Professional Documents

Culture Documents

LOG-563-03 Receiving Inspection Checklist Rev.1

LOG-563-03 Receiving Inspection Checklist Rev.1

Uploaded by

Emy SumartiniCopyright:

Available Formats

You might also like

- MIR FormatDocument3 pagesMIR Formatalisha karimNo ratings yet

- Attendance ListDocument2 pagesAttendance ListYusup MulyanaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Transmittal SampleDocument1 pageTransmittal SamplekokocdfNo ratings yet

- ELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Document2 pagesELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Muhammad IrfanNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- UntitledDocument2 pagesUntitledIrfan NaqibNo ratings yet

- Request For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsDocument3 pagesRequest For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsUr FriendNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateDocument1 pageDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueNo ratings yet

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 pagesManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Material Request For Approval (MRA)Document2 pagesMaterial Request For Approval (MRA)مهندس حسين100% (1)

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNo ratings yet

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96No ratings yet

- QC-GF-001 - Request For InspectionDocument1 pageQC-GF-001 - Request For InspectionDarrel Espino AranasNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- 2015 VENTILATION PRODUCTS CATALOGUE. Ms Trang 0981523387 PDFDocument46 pages2015 VENTILATION PRODUCTS CATALOGUE. Ms Trang 0981523387 PDFhvachcm vnkNo ratings yet

- Mechanical Completion CertificateDocument1 pageMechanical Completion CertificateJoanrenis SaranyaNo ratings yet

- NCR Tracking Log AAILDocument5 pagesNCR Tracking Log AAILssenthil04No ratings yet

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Document10 pagesMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNo ratings yet

- Itp Bored Pile Rev 1Document10 pagesItp Bored Pile Rev 1Pandar HasibuhanNo ratings yet

- 2 Contractor Quality Control Plan For Civil WorkDocument6 pages2 Contractor Quality Control Plan For Civil Workbehzad esNo ratings yet

- MGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationDocument16 pagesMGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationKarrar TalibNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- RUX Ball ValveDocument1 pageRUX Ball Valvejustine lopez100% (1)

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Document1 pageIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Water Tightness Test Report For Water Retaining StructureDocument2 pagesWater Tightness Test Report For Water Retaining StructureLakshithaGonapinuwalaWithanageNo ratings yet

- ITP - General Fill For The Roads - SampleDocument12 pagesITP - General Fill For The Roads - SamplezubairNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- Leak Test Inspection ReportDocument2 pagesLeak Test Inspection ReportDaengkulle Firmansyah PuteraNo ratings yet

- MTS Check ListDocument1 pageMTS Check Listabdlelah.zreikNo ratings yet

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul Jabbar100% (1)

- DB ChecklistDocument4 pagesDB ChecklistJabinNo ratings yet

- ESMP ReportDocument11 pagesESMP ReportAshebir100% (1)

- Field Inspection Plan (Brick and Masonry Walling)Document1 pageField Inspection Plan (Brick and Masonry Walling)christopher AdajoNo ratings yet

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocument1 pageInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothNo ratings yet

- F-Qa-04 General Inspection ReportDocument1 pageF-Qa-04 General Inspection ReportHilal mohamedNo ratings yet

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- Attachment 6 - Technical Query FormDocument1 pageAttachment 6 - Technical Query FormLai HuynhNo ratings yet

- Material Receiving Inspection ReportDocument1 pageMaterial Receiving Inspection ReportktwfaevlmhtfbdgeojNo ratings yet

- Factory Acceptance Test & SAT Site Acceptance TestDocument3 pagesFactory Acceptance Test & SAT Site Acceptance TestMohamedNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- Hydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentDocument1 pageHydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentgjoeNo ratings yet

- PRO-5711-03 Pressure Test Form Rev.04Document2 pagesPRO-5711-03 Pressure Test Form Rev.04Emy SumartiniNo ratings yet

- FM-IQA-001 IQA System Schedule Rev.01Document2 pagesFM-IQA-001 IQA System Schedule Rev.01Emy SumartiniNo ratings yet

- PRO-5711-01 Shop Order Rev.0Document2 pagesPRO-5711-01 Shop Order Rev.0Emy SumartiniNo ratings yet

- PM-578-04 Maintenance Record Rev.0Document2 pagesPM-578-04 Maintenance Record Rev.0Emy SumartiniNo ratings yet

- FM NCR 001 Non Conformance Report Rev.02Document2 pagesFM NCR 001 Non Conformance Report Rev.02Emy SumartiniNo ratings yet

- FM-CR-001 Master List of Records Rev.01Document3 pagesFM-CR-001 Master List of Records Rev.01Emy SumartiniNo ratings yet

- FM-DOC-002 Index and Review Schedule Rev.01Document2 pagesFM-DOC-002 Index and Review Schedule Rev.01Emy SumartiniNo ratings yet

- FM-IQA-003 Internal Audit Checklist Rev.01Document21 pagesFM-IQA-003 Internal Audit Checklist Rev.01Emy SumartiniNo ratings yet

- FM-CPA-001 Corrective Preventif Action Request Rev.02Document2 pagesFM-CPA-001 Corrective Preventif Action Request Rev.02Emy SumartiniNo ratings yet

- Im MT 018Document5 pagesIm MT 018Emy SumartiniNo ratings yet

- Im MT 019Document5 pagesIm MT 019Emy SumartiniNo ratings yet

- Im MT 013Document7 pagesIm MT 013Emy SumartiniNo ratings yet

- Im MT 017Document5 pagesIm MT 017Emy SumartiniNo ratings yet

- Project Captive 2019 10kDocument6 pagesProject Captive 2019 10kEmy SumartiniNo ratings yet

- Im MT 001Document5 pagesIm MT 001Emy SumartiniNo ratings yet

- Astm A0105&a0105m-14Document5 pagesAstm A0105&a0105m-14Emy SumartiniNo ratings yet

- Jadwal Kegiatan EmyDocument14 pagesJadwal Kegiatan EmyEmy SumartiniNo ratings yet

- FM-CPA-001 Corrective Preventif Action Request Rev.02Document2 pagesFM-CPA-001 Corrective Preventif Action Request Rev.02Emy SumartiniNo ratings yet

LOG-563-03 Receiving Inspection Checklist Rev.1

LOG-563-03 Receiving Inspection Checklist Rev.1

Uploaded by

Emy SumartiniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LOG-563-03 Receiving Inspection Checklist Rev.1

LOG-563-03 Receiving Inspection Checklist Rev.1

Uploaded by

Emy SumartiniCopyright:

Available Formats

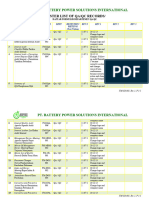

Doc. Id. No.

: LOG-563-03

Revision No.: 1

RECEIVING INSPECTION CHECKLIST Effective Date: 04.08.2014

Doc. Ctrl. No.:

Supplier Name: Valve Type: Checklist Number:

Size:

Pressure rating: Date:

Quantity: Temp. rating: PO No.:

Date Received : End connection:

Status of

Work Item / Activities to be verified Initialled Comments

Compliance

1. Certificate of Conformity

a) Valid API Spec Q1 / ISO TS 2009 certificate

b) API Licensee - API Spec 6A

c) API Licensee - API Spec 6D

d) API Licensee - API Spec 16A

e) PR1 / PR2 certificate or relevant document

2. Certificate of Quality

a) Valid ISO 9001 certificate

3. Design Requirement

a) Manufacture Valve Data Sheet

b) Technical Specification (part & materials list, dimension, torque,

flow coeficient [Kv])

c) Valve as build drawing

d) Assembly drawing

e) Design valve torque value & total valve torque requirement

(actuator)

f) Maximum Allowable Stem Torque (MAST)

g) Design calculation containing and controlling parts

h) Design verification by certification body / agency

4. Material & Mechanical Properties

a) Chemical composition

Incoming Receiving

Inspection: b) Material traceability & material test certificate (valve body / plate /

Manufacturer seat / stem / flange)

Compliance,

Drawing, List c) Material test certificate - the heat treatment & hardness test

Certificates, Others record (Rockwell Test [ASTM E-18] / Vickers Test [ASTM E-92] or

Document Needed Brinell Test [ASTM E-10])

d) Material test certificate - Tensile & Impact Test Record (ASTM A-

370)

e) Non Destructive Testing inspection report (NDT) - Ultrasonic Test

Report (ASTM A-609) / Magnetic Powder Test Report (ASTM A-709) /

Permeability Test Report (ASTM E-165)

f) Coating & plating certification

5. Welding Requirement

a) Welder Performance Qualification (WPQ)

b) Welding Procedure Specification (WPS)

c) Welding Quality Control Report - Performance Qualification Report

(PQR) - [NDE Records & Heat Treatment Record]

d) NDE Personnel Qualification Record

6. Product Testing

a) Pressure Test Certificate

b) Fire Type Test Certificate

7. Others Requirement

a) Installation, Operation and Maintenance Manual

b) Catalogue / Brochure

c) Supporting Letter

d) Guarantee Letter

e) Equipment Calibration Record

Note: I have carried out all necessary inspections and verify that the above items / activities conform to the contract specification / documents.

Inspected by:

QC Inspector

Date:

You might also like

- MIR FormatDocument3 pagesMIR Formatalisha karimNo ratings yet

- Attendance ListDocument2 pagesAttendance ListYusup MulyanaNo ratings yet

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Transmittal SampleDocument1 pageTransmittal SamplekokocdfNo ratings yet

- ELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Document2 pagesELECT-TIC-8.1 (Diesel-Generator MaterialReceiving)Muhammad IrfanNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 pagesPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNo ratings yet

- UntitledDocument2 pagesUntitledIrfan NaqibNo ratings yet

- Request For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsDocument3 pagesRequest For Inspection: Fixing of Tower Crane Tie-Ins at ColumnsUr FriendNo ratings yet

- 13427-01weekly QAQC ReportDocument1 page13427-01weekly QAQC ReportShyam SinghNo ratings yet

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateDocument1 pageDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueNo ratings yet

- Manufacturers Data Report (MDR) - Plant Projects EP-08-030-37Document17 pagesManufacturers Data Report (MDR) - Plant Projects EP-08-030-37MekhmanNo ratings yet

- Receiving Material Procedure CoverDocument1 pageReceiving Material Procedure Covergst ajahNo ratings yet

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- Itp For Installation of Pressurization UnitDocument1 pageItp For Installation of Pressurization UnitvictorNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- PO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDocument1 pagePO No 2037-PL-PL-0058 Inspection Notification No-015 r1 PDFDadaso Baburao JamdarNo ratings yet

- Portacabin Inspection ChecklistDocument2 pagesPortacabin Inspection ChecklistApm FoumilNo ratings yet

- Material Request For Approval (MRA)Document2 pagesMaterial Request For Approval (MRA)مهندس حسين100% (1)

- Anand Engineering Products Private Limited: Before Welding Inspection Check ListDocument1 pageAnand Engineering Products Private Limited: Before Welding Inspection Check ListAnilkumarGopinathanNairNo ratings yet

- AYC IC & ITP - GRP Shade InstallationDocument7 pagesAYC IC & ITP - GRP Shade Installationmoytabura96No ratings yet

- QC-GF-001 - Request For InspectionDocument1 pageQC-GF-001 - Request For InspectionDarrel Espino AranasNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- ITP For Hydraulic BarrierDocument4 pagesITP For Hydraulic Barriermoytabura96No ratings yet

- 2015 VENTILATION PRODUCTS CATALOGUE. Ms Trang 0981523387 PDFDocument46 pages2015 VENTILATION PRODUCTS CATALOGUE. Ms Trang 0981523387 PDFhvachcm vnkNo ratings yet

- Mechanical Completion CertificateDocument1 pageMechanical Completion CertificateJoanrenis SaranyaNo ratings yet

- NCR Tracking Log AAILDocument5 pagesNCR Tracking Log AAILssenthil04No ratings yet

- Main - Product - Report-Tangshan Shengcai Steel Co., Ltd.Document10 pagesMain - Product - Report-Tangshan Shengcai Steel Co., Ltd.hbookNo ratings yet

- Itp Bored Pile Rev 1Document10 pagesItp Bored Pile Rev 1Pandar HasibuhanNo ratings yet

- 2 Contractor Quality Control Plan For Civil WorkDocument6 pages2 Contractor Quality Control Plan For Civil Workbehzad esNo ratings yet

- MGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationDocument16 pagesMGP1 CP2 KMS Qa 6050 0003 007 Site Positive Material IdentificationKarrar TalibNo ratings yet

- LPS-01-HTI-ITP-EL-005 - Point WiringDocument5 pagesLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNo ratings yet

- Instrumentation and ControlsDocument2 pagesInstrumentation and ControlsTrí NguyễnNo ratings yet

- RUX Ball ValveDocument1 pageRUX Ball Valvejustine lopez100% (1)

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Document1 pageIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarNo ratings yet

- 02 MechanicalDocument44 pages02 Mechanicalmusaismail8863No ratings yet

- Water Tightness Test Report For Water Retaining StructureDocument2 pagesWater Tightness Test Report For Water Retaining StructureLakshithaGonapinuwalaWithanageNo ratings yet

- ITP - General Fill For The Roads - SampleDocument12 pagesITP - General Fill For The Roads - SamplezubairNo ratings yet

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocument3 pagesQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNo ratings yet

- Leak Test Inspection ReportDocument2 pagesLeak Test Inspection ReportDaengkulle Firmansyah PuteraNo ratings yet

- MTS Check ListDocument1 pageMTS Check Listabdlelah.zreikNo ratings yet

- QUALITY CONTROL PROCEDURE FOR Access Control System InstallationDocument8 pagesQUALITY CONTROL PROCEDURE FOR Access Control System InstallationAbdul Jabbar100% (1)

- DB ChecklistDocument4 pagesDB ChecklistJabinNo ratings yet

- ESMP ReportDocument11 pagesESMP ReportAshebir100% (1)

- Field Inspection Plan (Brick and Masonry Walling)Document1 pageField Inspection Plan (Brick and Masonry Walling)christopher AdajoNo ratings yet

- Installation of Instrument Switches (Pressure - Flow - Temperature - Level) CLDocument1 pageInstallation of Instrument Switches (Pressure - Flow - Temperature - Level) CLZulfequar R. Ali KhanNo ratings yet

- Inspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyDocument4 pagesInspected by QCP Approval 1-APC 1 - APC 2 - DAR 2 - DAR Al-Handeseh 3 - Negemco 4 - Vendor 5 - Third PartyAhmad DagamsehNo ratings yet

- QA-R-05 - Weld Traceability RecordDocument1 pageQA-R-05 - Weld Traceability RecordvinothNo ratings yet

- F-Qa-04 General Inspection ReportDocument1 pageF-Qa-04 General Inspection ReportHilal mohamedNo ratings yet

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- Itp PWHTDocument1 pageItp PWHTTridib DeyNo ratings yet

- Attachment 6 - Technical Query FormDocument1 pageAttachment 6 - Technical Query FormLai HuynhNo ratings yet

- Material Receiving Inspection ReportDocument1 pageMaterial Receiving Inspection ReportktwfaevlmhtfbdgeojNo ratings yet

- Factory Acceptance Test & SAT Site Acceptance TestDocument3 pagesFactory Acceptance Test & SAT Site Acceptance TestMohamedNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- Testing and CommisioningDocument2 pagesTesting and CommisioningKrishna PatilNo ratings yet

- Hydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentDocument1 pageHydrostatic Test Report: Project Description Job Order No. Test Date Qty EquipmentgjoeNo ratings yet

- PRO-5711-03 Pressure Test Form Rev.04Document2 pagesPRO-5711-03 Pressure Test Form Rev.04Emy SumartiniNo ratings yet

- FM-IQA-001 IQA System Schedule Rev.01Document2 pagesFM-IQA-001 IQA System Schedule Rev.01Emy SumartiniNo ratings yet

- PRO-5711-01 Shop Order Rev.0Document2 pagesPRO-5711-01 Shop Order Rev.0Emy SumartiniNo ratings yet

- PM-578-04 Maintenance Record Rev.0Document2 pagesPM-578-04 Maintenance Record Rev.0Emy SumartiniNo ratings yet

- FM NCR 001 Non Conformance Report Rev.02Document2 pagesFM NCR 001 Non Conformance Report Rev.02Emy SumartiniNo ratings yet

- FM-CR-001 Master List of Records Rev.01Document3 pagesFM-CR-001 Master List of Records Rev.01Emy SumartiniNo ratings yet

- FM-DOC-002 Index and Review Schedule Rev.01Document2 pagesFM-DOC-002 Index and Review Schedule Rev.01Emy SumartiniNo ratings yet

- FM-IQA-003 Internal Audit Checklist Rev.01Document21 pagesFM-IQA-003 Internal Audit Checklist Rev.01Emy SumartiniNo ratings yet

- FM-CPA-001 Corrective Preventif Action Request Rev.02Document2 pagesFM-CPA-001 Corrective Preventif Action Request Rev.02Emy SumartiniNo ratings yet

- Im MT 018Document5 pagesIm MT 018Emy SumartiniNo ratings yet

- Im MT 019Document5 pagesIm MT 019Emy SumartiniNo ratings yet

- Im MT 013Document7 pagesIm MT 013Emy SumartiniNo ratings yet

- Im MT 017Document5 pagesIm MT 017Emy SumartiniNo ratings yet

- Project Captive 2019 10kDocument6 pagesProject Captive 2019 10kEmy SumartiniNo ratings yet

- Im MT 001Document5 pagesIm MT 001Emy SumartiniNo ratings yet

- Astm A0105&a0105m-14Document5 pagesAstm A0105&a0105m-14Emy SumartiniNo ratings yet

- Jadwal Kegiatan EmyDocument14 pagesJadwal Kegiatan EmyEmy SumartiniNo ratings yet

- FM-CPA-001 Corrective Preventif Action Request Rev.02Document2 pagesFM-CPA-001 Corrective Preventif Action Request Rev.02Emy SumartiniNo ratings yet