Professional Documents

Culture Documents

MST-0010-00 For Pavement Road Works

MST-0010-00 For Pavement Road Works

Uploaded by

Ismail MydeenCopyright:

Available Formats

You might also like

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- TENDER - BRO Himachal Pradesh Rs.87 CR PDFDocument168 pagesTENDER - BRO Himachal Pradesh Rs.87 CR PDFVishal ChaudharyNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanNo ratings yet

- Method Statement Submittal - MSS: Part A: Project InformationDocument2 pagesMethod Statement Submittal - MSS: Part A: Project InformationMuhammad Jamil KhanNo ratings yet

- SHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Document334 pagesSHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Akhtar JavedNo ratings yet

- Fma - Civilmaint.18.003 Ms BDP 009 Asphalt Paving WorkDocument11 pagesFma - Civilmaint.18.003 Ms BDP 009 Asphalt Paving Workbaig habibNo ratings yet

- HFY-3800-0000-CIV-TQ-0006 - Bottom Section Length Change For Precast Piles Responded - Approved-SignedDocument3 pagesHFY-3800-0000-CIV-TQ-0006 - Bottom Section Length Change For Precast Piles Responded - Approved-SignedNashaat DhyaaNo ratings yet

- 235 MPHs SPORTS EQUIPMENT'S MISSING DETAILSDocument1 page235 MPHs SPORTS EQUIPMENT'S MISSING DETAILSusmanNo ratings yet

- 12-MS For Drain Work Cast in Situ & Pre-Cast R1Document25 pages12-MS For Drain Work Cast in Situ & Pre-Cast R1Rabnawaz ImamNo ratings yet

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- Document Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionDocument15 pagesDocument Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionComsip400No ratings yet

- Method Statement For Trial LoadingDocument5 pagesMethod Statement For Trial LoadingPunithan PunithanNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28625 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28625 R0-SignedMa NadeemNo ratings yet

- Tadian General Constructio/Chuwarcho Construction (JV)Document16 pagesTadian General Constructio/Chuwarcho Construction (JV)Jess L. MalecdanNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- QS049-P04-ASH-GEN-GEN-IR-28627 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28627 R0-SignedMa NadeemNo ratings yet

- MS For Installation of Chilled Water FlushinDocument27 pagesMS For Installation of Chilled Water FlushinAnandu AshokanNo ratings yet

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanNo ratings yet

- Icn 79Document1 pageIcn 79TPF Sneha KiranNo ratings yet

- NCR TemplateDocument2 pagesNCR TemplatechikannosNo ratings yet

- GGME - CX-393 - MS - RA - PHT - 01 Rev.1Document23 pagesGGME - CX-393 - MS - RA - PHT - 01 Rev.1akshay babuNo ratings yet

- Soft Landscape Prequalification Application FormDocument12 pagesSoft Landscape Prequalification Application FormGulf RubberNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28624 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28624 R0-SignedMa NadeemNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR - R0-SignedDocument7 pagesQS049-P04-ASH-GEN-GEN-IR - R0-SignedMa NadeemNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28626 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28626 R0-SignedMa NadeemNo ratings yet

- MS For Installation of Air Handling UnitsDocument22 pagesMS For Installation of Air Handling UnitsAnandu AshokanNo ratings yet

- 1008-OAJ-MS-R0 1017 - HDPE Pipes InstallationDocument9 pages1008-OAJ-MS-R0 1017 - HDPE Pipes InstallationrongohcolemanNo ratings yet

- NIT22Document275 pagesNIT22Mansoor Ahamed AbbasNo ratings yet

- PL-MEP-001 Connection Installation PPR Pipe With Stubout PPRDocument22 pagesPL-MEP-001 Connection Installation PPR Pipe With Stubout PPRMina KhalilNo ratings yet

- MS 29 Aggregate Road Base Road Works Rev00Document9 pagesMS 29 Aggregate Road Base Road Works Rev00Jojee Catap YabutNo ratings yet

- 08976-GCC-HS-ZZ-HP-Z-00001-01 HSE Plan-BDocument351 pages08976-GCC-HS-ZZ-HP-Z-00001-01 HSE Plan-BSam AzzNo ratings yet

- MOS Installation of Underground and Above Fuel PipeDocument110 pagesMOS Installation of Underground and Above Fuel PipeZawirul faizNo ratings yet

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- Project Implementation Unit (Piu) : Consulting FirmDocument43 pagesProject Implementation Unit (Piu) : Consulting Firmrandhir singhNo ratings yet

- Procedure For Working in Live TrafficDocument20 pagesProcedure For Working in Live TrafficGian Carlo MiguelNo ratings yet

- Supplier Approval Request Form-Rev.0Document2 pagesSupplier Approval Request Form-Rev.0Antonio Tomas Gonzalez LosaNo ratings yet

- Soil Investigation and Topographical Works Rev ADocument5 pagesSoil Investigation and Topographical Works Rev ARiko Bin ZulkifliNo ratings yet

- 01 Mes Mep 002 Ms+for+Water+Supply+WorksDocument12 pages01 Mes Mep 002 Ms+for+Water+Supply+WorksJeffersonDeGuiaNo ratings yet

- 23L00203 BIDDING DOCUMENTS MinDocument37 pages23L00203 BIDDING DOCUMENTS MinEdz CareNo ratings yet

- Tender 69223Document150 pagesTender 69223Ajit JadhavNo ratings yet

- EOT FormDocument3 pagesEOT FormSai CharanNo ratings yet

- DN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsDocument2 pagesDN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsSudhakar JayNo ratings yet

- Proforma For Submission of Extension / Compensation Proposal Under Clause - 2Document5 pagesProforma For Submission of Extension / Compensation Proposal Under Clause - 2Siba Prasad SatapathyNo ratings yet

- IASLC-MS-006 - Raft Concrete WorksDocument6 pagesIASLC-MS-006 - Raft Concrete WorksJoe PsNo ratings yet

- Method Statement of Casting (Manhole and Chamber) (Rev C0)Document20 pagesMethod Statement of Casting (Manhole and Chamber) (Rev C0)Isam GhawadrehNo ratings yet

- Lus CP7B QDSBG Inr CV 85502 00Document12 pagesLus CP7B QDSBG Inr CV 85502 00AnwarologyNo ratings yet

- Cms 0031 Concrete Crack Repair at WWTP Rev. ADocument18 pagesCms 0031 Concrete Crack Repair at WWTP Rev. Azahangir100% (1)

- MS Traffic Signs Installations (Rev. 01)Document6 pagesMS Traffic Signs Installations (Rev. 01)moytabura96100% (1)

- CV of Masud Hasan - Sr. Project EngineerDocument8 pagesCV of Masud Hasan - Sr. Project Engineermasud_hasan2004No ratings yet

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of FCUDocument20 pagesMS For Installation of FCUAnandu AshokanNo ratings yet

- Method Statement For Installation of UPVC Ducts.Document22 pagesMethod Statement For Installation of UPVC Ducts.Haggag AbouelkhairNo ratings yet

- MS 29 Aggregate Base Course Road Works Rev00Document7 pagesMS 29 Aggregate Base Course Road Works Rev00Jojee Catap YabutNo ratings yet

- MS 28 Sub Grade Road Works Rev00Document7 pagesMS 28 Sub Grade Road Works Rev00Jojee Catap YabutNo ratings yet

- SHM in CGC ZZ ZZ XX GN QM 00002Document276 pagesSHM in CGC ZZ ZZ XX GN QM 00002Akhtar JavedNo ratings yet

- NS Grout - Sec by Al FanarDocument3 pagesNS Grout - Sec by Al FanarAngelo Carlo MalabananNo ratings yet

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanNo ratings yet

- Guide to Performance-Based Road Maintenance ContractsFrom EverandGuide to Performance-Based Road Maintenance ContractsNo ratings yet

- Delete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Document4 pagesDelete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Ismail MydeenNo ratings yet

- TDL of Ledger, Stock ReportsDocument2 pagesTDL of Ledger, Stock ReportsIsmail MydeenNo ratings yet

- Auto To Manual Vourchar NoDocument7 pagesAuto To Manual Vourchar NoIsmail MydeenNo ratings yet

- Voucher ReportDocument2 pagesVoucher ReportIsmail MydeenNo ratings yet

- CL 0010 00Document1 pageCL 0010 00Ismail MydeenNo ratings yet

- CL-00010-02 Pavement Road WorksDocument1 pageCL-00010-02 Pavement Road WorksIsmail MydeenNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- RAS 0010 Pavement Road WorksDocument8 pagesRAS 0010 Pavement Road WorksIsmail MydeenNo ratings yet

MST-0010-00 For Pavement Road Works

MST-0010-00 For Pavement Road Works

Uploaded by

Ismail MydeenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MST-0010-00 For Pavement Road Works

MST-0010-00 For Pavement Road Works

Uploaded by

Ismail MydeenCopyright:

Available Formats

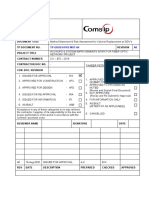

METHOD STATEMENT

Part A: Project Information:

Project Name UPGRADING OF E15 HIGHWAY from GHAYATHI to RUWAIS (PHASE 1)

Contract No. PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Abu Dhabi General Services Company

Client (Musanada)

Engineer AAW Consulting Engineers

PMC N.A. Contractor BIN HAFEEZ GENERAL CONT. L.L.C.

Part B: Method Statement Submittal Record:

MSS Ref No. 54350-00SIT-GE-BHG191-CRW-MST-00010-00 Rev. No: 00 Submittal Date 27.09.2018

☒ Civil ☐ Architectural ☐ Electrical

Related

Discipline Others (Specify

☐ Mechanical ☐

………………………………………....)

Part C: Contents are covered within the Method Statement:

Method Statement For

Pavement Road Works

Contractor’s Review:

Description Discipline Engineer QA/QC OSH Project Manager

Name Bashar Qabbany Michael Macalino Mohamed Abdullah Tarif Elamine

Designation Project Engineer QA/QC Manager OSH Team Leader Project Manager

Signature

Date

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 2 of 13

Part D: Employer/ Engineer Review and Approval:

Engineer’s Comments

☐ A: Approved ☐ B: Approved with Comments

Engineer Approval

☐ C: Revise & Resubmit ☐ D: Rejected

Employer/ Engineer Approval :

For Engineer For Client

Name Eng. Hany Weheda Eng. Karam Hussein

Designation Project Manager

Signature

Date

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 3 of 13

Table of Contents

Table of Contents...............................................................................................................................................3

1. Purpose:........................................................................................................................................................4

2. Scope:............................................................................................................................................................4

3. Legislation and code of practice:................................................................................................................4

4. References:...................................................................................................................................................4

5. Definitions:...................................................................................................................................................4

6. Resources:.....................................................................................................................................................5

7. Safety Precautions:......................................................................................................................................7

8. Detailed Construction Sequence (Methodology):......................................................................................7

9. Inspection and Testing...............................................................................................................................12

10. Related Forms:.........................................................................................................................................13

11. Attachments..............................................................................................................................................13

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 4 of 13

1. Purpose:

The purpose of method statement is to define the proper sequence of work and inspection activities

related to construction of pavement roadworks. The aforesaid activities are in accordance with

requirements of the project and authorities’ specification and approved shop drawings.

2. Scope:

This statement covers the various steps involved for asphalt road works.

2.1 All prior activities

2.2 Survey works

2.3 Formation preparation

2.4 Subgrade

2.5 Aggregate sub base course

2.6 Aggregate base course

2.7 Wet Mix Macadam Road Base

2.8 Prime coat

2.9 Asphalt base course

2.10 Tack coat

2.11 Asphalt Wearing course

3. Legislation and code of practice:

3.1 NOC from concerned authorities

3.2 Other appropriate legal requirement which applicable to this particular process of construction

activity is applicable

3.3 Federal Labour Laws

3.4 Respective Municipalities Code of Construction Safety Practice

4. References:

4.1 Volume 3B: Particular specification, November 2017

4.2 Volume 3A: Standard Specifications-Part 1 to 3 – Document No.AD-C-01 First Edition 2014

4.3 Approved Shop drawing

4.4 Approved material submittal

4.5 Approved surveying work

4.6 Municipalities Traffic Control Devices Manual (if any)

4.7 Method Statement for Survey Works

4.8 Method Statement for Clearing,Grubbing & Trial Pit

4.9 Method Statement for Dewatering.

5. Definitions:

5.1 MS:Method Statement

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 5 of 13

5.2 NOC: No Objection certificate

5.3 GS: General Specification

5.4 PS: Particular Specification

5.5 DOT: Department of Transport

5.6 ITP :Inspection and Test Plan

5.7 OSH:Occupational Safety and Health

6. Resources:

6.1. Materials and their Approval

1. Embankment material

2. Subgrade

3. Aggregate sub base course

4. Aggregate base course

5. Wet Mix Macadam road base

6. Prime coat

7. Asphalt base course

8. Tack coat

9. Asphalt wearing course

All material shall be approved by Employer/Engineer prior to commencement of the work.

6.2. Subcontractor Approval

Subcontractor prequalification submittal will be submitted to Employer/Engineer approval

(if required).

6.3. Shop drawings approval

Shop drawing will be submitted for approval to the Employer/Engineer prior to commencement

of the work

6.4. Equipment

1. Survey Equipment 12. Milling / Cold-road profile Machine

2. Graders 13. Tipper Truck

3. Dozers 14. Compressor

4. Excavator 15. Saw Cutting Machine

5. Water Tanks 16. Asphalt Paver machines

6. Dump Trucks 17. Asphalt batching plant

7. Wheel Loader 18. Compactors

8. Double drum roller 19. Jack hammer

9. Pneumatic Tire roller 20. Small hand tools as necessary

10. Vibrator roller 21. Asphalt saw cutter

11. Steel roller (Tandem) 22. Safety PPE

All Heavy equipments should have valid third party certificates prior to commencement of the

work.

6.5. Human Resource

1. Survey team

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 6 of 13

2. Site Engineer

3. Safety Officers

4. Equipment operators

5. Labors

The person involved in execution of works, their roles are clearly defined but not limited to the

following:

A. Project Manager

Overall site management, quality & safety;

Full authority and overall responsibility to manage, supervise and control the works.

B. Project Engineer / Site Engineer

Supervision of this work activity, and will ensure that the concerned work force is familiar

with the activity and the site preparation activities are conducted according to the approved

Method Statement.

To ensure that work permit is obtained from Employer /Engineer prior to start this work

activity.

To explain and provide all necessary information for execution of this job to his foreman,

surveyor and site group.

To ensure that the foreman is aware of the specific job, supervision, inspection and

Employer /Engineer requirements for execution of this process and all of the associated

activities.

To liaison with safety officer and coordinate the same with the pertinent foreman.

C. Project QA/QC Team Leader

Ensuring that this work activity is according to the Project Specifications.

To ensure full compliance with contract documents, specifications and this Method

Statement duly approved by Engineer /Employer

Ensure required inspections done at site as notified for all the works.

To maintain all required quality records.

Shall check the site activities done as per approved Method Statement and Contract

specification.

D. Surveyor

Establishing the control point consist of scouting existing reference points on site with

reference to existing control point defined and as indicated by the ENGINEER.

Regular checks on the control points & bench marks.

Responsible for setting out, checking of level, elevation and alignment.

E. Safety Officer

Ensure implementation of all OSH procedure related to the nature of the work being carried

out.

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 7 of 13

7. Safety Precautions:

All PPEs will be worn at site after proper Safety and Daily task briefings by respective

supervisors.

Usage of sharp tools, and removal of heavy objects by crane/ boom loader etc., appropriate

lifting equipment, certified equipment etc.

All site heavy earth moving vehicles fitted with audible reverse alarm/ flash lights/a flag

man guide in case of required operation move around close vicinity of high traffic

movement.

Gas cutting while removal of items will be supported with HOT work Permit.

Any excavation required relevant approval from respective authorities etc.

Special care to be taken while carrying out hand excavation if required removal of

structures/ Obstructions–Approval copy of NOC must be available.

Salvaged items will be kept well separated from debris. Waste items will be segregated and

stored separately and decided for appropriate disposal as per waste management procedure.

Fire precautionary measures, instructions, signs will be displayed as required at site.

All site personnel will receive necessary information about emergency situation and practice

mock drill in case of potential emergency situation like fire/ sand storm/rain/road traffic

incidents/other potential emergencies.

Proper barricading and appropriate hazard signs will be displayed to inform the site

personnel/ road users/ and visitors to the site.

After removal of fence which prevents camels from crossing into roads, additional safety

measures shall be placed well away from such location to prevent camel crossing into such

areas.

8. Detailed Construction Sequence (Methodology):

8.1. Prior Activities:

a. All necessary work permits (such as NOI / NOC will be obtained prior to starting the work.

b. Engineer will be notified of beginning of work through IR (Inspection request).

c. Existing services will be protected whenever required.

d. Necessary access roads leading to the site and within the site shall be provided with safety

precautions.

e. Obtain engineers approval for previous layer prior to laying of next layer.

f. Approved shop drawings shall be made available at site all the

time and shall be followed strictly by construction crew. The extents limits of excavation

and elevations shall be demarked with available survey point / reference bench marks

approved by Employer /Engineer. .

g. Conduct site survey to record existing ground levels, conditions, excavation limits and record

any site instructions.

h. A site survey will be conducted to record existing ground level conditions, mark Underground

utility locations and define the limits for clearing and grading/ Excavation .

i. Drawings will be checked for existing underground utilities or obstructions.

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 8 of 13

j. Checking and sampling of existing soil to determine soil suitability.

k. Mobilize all required equipment, tools and manpower.

8.2 Methodology:

8.2.1 Surveying and Dewatering

a. Install survey stakes and demarking the limits and extents of asphalt road works.

b. Dewatering shall be done as per approved method statement (If required).

8.2.2 Clearing and Grubbing

a. Clearing and grubbing will be carried out in accordance with General specification as per the

Approved MS for Clearing, Grubbing and Trial Pit.

b. All excavation shall be carried out to the grades and levels as shown on the drawings.

c. Dozing and heaping excavations will be carried out by the use of bulldozers, to the required

capacity, to reach the required construction level in accordance with approved Construction

/shop drawing. The obtained construction level requirements as specified and as directed by the

Engineer.

d. Manual (hand) excavation and other work which is required to locate existing utilities within the

limits of the contract or off-site locations in accordance with the requirements as specified and as

directed by the Engineer

e. Existing trees and plants shall be removed / treatment whenever needed.

8.2.3 Formation Preparation

a. Excavate existing soil to road formation level & alignment as required in approved shop

drawings.

b. If existing soil at road formation is found as unsuitable soil, Contractor shall replace all

unsuitable soil with approved material.

c. Soil replacement shall be done according to the lines, levels and alignment shown in approved

shop drawing.

d. Compact road formation level to compaction test minimum 95% MDD as determined by

AAASHTO Designation T180,Method C or ASTMD and D4564

8.2.4 Embankment

a. Prepare the Embankment layer line, levels and grades as required in approved shop drawings.

b. Spread Embankment layers in 150mm maximum compacted depth.

c. The Embankment material for load bearing area shall be CBR more than 20% .

d. Compact embankment layer to minimum of 95% MDD as per General specification vol.3.A

clause s section 2.5.2.2

8.2.5 Improved Subgrade preparation

a. Prepare the sub-grade layer line, levels and grades as required in approved shop drawings.

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 9 of 13

b. Spread sub-grade layers in 150mm maximum compacted depth.

c. The subgrade material for load bearing area shall be CBR more than 30% at 95% of MDD.

d. Compact subgrade layer to minimum of 95% MDD as per General specification

8.2.6 Aggregate subbase course

a. Granular Sub Base will be stock piled and shall be tested. Approved stockpile shall be mixed

with water to the required moisture and to be transported to site by tipper trucks.

b. Site laboratory shall take sample from stock pile of aggregate subbase course and check that

minimum CBR value for aggregate subbase course.

c. Aggregate sub base shall be spread on the approved layer of sub grade each layer must not

exceed 150 mm compacted thickness.

d. Care shall be taken while spreading the sub base to avoid segregation .The segregated material

shall be remixed to uniform gradation.

e. The moisture content of the sub base material shall be adjusted prior to compaction, by

watering with approved sprinkler trucks or by drying out, as directed by the Engineer, to that

required to obtain the specified density for sub base. Sub-base shall be compacted to 98% MDD

.

f. Each Layers of Sub base shall be approved by Engineer prior to the delivery of materials for a

succeeding layer.

g. Hauling trucks for material shall be covered during transportation.

h. Moisturizing of subgrade surface, level control, rolling immediately after spreading, minimum

tolerance from required elevation shall be implemented during construction activities.

i. Field density test shall be carried out as per attached Inspection and Test Plan and project

specification.

8.2.7 Aggregate Base course

a. Site laboratory shall take sample from stock pile of aggregate base course and check that

minimum CBR value for aggregate base course is 80 % at 98% of MDD.

b. Aggregate base course shall be spread on the approved layer of aggregate sub base

course/capillary break layer .Each layer must not exceed 150 mm compacted thicknesses.

c. Care shall be taken while spreading the aggregate base course to avoid segregation .The

segregated material shall be remixed to uniform gradation.

d. The moisture content of the sub base material shall be adjusted prior to compaction, by

watering with approved sprinkler trucks or by drying out, as directed by the Engineer, to that

required to obtain the specified density for base course. Aggregate base course shall be

compacted to 98% M.D.D.

e. Hauling trucks for material shall be covered during transportation.

f. Moisturizing of subgrade surface, level control, rolling immediately after spreading, minimum

tolerance from required elevation shall be implemented during construction activities.

g. Field density test shall be carried out as per attached Inspection and Test Plan and project

specification.

8.2.8 Wet Mix Macadam Road Base

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 10 of 13

a. Site laboratory shall take sample from stock pile of Wet mix macadam road base material and

check that minimum CBR value of 80% at 98% of MDD.

b. Wet mix macadam road base shall be spread on the approved layer of sub base course

layer .Each layer must not exceed 150 mm compacted thicknesses.

c. Care shall be taken while spreading the wet mix macadam road base to avoid segregation .The

segregated material shall be remixed to uniform gradation.

d. The moisture content of the wet mix macadam road material shall be adjusted prior to

compaction, by watering with approved sprinkler trucks or by drying out, as directed by the

Engineer, to that required to obtain the specified density for wet mix macadam road base of 98%

MDD.

e. Hauling trucks for material shall be covered during transportation.

f. Moisturizing of subgrade surface, level control, rolling immediately after spreading, minimum

tolerance from required elevation shall be implemented during construction activities.

g. Field density test shall be carried out as per attached Inspection and Test Plan and project

specification.

8.2.9 Asphalt base Course

a. Prior to commence laying of asphalt base course, Contractor Site engineer shall ensure that wet

mix macadam road base layer is constructed according to the lines, grades and elevations as

shown in the approved shop drawings and has complied with the compaction requirements.

b. Prepare the surface of wet mix macadam road base by removing all loose materials and dust by

air jetting, mechanical sweeping and/or hand brooms.

c. Spray the surface of aggregate base course with prime coat (MC-70) at a rate of between 0.25-

0.5 kg/m2 as per ASTM D2995

d. Application temperature for the MC-70 liquid asphalt shall be between 60° C and 85° C as

directed by the Engineer.

e. Prime coat shall not be applied when the ambient temperature is less than 13° C nor during

rain, fog, dust-storms or other unsuitable weather.

f. Site laboratory shall perform the required test to measure the rate of application of prime coat.

g. Curing time for prime coat shall be between 24 hours to 48 hours prior to placement of asphalt

base course.

h. Contractor Site engineer shall ensure that contact surfaces of curbs, gutters, manholes and

similar structures are sprayed with thin uniform coating of Prime coat.

i. Production and spreading of asphaltic concrete mix shall not be permitted when the ambient

temperature is less than 8°C, nor during rain, fog, dust-storms or other unsuitable weather.

j. All bituminous mixes shall be introduced to the paver at a temperature not less than 135 ˚C and

not more than 163 ˚C as per specification.

k. Each layer of base course thickness shall be min 6cm to max 10cm.

l. Spreading of asphalt base course shall be done by automatic controlled asphalt finishers. These

pavers are equipped with automatic sensors that accurately control the grades and cross

slopes.

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 11 of 13

m. Road density and pavement thickness of asphalt base course shall be determined by site

laboratory from asphalt core samples and compacted density shall be minimum 97% of

marshal density.

8.2.10 Asphalt wearing course

a. Prior to commence laying of asphalt wearing course, Contractor Site engineer shall ensure that

all required quality test requirements for asphalt base course layer has been complied and

approval is granted by the Employer/Engineer to proceed placement of wearing course.

b. Prepare the surface of asphalt base course by removing all loose materials and dust by air

jetting, mechanical sweeping and/or hand brooms.

c. Spray the surface of asphalt base course with tack coat (SS-1-H) at a maximum rate of 0.5

kg/m2 as per specifications or as directed by the Engineer.

d. Site laboratory shall perform the required test to measure the rate of application of tack coat.

e. A minimum curing time of 30 minutes for tack coat shall be required prior to placement of

asphalt wearing course.

f. Contractor Site engineer shall ensure that contact surfaces of curbs, gutters, manholes and

similar structures are sprayed with thin uniform coating of tack coat.

g. Production and spreading of asphaltic concrete mix shall not be permitted when the ambient

temperature is less than 8°C, nor during rain, fog, dust-storms or other unsuitable weather.

h. All bituminous mixes shall be introduced to the paver at a temperature not less than 135 ˚C and

not more than 163 ˚C as per specification.

i. Spreading of asphalt wearing course shall be done by automatic controlled asphalt finishers.

These pavers are equipped with automatic sensors that accurately control the grades and cross

slopes.

j. Each layer of asphalt wearing course thickness shall be min.4cm to max.6cm.

k. Road density and pavement thickness of asphalt wearing course shall be determined by site

laboratory from asphalt core samples and density shall be minimum 98% of Marshall Density.

l. Test holes (cores) shall be filled with asphalt mix and compacted after washing and cleaning.

m. A straight edge 5m length can be used to check longitudinal/transverse surface regularity.

n. Surveyor shall check and ensure that the completed asphalt wearing course surface level at

within the tolerance specified in Gen. Spec. Vol. 3.1 Clause 3/43.1.

o. After the asphalt wearing course have been completed and cure properly, IRI International

Roughness Index shall be performed as per the specification requirements in Gen. Spec. Vol.

3.A Clause 3.8.3.10.b

8.2.11 Pavement Joints

a. Longitudinal joints-Roller shall be shifted over onto the previously placed lane so that not more

than 150 mm of the roller wheel rides on the edges of the newly laid lane. Rollers shall then

be operated to pinch and press the fine material gradually across the joint. Rolling shall be

continued until a thoroughly compacted, neat joint is obtained.

b. Transverse joints-Roller shall be placed on the previously compacted material transversely so

that not more than 150 mm of the rear rolling wheel rides on the edge of the joint. Roller shall

be operated to pinch and press the mix into place at the transverse joint. Roller shall continue

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 12 of 13

to roll along this line, shifting its position gradually across the joint, in 150 to 200 mm

increments, until the joint has been rolled with the entire width of the roller wheel. Rolling

shall be continued until a thoroughly compacted, neat joint is obtained more than 150 mm of

the rear rolling wheel rides on the edge of the joint.

c. Transverse joints in succeeding layers shall be offset at least 2 m.

8.2.12 Asphalt Production

a. Bituminous mix will be prepared based on the approved Job Standard Mix.

b. Prior to start of asphalt, Engineer shall be informed about programme (e.g. Quantity, Labor,

Machinery, etc.)

c. The asphalt batching plant and equipment shall be provided with calibration certificates.

d. Only approved type of aggregates and bituminous materials as per approved mix design shall

be used.

e. During the course of production strict control will be exercised at the plant in controlling the

grading, bitumen content etc. and the quality of the Mix to achieve the specified Job Standard

Mix. This step shall be continuous.

f. Asphalt cement shall be heated to a temperature to viscosities in min.240 centistokes for Pen.

Grade 60-70 and min.280 centistokes for Pen. Grade 40-50 when delivered to the mixer, as

determined from the temperature viscosity chart of the product used. Asphalt cement shall not

be used if foaming occurs nor shall it be heated above 175° C at any time.

8.2.13 Asphalt Transportation

a. Transportation of asphalt concrete from mixing plant to the asphalt finishers will be by dump

trucks.

b. Asphalt shall be transported in clean vehicles and shall be covered to minimize heat loss during

transit.

c. The number of dump trucks to be used for hauling asphalt shall be sufficient to avoid any

interruption in the paving operation and complete the required area to be paved as planned.

d. Delivery of material shall be at a uniform rate and in an amount well within the capacity of the

paving and compacting equipment.

8.2.14 Connection between Existing and New Pavement layers

a. Connection between existing/milled and new pavement layers will be submitted and presented

in a separate Method statement .

9. Inspection and Testing

9.1 Inspection and Test Plan for asphalt road works shall be conducted in reference to attached ITP

Ref. # 54350-00SIT-GE-BHG119-CIV-ITP-0010-00 ITP and in conjunction with relevant

approved ITP’s

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

UPGRADING OF E15 HIGHWAY from GHAYATHI to

Project Title:

RUWAIS (PHASE 1)

Contract NO: PD/CA/BPS/SY/R35/P363-2018-DOT/18/90

Client DOT Department of Transport

PMC MUSANADA

Engineer: AAW Consulting Engineers

Contractor: BIN HAFEEZ. GEN. CONT. L.L.C.

Ref No: 54350-00SIT-GE-BHG119-CRW-MST-0010-00 Method Statement for Pavement Road Works Page 13 of 13

10. Related Forms:

10.1 Check List Ref #: 54350-00SIT-GE-BHG119-CIV-FRM-00010-00 for Road pavement works.

11. Attachments

11.1 ITP Ref. # 54350-00SIT-GE-BHG119-CIV-ITP-0010-00 ITP

11.2 Check List Ref #: 54350-00SIT-GE-BHG119-CIV-FRM-0010-00

11.3 Risk Assessment No.54350-00SIT-GE-BHG119-HSE-RAS-0010-00

Form Ref. TMT129, Rev- 1, Date: 09-Feb-17

You might also like

- MS For MEP IsolationDocument19 pagesMS For MEP IsolationAnandu Ashokan67% (3)

- TENDER - BRO Himachal Pradesh Rs.87 CR PDFDocument168 pagesTENDER - BRO Himachal Pradesh Rs.87 CR PDFVishal ChaudharyNo ratings yet

- MS For Installation of Grills, Diffuser & LouversDocument21 pagesMS For Installation of Grills, Diffuser & LouversAnandu AshokanNo ratings yet

- MS For Installation of SMDB, DB PanelsDocument20 pagesMS For Installation of SMDB, DB PanelsAnandu AshokanNo ratings yet

- Method Statement Submittal - MSS: Part A: Project InformationDocument2 pagesMethod Statement Submittal - MSS: Part A: Project InformationMuhammad Jamil KhanNo ratings yet

- SHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Document334 pagesSHM in CGC ZZ ZZ XX QP QM 00001 p01 Project Quality Plan (PQP)Akhtar JavedNo ratings yet

- Fma - Civilmaint.18.003 Ms BDP 009 Asphalt Paving WorkDocument11 pagesFma - Civilmaint.18.003 Ms BDP 009 Asphalt Paving Workbaig habibNo ratings yet

- HFY-3800-0000-CIV-TQ-0006 - Bottom Section Length Change For Precast Piles Responded - Approved-SignedDocument3 pagesHFY-3800-0000-CIV-TQ-0006 - Bottom Section Length Change For Precast Piles Responded - Approved-SignedNashaat DhyaaNo ratings yet

- 235 MPHs SPORTS EQUIPMENT'S MISSING DETAILSDocument1 page235 MPHs SPORTS EQUIPMENT'S MISSING DETAILSusmanNo ratings yet

- 12-MS For Drain Work Cast in Situ & Pre-Cast R1Document25 pages12-MS For Drain Work Cast in Situ & Pre-Cast R1Rabnawaz ImamNo ratings yet

- IASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksDocument8 pagesIASLC-MS-001& 002 - Excavation, Back Filling and Compaction WorksJoe PsNo ratings yet

- Document Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionDocument15 pagesDocument Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionComsip400No ratings yet

- Method Statement For Trial LoadingDocument5 pagesMethod Statement For Trial LoadingPunithan PunithanNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28625 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28625 R0-SignedMa NadeemNo ratings yet

- Tadian General Constructio/Chuwarcho Construction (JV)Document16 pagesTadian General Constructio/Chuwarcho Construction (JV)Jess L. MalecdanNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- QS049-P04-ASH-GEN-GEN-IR-28627 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28627 R0-SignedMa NadeemNo ratings yet

- MS For Installation of Chilled Water FlushinDocument27 pagesMS For Installation of Chilled Water FlushinAnandu AshokanNo ratings yet

- MS For Installation of Toilet Exhaust FanDocument20 pagesMS For Installation of Toilet Exhaust FanAnandu AshokanNo ratings yet

- Icn 79Document1 pageIcn 79TPF Sneha KiranNo ratings yet

- NCR TemplateDocument2 pagesNCR TemplatechikannosNo ratings yet

- GGME - CX-393 - MS - RA - PHT - 01 Rev.1Document23 pagesGGME - CX-393 - MS - RA - PHT - 01 Rev.1akshay babuNo ratings yet

- Soft Landscape Prequalification Application FormDocument12 pagesSoft Landscape Prequalification Application FormGulf RubberNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28624 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28624 R0-SignedMa NadeemNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR - R0-SignedDocument7 pagesQS049-P04-ASH-GEN-GEN-IR - R0-SignedMa NadeemNo ratings yet

- QS049-P04-ASH-GEN-GEN-IR-28626 R0-SignedDocument6 pagesQS049-P04-ASH-GEN-GEN-IR-28626 R0-SignedMa NadeemNo ratings yet

- MS For Installation of Air Handling UnitsDocument22 pagesMS For Installation of Air Handling UnitsAnandu AshokanNo ratings yet

- 1008-OAJ-MS-R0 1017 - HDPE Pipes InstallationDocument9 pages1008-OAJ-MS-R0 1017 - HDPE Pipes InstallationrongohcolemanNo ratings yet

- NIT22Document275 pagesNIT22Mansoor Ahamed AbbasNo ratings yet

- PL-MEP-001 Connection Installation PPR Pipe With Stubout PPRDocument22 pagesPL-MEP-001 Connection Installation PPR Pipe With Stubout PPRMina KhalilNo ratings yet

- MS 29 Aggregate Road Base Road Works Rev00Document9 pagesMS 29 Aggregate Road Base Road Works Rev00Jojee Catap YabutNo ratings yet

- 08976-GCC-HS-ZZ-HP-Z-00001-01 HSE Plan-BDocument351 pages08976-GCC-HS-ZZ-HP-Z-00001-01 HSE Plan-BSam AzzNo ratings yet

- MOS Installation of Underground and Above Fuel PipeDocument110 pagesMOS Installation of Underground and Above Fuel PipeZawirul faizNo ratings yet

- MS - Installation of Water Supply PipeDocument20 pagesMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- Project Implementation Unit (Piu) : Consulting FirmDocument43 pagesProject Implementation Unit (Piu) : Consulting Firmrandhir singhNo ratings yet

- Procedure For Working in Live TrafficDocument20 pagesProcedure For Working in Live TrafficGian Carlo MiguelNo ratings yet

- Supplier Approval Request Form-Rev.0Document2 pagesSupplier Approval Request Form-Rev.0Antonio Tomas Gonzalez LosaNo ratings yet

- Soil Investigation and Topographical Works Rev ADocument5 pagesSoil Investigation and Topographical Works Rev ARiko Bin ZulkifliNo ratings yet

- 01 Mes Mep 002 Ms+for+Water+Supply+WorksDocument12 pages01 Mes Mep 002 Ms+for+Water+Supply+WorksJeffersonDeGuiaNo ratings yet

- 23L00203 BIDDING DOCUMENTS MinDocument37 pages23L00203 BIDDING DOCUMENTS MinEdz CareNo ratings yet

- Tender 69223Document150 pagesTender 69223Ajit JadhavNo ratings yet

- EOT FormDocument3 pagesEOT FormSai CharanNo ratings yet

- DN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsDocument2 pagesDN001-P02 - List of Pre-Qualified Asphalt Plant and Mixes For PWA ProjectsSudhakar JayNo ratings yet

- Proforma For Submission of Extension / Compensation Proposal Under Clause - 2Document5 pagesProforma For Submission of Extension / Compensation Proposal Under Clause - 2Siba Prasad SatapathyNo ratings yet

- IASLC-MS-006 - Raft Concrete WorksDocument6 pagesIASLC-MS-006 - Raft Concrete WorksJoe PsNo ratings yet

- Method Statement of Casting (Manhole and Chamber) (Rev C0)Document20 pagesMethod Statement of Casting (Manhole and Chamber) (Rev C0)Isam GhawadrehNo ratings yet

- Lus CP7B QDSBG Inr CV 85502 00Document12 pagesLus CP7B QDSBG Inr CV 85502 00AnwarologyNo ratings yet

- Cms 0031 Concrete Crack Repair at WWTP Rev. ADocument18 pagesCms 0031 Concrete Crack Repair at WWTP Rev. Azahangir100% (1)

- MS Traffic Signs Installations (Rev. 01)Document6 pagesMS Traffic Signs Installations (Rev. 01)moytabura96100% (1)

- CV of Masud Hasan - Sr. Project EngineerDocument8 pagesCV of Masud Hasan - Sr. Project Engineermasud_hasan2004No ratings yet

- MS For Installation of Duct & AccessariesDocument21 pagesMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of FCUDocument20 pagesMS For Installation of FCUAnandu AshokanNo ratings yet

- Method Statement For Installation of UPVC Ducts.Document22 pagesMethod Statement For Installation of UPVC Ducts.Haggag AbouelkhairNo ratings yet

- MS 29 Aggregate Base Course Road Works Rev00Document7 pagesMS 29 Aggregate Base Course Road Works Rev00Jojee Catap YabutNo ratings yet

- MS 28 Sub Grade Road Works Rev00Document7 pagesMS 28 Sub Grade Road Works Rev00Jojee Catap YabutNo ratings yet

- SHM in CGC ZZ ZZ XX GN QM 00002Document276 pagesSHM in CGC ZZ ZZ XX GN QM 00002Akhtar JavedNo ratings yet

- NS Grout - Sec by Al FanarDocument3 pagesNS Grout - Sec by Al FanarAngelo Carlo MalabananNo ratings yet

- MS For Installation of Sanitary WaresDocument22 pagesMS For Installation of Sanitary WaresAnandu AshokanNo ratings yet

- Guide to Performance-Based Road Maintenance ContractsFrom EverandGuide to Performance-Based Road Maintenance ContractsNo ratings yet

- Delete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Document4 pagesDelete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Ismail MydeenNo ratings yet

- TDL of Ledger, Stock ReportsDocument2 pagesTDL of Ledger, Stock ReportsIsmail MydeenNo ratings yet

- Auto To Manual Vourchar NoDocument7 pagesAuto To Manual Vourchar NoIsmail MydeenNo ratings yet

- Voucher ReportDocument2 pagesVoucher ReportIsmail MydeenNo ratings yet

- CL 0010 00Document1 pageCL 0010 00Ismail MydeenNo ratings yet

- CL-00010-02 Pavement Road WorksDocument1 pageCL-00010-02 Pavement Road WorksIsmail MydeenNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- RAS 0010 Pavement Road WorksDocument8 pagesRAS 0010 Pavement Road WorksIsmail MydeenNo ratings yet