TUA Knights and will be- nents including the Bradley engine, trans-

Knights consist of a laser designator and gin fielding in FY 2013. mission, final drives and suspension. PIM

rangefinder, thermal imager, digital com- uses the existing M109A6 main armament,

mand-and-control system, blended iner- Product Manager Fire Support recently designed cab structure, and the

tial/global positioning system navigation Platforms Chief of Section Protection while replacing

and targeting capability, and a self-defense Product Manager Fire Support Platforms outmoded chassis components with ad-

weapon. COLTs use the Knight precision manages approximately 1,934 platforms, vanced components from the Bradley

targeting systems, along with the forward including the M109A6 Paladin/M992A2 fighting vehicle to increase sustainability

observer system (FOS) software, to provide FAASV System, the Paladin/Carrier Ammu- and commonality across the HBCT. PIM

precise far-target location and laser desig- nition Tracked (CAT) and Paladin Integrated also incorporates select technologies from

nation for conventional ordnance, laser- Management (PIM) program vehicles. the non-line-of-sight cannon (NLOS-C), in-

guided munitions and precision-guided Paladin/FAASV. The M109A6 Paladin cluding a (modified electric) projectile

346 ARMY ■ October 2010

2007. The M777A2, which adds the ability

to fire the Excalibur precision-guided mu-

nition, was approved for use in September

2007.

The LW155 was first fielded by the Ma-

rine Corps in April 2005, and since then the

Paladin/FAASV 10th, 11th, 12th and 14th Marines and the

schoolhouses have been fielded. The Army

has been fielding the system to its Stryker

brigades, fires brigades, National Guard

and schools. The LW155 has seen signifi-

cant action in Afghanistan, receiving high

marks for its performance. The LW155 has

also been fielded through foreign military

sales to Canadian forces who have used it

extensively in Afghanistan with very posi-

tive feedback. Australia accepted its first

LW155 delivery in August 2010. Field ser-

vice representatives have been deployed to

support M777A2 weapons in theater and

em

s provide continuous technical and supply

Syst

BAE support to ensure that systems are fully

supported and maintained at a high state

of system readiness.

rammer and modern electric-gun drive vides direct, reinforcing and general sup- Every fielding by the LW155 office has

systems to replace the current hydrauli- port fires to maneuver forces. The first been conducted on schedule. In October

cally operated elevation and azimuth dri- ground system to make extensive use of 2009, Army Forces Command contacted the

ves that were designed in the early 1960s. high-strength titanium alloy for its major LW155 office to discuss the possibility of im-

The M109 FOV platforms will be fitted structures, the LW155 has achieved an al- mediately equipping an IBCT with the

with Blue Force Tracker capability to en- most 50 percent reduction in weight from LW155. This urgent requirement created

sure compatibility with future architec- the previous system. It is an excellent exam- challenges because IBCTs were never in-

tures. These upgrades and better commu- ple of a successful joint service program, tended to receive the LW155, the new equip-

nication technology will significantly with the Marine Corps and Army working ment training (NET) team was already

improve operational awareness on the bat- together to develop, produce and field the scheduled to train another unit, the Army

tlefield and reduce the logistics footprint howitzer and its Digital Fire Control Sys- did not want to forego any upcoming field-

within the HBCT. The new electric-gun tem (DFCS). The DFCS enables the weapon ings to make this happen, and the unit was

drives and rammer components as well as to program and fire the improved Excalibur deploying in just three months. Under-

a microclimate air conditioning system precision-guided munition to ranges in ex- standing the importance of this task, the

will be powered by the Common Modular cess of 25 miles, providing the capability to LW155 office quickly identified all the con-

Power System (CMPS). CMPS, which will deliver precision fire on the battlefield. straints. An innovative plan was developed,

also be installed on Stryker and has been The LW155 uses the M776 155 mm can- allowing the 4-25 FA to be fielded by taking

installed on Humvee demonstrator vehi- non, giving it a maximum firing range of weapons that had already been fielded to

cles, is based on architecture jointly devel- approximately 30 kilometers with rocket the 1st Stryker Brigade and sending them

oped by the Army Tank-Automotive Re- assisted projectiles and 24.7 kilometers directly to the port at Philadelphia, Pa. An

search Development and Engineering with standard rounds. It has a maximum additional six weapons were borrowed

Center and the Program Executive Office- firing rate of four rounds per minute and a from the 1-321 FA at Fort Bragg, N.C., and

Ground Combat Systems. Once delivered sustained rate of two rounds per minute. were sent to Fort Drum, N.Y., to support

to the field, the PIM vehicles will give The M777A1 is fitted with onboard elec- NET. Meanwhile, the NET team was split in

HBCT commanders a more sustainable ve- tronics, giving it self-locating, self-laying two, and an alternative program of instruc-

hicle, providing commanders increased and digital communications similar to the tion was developed to support the needs of

confidence in their artillery fleet. M109A6 Paladin. this light unit. The result was the successful

The M777A1 was unconditionally ap- equipping of the 4-25 in Afghanistan with

PM Joint Lightweight Howitzer proved for use by Army units in January the LW155 with no adverse effects to other

The Project Manager for the Joint Light- fieldings.

weight Howitzer takes a joint (Army and At present, 955 LW155s have been or-

Marine Corps) perspective in managing dered, with approximately 638 fielded.

the development, acquisition, testing, sys- While the prime contractor is BAE Systems

tems integration, product improvement of the United Kingdom, a strong U.S. sup-

and fielding of the M777A2 155 mm joint ply chain accounts for about 70 percent of

lightweight howitzer system, designed to the production and assembly work. Final

enhance strategic mobility and provide the

infantry soldier and marine with effective

and responsive fire support. Their task is

to provide a world-class, supportable how-

itzer system to artillery cannoneers, per-

mitting them to accomplish their missions.

The Lightweight 155 mm Howitzer

(LW155), also known as the M777A2, pro- M777 joint lightweight howitzer

October 2010 ■ ARMY 347

A program to integrate a digital fire-

control capability onto the M119A2 how-

itzer (becoming the M119A3 howitzer) was

approved by the PEO GCS and the com-

manding general of the Field Artillery

School Center of Excellence in January

2008. Direction was provided to maximize

commonality across the IBCTs to the maxi-

M119A2 howitzer mum extent possible, thus minimizing the

IBCT logistics footprint. Leveraging the

software for the M777A2 155 mm howitzer

maximizes commonality in operation and

training while minimizing program cost,

schedule and risk. The requirement for

this capability is the materiel change pack-

age for digitization of the M119A2 105 mm

light towed howitzer. The application of a

digital fire control will allow the digitized

integration and assembly is at a state-of- creased the M119A2 authorized acquisi- M119A2 to emplace and displace faster,

the-art lean manufacturing facility estab- tion objective to 893 systems. A decision to provide more responsive fires and allow

lished in Hattiesburg, Miss. reenter production was made by the gen- the system to become more survivable on

In addition to the M777 series how- eral officer steering committee. In 2005, the the battlefield.

itzers, other towed artillery systems being Program Executive Officer for Ground To provide even greater range and

supported in U.S. Army inventories in- Combat Systems (PEO GCS), through the lethality for light-unit fire-support ele-

clude the M119A2 105 mm howitzer as commanding general, TACOM Life Cycle ments, the Army began fielding the M198

well as the M198 155 mm howitzer. Management Command, endorsed the 155 mm Towed Howitzer in early 1979. As

The M119A2 is a lightweight 105 mm make-or-buy recommendation to produce a successor to the older M114A1 155 mm

howitzer that provides continuous close the M119A2 towed howitzer at Rock Is- towed system, the 15,750-pound (original

fires to the Infantry brigade combat teams. land Arsenal. The analysis was conducted fielded weight) M198 provided a maxi-

The system weighs 4,270 pounds and is air under the authority of 10 USC 4532 and in mum range of 30 kilometers (with rocket-

assault/air-drop capable. It has a range of accordance with the Army Industrial Base assisted projectiles) and the capability to

19.5 kilometers with rocket assisted muni- Process, Army Regulation 700-90 dated fire a broader range of ammunition op-

tions (14 kilometers unassisted). It fires all December 14, 2004. Cannons would con- tions than those available for 105 mm

currently fielded U.S. munitions and has a tinue to be produced at Watervliet Arsenal, units. Normally towed by a 5-ton truck,

rate of fire of six rounds per minute. Each N.Y., and basic issue items for the system the M198 can also be moved by a CH-47D

M119A2 section has seven crew members. are being purchased out of the govern- Chinook helicopter or Air Force assets, C-

The M119A2 is fielded as two eight-gun ment supply system. Production at Rock 130 and larger.

batteries for each M119A2 battalion. Island and Watervliet Arsenals com- The Project Manager for Mine Resis-

The M119 was originally acquired in menced with the receipt of the FY 2005 De- tant Ambush Protected (MRAP) Vehicles

1986 as a nondevelopmental item from fense Supplemental funding. The last program has been rapidly fielding highly

Royal Ordnance Plc. The original 147 how- weapon order was in FY 2009, and the last survivable, mobile, multimission vehicles

itzers were manufactured in the United deliveries will be taken in FY 2012. A full to the joint force to meet urgent operational

Kingdom and the balance produced at materiel release of these new production requirements. MRAP vehicles are commer-

Rock Island Arsenal, Ill. The current fleet howitzers was approved by the command- cial off-the-shelf vehicles designed from

of M119A2s in the inventory from the first ing general, U.S. Army TACOM Life Cycle the ground up to reduce casualties and in-

production run is 382 systems. U.S. fire Management Command, in June 2008. crease survivability for personnel subjected

control and a low-temperature-capable re-

cuperator were implemented as the

M119A1 in 1991. The light artillery system

improvement program resulted in the

M119A2, which possessed a number of im-

provements to enhance the ease of opera-

tion and maintenance of the weapon sys-

tem. Approved prime movers include the

Humvee and 2.5-ton and 5-ton trucks.

In 2004, it was determined that U.S.

Army modularity requirements had in-

M198 155 mm towed howitzer

348 ARMY ■ October 2010

The Stryker

eration Enduring Freedom and Operation

Iraqi Freedom. The primary design has

two variants: the M1126 infantry carrier

vehicle (ICV) and the M1128 mobile gun

system (MGS).

The ICV is a troop transport vehicle ca-

pable of carrying nine infantry soldiers

and their equipment and requires a crew

of two: a driver and a vehicle commander.

There are eight other ICV configurations

with combat service and combat support

roles. Those configurations include the

to mine explosions, improvised explosive oped under the GCV effort. The GCV ac- M1130 commander ’s vehicle, the M1127

device detonations and small-arms fire. quisition program will follow Department reconnaissance vehicle, the M1131 A1 fire-

Multiple missions are being supported by of Defense best acquisition practices and support vehicle, the M1129 A1 mounted

the MRAP fleet, including recon, convoy be a competitive program with up to three mortar carrier, the M1134 antitank guided

operations, troop transport, ambulance, contract awards. GCV development will missile vehicle, the M1132 engineer squad

combat engineer and explosive ordnance consist of three phases: technology devel- vehicle, the M1133 medical evacuation ve-

disposal missions for maneuver units. opment, engineering and manufacturing hicle and the M1135 nuclear-biological-

The Ground Combat Vehicle, managed design, and low-rate initial production. chemical reconnaissance vehicle. The MGS

by PM GCV as a part of PEO Ground The Army anticipated awarding the first is based on the ICV but modified to incor-

Combat Systems, will take an incremental contracts for the technology development porate a 105 mm turreted gun, an au-

development approach that enables initial phase in the fourth quarter of fiscal year toloader system and a crew of three. The

fielding by 2017, while establishing a basis 2010. ICV is armed with a remote weapons sta-

from which to adapt. The Project Manager for Stryker tion that supports the M2 .50-caliber ma-

The GCV’s modular design will allow Brigade Combat Team (PM SBCT) devel- chine gun or the Mk 19 automatic grenade

for growth in size, weight, power and ops, produces and sustains the full range launcher, the M6 countermeasure device

cooling which enables rapid integration of of safe, reliable, supportable and effective (smoke grenade launcher) and an inte-

improved capabilities in subsequent incre- Stryker vehicle systems, a diverse fleet of grated thermal weapon sight.

ments. In addition, the vehicle’s modular medium-weight vehicles capable of being The Stryker supports communications

design, particularly for armor and arma- rapidly deployed to trouble spots around suites that integrate the single-channel

ments, will provide commanders with con- the world. ground-and-air radio system (SINCGARS)

figuration and employment options and Stryker Family of Vehicles. The Stryker radio family; enhanced position location

complements the Army’s versatile mix of is an eight-wheeled combat platform, and reporting system (EPLRS); Force XXI Bat-

forces. the Stryker family of vehicles consists of 10 tle Command Brigade and Below (FBCB2)

The ground combat vehicle effort is part unique mission equipment packages in- or Blue Force Tracker (BFT); global posi-

of a holistic Army plan to modernize its corporated into the common combat vehi- tioning system (GPS); high-frequency (HF)

combat vehicle fleet. This includes incor- cles platform configurations. In 2000, the and multiband very high and ultrahigh

porating mine resistant ambush protected Stryker was the first new combat vehicle frequency (VHF/UHF) radio systems. The

vehicles into the fleet while modernizing to be acquired by the Army for more than Stryker provides up to 14.5 mm of ballistic

current vehicle fleets including Stryker. 20 years. The procurement of the Stryker protection. General Dynamics Land Sys-

The first ground combat vehicle will be an emerged from the following challenge tems produces the Stryker, which is pow-

infantry fighting vehicle offering a highly given in 1999 by then-Army Chief of Staff ered by a 350-hp diesel engine, runs on

survivable platform for delivering a nine- GEN Eric K. Shinseki: “We must provide eight wheels that possess a run-flat capa-

man infantry squad to the battlefield. The early entry forces that can operate jointly bility and has a central tire inflation sys-

GCV is the first vehicle that will be de- without access to fixed forward bases, but tem. It also incorporates a vehicle height

signed from the ground up to operate in we still need the power to slug it out and management system.

an improvised explosive device (IED) en- win decisively.” The response was brigade

vironment. It is envisioned to have greater combat teams and the Stryker family of Robotic Systems Joint Project Office

lethality and ballistic protection than a vehicles. The Army’s responsibility to sat- PEO GCS’s Robotic Systems Joint Pro-

Bradley, greater IED and mine protection isfy 21st-century requirements for effective ject Office (RS JPO) takes a joint (Army

than an MRAP, and the cross-country mo- full spectrum operations requires an im- and Marine Corps) perspective in manag-

bility of an Abrams. The GCV will be proved capability for the rapid deploy- ing the development, acquisition, testing,

highly survivable, mobile and versatile, ment of highly integrated, combined arms systems integration, product improvement

but the Army has not set specific require- forces possessing overmatching capabili- and fielding of robotic systems that will

ments such as weight, instead allowing in- ties, exploiting the power of information form the backbone of the combat force of

dustry to propose the best solution to meet and human potential, and combining the the future. RS JPO is spearheading devel-

the requirements. advantages of both light and mechanized opment of the systems to employ the latest

In February 2010, the program executive forces across the full range of military and sensors, remote navigation and command-

office released a request for proposal (RFP) nonmilitary operations. and-control technologies to integrate ro-

for the technology development phase of To date, Strykers have accumulated botics into the battlefield. Speeding these

the infantry fighting vehicle being devel- more than 25 million combat miles in Op- technologies to the battlefield has the po-

October 2010 ■ ARMY 349

tion and certification of a set of interface

specifications and open architecture stan-

dards that will enable interoperability, pay-

load integration and product improvement.

RS JPO, serving as the system integrator of

Multifunctional, agile, payloads on any robotic platform, is respon-

remote-controlled sible for managing space, weight and power

robot IV trades. This will drive the Army and Marine

Corps to a family of robotic platforms with a

common set of payload, communication

and command-and-control interface stan-

dards. The benefits of this discipline are po-

tential plug-and-play mission payloads,

common controllers and true modularity of

systems.

As the attention of U.S. military forces

has shifted from Iraq to Afghanistan, the

RS JPO is responding to additional require-

ments and new applications for ground ro-

bots. Combat in Operation Enduring Free-

dom (OEF) is significantly different from

that in OIF. Unlike in Iraq, the transporta-

tion, communication and utility infrastruc-

tures are rugged mountain trails and mud

huts. In Afghanistan, smaller, lighter ro-

bots with increased agility and mobility

will be needed by infantry units and ma-

neuver elements hiking the high-altitude

trails. Also, more EOD and route-clearance

robots will be needed with the continuing

buildup of force. Hazardous material and

explosives detection sensors, high-resolu-

tion cameras, dextrous manipulators and

tential to revolutionize combat operations. robots on the battlefield. Initially, EOD units other payloads will be required to enhance

Per the Army Acquisition Executive Policy and route-clearance teams adopted ground warfighter capability in OEF. The RS JPO

Memorandum of November 24, 2009, the robots to interrogate and neutralize impro- is poised to meet these emerging ground

RS JPO serves as the life-cycle manager for vised explosive devices or unexploded ord- robotic requirements. Modernization and

all current and future Army unmanned nance. Warfighters have since identified standardization of “veteran” assets from

ground systems. The following are priori- mission applications for robots to inspect OIF will occur during a reset process. Re-

ties of the RS JPO mission: support the vehicles; search caves, rubble and tunnels; set and new procurements will facilitate

joint warfighter, modernize current un- extend reach; and provide enhanced situa- the transformation to the Future Force.

manned systems, facilitate the transforma- tional awareness. The U.S. industrial base Regardless of how robots are integrated

tion to the Future Force, apply continuous has grown to meet the demand for un- into the heavy, Infantry or Army modern-

process improvement, conduct sound sys- manned systems. This growth is evident ization brigade combat teams, interoper-

tems-engineering practices and develop across all sectors of the market, including ability and modular payloads are two ne-

the workforce. A healthy partnership with basic and applied research at academic insti- cessities. These capabilities can be delivered

industry, academia, government research tutions and government laboratories, proto- to the warfighter only through the collabo-

centers and the user community has en- typing and commercialization by small busi- ration and cooperation of the RS JPO and

abled the RS JPO to develop, acquire, field nesses, and manufacturing, production and its partners. The RS JPO is committed to

and sustain robotic systems, while exceed- sustainment operations by traditional de- building strategic and tactical relationships

ing warfighter expectations. The RS JPO fense contractors, automotive suppliers, new to support the joint warfighter in the life-

vision is continuous improvement of un- companies and government organizations. cycle management of unmanned systems.

manned system capabilities to meet cur- In the rush to field robots to Operation

rent and future joint warfighter objectives. Iraqi Freedom (OIF) in 2003, commercial off-

Support to the joint warfighter in overseas the-shelf equipment was procured and

contingency operations has greatly accel- fielded to get systems in the hands of sol-

erated acquisition and fielding time lines. diers and marines as quickly as possible.

Delivering safe, effective unmanned sys- Initially, demand for robots outpaced the

tems with a variety of mission payloads in supply capability of industry. Industry re-

response to joint urgent operational needs sponded by increasing production capabil-

statements has created a number of oppor- ity, which spawned a number of subtier

tunities as well as challenges for the RS JPO suppliers and upstart robotic companies. As

and its partners. Operational needs from competition increased, innovative, high-

theater have defined mission requirements quality products ensued. This dynamic

for ground robots from explosive ordnance seven-year period has created a configura-

disposal (EOD) to area- and route-clearance tion management and interoperability chal-

and reconnaissance and surveillance. This lenge for the RS JPO. A key tenet of RS JPO’s

has resulted in the proliferation of ground strategic vision is the development, applica-

350 ARMY ■ October 2010

You might also like

- Amap BDocument6 pagesAmap Ba19952083100% (1)

- Merkava 4 Heavy TanksDocument3 pagesMerkava 4 Heavy TanksBồ Câu ThưNo ratings yet

- MortarsDocument12 pagesMortarsAji Wijanarko100% (1)

- Leopard 2 A4 EvolutionDocument6 pagesLeopard 2 A4 EvolutionAlexjohn2009100% (3)

- AMX 56 LeclercDocument10 pagesAMX 56 LeclercAlexandru StroeNo ratings yet

- Three Sisters Full PacketDocument16 pagesThree Sisters Full PacketRinny FischerNo ratings yet

- The ScarDocument12 pagesThe ScarMacmillan Publishers27% (15)

- Artillery 05Document11 pagesArtillery 05Jet Vissanu100% (1)

- Abrams Upgrade: Investment ComponentDocument2 pagesAbrams Upgrade: Investment ComponentAlexanderPetrovNo ratings yet

- Abrams Tank Upgrade (M1A2) : Investment ComponentDocument2 pagesAbrams Tank Upgrade (M1A2) : Investment ComponentSuzuki ImproNo ratings yet

- Ground VehiclesDocument18 pagesGround Vehicleswlamiller100% (2)

- General Dynamics - MACS M231/M232A1 Modular Artillery Charge SystemDocument1 pageGeneral Dynamics - MACS M231/M232A1 Modular Artillery Charge SystemYamvea100% (1)

- U.S. Army Weapon Systems Handbook 2012Document2 pagesU.S. Army Weapon Systems Handbook 2012joaoguilhermealbertoNo ratings yet

- Ada 323152Document6 pagesAda 323152TenshiJibril100% (1)

- 06 Weapons AmmunitionDocument6 pages06 Weapons AmmunitionChonk LeeNo ratings yet

- This We'll Defend: The Weapons & Equipment of the U.S. ArmyFrom EverandThis We'll Defend: The Weapons & Equipment of the U.S. ArmyRating: 3.5 out of 5 stars3.5/5 (2)

- Army - Mil-Army Rolls Out Latest Version of Iconic Abrams Main Battle TankDocument3 pagesArmy - Mil-Army Rolls Out Latest Version of Iconic Abrams Main Battle TankOsorio LuisNo ratings yet

- BAE - Digital - USL - Landscape - AMPV - Mortar CarrierDocument2 pagesBAE - Digital - USL - Landscape - AMPV - Mortar CarrierLuciano PinheiroNo ratings yet

- General Dynamics Awarded $34 Million For M1A1 Abrams Tank Upgrades - General Dynamics PDFDocument2 pagesGeneral Dynamics Awarded $34 Million For M1A1 Abrams Tank Upgrades - General Dynamics PDFOsorio LuisNo ratings yet

- 2020,年m1a2sepv3Document4 pages2020,年m1a2sepv3龙成No ratings yet

- 2015 M 270 A 1 MlrsDocument2 pages2015 M 270 A 1 MlrsBee AscenzoNo ratings yet

- MILTEC KPZDocument15 pagesMILTEC KPZWolfgang SchneiderNo ratings yet

- 4 Agds 96Document6 pages4 Agds 96Michael CummingsNo ratings yet

- Multiple Launch Rocket System (MLRS) M270A1: Investment ComponentDocument2 pagesMultiple Launch Rocket System (MLRS) M270A1: Investment ComponentBee AscenzoNo ratings yet

- Tank Employment in Expeditionary Operations Submitted by Rummler, P. MDocument16 pagesTank Employment in Expeditionary Operations Submitted by Rummler, P. MChris BeckmanNo ratings yet

- 121 Ground Combat ElementDocument5 pages121 Ground Combat ElementCody JacksonNo ratings yet

- MRAP Family of VehiclesDocument8 pagesMRAP Family of Vehiclessudhavel100% (1)

- High Mobility Artillery Rocket System (HIMARS)Document2 pagesHigh Mobility Artillery Rocket System (HIMARS)Zoran Vulovic100% (3)

- Gicat Brochure-Capacites Mrav Uk Exe-150Document28 pagesGicat Brochure-Capacites Mrav Uk Exe-150malaoui44No ratings yet

- TOE 05337F1000 or L000 - 5 - Company - Engineer Co Heavy Division XXI (FAS - Org) - ToE 05337F1000 or L000 - BDocument5 pagesTOE 05337F1000 or L000 - 5 - Company - Engineer Co Heavy Division XXI (FAS - Org) - ToE 05337F1000 or L000 - BMartin WhitenerNo ratings yet

- WiSENT 2Document8 pagesWiSENT 2jrigorighiNo ratings yet

- Amx-56 Leclerc Main Battle TankDocument5 pagesAmx-56 Leclerc Main Battle TankTimia TalashekNo ratings yet

- Abrams Brochure ModernizationDocument2 pagesAbrams Brochure ModernizationLavi1889100% (1)

- FM 11-24 Signal Tactical Satellite CompanyDocument64 pagesFM 11-24 Signal Tactical Satellite CompanyMark CheneyNo ratings yet

- Anti-Tank Missile Systems: Missiles and ArtilleryDocument5 pagesAnti-Tank Missile Systems: Missiles and ArtilleryDeez34PNo ratings yet

- JSC Research and Production Corporation UralVagonZavod EngDocument27 pagesJSC Research and Production Corporation UralVagonZavod EngAlex Cerneavschi100% (1)

- M1A2: One Year Later: by Captain John BassoDocument4 pagesM1A2: One Year Later: by Captain John BassoMuhammad FerialNo ratings yet

- Rheinmetall DSEI LANCE enDocument2 pagesRheinmetall DSEI LANCE enJulien Beleno AranetaNo ratings yet

- MK41 VLS Product CardDocument2 pagesMK41 VLS Product Cardpvssrh9929100% (1)

- Global Mortar Systems: Market UpdateDocument31 pagesGlobal Mortar Systems: Market UpdateejgarciacabralNo ratings yet

- M1A1 A2 AbramsDocument50 pagesM1A1 A2 AbramsHandrey Zoz100% (2)

- ASBFY20 BF2040 Ex SumDocument58 pagesASBFY20 BF2040 Ex Sumdebrah heatonNo ratings yet

- Body mm07761 Mirach 100 5 LQDocument2 pagesBody mm07761 Mirach 100 5 LQultrapampersNo ratings yet

- FM7 7Document399 pagesFM7 7Babrak BabrakovicNo ratings yet

- ADA329084Document18 pagesADA329084mahanramtin100% (1)

- PositionedDocument9 pagesPositionedMohamad HaizarNo ratings yet

- 44 Armoured VehiclesDocument15 pages44 Armoured Vehiclespieffepi03No ratings yet

- Amx Leclerc Main Battle Tank For The Year 2000Document6 pagesAmx Leclerc Main Battle Tank For The Year 2000Timia TalashekNo ratings yet

- Light Mine Resistant VehiclesDocument4 pagesLight Mine Resistant Vehiclestaktik(z), Inc.100% (2)

- S 300VDocument49 pagesS 300VSohail SafeerNo ratings yet

- Army Aviation Digest - May 1991Document68 pagesArmy Aviation Digest - May 1991Aviation/Space History LibraryNo ratings yet

- M1 AbramsDocument30 pagesM1 AbramsrameshNo ratings yet

- Catalog Artillery Ammunition 13 WebDocument6 pagesCatalog Artillery Ammunition 13 WebDavid Alarcon Ulloa100% (1)

- Breaking The Tether of Fuel 2007Document5 pagesBreaking The Tether of Fuel 2007j_s_fuchsNo ratings yet

- UTMT-30-6pgs 3 PRINTDocument6 pagesUTMT-30-6pgs 3 PRINTFranco LuceroNo ratings yet

- MCRP 3-12.1 Tank PlatoonDocument380 pagesMCRP 3-12.1 Tank PlatoonBenjamin David Spaeth100% (1)

- 20x102mm Fact SheetDocument2 pages20x102mm Fact SheetHossam AliNo ratings yet

- 120-mm Advanced Multi-Purpose (AMP), XM1147: Fy20 Army ProgramsDocument2 pages120-mm Advanced Multi-Purpose (AMP), XM1147: Fy20 Army ProgramsmattNo ratings yet

- Mgm-166 Losat - WikipediaDocument3 pagesMgm-166 Losat - WikipediasorinartistuNo ratings yet

- War Emergency Power: Unleashing Tactical Dominance in Critical Combat ScenariosFrom EverandWar Emergency Power: Unleashing Tactical Dominance in Critical Combat ScenariosNo ratings yet

- Training Strategies For The M1 Abrams Tank Driver TrainerDocument100 pagesTraining Strategies For The M1 Abrams Tank Driver TrainerThallezNo ratings yet

- TURMS D LQ mm07939Document4 pagesTURMS D LQ mm07939ThallezNo ratings yet

- Lothar LQ mm07836Document2 pagesLothar LQ mm07836ThallezNo ratings yet

- C-27J Next Gen - Datasheet - ENGDocument2 pagesC-27J Next Gen - Datasheet - ENGThallez0% (2)

- 93doc04 0Document85 pages93doc04 0ThallezNo ratings yet

- C-27J Next Gen - Brochure - ENGDocument11 pagesC-27J Next Gen - Brochure - ENGThallezNo ratings yet

- WEB DATA SHEET - M345 Pattuglia - CANADADocument2 pagesWEB DATA SHEET - M345 Pattuglia - CANADAThallezNo ratings yet

- VBM Freccia Amc: Dimensions (Approx.) Driveline / Suspension ArmamentDocument1 pageVBM Freccia Amc: Dimensions (Approx.) Driveline / Suspension ArmamentThallezNo ratings yet

- Aermacchi M-346 Brochure ENG NewDocument11 pagesAermacchi M-346 Brochure ENG NewThallez100% (1)

- Dardo FamilyDocument1 pageDardo FamilyThallezNo ratings yet

- VBM Freccia Land Tactical Command PostDocument1 pageVBM Freccia Land Tactical Command PostThallezNo ratings yet

- Aermacchi M-346 AJT - Datasheet - ENG - NewDocument2 pagesAermacchi M-346 AJT - Datasheet - ENG - NewThallezNo ratings yet

- Aermacchi M-345: The Next Generation TrainerDocument2 pagesAermacchi M-345: The Next Generation TrainerThallezNo ratings yet

- Amphibious Armoured Vehicle: Dimensions Wheels Firing Direction SystemDocument1 pageAmphibious Armoured Vehicle: Dimensions Wheels Firing Direction SystemThallezNo ratings yet

- Puma 4x4 Puma 6x6Document1 pagePuma 4x4 Puma 6x6ThallezNo ratings yet

- Aermacchi M-345: The Next Generation TrainerDocument7 pagesAermacchi M-345: The Next Generation TrainerThallez0% (1)

- VBM Freccia Arv: Dimensions Driveline / SuspensionDocument1 pageVBM Freccia Arv: Dimensions Driveline / SuspensionThallezNo ratings yet

- Ariete MBTDocument1 pageAriete MBTThallezNo ratings yet

- Freccia OWSDocument1 pageFreccia OWSThallezNo ratings yet

- VBM Freccia Aifv/Atgm: Driveline / Suspension Crew DimensionsDocument1 pageVBM Freccia Aifv/Atgm: Driveline / Suspension Crew DimensionsThallezNo ratings yet

- Textron Lycoming AGT1500 Engine - Transitioning For Future ApplicationsDocument11 pagesTextron Lycoming AGT1500 Engine - Transitioning For Future ApplicationsThallez100% (1)

- Centauro I: 105 MM /120 MMDocument1 pageCentauro I: 105 MM /120 MMThallezNo ratings yet

- Testing Battle Tank Gas TurbinesDocument2 pagesTesting Battle Tank Gas TurbinesThallezNo ratings yet

- Dardo Aifv/Atgm: Dimensions Driveline / Suspension CrewDocument1 pageDardo Aifv/Atgm: Dimensions Driveline / Suspension CrewThallezNo ratings yet

- InterSKY 4MDocument4 pagesInterSKY 4Mvsatdog100% (1)

- G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - &Document44 pagesG 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - & G 'Mo (JVMÑD' Da - &sreekrishna9No ratings yet

- S.J.Lurje - Arhimed (1952) PDFDocument274 pagesS.J.Lurje - Arhimed (1952) PDFIvana PaunovicNo ratings yet

- Seven Ages Collector Edition RulesDocument37 pagesSeven Ages Collector Edition RulesRaulonescribdNo ratings yet

- Candidly, One Friend To Another Pub1022Document2 pagesCandidly, One Friend To Another Pub1022scparcoNo ratings yet

- Data Produksi Machining Bulan Juli 2022Document301 pagesData Produksi Machining Bulan Juli 2022yuli dwi atmokoNo ratings yet

- Fomrhi Q135Document42 pagesFomrhi Q135Gaetano PreviteraNo ratings yet

- Hot Toys Iron Man Action Figures ChecklistDocument8 pagesHot Toys Iron Man Action Figures ChecklistmarcotuliocNo ratings yet

- Notice: Meetings: Defense Language Institute Foreign Language Center Board of VisitorsDocument1 pageNotice: Meetings: Defense Language Institute Foreign Language Center Board of VisitorsJustia.comNo ratings yet

- New Flight Plan Bonus ScenariosDocument12 pagesNew Flight Plan Bonus ScenariosHistorylover88No ratings yet

- KriegsspielDevelopments Mouat ODocument34 pagesKriegsspielDevelopments Mouat OFabio RiggiNo ratings yet

- How To Read A Nautical Chart Course PresentationDocument80 pagesHow To Read A Nautical Chart Course PresentationVirgil Titimeaua100% (2)

- My Infinity Army List - PanOceaniaDocument1 pageMy Infinity Army List - PanOceaniaDražen BičanićNo ratings yet

- Establishment of MadrasDocument16 pagesEstablishment of MadrasWilliam StainsNo ratings yet

- Compare and Contrast Italian and German UnificationDocument2 pagesCompare and Contrast Italian and German UnificationCameron CampbellNo ratings yet

- Data - STR 191018 192025Document68 pagesData - STR 191018 192025hainh036188No ratings yet

- Take Five Brubeck - 3 Tons - EbmDocument3 pagesTake Five Brubeck - 3 Tons - EbmEduardoSantosNo ratings yet

- Velasco, Lino Paul History Activity Semi FinalsDocument3 pagesVelasco, Lino Paul History Activity Semi FinalsGlitchedBoiiNo ratings yet

- Zimmerman - Origins of A Catastrophe - Yugoslavia and Its Destroyers (1999)Document287 pagesZimmerman - Origins of A Catastrophe - Yugoslavia and Its Destroyers (1999)milosdimic83% (6)

- Imp Wars TN1643762536457Document4 pagesImp Wars TN1643762536457monica lallichettiNo ratings yet

- FM 90-13 - River Crossing OperationsDocument152 pagesFM 90-13 - River Crossing OperationsSurvivIt100% (1)

- The Dangerous of Nuclear WarDocument12 pagesThe Dangerous of Nuclear WarAhmed KhanNo ratings yet

- Gun Swell DataDocument4 pagesGun Swell DataMcSOLA ONo ratings yet

- Lobster 15Document58 pagesLobster 15belga197100% (1)

- Combat Commander Europe RulesDocument24 pagesCombat Commander Europe Ruless_hager100% (3)

- Consti2Digest - People vs. de Gracia, 233 SCRA 716, GR 102009 (6 July 1994)Document2 pagesConsti2Digest - People vs. de Gracia, 233 SCRA 716, GR 102009 (6 July 1994)Lu Cas100% (1)

- (Birol Başkan (Auth.) ) Turkey and Qatar in The Ta (B-Ok - Xyz)Document153 pages(Birol Başkan (Auth.) ) Turkey and Qatar in The Ta (B-Ok - Xyz)jojoNo ratings yet

- Understanding Hadrians WallDocument5 pagesUnderstanding Hadrians WallBernardo Milazzo0% (1)