Professional Documents

Culture Documents

Twi 3.2 Training Spec 05-21 Rev.4 - Student

Twi 3.2 Training Spec 05-21 Rev.4 - Student

Uploaded by

misthahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Twi 3.2 Training Spec 05-21 Rev.4 - Student

Twi 3.2 Training Spec 05-21 Rev.4 - Student

Uploaded by

misthahCopyright:

Available Formats

Document Number: TWI-WIS10 EX-MSR-001

Revision: 2

CSWIP 3.2 – Welding Inspector WIS10

Welding & Fabrication

Training Specification

Training & Examination Services

Granta Park, Great Abington

Cambridge CB21 6AL, UK

Copyright © TWI Ltd 2017

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Table of Contents

1 GENERAL 5

1.1 Scope 5

1.2 Reference Codes and Standards 5

2 DEFINITION OF TERMS 6

2.1 General 6

2.2 Definitions 6

3 QUALITY CONTROL 8

3.1 Contractor Requirements 8

3.2 Fabrication Requirements 8

4 JOINT PREPARATION DETAILS 8

4.1 Base Metal Preparation 8

4.2 Bevels 8

4.3 Alignment 9

4.4 Assembly for Welding 9

4.5 Temporary Attachments 10

4.6 Weather Conditions 10

5 WELDING DETAILS 10

5.1 General Requirements 10

5.2 Butt Welds 10

5.3 Fillet Welds 11

5.4 Preheating 11

5.5 Interpass Temperature 12

5.6 Arc Strikes 13

5.7 Weld Identification 13

5.8 Interruption of Welding 13

5.9 Tack Welding 13

5.10 Inter-run Cleaning 14

6 WELDING ACCEPTANCE LEVELS 14

6.1 General 14

6.2 Excess weld metal 14

6.3 Root Profile 14

6.4 Cracks 14

6.5 Porosity and Cavities 14

7 ELDING EQUIPMENT 15

7.1 General 15

7.2 Welding and Cutting Equipment 15

7.3 Equipment for Measuring 16

TWI-WIS10-EX-MSR-001 (rev. 2) Page 1 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

8 WELDING CONSUMABLES 16

8.1 General 16

8.2 Storage and Handling 16

9 MATERIALS 17

9.1 General 17

9.2 Material Requirements 17

9.3 Material Marking 17

9.4 Material Storage and Handling 17

10 DEFECT REPAIR AND CUT-OUTS 18

10.1 General 18

10.2 Removal of Defects 18

10.3 Preparation for Re-Welding 18

10.4 Re-Welding 18

11 NON-DESTRUCTIVE TESTING 18

11.1 General 18

11.2 Equipment 19

11.3 Health and Safety Requirements 19

11.4 Documentation and Records 19

11.5 Magnetic Testing Details 19

11.5.1 General 19

11.5.2 Equipment and Consumables 19

11.5.3 Material Preparation 20

11.5.4 Techniques 20

11.6 Penetrant Testing Details 20

11.6.1 General 20

11.6.2 Equipment and Consumables 20

11.6.3 Material Preparation 20

11.6.4 Techniques 21

11.7 Ultrasonic Inspection Details 21

11.7.1 General 21

11.7.2 Equipment and Consumables 21

11.7.3 Material Preparation 22

11.7.4 Scanning 22

11.8 Radiographic Inspection 22

11.8.1 General 22

11.8.2 Equipment and Consumables 22

11.8.3 Radiographic Sensitivity 23

11.8.4 Techniques 23

11.8.5 Required image quality 24

TWI-WIS10-EX-MSR-001 (rev. 2) Page 2 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

12 INSPECTION PERSONNEL 24

12.1 General 24

12.2 Vision Requirements 24

13 RECORDS AND REPORTS 25

13.1 General 25

13.2 Frequency of Reports 25

14 SPECIFIC DETAILS FOR WELDING STAINLESS AND DUPLEX STAINLESS STEELS 25

14.1 General 25

14.2 Material Details 25

14.3 Joint Preparation Details 26

14.4 Welding Details 26

14.5 Non-Destructive Testing Requirements 26

15 SPECIFIC WELDING DETAILS FOR ALUMINIUM AND ALUMINUM ALLOYS 27

15.1 General 27

15.2 Material Details 27

15.3 Joint Preparation Details 27

15.4 Welding Details 28

15.5 Process 131 28

15.6 Process 141 29

15.7 Non-Destructive Testing Requirements 29

16 SPECIFIC WELDING DETAILS FOR QUENCHED AND TEMPERED STEELS 30

16.1 General 30

16.2 Welding Details 30

16.3 Non-Destructive Testing Requirements 31

17 QUALIFICATION OF WELDING PROCEDURES 31

17.1 General 31

17.2 Documentation and Records 32

17.3 Essential Variables 32

17.4 Welding of Test Joint 33

17.5 Extent of Testing 33

17.6 Welding Positions 34

17.7 Joint Configuration 34

17.8 Location and Cutting of Test Specimens 34

17.9 Impact Testing (Charpy V-notch) 35

17.10 Tensile Testing 35

17.11 Macro-Examination 36

17.12 Hardness Testing 36

17.13 Fillet Fracture Test 36

17.14 Bend Test 37

TWI-WIS10-EX-MSR-001 (rev. 2) Page 3 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

18 Qualification of Welders 37

18.1 General 37

18.2 Documentation and Records 37

18.3 Examination and Testing 37

18.4 Essential Variables and Range of Approval. 38

18.5 Re Tests 40

18.6 Period of Validity 40

18.7 Welding Position Qualification Range. 40

18.8 Tests to be Conducted 41

19 Post Weld Heat Treatment (PWHT) 41

19.1 General 41

19.2 Temperature Measurement 41

19.3 Temperatures and Heating/Cooling Rates 42

19.4 Reports and Records 42

20 Hydrostatic Testing 43

20.1 General 43

20.2 Test Preparation 43

20.3 Flushing 43

20.4 Conducting the Test 43

20.5 Inspection 44

20.6 Reports and Records 44

21 Pneumatic Testing 44

21.1 General 44

21.2 Test Preparation 45

21.3 Conducting the Test 45

21.4 Inspection 45

21.5 Reports and Records 45

22 Coatings for Structures and Piping 46

22.1 General 46

22.2 Surface Preparation 46

22.3 Coating Application 47

22.4 Inspection 47

22.5 Repair of Damaged Areas (touch-up) 48

22.6 Reports and Records 48

23 Protection and Preservation 48

23.1 General 48

TWI-WIS10-EX-MSR-001 (rev. 2) Page 4 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

1 GENERAL

1.1 Scope

This document defines the technical requirements for the welding and fabrication of both

onshore and offshore structures.

This specification outlines the minimum quality and technical standards for materials,

fabrication and welding, testing, inspection and all personnel involved in the fabrication of

structures used for both the offshore and onshore environments. This document covers

the arc welding of fillet, butt and socket welds in carbon steels, low alloy steels, Austenitic

stainless steels, Austenitic-Ferritic stainless steels and Aluminium.

All the requirements of this document shall be strictly adhered too; no deviation shall be

permitted without a written approval from the Company.

All fabrication and welding activities shall be carried out in a safe manner in accordance

with the applicable codes and standards, to comply with the local government regulations.

1.2 Reference Codes and Standards

The following list of codes and standards are to be used in conjunction with this document,

if any conflicts exist between this document and the codes and standards listed; the

requirements of this document shall apply. The latest revision of all applicable codes and

standards shall be adopted.

BS 499-1 Welding Terms - Glossary for welding, brazing and thermal cutting

BS ENISO 17637 Non-destructive examination of fusion welds – visual examination

BS EN ISO 6520-1 Classification of geometric imperfections in metallic materials – fusion

welding

BS EN 10204 Metallic products - Types of inspection documents

BS EN ISO 2553 Welded, brazed and soldered joints – Symbolic representation on

drawings

BS EN ISO 4063 Welding and allied processes - Nomenclature of processes and

reference numbers

BS EN ISO 2560 Welding consumables - covered electrodes for manual metal arc

welding of non-alloy and fine grain steels - Classification

AWS A5.1 Specification for carbon steel electrodes

AWS A5.4 Specification for stainless steel electrodes for shielded metal arc

welding

AWS A5.5 Specification for low-alloy steel electrodes for shielded metal arc

welding

BS EN ISO 14341 Welding consumables - Wire electrodes and deposits for gas shielded

metal arc welding of non-alloy and fine grain steels - Classification

BS EN 1011 Welding - Recommendations for welding of metallic materials

TWI-WIS10-EX-MSR-001 (rev. 2) Page 5 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

2 DEFINITION OF TERMS

2.1 General

For the purpose of this document the following definitions shall apply. The terms used in

this documentation are in accordance with BS 499-1 and BS EN ISO 6520-1, other terms

may be encountered from other codes and standards not listed. Where terms encountered

in this document that are not clearly defined, common sense shall prevail.

2.2 Definitions

Company: TWI Ltd

Contractor: An entity performing specific work under contract of the company

Defect: An imperfection of sufficient magnitude to warrant rejection

Imperfection: A discontinuity or irregularity

Indication: Evidence obtained by Non-destructive testing

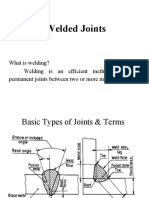

Welding: An operation in which two or more parts are to be united, by

means of heat or pressure or both.

Weld: A union of pieces of metal made by welding

Welder: The operator who performs the welding

Shop weld: A weld made within the premises of the manufacturer of the

welded assembly

Site weld: A weld made at the location where the assembly is to be installed

Parent metal: Metal to be joined or surfaced during welding

Filler metal: Metal added during welding

Heat affected zone: The part of the parent metal that is metallurgically affected by

the heat of welding

Joint: A connection where the individual components, suitably prepared

and assembled, are joined by welding

Manual welding: Welding in which the operator controls the welding parameters

and the means of making the weld are controlled by hand

Continuous welding: A weld extending along the entire length of the joint

Intermittent welding: A series of welds of the same type and dimension at intervals

along the joint

Arc welding current: Current passing through the electrode.

Are voltage: Electrical potential between contact tip or electrode holder and

work piece

Interpass temperature: Temperature in a multi-run and adjacent parent metal

immediately prior to the application of the next run

Heat input: Energy introduced into the weld region during welding per unit

run Length

Preheat temperature: Temperature of the work piece immediately prior to any welding

operations.

Shall: Denotes a mandatory action.

Should: Denotes a strongly recommended action.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 6 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Table 1 - Abbreviations and Symbols

Abbreviations and symbols Term

I Arc welding current

V Arc welding voltage

W Welding speed

k Thermal efficiency factor

Q Heat input

a Nominal throat thickness of a fillet weld

d Diameter of pore

h Height or width of imperfection

l Length of imperfection in longitudinal direction of the

weld

s

Nominal butt weld thickness

t

Parent material thickness

z

Leg length of a fillet weld

CE

Carbon Equivalent

MTC

Material Test Certificate

<

Less than

>

Greater than

≤

Less than and equal to

≥

Greater than and equal to

≈

Approximately

TWI-WIS10-EX-MSR-001 (rev. 2) Page 7 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

3 QUALITY CONTROL

3.1 Contractor Requirements

All contracting parties involved with the fabrication and welding of structures in accordance

with this document shall have in place a quality management system and quality control

manual. This document shall cover all construction activities.

3.2 Fabrication Requirements

All fabrication and welding activities shall be conducted in accordance with detailed

procedures for the control of quality. The following procedures shall be available and

approved prior to the commencement of fabrication and welding works, all welding and

fabrication works shall be 100% visually inspected.

Welding and repairs

Storage, control, and identification of welding consumables

Welder qualification records

Inspection/NDT

Post weld heat treatments (where applicable)

Parameter checks, and progress of welding

Material traceability

NDT traceability

Inspection test plans (ITP's)

4 JOINT PREPARATION DETAILS

4.1 Base Metal Preparation

All surfaces to be welded shall be visually examined and shall be cleaned to bright metal

for a distance of not less than 30 mm from the edge of the weld bevel. All surface

contaminants including paints, oils, grease, or other foreign substances shall be removed

from the weld bevel. Surface cleaning should be carried out using power cleaning tools,

any cleaning on flame cut bevels shall be carried out using a disc grinder to a smooth finish

sufficiently as to remove the first 3 mm from the flame cut edge. Surface rusting shall be

removed with a rotary wire brush, where the area shows visible pitting, grinding and

ultrasonic thickness checking shall be carried out to ensure reduction of wall thickness has

not exceeded 2%

Note: for specific details on stainless, duplex, QT steels and aluminium, refer to the relevant

sections of this document

4.2 Bevels

The welded bevels shall be bevelled to the dimensions specified in the approved procedure.

In the case of manual welding in the PA, PB, PE, PF, PG, PH, PJ, H-LO 45, J-LO 45 positions,

the bevel angle should be 30° +5° , -0°. In the PC position the bottom bevel 15° +5° , -

0°, top bevel 45° +5° , -0°. For alternative welding processes such as automatic welding

alternative bevel angles may be considered providing they are in accordance with the

approved procedures.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 8 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

All welded bevels shall be carried out by machining or by machine thermal cutting,

manually or mechanically operated. Manual thermal cutting shall not be used. The only

time that manual thermal cutting shall be considered is the cutting of pipes/plates for

attachment fittings, weldolets, sweepolets, etc., where machining or machine thermal

cutting is not practicable and only if the company gives approval.

Prior to fit-up all bevels shall be subjected to visual and Magnetic Particle (in the case of

ferritic materials) or Penetrant (in the case of non-ferritic materials) inspection.

Any indications found on the bevel faces, score marks, surface breaking laminations,

mechanical damage, lapping or any other imperfection shall be removed by grinding.

This shall be acceptable providing the thickness/depth of the repair area doesn’t exceed

3% of the material thickness. This shall be qualified by the use of UT or a suitable depth-

measuring gauge.

Where pipes/plates are to be cut back for the purpose of attachment fittings, a zone

extending 90 mm back from the proposed position shall be fully examined visually and by

ultrasonic inspection for material imperfections, laminations, laps, folds, segregations etc.

Visual acceptance is given in section 9 of this document.

4.3 Alignment

The alignment of abutting ends shall minimize the offset between surfaces, for pipe and

plate ends, linear misalignment is permissible if the maximum dimension does not exceed

1.5mm. Where parent materials of different thicknesses exist, the thinner of the two

materials shall be taken as the material thickness, in the case of plate welds angular

distortion shall not exceed 5mm.

In the case of longitudinal seamed pipes/vessels, the longitudinal seams shall be offset by

90°. Mitres of welded pipe joints shall not be permitted. Angular misalignment at the weld

toes of less than 3° is not to be classed as a mitre, and is acceptable providing that the

angular misalignment is equally distributed on both sides of the joint to a maximum of

1.5° per side.

In the case of fillet welds, unless otherwise specified, the fusion faces to be joined by fillet

welds shall be in as close contact as possible, maximum gap permitted shall not exceed 3

mm.

A fillet weld as deposited shall not be of less than the specified dimension, see section 5

for more details.

4.4 Assembly for Welding

Parts to be welded shall be assembled in such a way that adequate access is available to

all personnel involved with the welding, inspection and other related activities for

producing the welded joint. Jigs and fixtures may be used where applicable providing no

undue stress is applied to the joint during the welding operation. To minimize stress and

distortion it may be necessary to pre-set joints prior to welding and/or to specify the

welding sequence to assist in the control of stress and distortion, e.g. back step/back skip

welding.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 9 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

4.5 Temporary Attachments

The use of temporary attachments may be used for the purpose of assembly where the

applicable procedures require them. They shall be used in such a way that they can be

easily removed without any damage occurring to the structure, all materials used for the

temporary attachments shall be compatible with the parent material. All temporary

attachments shall be carefully removed after use, where removal is carried out by air-arc

gouging, arc gouging or flame cutting; the cut shall be made clear of any parent material

such that 3.0 mm of the temporary attachment is left for final removal by grinding smooth.

After such an operation, 100% inspection on the affected area of the parent material shall

be carried out. If any imperfections are found e.g. undercut or under flushing these areas

shall be blended smooth, they shall be considered acceptable proving the depth doesn’t

exceed 2% of the parent materials thickness. This shall be verified by the used of ultrasonic

inspection or a suitable depth gauge.

Note: Removal of temporary attachments by hammering or bending is not permitted.

4.6 Weather Conditions

All areas of welding shall be adequately protected from wind, moisture, snow blizzards etc.

Maximum air velocity for welding processes shall be limited as follows:

111. 20 mph (32 km/h)

136. 15 mph (24 km/h

141. 5.0 mph (8 km/h)

Note: The engineer shall state whether welding shall not be carried out because prevailing weather

conditions could impair the quality of the completed weld.

5 WELDING DETAILS

5.1 General Requirements

Only qualified welders shall carry out the welding in accordance with the applicable

qualified

welding procedures. The surface to be welded shall be free from any contaminants, grease,

paints, scale, rust and any other foreign materials that may adversely affect the quality of

the welded joint. The joint design, root gap, root face, bevel angles, alignments etc. shall

be in accordance with this document and the approved welding procedure specifications

applicable.

5.2 Butt Welds

All butt welds shall be welded in such a way that the entire groove is completely filled (at

no point shall the weld face be lower than the parent material). The ends of the butt weld

shall be welded in such a way as to allow the full length and thickness of the groove to be

filled; this may be achieved by the use of run-off/run-on plates. If required a suitable

backing material may be used to support the root during welding, this material shall be

metallurgically compatible with both the filler and parent plate/pipe material. No

permanent backing materials shall be used.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 10 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

In all butt welds, no joints shall be completed with a single pass welding technique, i.e. a

minimum of two weld passes shall be applied. Excessive weaving techniques shall be

avoided with a maximum weave of 2 times that of the electrode diameter permitted.

In the case of full penetration butt welds, which are to be welded from both sides, the

back of the first run shall be cleaned out prior to the welding of the second side. This shall

be achieved by a suitable means to clean to sound metal, this shall be inspected before

commencement of welding on the second side by both visual and magnetic particle

inspection, in the case of non-ferrous materials both visual and dye penetrant inspection.

5.3 Fillet Welds

Welding shall not have start/stop near corners; the welding shall be continued around the

corners. All fillet welds shall be made with a minimum of two weld passes, in the case of

a two weld pass fillet weld, the second pass to be applied as close to the extremity of the

first pass without impinging onto the pipe. Slip on flanges ≤ 100 mm shall have one weld

run deposited on the inside providing any tack welds are positioned on the backside prior

to welding.

The deposited fillet weld dimensions shall be as follows:

Leg Length Throat Thickness

Minimum = t Minimum = t x 0.7

Maximum = t + 3 mm Maximum = t + 0.5 mm

Note: In the case of different thicknesses, welding is to be based on the minimum t

5.4 Preheating

For the welding of ferritic steels, the area of the joint that is subjected to preheat shall

extend around the entire periphery of the pipe or the parts to be welded. In each case the

area extending not less than 100 mm on each side of the joint shall be maintained at the

required temperature. Where practicable, the temperature shall be measured on the face

opposite to that on which the heat is applied. If this is not practicable, the temperature

shall be confirmed on the heated faces at a time after the removal of the heat source, this

shall be related to the parent material thickness, this is to allow for temperature

equalization. The time shall be 2 minutes for a thickness not greater than 25 mm, with an

additional 1 minute for each 12 mm above that thickness. Preheating shall be applied by

either gas or electrical means but under no circumstances shall preheating be carried out

using a gas flame cutter. Care should always be taken to avoid damage to the parent

material and any applicable coatings.

The Minimum shall be determined by temperature indicating crayons, the type which melt

or by suitably attached calibrated thermocouples or pyrometers.

Note: Crayons or paints, which indicate temperature by colour change, are not permitted.

The above only refers to the welding of ferritic steels, when welding stainless steels preheat

should be avoided. See section 14 for specific details on the welding of stainless steels

The pre-heats are based on weldability trials and the following factors:

𝑉𝑜𝑙𝑡𝑠 𝑥 𝐴𝑚𝑝𝑠 𝑥 𝑘

Heat Input:

𝑡𝑟𝑎𝑣𝑒𝑙 𝑠𝑝𝑒𝑒𝑑 𝑥 1000

TWI-WIS10-EX-MSR-001 (rev. 2) Page 11 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Hydrogen scale: A, B, C, D, E

Combined material thickness

𝑀𝑛 𝐶𝑟+𝑀𝑜+𝑉 𝑁𝑖+𝐶𝑢

Carbon equivalent: 𝐶𝐸% = 𝐶 + + +

5 5 15

Note: Thermal efficiency values to be applied.

Table 2 – Preheat Values

Hydrogen Scale A & B,

Heat Input Temperature °C Combined Carbon Equivalent (CE)

Value kJ/mm Thickness

< 0.5 175°C Any thickness < 0.45 %

≥ 0.5 < 2.0 150°C Any thickness < 0.45 %

≥ 2.0 < 4.0 100°C ≤ 80 mm < 0.45 %

≥ 4.0 < 5.0 125°C > 80 mm < 0.45 %

≥ 5.0 No Preheat required Any thickness < 0.45 %

Table 2a – Preheat Values

Hydrogen Scale C, D & D, E

Heat Input Temperature °C Combined Carbon Equivalent (CE)

Value kJ/mm Thickness

< 0.5 150°C Any thickness < 0.45 %

≥ 0.5 ≤2.0 125°C Any thickness < 0.45 %

≥ 2.0 < 4.0 75°C ≤ 80 mm < 0.45 %

≥ 3.0 < 4.2 50°C > 80 mm < 0.45 %

≥ 5.0 No Preheat required Any thickness < 0.4 %

Note: For CE values of 0.45% and above an additional 50°C preheat temperature is required from

the values shown in the above tables.

5.5 Interpass Temperature

The maximum interpass temperature or preheat temperature for ferritic steels shall not

exceed 250°C. The minimum interpass temperature shall not drop below the minimum

calculated preheat temperature. Temperatures shall be monitored by the same as for

preheat temperatures.

Note: The above only refers to the welding of ferritic steels, when welding stainless steels. See

section 14 for specific details on the welding of stainless steels.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 12 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

5.6 Arc Strikes

Arc strikes outside the weld groove area shall be removed by grinding. All arc strikes

outside the groove area shall be subjected to magnetic particle inspection. (In the case of

non-ferritic steels Penetrant inspection shall be used). All indications of cracking shall be

again subjected to grinding and re-inspection to ensure complete removal.

Where arc strikes have been repaired by grinding confirmation that the thickness of the

parent material is within the permitted tolerances, this shall be a thickness reduction of

no more than 2% of the original material thickness, confirmation shall either be by

ultrasonic inspection or a suitable depth gauge.

5.7 Weld Identification

A weld number shall identify all welds; if the weld has been repaired the letter “R”

indicating a “repair weld” shall follow the weld number. If the weld has to be removed the

letters “RW”, indicating a re-weld, shall follow the weld number. If the re-weld has to be

repaired, the letters “RWR”, indicating re-weld repair, shall follow the weld number.

Note: Either a permanent paint stick marker or a low stress metal stamp shall only be used for

weld identifications.

5.8 Interruption of Welding

Whenever possible, welding of joints shall be completed in one continuous operation.

Where interruption is unavoidable the following shall apply:

For material thicknesses ≤ 25 mm, a minimum of two weld passes shall be completed

over the full weld thickness and length (root and hot pass).

For material thicknesses > 25 mm, a minimum of three weld passes shall be

completed over the full weld thickness and length.

In the case of all joints, when welding is interrupted the joint shall be protected from

contamination, moisture etc. and shall be cooled in a slow uniform manner.

Prior to the recommencement of welding, the joint shall be subjected to the same preheat

temperatures as specified.

Note: In all cases the company shall approve all interruption of welding.

5.9 Tack Welding

In all cases the use of clamps is preferred over tack welding. If tack welds are to be used,

tack welding shall only be carried out by qualified welders, these tack welds shall be

subjected to the same preheat and interpass temperatures as groove/fillet welding and

the following shall apply:

All tack welds performed to hold members in alignment which will not be incorporated

into the completed weld (bridge tacking) shall be removed by grinding prior to the

welding approaching the tack area.

All tack welds that will be incorporated into the completed weld, prior to the

continuation of welding, the tack weld shall be ground to a feather edge to permit

acceptable weld metal tie-in. The tack weld shall have a minimum length of 45 mm

or 20% of the total weld length whichever is the less.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 13 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

5.10 Inter-run Cleaning

Each weld pass shall be thoroughly cleaned before the commencement of the next weld

pass. The cleaning may be performed by hand or power tools. All scale and slag shall be

removed. All stop/starts shall be blended smooth.

6 WELDING ACCEPTANCE LEVELS

6.1 General

All welds shall be subjected to visual inspection. Inspection of welds during welding shall

be carried out on the root pass where practicable. All weld caps shall be examined, all

inspected welds shall comply with the acceptance levels in this document, any imperfection

found which does not comply to the acceptance levels of the document shall be cause for

rejection.

6.2 Excess weld metal

Excess weld metal (reinforcement) shall be uniform and not greater than 2.0 mm in height.

The toes of the weld shall blend smoothly with the parent material with no sharp indications

visible. The weld toes shall not extend into the parent material by more than 2.5 mm on

either side of the weld. At no point shall the weld face be lower than the plate/pipe surface.

Note: Acceptance for fillet weld sizes shall comply with section 5 of this document.

6.3 Root Profile

The root pass shall blend smoothly with the parent material with no sharp indications

visible. The penetration bead shall not exceed 3 mm.

6.4 Cracks

Not permitted

If cracks are found in a weld the entire weld shall be cut out, under no circumstances shall

welds with positively identified cracks be repaired.

Note: With the approval of the company, crater cracks of no less than 5 mm maybe repaired.

6.5 Porosity and Cavities

Maximum permitted individual pore dimension

Butt Welds: 1.5mm max

Fillet Welds: 1.5mm max

In the case of elongated cavities (wormholes), the maximum length permitted shall not

exceed 15 mm in any continuous or intermittent length.

In the case of clustered porosity the area shall not exceed 50mm2.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 14 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Table 3 - Acceptance Criteria for Welds

No Defect Type Acceptance Criteria

1 Slag/Silica inclusions The length of the slag/silica inclusion shall not exceed 50 mm in

any continuous or intermittent length. Accumulative total length

shall not exceed 50 mm.

2 Undercut No sharp undercut shall be permitted. The maximum length

shall not exceed 50mm in any continuous or intermittent length.

Accumulative total length shall not exceed 50 mm. The depth

shall not be greater than 1.0 mm. Root undercut not permitted

3 Lack of fusion Surface breaking lack of sidewall fusion shall not exceed 15 mm

in any continuous or intermittent length. Accumulative total

length shall not exceed 15 mm in any weld length

4 Lack of root penetration Not permitted

5 Lack of root fusion Accumulative 50 mm max, continuous or intermittent

6 Burn Through Not permitted

7 Root concavity 50 mm maximum length. 3mm maximum depth

8 Cold Lap/Overlap Not Permitted.

9 Oxidized Root Not Permitted.

10 Mechanical damage No stray tack welds permitted. All grinding/chipping/hard

stamping/hammer marks shall be blended smoothly

7 ELDING EQUIPMENT

7.1 General

The contracting parties carrying out the fabrication works shall be responsible for ensuring

that all the equipment required is in a good safe working order.

7.2 Welding and Cutting Equipment

All welding plant and cutting equipment shall have the capacity necessary to produce a

sound weld in accordance with the relevant procedures being adopted. All welding plant

and cutting equipment shall be calibrated every 3 months with maintenance records

available. Cabling must be sufficiently insulated and of a sufficient cross section to carry

the required value without overheating. Equipment not meeting these requirements shall

be replace

Note: All welding plant shall have an OCV not exceeding 90 volts.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 15 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

7.3 Equipment for Measuring

All equipment required for measuring shall have a valid certificate of calibration, calibration

shall be carried out every 12 months, these dates shall be clearly visible either on the

measuring device itself or be available in the form of documentation, with a clear

traceability to the measuring device in question.

Adequate means of measuring welding parameters such as welding current, welding

voltage and travel speeds shall be available.

8 WELDING CONSUMABLES

8.1 General

Electrodes, filler wires, wire/flux combinations and flux types shall be such that they

produce a sound weld meeting the requirements of the applicable procedures being

adopted. The completed weld metal shall have a tensile strength value at least equal to

the minimum specified for the parent material. In the case of dissimilar joints, the weld

metal shall have a tensile strength at least equal to that of the higher strength material.

The chemical composition of the deposited weld metal shall be compatible to that of the

parent material. All welding consumable shall be free from damage, chips, contamination,

and used within the recommendations of the manufacturer.

8.2 Storage and Handling

All SAW fluxes shall be stored in accordance with the manufacturer’s recommendations.

SAW flux maybe recycled provided the reused flux is free from all contaminates, slag, mill

scale and another foreign matter. All recycled fluxes shall be mixed with an equal amount

of new flux before being used (50:50ratio)

All MMA welding consumable shall be treated in accordance with the manufacturer's

detailed recommendations. When it is necessary to dry and bake the consumable, the

consumables shall be removed from its original container prior to any applicable heat

treatments, after the heat treatment the consumables shall be stored in such a way as to

keep them free from moisture intake, i.e. drying ovens. In the case of consumables that

have been vacuum packed, these shall be used in accordance with the manufacturer’s

recommendations. In the case of hydrogen controlled consumables it is recommended that

the welders be issued with electrodes in a heated quiver.

Note: All drying and baking ovens for welding consumables shall be provided with the means of

measuring the oven temperatures.

Shielding gases shall be stored and kept in the original supplied containers and these shall

be stored in such a way as to avoid extreme temperatures. Gases shall only be used in the

containers supplied by the manufacturer with no mixing of gases to be conducted on site.

All gas containers shall be clearly marked without any signs of damage; containers, which

don’t comply, shall not be used.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 16 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

9 MATERIALS

9.1 General

All materials to be used in fabrication shall be in a clean, corrosion free condition; no

evidence of surface pitting shall be visible. Materials with laminations shall not be used in

any fabrication,

C-Mn steel >25mm thickness must have a lamination check and this must be referenced

on the mill certificate. Materials not having a valid mill certificate shall not be used under

any circumstances. Both contractor and client inspectors shall inspect all materials arriving

on site; materials not complying with the requirements shall be quarantined until the

materials do comply with the requirements of this document. All materials arriving on site

shall only be purchased from company approved manufacturers list.

9.2 Material Requirements

All structural steel shall be new stock.

Spiral welded pipe shall not be used.

Electric-resistance welded (ERW) pipes shall not be used.

No materials with a CE% above 0.48 shall be used for fabrication purposes.

Contractor shall maintain all material traceability, showing the material heat

numbers of all major load bearing structural members.

Contractor shall mark each mill certificate with the contractor’s job number, item

number to be used, quantity to be used, e.g. number of meters and the area of

structure for the material.

Contractor shall maintain traceability maps showing the material heat numbers of all major

load-bearing structural members.

Note: for specific details on stainless, duplex, QT steels and aluminium, refer to the relevant

sections of this document

9.3 Material Marking

All steels shall be suitably marked upon delivery to the contractor’s fabrication yard. The

steel shall be marked in such a way that the type of steel, heat number and any applicable

special tests can be easily recognized.

All heat numbers or other identification markings shall be transferred from piece to piece

prior to cutting, cut pieces shall be remarked in the same way as the original markings.

All markings shall be stencilled with a suitable marker or a low stress concentration die on

both ends of each item.

9.4 Material Storage and Handling

All structural materials shall be stored above ground on flat surfaces or platform type skids.

Materials shall be stored in such a way that they are kept free from dirt, grease, paint

spray or any other foreign matter and kept free from corrosion. In the case of stainless

steel grades these shall be stored in a separate area from ferritic steels, covered over at

all times, and no contact to be made with ferritic materials at any time, e.g. fork lift trucks

TWI-WIS10-EX-MSR-001 (rev. 2) Page 17 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

shall be suitably protected against steel to steel contact, all lifting equipment shall be used

in such a way as to avoid ferritic contact with the stainless materials.

10 DEFECT REPAIR AND CUT-OUTS

10.1 General

All weld repairs shall be conducted in accordance with the weld repair procedures and only

conducted by qualified welders. No weld repair or cut-out shall be conducted without the

authorization of the company. All repairs shall be witnesses 100% by a qualified welding

Inspector. A weld may only be repaired once, if the weld still contains unacceptable defects

in accordance with this document the entire weld shall be removed. Cracks, see general

acceptance levels section 6.

10.2 Removal of Defects

All welds that fail to comply with the requirements of this document shall either be repaired

or the entire weld removed. Repairs shall not be carried out until full inspection has been

conducted.

Defects shall be removed by grinding or air-arc gouging. When arc-air gouging is

employed, the resultant removal cavity shall be ground to clean base metal before any

welding can commence. Entire weld removal may be carried out by thermal cutting.

When thermal gouging or thermal cutting is being used, the last 10% through the root of

the weld shall be removed by mechanical grinding.

10.3 Preparation for Re-Welding

In the case of a partial weld removal, the cut out portion shall be sufficiently deep and

long enough to remove the entire defect. At the ends and sides of the excavation area

there shall be a gradual taper from the base of the cut to the surface of the weld metal.

The width and profile of the excavation shall give adequate access for re-welding. The

repair groove shall be inspected by dye penetrant or magnetic particle inspection to ensure

that the defect has been entirely removed.

In the case of a cut-out, involving the entire defective weld to be removed, the weld

preparation shall be re-made in accordance with the requirements of this document.

10.4 Re-Welding

A repair weld shall be subjected to the same testing and inspection as the original weld,

with a pre-heat temperature 75°C above that of the original weld preheat temperature.

Repair welds shall be limited to 25% of the original weld length, defects that exceed this

value require the entire weld to be removed. All re-welding shall only be carried out under

full supervision from a qualified welding inspector; no vertical down welding is permitted

for weld repairs. Full records and reports of all repairs shall be maintained.

11 NON-DESTRUCTIVE TESTING

11.1 General

Contractor shall propose specific procedures for all NDT methods to be used e.g. MT, PT,

UT and RT. Contractor shall only use NDT personnel qualified to EN ISO 9712 level II as a

TWI-WIS10-EX-MSR-001 (rev. 2) Page 18 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

minimum in the applicable discipline, this also includes any third party inspection services.

All third party inspection service companies can only be used with approval from the

company.

Whenever radiography is employed as the main NDT method, a percentage of welds shall

be inspected by ultrasonic testing. As a minimum 100% of the first 10 welds, after which

100% of one weld after every 25 welds completed.

Note: 100% of the weld shall be tested by the inspection method being used.

11.2 Equipment

All contracting and third parties conducting NDT shall provide a full list of all inspection

equipment to be used including all relevant calibration certificates; this shall also include

a comprehensive spare parts list.

11.3 Health and Safety Requirements

Contractor shall be solely responsible for all safety concerns associated with the NDT

methods being employed. When using radioactive materials these shall comply with the

government regulations and possess a permit from the relevant national atomic energy

agency.

11.4 Documentation and Records

All completed NDT reports shall be submitted to the company for approval and signature.

The NDT technician performing the inspection shall sign all reports.

All NDT reports shall have an original copy issued to the company and a soft and hard copy

retained in the job file.

All discontinuities detected shall have both the length and position from datum reported.

UT reports shall also include the discontinuities depth.

11.5 Magnetic Testing Details

11.5.1 General

MT is for the purpose of detecting surface discontinuities in ferrous butt welds, fillet welds

and ferromagnetic components. Wet continuous technique shall be used in all cases except

for the inspection of hot materials and components (>60°C).

11.5.2 Equipment and Consumables

Magnetization shall only be carried out using an AC Yoke (DC Yokes shall not be used).

Pole spacing’s shall be a minimum of 150mm and a maximum of 300mm. AC yolk lift test

with a weight of 4.5kg, Permanent magnets lift test with a weight of 18kg

Magnetizing method to be used shall show three indications on a Castrol Burma Strip

(Brass type). If this cannot be achieved then the magnetizing method must be changed or

adjusted.

Indicating medium shall be a water or solvent suspension of black ferromagnetic particles.

Only company-approved trade names may be used. Indicating medium shall be

periodically agitated to assure correct concentration of particles, only aerosol magnetic

inks supplied by the manufacturer shall be used. Where black ink particles are being used

TWI-WIS10-EX-MSR-001 (rev. 2) Page 19 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

a white contrast paint shall be applied prior to inspection, this shall be supplied by the

same manufacturer as the black ink particles i.e. no mixing of manufacturers shall be

permitted.

Note: The use of permanent magnets shall only be used on live plant as a safety precaution and

then only by prior Company approval.

Fluorescent methods shall not be considered.

11.5.3 Material Preparation

All surfaces at least 30 mm either side of the area to be tested shall be free from welding

slag, scale, grease, oil, excessive weld spatter and any other foreign material which may

interfere with inspection.

11.5.4 Techniques

Apply white contrast paint where black particles are to be used.

Magnetize the weld area or area to be inspected. Large weld areas may require

multiple inspections to cover the entire surface or test area to be inspected.

While the component is magnetized, apply ink and inspect for indications. Black

particle inks shall be inspected in a well-lit area of no less than 500 Lux.

Evaluation of imperfections shall be assessed in accordance with section 6 of this

document.

11.6 Penetrant Testing Details

11.6.1 General

Penetrant testing shall only be used for the detection of surface breaking defects on non-

ferrous materials e.g. austenitic grade stainless steels, Duplex grade stainless steels and

copper, Aluminium based materials. Colour contrast solvent based penetrants shall be

used at all times, the use of any other penetrant technique e.g. water based or fluorescent

may only be used with company approval. PT shall only be used at a temperature between

10°C and 50°C.

11.6.2 Equipment and Consumables

For colour contrast inspections the test area shall be illuminated by daylight or artificial

light not less than 500 Lux.

When company permits fluorescent inspections the UV-A irradiance at the surface under

inspection shall not be less than 10 W/m2 (1000 µW/cm2) with a maximum background

light of 20 Lux.

Only company approved trade names shall be used, all consumables used shall be from

the same manufacturer i.e. no mixing of manufacturers shall be permitted.

11.6.3 Material Preparation

All surfaces at least 30 mm either side of the area to be tested shall be free from welding

slag, scale, grease, oil, excessive weld spatter and any other foreign material which may

interfere with inspection. All surfaces to be inspected by PT shall be cleaned thoroughly

using a solvent based cleaner.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 20 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

11.6.4 Techniques

Cleaning, all cleaning shall be carried out as above

Application, the entire area to be tested shall have a uniform coating of penetrant

applied by spraying or brushing. Penetrant shall be left in contact with the component

under test for a minimum of 5 minutes and a maximum of 15 minutes; at no time

shall the penetrant be allowed to dry. If this does occur the penetrant process must

be started again.

Penetrant removal, all excess penetrant shall be removed initially by wiping with a

lint free cloth. If further traces of penetrant are still present, this may be removed

by a solvent dampened cloth; under no circumstances shall solvent remover be

applied directly to the component. Before the application of the developer it is

essential that all surfaces are completely dry.

Application of Developer, a non-aqueous developer shall be applied uniformly in a

thin layer across the entire test surface

Inspection, inspection of the test surface shall start immediately the developer is

applied, any signs of penetrant bleed-out may indicate the presence of

discontinuities.

Evaluation of imperfections shall be assessed in accordance with section 6 of this

document.

11.7 Ultrasonic Inspection Details

11.7.1 General

UT shall be used for the detection of sub-surface discontinuities; UT shall not be carried

out on any Austenitic grade stainless steels. Duplex stainless steels and Aluminium may

be considered providing sufficient attenuation checks have been conducted and then only

by company approval. All UT technicians supplied by either contractor or third party NDT

companies shall be subjected to company UT cross checking. UT shall only be considered

as a primary NDT method for the following:

Material thicknesses > 80 mm

Tee butt welds

Cruciform Butt welds

Set-through Butt welds (including nozzles)

Set-on Butt welds (including nozzles)

11.7.2 Equipment and Consumables

Couplant used shall be a gel or grease (water based couplants shall not be considered)

suitable for transmission of sound waves into the material under test. Couplant used for

calibration shall be identical to that used for testing.

Reference blocks shall be V1 (A2) and or V2 (A4), IOW Black (used for beam profiles) and

RC Block (used for resolution checks).

Probes to be used for weld body scanning (cap as welded) are 45°, 60° and 70° refraction

angles, 4MHz to 5MHz frequency with a single crystal area approximately 80 mm2. Parent

material scanning and weld cap dressed flush, 0° 4MHz to 5MHz with a twin crystal area

approximately 80 mm2.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 21 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

The detection unit used shall be calibrated and shall be capable of operating with a

frequency range of 1.5 MHz to 6 MHz.

Note: For materials < 15mm, the omission of a 450 probe shall apply

11.7.3 Material Preparation

Before ultrasonic inspection is carried out a zone of sufficient size (no less than 90 mm)

shall be thoroughly cleaned with all spatter, scale, slag removed, either side of the weld.

Any paint or other surface coatings, which interfere with the weld scanning, shall be

removed. The surface profile shall be sufficiently regular as to permit a uniform contact

between probe and parent material throughout the test. When echoes from the

reinforcement are likely to interfere with the test, the reinforcement shall be dressed to a

smooth profile. Prior to inspection the area adjacent to the weld is to be inspected by a 0o

compression probe to confirm the material thickness under test and to detect the presence

of any laminations, which may interfere with the ultrasonic inspection.

11.7.4 Scanning

Test sensitivity for angle probes shall be set so that the echo from a 1.5 mm side drilled

hole (V1 (A2) or V2(A4) block) is 80% full screen height. Test sensitivity for compression

probes shall be set so the 2nd back wall echo from test depth is 80% full screen height. In

both cases, when scanning an addition 6 dB shall be added. The weld shall be scanned in

a zig zag manner, the probe being moved between the weld reinforcement and skip

distance/full skip distance. The beam shall be directed at the weld length normally. The

weld shall be scanned from both sides. Evaluation of imperfections shall be conducted in

accordance with section 6 of this document.

The methods which shall be used for the sizing of any imperfection found.

20 dB drop method:

For imperfections with dimensions smaller than the probe beam spread at the

discontinuity beam path.

6 dB drop method:

For imperfection with dimensions larger than the probe beam spread at the

discontinuity beam path.

Note: Automatic Ultrasonic Inspection may be considered but only with the approval of the

company.

11.8 Radiographic Inspection

11.8.1 General

RT shall be used for the detection of sub-surface discontinuities (surface discontinuities

may also be detected with RT which may have been missed by a surface detection NDT

method) RT shall be considered as the primary NDT method unless the conditions of 11.7.1

exist. RT (X and/or Gamma) shall be conducted on Butt Welded Joints (including the HAZ

area) for pipes, plate, vessels and structures of both ferrous and non-ferrous materials.

Radiography shall only be conducted by personnel holding a current national radiation

safety certificate.

11.8.2 Equipment and Consumables

Radiation sources Ir 192 shall have a maximum source dimension of 3 x 3 mm; no sources

shall be used for the purpose of weld inspection that have an intensity less than 444 GBq.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 22 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

For the purposes of safety a maximum of 60 Ci isotopes are permitted for use on site. The

use of Se 75 is preferable for the inspection of welds with a penetrated thickness from 14

up to 40 mm.

X-Ray units shall be capable of an output not less than 250 kV, with a focal spot size no

greater than 4 mm; any radiation source used shall be subject of annual stability check.

Radiographic film for industrial purpose shall be used, film class C4, C5 or C6. For all

gamma radiography and X radiography above 120 kV, lead screens shall be used. All

unexposed film shall be stored in a clean dry area where surrounding conditions will not

deteriorate the condition of the film

All chemicals used for the processing of films shall be in accordance with the

manufacturer’s recommendations.

The following equipment shall be available in the viewing area:

Densitometer with a certified density strip

Film viewer capable of viewing exposed films of optical densities up to 4.

Magnifying glass (10x magnification)

All applicable codes and standards

Film Identification, films shall be identified as to the company requirements with lead

letters. A number belt with numbers at regular intervals shall be used to ensure complete

coverage. The minimum identification to be provided on the radiograph shall be:

Date

Job Number and Weld Identification number

Datum point

Image Quality Indicator (IQI)

11.8.3 Radiographic Sensitivity

Exposed radiographs shall have an optical density within region of interest of a minimum

of 2.0 and a maximum of 3.5, the density shall be assessed by a calibrated densitometer.

11.8.4 Techniques

The following radiographic techniques (where possible and practicable) shall be used as

required to ensure full radiographic coverage.

Double wall Double Image (DWDI perpendicular arrangement) for pipe diameter up

to 100 mm, minimum of three exposures.

Double wall Double Image (DWDI elliptical arrangement) for pipe diameter up to 100

mm and wall thickness up to 8 mm, minimum of two exposures

Double Wall Single Image (DWSI) for pipe diameters above 100 mm up to 660 mm,

a minimum of four exposures are required. Pipe diameters above 660 mm to 1100

mm, a minimum of 5 exposures are required. Pipe diameters above 1100 mm require

a minimum of 6 exposures; more may be required as to the Company requirements.

Single Wall Single Image (panoramic technique) is preferable for all pipe diameters

above 300 mm up to 2000 mm.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 23 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Single Wall Single Image (source outside film inside) is preferable for all pipe

diameters above 660, mm maximum length of inspected area is 160 mm.

Note: Minimum SFD/FFD shall be calculated using the material thickness and the maximum Ug

value (0.25 mm) permitted.

Evaluation of imperfections shall be conducted in accordance with section 6 of this

document.

Note: Only an BS EN ISO 9712 Radiographic level II qualified person shall be permitted to sign off

viewed radiographs.

11.8.5 Required image quality

IQI position (on the…)

Penetrated thickness

source side film side

Over 1.8 mm through 3.2 mm W16 W17

Over 3.2 mm through 5 mm W15 W16

Over 5 mm through 7 mm W14 W15

Over 7 mm through 10 mm W13 W14

Over 10 mm through 15 mm W12 W13

Over 15 mm through 20 mm W11 W12

Over 20 mm through 25 mm W10 W11

Over 25 mm through 32 mm W9 W10

Over 32 mm through 48 mm W8 W9

Over 48 mm through 64 mm W7 W8

Over 64 mm through 80 mm W6 W7

12 INSPECTION PERSONNEL

12.1 General

All personnel involved with the inspection of welds and related activities shall be qualified

to a minimum of level II and certified by an approved certification body, which meet the

current requirements of BS EN ISO 9712

12.2 Vision Requirements

All inspection personnel shall have satisfactory vision as determined by an oculist,

optometrist or medically recognized person in accordance with the following

requirements

Near vision acuity shall permit reading a minimum of Jaeger number 1 or Times

Roman N4.5 at not less than 30 cm with one or both eye, either corrected or

uncorrected.

Colour vision shall be sufficient that they can distinguish and differentiate contrast

between colours used in the NDT method concerned as specified by the company.

Note: A documented vision test shall be carried out at least once a year.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 24 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

13 RECORDS AND REPORTS

13.1 General

Contractor shall provide Company's welding inspector with a daily report of all welding and

related activities. The report shall show as a minimum, weld number, radiograph number

(if applicable), All UT, MPI, DPI report numbers (If applicable), status of each welded joint

(accepted, repaired and accepted, rejected or cut-out), welder(s) ID numbers, heat

treatment reports and any other applicable details. The reports shall be presented on a

format approved by the Company; no other report formats shall be permitted.

13.2 Frequency of Reports

The time between inspection date and report shall not exceed 48 hours for all inspection

methods.

14 SPECIFIC DETAILS FOR WELDING STAINLESS AND DUPLEX STAINLESS

STEELS

14.1 General

All fabrication of stainless steel and duplex grades shall be segregated from all other works

and kept free from any possible contaminating materials such as copper, carbon steels,

zinc etc.

All tools used in the fabrication of stainless steels shall be kept separate from other tools

and clearly marked with a colour code. This includes grinding wheels; wire brushes

(stainless wire only) etc. and should be kept in thoroughly cleaned condition. All

workbenches shall be either stainless steel or suitably covered with a covering material of

sufficient thickness as to avoid carbon to stainless contact.

All stainless steels shall be stored under cover and on wooded blocks of sufficient thickness

for the material to be stored a minimum of 320 mm off the ground.

14.2 Material Details

All Austenitic Stainless steels for fabrication welding shall be of the grade 316L, with a

maximum carbon content of 0.03%. All Austenitic Stainless Steels shall be supplied in a

solution-annealed condition, de-scaled, pickled and passivated. Any cold working should

be carried out before final heat treatment. All Austenitic Stainless Steels shall be subjected

to positive material identification (PMI) before being issued for site use for alloy content

verification.

All Duplex Stainless Steels for fabrication and welding shall have a Nitrogen content not

less than 0.14% and a ferrite content between 40% and 60% for the base material and

30% to 55% for the weld metal. All Duplex Stainless Steels shall be supplied in a solution-

annealed condition, de-scaled, pickled and passivated, after welding the weld shall

undergo the same treatment. Any cold working should be carried out before final heat

treatment. All Duplex Stainless Steels shall be subjected to a ferrite check after welding

and positive material identification (PMI) before being issued for site use for alloy content

verification.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 25 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

14.3 Joint Preparation Details

Generally no special joint preparations are required for the welding of Austenitic Stainless

steels and Duplex stainless steels. Any thermally cut bevels for welding shall be

mechanically ground or machined back from the cut edge by at least 5 mm to eliminate

any contamination from the thermal cutting process. Hard stamping should be avoided;

when this is unavoidable the hard stampings shall be of the rounded type and not applied

in any high stress concentration areas.

14.4 Welding Details

The use of preheat should be avoided and may only be considered when approved by the

Company. All welding of stainless steels and duplex grades shall be monitored 100% by

an approved welding inspector with amps, volts, travel speed and heat input being

recorded at all times, these records shall be made available to the company upon request.

Only welding process 141 shall be used for the root pass and second pass on all Austenitic

and Duplex stainless steels, other welding processes may be considered for the filler and

capping passes with Company approval. In all cases stringer beads only shall be applied.

Shielding gasses for both Austenitic and Duplex stainless steels shall be of a purity of

99.99% Ar with oxygen content for backing gasses prior to welding 500ppm maximum.

The following variables shall be strictly adhered to at all times:

Heat Input: 18 to 22Cr 0.5 to 1.75 kJ/mm

Heat Input: 23 to 25Cr 0.5 to 1.50 kJ/mm

Interpass Temperature: 18 to 22Cr 175°C Maximum

Interpass Temperature: 23 to 25Cr 150°C Maximum

After welding it is essential that all surface slag, scale and any other contaminations are

removed this may be conducted by mechanical means or by wire brushing (stainless steel

only).

Post weld heat treatments are generally not necessary for both Austenitic and Duplex

stainless steels. Heat treatments however may be required for the purpose of stress

reliving after extensive cold working, cold deformation etc. These heat treatments may

only be carried out if approved by Company at a maximum temperature of 450°C

14.5 Non-Destructive Testing Requirements

For both Austenitic and Duplex stainless steels the following shall be applied

100% Visual Inspection on all welds

100% Penetrant testing on all welds

100% Radiography on all butt welds

Evaluation of imperfections shall be conducted in accordance with section 6 of this

document.

Note: Ultrasonic Inspection may be considered as a back-up only on Duplex stainless steel and

only with prior Company approval.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 26 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

15 SPECIFIC WELDING DETAILS FOR ALUMINIUM AND ALUMINUM ALLOYS

15.1 General

All fabrication of Aluminium and Aluminium alloys shall be segregated from all other works

and kept free from any possible contaminating materials such as copper, carbon steels,

zinc etc.

All tools used in the fabrication of Aluminium and Aluminium alloys shall be kept separate

from other tools and clearly marked with a colour code. This includes grinding wheels; wire

brushes (stainless wire only) etc. and should be kept in thoroughly cleaned condition. All

workbenches shall be free from any ferritic base material or suitably covered with a

covering material of sufficient thickness as to avoid ferrite to aluminium contact.

All aluminium and aluminium alloys shall be stored under cover, Plates are to be stored in

the vertical position as to minimize moisture condensation and long term moisture

collection between layers. All aluminium and aluminium shall be stored on wooded blocks

of sufficient thickness for the material to be stored a minimum of 320 mm off the ground.

Note: All filler materials and base materials shall be brought into the welding area no less than 24

hours before the commencement of all welding operations, to ensure they are at room

temperature.

15.2 Material Details

Series 1XXX, 3XXX and 7XXX aluminium and aluminium alloys shall not be used for the

purpose of fabrication and welding. All aluminium and aluminium alloys shall be free from

all cutting oils and other contaminations.

15.3 Joint Preparation Details

All cutting of Aluminium and aluminium alloys shall be conducted using either; plasma arc,

laser or by suitable mechanical means (the use of cutting lubricants shall be avoided). The

use of oxy-fuel gas cutting, carbon arc cutting or gouging shall not be used. When plasma

and laser cutting is used on series 2XXX and 6XXX, a minimum of 3 mm shall be removed

by mechanical means from the cut edge, after removal the cut edge shall be inspected by

DPI to ensure no cracking is present on the cut edge.

Note: when cutting Aluminium by thermal methods on series 2XXX and 6XXX the cut edge my

contain solidification cracking and detrimental parent material conditions.

Before the commencement of welding all fusion faces shall be cleaned and degreased by

solvents and the oxide layer removed by mechanical means. The period between cleaning

and welding shall not exceed 30 minutes to avoid recontamination.

Note: Degreasing by chemical etching will remove the surface oxide; this method can be considered

but only by Company approval. If chemical etching is to be used, stainless steel wire brushing

shall be carried out on all etched surfaces to remove the by-product residuals which may

have a detrimental effect on the weld quality.

In all cases after cleaning the fusion faces shall be free from moisture, compressed air

blowing should be avoided as compressed air my contain moisture and oil contaminates.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 27 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Table 4 – Joint details for Aluminium Butt Welds

Welding Material Thick Root Gap Root Face Included Bevel

Position Angle

< 12.5 mm 0 to 0.5 mm 0 to 0.5 mm 0°to 70°

PA 12.5 to 25 mm 0.5 to 1.25 mm 1.6 to 3.2 mm 70°

> 25 mm 0.5 to 1.5 mm 2.0 to 4.5 mm 70°

< 12.5 mm 0.5 to 1.25 mm 0 to 1.6 mm 0°to 70°

PC, PE

≥ 12.5 mm 1.0 to 1.5 mm 1.6 to 3.2 mm 70°

PF, PH, < 12.5 mm 0 to 1.0 mm 0 to 1.6 mm 0° to 70°

H-LO45 ≥ 12.5 mm 1.0 to 1.5 mm 1.6 to 3.2 mm 70°

Fillet weld dimensions shall be in accordance with section 5.3 of this document.

Note: PG, PJ and J-LO45 welding positions shall not be considered for the welding of Aluminium

and aluminium alloys.

15.4 Welding Details

Only welding processes 141 and 131 shall be considered for the welding of aluminium and

aluminium alloys. In both argon (99.997% pure) shall be used as a shielding gas. All pipe

butt joints to be welded using process 141

Note: argon/helium mixes may be considered but only by Company approval and only by using

fully approved WPS’s

During the welding duration for both 131 and 141 welding processes, interpass

temperatures shall not exceed 110°C; series 6XXX aluminium shall not exceed 90°C.

Pre-heating shall not be applied to heat treatable base materials and series 5XXX base

materials containing Mg contents above 3%. All other base materials shall be subjected to

a pre-heat temperature as to the approved WPS, but no greater than 120°C.

15.5 Process 131

Leading arc (push) technique to be used for increased cleaning action.

Spray transfer mode (pulse transfer mode may be considered for positional welding

and on thinner materials < 3.5 mm)

Filler wire to match the melting point as close as possible to the base materials

melting point.

Constant voltage characteristic welding plant.

Travel speeds shall not be less than 6.5 mm/s

Welding current DC EP

Heat Inputs

TWI-WIS10-EX-MSR-001 (rev. 2) Page 28 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Table 5– Process 131 Heat Input Values

Material Thickness Minimum Heat Input Maximum Heat Input

(kJ/mm) (kJ/mm)

< 3.5 mm 0.24 0.32

≥ 3.5 mm < 6.5 mm 0.35 0.41

≥ 6.5 mm 0.57 0.85

15.6 Process 141

Filler wire to match the melting point as close as possible to the base materials

melting point.

Constant current characteristic welding plant.

Zirconiated or Lanthanated tungsten electrode (smooth hemisphere electrode tip)

Electrode diameter as to the approved WPS, min diameter 1.6mm, max diameter

4.5mm

Welding current AC

Heat Inputs

Table 5a – Process 141 Heat Input Values

Material Thickness Minimum Heat Input (kJ/mm) Maximum Heat Input (kJ/mm)

< 3.5 mm 0.42 0.57

≥ 3.5 mm < 6.5 mm 0.89 1.2

≥ 6.5 mm 1.98 3.2

15.7 Non-Destructive Testing Requirements

For aluminium and aluminium alloys, the following shall be applied

100% Visual Inspection on all welds

100% Penetrant testing on all welds

100% Radiography on all butt welds

Evaluation of imperfections shall be conducted in accordance with section 6 of this

document.

Note: Ultrasonic Inspection may be considered as a back-up only on Duplex stainless steel and

only with prior Company approval.

TWI-WIS10-EX-MSR-001 (rev. 2) Page 29 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

16 SPECIFIC WELDING DETAILS FOR QUENCHED AND TEMPERED STEELS (QT

Steels)

16.1 General

No special joint requirements are required for QT steels, material preparations, joint

configurations, bevel angles etc. shall be carried out in accordance with section 4 of this

document. Only Grade A514/QT-100 steels shall be considered, specified minimum yield

100,000 psi (689 N/mm2), maximum 110,000 psi (758 N/mm2) UTS, for thicknesses up

to 63 mm. QT steel Plate thicknesses > 63 mm shall not be considered for fabrication and

welding unless specifically approved by Company

16.2 Welding Details

All welding operations shall be conducted using a welding process/welding consumable

capable of depositing hydrogen levels < 10 ml of hydrogen per 100 g of weld metal

deposited (scale B). If the MMA welding process is being used for the welding

operations the use of a basic (Low hydrogen) electrode only may be considered.

The electrode shall be baked/dried in accordance with the manufacturers

recommendations and the approved consumable procedure (refer to section 8 of this

document)

Note: All basic electrodes shall be issued in quivers (hot boxes) at a temperature between 70°C to

90°C; all returned electrodes shall not be re-baked.

If the SAW welding process is being used only agglomerated-high basic fluxes shall be

considered. All flux treatments shall be carried out in accordance with the manufacturers

recommendations and the approved consumable control procedure (refer to section 8 of

this document)

Note: When using SAW on QT steels the flux recycling shall only be permitted to a ratio of 50%

new to 50% old.

When welding QT steels with the MMA welding process the electrode must match the

materials UTS value as close as possible, only electrodes depositing between 110,000 psi

UTS (AWS A5.5 E110 1 8 M) to 120,000 psi UTS (AWS A5.5 E120 1 8 M) values shall be

considered.

Note: Welding processes 131, 135 and 136 shall not be considered for the welding of QT steels.

Minimum preheat values and interpass temperatures shall be as follows:

Table 6 – Minimum Preheat and Interpass Temperatures for QT Steels

Plate Thickness Minimum Preheat Temperature Minimum Interpass Temperature

< 12.5 mm 25°C 20°C

≥ 12.5 to 25 mm 50°C 50°C

≥ 25 to ≤ 50 mm 75°C 80°C

≤ 50 mm 100°C 100°C

TWI-WIS10-EX-MSR-001 (rev. 2) Page 30 of 52

TWI WELDING & FABRICATION

TRAINING SPECIFICATION

Document Number: TWI-WIS10-EX-MSR-001 Revision: 2 Date: May 2021

Note: Preheat temperature shall not exceed 110oC

Table 6a – Minimum Heat Input Values for QT Steels

Plate Thickness

Preheat

Temperature

< 12.5 mm ≥ 12.5 to 25 mm ≥ 25 to ≤50mm >50 mm

25°C 0.9 kJ/mm 2.24 kJ/mm 4.7 kJ/mm 6.06 kJ/mm

75°C 0.8 kJ/mm 2.09 kJ/mm 4.2 kJ/mm 5.3 kJ/mm

100°C 0.75 kJ/mm 1.6 kJ/mm 3.40 kJ/mm 4.8 kJ/mm

150oC 0.62 kJ/mm 1.2 kJ/mm 2.55 kJ/mm 3.7 kJ/mm

16.3 Non-Destructive Testing Requirements

No special inspection requirements are required for QT steels. All NDT requirements shall

comply with section 11 of this document. Evaluation of imperfections shall be conducted

in accordance with section 6 of this document.

17 QUALIFICATION OF WELDING PROCEDURES

17.1 General

For all new welding procedure qualification tests, contractor shall submit to Company a

Preliminary Welding Procedure Specification (pWPS) for approval before the

commencement of the qualification test. Contractor shall also submit to Company a repair

pWPS for all main welding procedures. In the case of Stainless steels and Duplex stainless

steels pre-qualified WPS's shall under no circumstances be used. In the case of carbon

steels generally, unless approved by Company pre-qualified WPS, shall not be permitted

for use. WPS's previously used by a Contractor and meeting all the requirements of this

document may be submitted to Company for approval. Only WPS's approved by Company

shall be used.

Approval and testing of welding procedure specifications shall consist of the following

stages

I. The Contractor shall submit to the Company a detailed pWPS for all welding and

repair welding procedure specifications

II. The Company shall provide approval before any testing can commence

III. Before any production welding can commence, test welds shall be made using

these procedures under simulated site conditions.

IV. The quality of the test welds shall be determined by non-destructive and

destructive testing after the specimens have been allowed to cool to ambient

temperature for no less than 48 hours.

V. For the WPS's to be approved for use in production the test results shall meet the

requirements of this document.

Note: If the test piece fails to comply with the requirements of this document, one further test

piece may be welded and subjected to the same test conditions. If the second test piece fails