Professional Documents

Culture Documents

New Microsoft Excel Worksheet

New Microsoft Excel Worksheet

Uploaded by

PranayOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Microsoft Excel Worksheet

New Microsoft Excel Worksheet

Uploaded by

PranayCopyright:

Available Formats

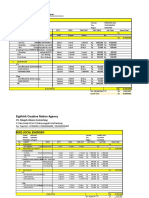

1ST Method

PRODUCTION CAPACITY CALCULATION

AVERAGE NO. OF BAGS THAT CAN BE MADE ON THE MACHINE PER MIN 60 MIN 12 HR 25 DAYS

(Based on a 12 hrs. working on a daily basis and 25 days working / month) 80 4800 57600 1,440,000

COST OF PRODUCTION

S.NO DETAIL COST

1 LABOUR 1 SKILLED @ 15,000/MONTH AND 2 UNSKILLED @ 8,000/MONTH 23,000

2 POWER TOTAL 9 KW POWER (PER MONTH) 8,500

3 RENTALS 1000 SQ FEET AREA 6,000

BANK INTREST ON

4 18 LACS @ 14% PER ANNUM 39,000

LOAN

5 MISC ADMINISTRATION AND OTHER EXPENSES 18,000

TOTAL EXPENSES FOR THE MONTH 94,500

1 COST OF PRODUCTION TOTAL EXP PER MONTH 94,500

2 PRODUCTION CAPACITY PER MONTH 1,440,000

AVERAGE PRODUCTION COST OF EACH BAG 0.066

2ND Method

PRODUCTION CAPACITY CALCULATION

60gsm fabric bag 25Days Per

60 gsm Bag Size Each bag Wt. 60 Min per hr. 12Hr Per Day

size 12” x 16 MONTH

AVERAGE (Kg) material

processing (based on a 12 Each Bag WT.14 12×16bag wt

hr working on a daily basis GRAMS FOR 60 12×16 Bag 14gr 1000gr/14gr 80 Kg 960 Kg 24,000 Kg

and 25 days working / GSM 1kg=71bag

month)

EXPENSE

D-CUT NON-WOVEN BAGS U-CUT NON-WOVEN BAGS

DESCRIPTION

Average cost of Raw 114 per Kg 114 per Kg

material

Per month cost of 114 x 24,000 = 27,36,000 114 x 24,000 = 27,36,000

material

Production cost per 94,500 94,500

month

Total expenses for one

month with material 2,830,500 2,830,500

10% of 24,000 kg = 2400 Kg (wastage can also sale at low

Total wastage 5 % of 24,000 Kg = 1200 Kg (Wastage can also sale at low price) price)

After wastage ready

material 22,800 Kg 21,600 Kg

Average selling price of 135 (Selling price depend on the market) 145 (selling price depends on the market)

Bag per Kg

Total selling price 135 x 22,800 = 30,78,000 145 x 21,600 = 31,32,000

Net Realization per 30,78,000 -28,30,500 = 2,47,500 31,32,000 - 28,30,500 = 3,01,500

month

You might also like

- Project Profile On Tissue Paper ManufacturingDocument5 pagesProject Profile On Tissue Paper ManufacturingKamalam Cloudsoft100% (4)

- Fibroblast Training ManualDocument49 pagesFibroblast Training Manual72034430100% (14)

- Business Plan For Hot Pepper BusinessDocument5 pagesBusiness Plan For Hot Pepper Businessoluwatobiloba esan100% (1)

- Task 1 - Model AnswerDocument4 pagesTask 1 - Model AnswerShauryaNo ratings yet

- Cost AnswerDocument14 pagesCost AnswerEliyas TemesgenNo ratings yet

- Tech Machine (India) PVT - LTD.: Email: WebsiteDocument6 pagesTech Machine (India) PVT - LTD.: Email: WebsiteAravindhan PalaniswamyNo ratings yet

- CHAPTER-III-2 (Draft)Document11 pagesCHAPTER-III-2 (Draft)Jenny PabualanNo ratings yet

- Eco Friendly Non Woven Mask Making Machine PDFDocument4 pagesEco Friendly Non Woven Mask Making Machine PDFJ MurugadasanNo ratings yet

- KP Tech Machine (India) PVT - LTD: KP-1000 &1 Fully Automatic Non Woven Tie Face Mask MachineDocument4 pagesKP Tech Machine (India) PVT - LTD: KP-1000 &1 Fully Automatic Non Woven Tie Face Mask MachineRicardo PirelaNo ratings yet

- Maize Production in Nigeria - A Business Plan - AgrorafDocument9 pagesMaize Production in Nigeria - A Business Plan - AgrorafOyebola Akin-Delu100% (1)

- Royal Cashew Nut FactoryDocument2 pagesRoyal Cashew Nut FactoryGarg AgamNo ratings yet

- QuUESTION BANK Relevant Cost For Decision MakingDocument22 pagesQuUESTION BANK Relevant Cost For Decision MakingTamaraNo ratings yet

- Cash Advance KPPS 44Document2 pagesCash Advance KPPS 44awasbahayaNo ratings yet

- Fully Automatic Elastic Face Mask Machine PDFDocument4 pagesFully Automatic Elastic Face Mask Machine PDFGitanjali DubeyNo ratings yet

- Expenses Amount: Projected Profitability Statement For 90 ML Paper CupDocument1 pageExpenses Amount: Projected Profitability Statement For 90 ML Paper CupPrince SantoNo ratings yet

- Sludge Dryer Payback Original FileDocument6 pagesSludge Dryer Payback Original FileumeshpatelNo ratings yet

- Planing MTG 2Document7 pagesPlaning MTG 2Ashraf AlamNo ratings yet

- Agarbatti Making MachineDocument12 pagesAgarbatti Making Machinehussen seidNo ratings yet

- Paper Cup Making MachineDocument2 pagesPaper Cup Making Machineambika65336533No ratings yet

- ProjectDocument9 pagesProjectAkhila AbheeshNo ratings yet

- Alwi Nebbi Profit Loss ProjectionDocument3 pagesAlwi Nebbi Profit Loss ProjectionAdriko NormanNo ratings yet

- Plan A: Initial FundingDocument12 pagesPlan A: Initial FundingAzzam SyahrulNo ratings yet

- Process Flow DiagramDocument1 pageProcess Flow DiagramKamil akalankaNo ratings yet

- Planing MTG 2Document7 pagesPlaning MTG 2Ashraf AlamNo ratings yet

- Input CostsDocument2 pagesInput CostsJim ClifNo ratings yet

- Story of A GarmentDocument14 pagesStory of A GarmentArunraj ArumugamNo ratings yet

- 20k Layers in NigeriaDocument15 pages20k Layers in Nigeriaablekuma684No ratings yet

- Cashflow EucalyptusDocument14 pagesCashflow Eucalyptusbung RezaNo ratings yet

- Rural Entrepreneurship and Marketing: National Institute of Rural Development and Panchayati RajDocument7 pagesRural Entrepreneurship and Marketing: National Institute of Rural Development and Panchayati RajSreekanth reddy100% (1)

- Rab Hauling BatubaraDocument1 pageRab Hauling BatubaraAbi Al ghifariNo ratings yet

- Empire Building Bill of Quantity For House Renovation-1Document4 pagesEmpire Building Bill of Quantity For House Renovation-1Onwubalili KelvinNo ratings yet

- No. Jenis Biaya Harga Konsumsi Satuan Total 1 Biaya ApdDocument3 pagesNo. Jenis Biaya Harga Konsumsi Satuan Total 1 Biaya ApdaisahNo ratings yet

- Textile Costing Lecture 08 CVP in TextilesDocument2 pagesTextile Costing Lecture 08 CVP in TextilesNeha Jain100% (1)

- Copy of Estimasi PerhitunganDocument21 pagesCopy of Estimasi Perhitungandadan100% (1)

- Name Qty Price Total: Fixed AssetsDocument2 pagesName Qty Price Total: Fixed AssetsmoodydoodyNo ratings yet

- Natanael Sirait - 21S20029 - Tugas 3Document5 pagesNatanael Sirait - 21S20029 - Tugas 3Natanael SiraitNo ratings yet

- Trashery Startup PlanDocument3 pagesTrashery Startup PlanMohsin AliNo ratings yet

- Manufacture of Paper Products (Paper Cups)Document4 pagesManufacture of Paper Products (Paper Cups)Ravi RajuNo ratings yet

- Load FactorDocument14 pagesLoad FactorShin QuinnNo ratings yet

- Healthcare Siddhartha Sarkar SP JainDocument10 pagesHealthcare Siddhartha Sarkar SP JainsudhirnairNo ratings yet

- CLUSTER 1-Magsaysay - DceDocument6 pagesCLUSTER 1-Magsaysay - DceJopheth RelucioNo ratings yet

- Dry Oyster Mushroom Production B-PlanDocument14 pagesDry Oyster Mushroom Production B-PlanAmruta WadatkarNo ratings yet

- Solved Case StudyDocument6 pagesSolved Case Studyasif lashariNo ratings yet

- Magramo Lusong CarpentryDocument3 pagesMagramo Lusong CarpentryRonnie ManaoNo ratings yet

- Hot and Cold Lamination Machine ProjectReportDocument4 pagesHot and Cold Lamination Machine ProjectReportIndhu SharmaKSNo ratings yet

- Organi StructureDocument2 pagesOrgani StructureJemalNo ratings yet

- Tutorial 4 AnswerDocument7 pagesTutorial 4 AnswernajihahNo ratings yet

- Cash Forcasting GreenhouseDocument1 pageCash Forcasting GreenhouseAdam MirzaNo ratings yet

- Ma. Kristina Plants Nursery: Quotation #1Document1 pageMa. Kristina Plants Nursery: Quotation #1Mary Ann AmparoNo ratings yet

- Project Report: M/S Raunak Enterprises (Prop. Smt. Deu Bai Bairagi)Document14 pagesProject Report: M/S Raunak Enterprises (Prop. Smt. Deu Bai Bairagi)PUNEET JAINNo ratings yet

- Practicals Budgetory ControlDocument18 pagesPracticals Budgetory Controlvihanjangid223No ratings yet

- Calculation Labor SupplyDocument11 pagesCalculation Labor SupplySu mantoNo ratings yet

- Budgetary Control - Practical ProblemsDocument18 pagesBudgetary Control - Practical Problemsdfljmls,100% (2)

- Soal KadekDocument3 pagesSoal Kadekkadek pranethaNo ratings yet

- Materials Mix & Yield Variances-ACCADocument9 pagesMaterials Mix & Yield Variances-ACCAEjaz AhmadNo ratings yet

- Unit BudgetingDocument2 pagesUnit BudgetingAde Farhan 9GNo ratings yet

- Rab KonferensiDocument1 pageRab KonferensiilhamNo ratings yet

- Ending Budget JatengDocument9 pagesEnding Budget Jatengilma hitriyahNo ratings yet

- Reflective Journal: My Group PresentationDocument4 pagesReflective Journal: My Group PresentationAnh MingNo ratings yet

- Covumaiphuongthionline Cacthituonglai 1Document2 pagesCovumaiphuongthionline Cacthituonglai 1Ngọc ThảoNo ratings yet

- Understanding The Transfer of Prepositions: Arabic To EnglishDocument7 pagesUnderstanding The Transfer of Prepositions: Arabic To Englishwaa2000No ratings yet

- On The Job Evaluation SheetDocument2 pagesOn The Job Evaluation Sheetmoonbright27No ratings yet

- Analisis de Pesticidas Usandom FragmentacionDocument159 pagesAnalisis de Pesticidas Usandom FragmentacionroxanaNo ratings yet

- Hitting LogsDocument3 pagesHitting LogsSTRESSEDD -No ratings yet

- Costing Breif CaseDocument2 pagesCosting Breif Casehema varshiniNo ratings yet

- Sentence ConnectorsDocument2 pagesSentence ConnectorsReeta Kannusamy100% (1)

- 1 MobilePass VPNDocument8 pages1 MobilePass VPNYashpal SinghNo ratings yet

- 20130401Document15 pages20130401SebNo ratings yet

- FCG - List of Top 100 Stockholders Q1 (Common Shares) Ending 31 March 2024Document5 pagesFCG - List of Top 100 Stockholders Q1 (Common Shares) Ending 31 March 2024Amino BenitoNo ratings yet

- PCK303 Understanding The Lesson 9Document2 pagesPCK303 Understanding The Lesson 9Japhet BagsitNo ratings yet

- Guidance and Career Development Action Plan 2021 - 2022Document3 pagesGuidance and Career Development Action Plan 2021 - 2022Anthony HernandezNo ratings yet

- Company LawDocument15 pagesCompany Lawpreetibajaj100% (2)

- New Hptu Syllabus CSEDocument138 pagesNew Hptu Syllabus CSEerankursharma1985No ratings yet

- MaldivesDocument15 pagesMaldivesRyhan AbuNo ratings yet

- Green Synthesis and Characterization of Silver Nanoparticles, by The Reductive Action of The Aqueous Extract of Blueberry (Vaccinium Corymbosum)Document6 pagesGreen Synthesis and Characterization of Silver Nanoparticles, by The Reductive Action of The Aqueous Extract of Blueberry (Vaccinium Corymbosum)TR DanieleNo ratings yet

- Treasure Trove Workbook Answers Daffodils: Passage-1Document4 pagesTreasure Trove Workbook Answers Daffodils: Passage-1Rohan CharlesNo ratings yet

- Study of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesDocument44 pagesStudy of Adhesion Properties of Natural Rubber, Epoxidized Natural Rubber, and Ethylene-Propylene Diene Terpolymer-Based AdhesivesZarathos SinghNo ratings yet

- Acupressure Animal SheltersDocument1 pageAcupressure Animal SheltersIoana SavaNo ratings yet

- Umbilical Catheterization in ServiceDocument11 pagesUmbilical Catheterization in ServiceLucian CaelumNo ratings yet

- A Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesDocument9 pagesA Critical Literature Review of World-Class Universities Characteristics, Enablers, and StrategiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Bluthner PRO 88 Owners enDocument20 pagesBluthner PRO 88 Owners enAnonymous pMgjvHvC41No ratings yet

- (Welding) ANSI-AWS Standard A5.5-96 Specification For Low-Alloy Steel Electrodes For Shielded Metal Arc Welding (Ebook, 55 Pages)Document55 pages(Welding) ANSI-AWS Standard A5.5-96 Specification For Low-Alloy Steel Electrodes For Shielded Metal Arc Welding (Ebook, 55 Pages)hammadNo ratings yet

- TridentDocument24 pagesTridentPrajod ThiruvambattilNo ratings yet

- Factsheet 210129 28 IdxbasicDocument1 pageFactsheet 210129 28 IdxbasicNeedlaregNo ratings yet

- Record Keeping MisconceptionsDocument9 pagesRecord Keeping MisconceptionsPeaceNo ratings yet

- Assam High School TET Pedagogy Old PaperDocument19 pagesAssam High School TET Pedagogy Old PaperSharba BoruahNo ratings yet