Professional Documents

Culture Documents

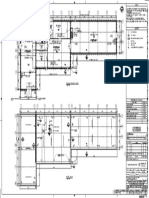

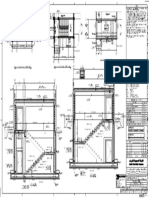

Passive Fire Proofing Layout For Proposed Equipments

Passive Fire Proofing Layout For Proposed Equipments

Uploaded by

Venkat RanganCopyright:

Available Formats

You might also like

- Eric Evans Domain Driven Design PDFDocument2 pagesEric Evans Domain Driven Design PDFMayra10% (10)

- Burn Pit CriteriaDocument28 pagesBurn Pit CriteriaVenkat Rangan100% (7)

- 1671 8560 71 C160 0165 Commented 25.10.22Document1 page1671 8560 71 C160 0165 Commented 25.10.22Venkat RanganNo ratings yet

- Major993502x12.2pscslab V5 Approve P12Document1 pageMajor993502x12.2pscslab V5 Approve P12rushi123No ratings yet

- 20100PE-DW02-0007 Rev1 11-SD-2123Document1 page20100PE-DW02-0007 Rev1 11-SD-2123Jovit BeaNo ratings yet

- 14july Inlet-Gad-1Document1 page14july Inlet-Gad-1varanasirk1No ratings yet

- 6starmhbasement-001 (Sheet 1 of 6)Document1 page6starmhbasement-001 (Sheet 1 of 6)Jacob FryeNo ratings yet

- Utility Mechanical Room Scada Room: - R KA 356289 01 - NA422Document1 pageUtility Mechanical Room Scada Room: - R KA 356289 01 - NA422John Philip BuntalesNo ratings yet

- B1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Document1 pageB1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Dessouki SamakNo ratings yet

- D 11 Rural Base ModelDocument1 pageD 11 Rural Base ModelMiller Daniel PardoNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocument1 pageUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30No ratings yet

- LAYOUTDocument3 pagesLAYOUTARUL SANKARANNo ratings yet

- GF GCOT B 14 4002 - 1 SignedDocument2 pagesGF GCOT B 14 4002 - 1 SignedYuan DiNo ratings yet

- B1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDocument1 pageB1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDessouki SamakNo ratings yet

- T572750001PD 1Document1 pageT572750001PD 1waqas21 nawafNo ratings yet

- Wa-345225 0004 0000Document1 pageWa-345225 0004 0000Gavriel NgNo ratings yet

- 9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Document1 page9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Michael Camit EsoNo ratings yet

- t76-R-pp-476561-001 - Rev B Utility Ome Building PlanDocument1 paget76-R-pp-476561-001 - Rev B Utility Ome Building PlanTayyab AchakzaiNo ratings yet

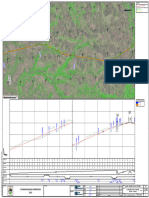

- 18-Alignment Plan &profile KM 90-100Document1 page18-Alignment Plan &profile KM 90-100Tamrayehu KuremaNo ratings yet

- CCCW Pumping & Heat Exchanger 3814-XZ-DM-122021-Is06DDocument1 pageCCCW Pumping & Heat Exchanger 3814-XZ-DM-122021-Is06DJose Alberto Uribe MinierNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Major1107202x12.2pscslab V4 Approve P11Document1 pageMajor1107202x12.2pscslab V4 Approve P11rushi123No ratings yet

- Wa-345225 0002 0000Document1 pageWa-345225 0002 0000Gavriel NgNo ratings yet

- Sơ Đ Nguyên Lý Thoát Nư C: Ghi Chuù - NotesDocument1 pageSơ Đ Nguyên Lý Thoát Nư C: Ghi Chuù - NotesHuy NguyễnNo ratings yet

- 132 KV HANSI-ModelDocument1 page132 KV HANSI-ModelShariq KhanNo ratings yet

- Major1047005x18.3pscgirder V5 Approve P13Document1 pageMajor1047005x18.3pscgirder V5 Approve P13rushi123No ratings yet

- For Guidance: Australasian HFG Standard Components DTUR-14 Dirty Utility, 14MDocument1 pageFor Guidance: Australasian HFG Standard Components DTUR-14 Dirty Utility, 14MChristdel VivarNo ratings yet

- 00 RA-610978 001 R 964 U211: NotesDocument1 page00 RA-610978 001 R 964 U211: NotesMohammedAmmarSalamehNo ratings yet

- 100 PH 323 30004 - 001Document2 pages100 PH 323 30004 - 001Muhammad Khoirul KhabibiNo ratings yet

- 100 PH 323 30003 - 002Document1 page100 PH 323 30003 - 002Muhammad Khoirul KhabibiNo ratings yet

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- 6starmhplatform-004 (Sheet 1 of 6)Document1 page6starmhplatform-004 (Sheet 1 of 6)Jacob FryeNo ratings yet

- PlanoDocument1 pagePlanoHELEN GREYS MONTALVAN SOLISNo ratings yet

- 18 Ocs General Assemblies OverlapDocument36 pages18 Ocs General Assemblies OverlapMounika100% (1)

- Elm 03 JGC CV Gas 0010Document1 pageElm 03 JGC CV Gas 0010Amin GNo ratings yet

- House Shilongo ERF 385Document2 pagesHouse Shilongo ERF 385Rosalia Loide Hauwanga NdafyaalakoNo ratings yet

- Wa-345225 0003 0000Document1 pageWa-345225 0003 0000Gavriel NgNo ratings yet

- Tooth Detail: Camber DiagramDocument1 pageTooth Detail: Camber DiagramCarl Lou BaclayonNo ratings yet

- Ea-000001.0002.0000 (Proposal-01)Document1 pageEa-000001.0002.0000 (Proposal-01)Noufal AsifNo ratings yet

- Longitudinal Section A-A View 'B': NotesDocument1 pageLongitudinal Section A-A View 'B': NotesMAULIK RAVALNo ratings yet

- Master Plan': B E Y R O U T HDocument1 pageMaster Plan': B E Y R O U T HYADNYAYEE PAWARNo ratings yet

- Bhandara Proposed Parking LayoutDocument1 pageBhandara Proposed Parking LayoutAyush GuptaNo ratings yet

- Final Jury Layout-ModelDocument1 pageFinal Jury Layout-Modelraneen zaidmNo ratings yet

- Tech Pecific: Section Pier Bed PlateDocument1 pageTech Pecific: Section Pier Bed PlateEr Navneet JassiNo ratings yet

- Zeiss CeilingDocument1 pageZeiss CeilingShantanuNo ratings yet

- Trial PlotDocument1 pageTrial PlotArmand Mikhail TempladoNo ratings yet

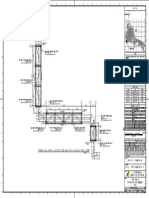

- Cantilever Upvc Duct Support Detail: 422-C220-SH-M-23-GF0301 03Document1 pageCantilever Upvc Duct Support Detail: 422-C220-SH-M-23-GF0301 03shoebNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06003 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06003 (A)hemanthsridharaNo ratings yet

- TGC NPC Eda GF Mep Ac SD 0001Document1 pageTGC NPC Eda GF Mep Ac SD 0001Shameel MoNo ratings yet

- Basemap - Kalitengah RW 12 Sampai RW 15Document1 pageBasemap - Kalitengah RW 12 Sampai RW 15ahmadanto170No ratings yet

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- 21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0Document1 page21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0arjunNo ratings yet

- Block A TB Layout Rev 2Document1 pageBlock A TB Layout Rev 2gagan.saluja85No ratings yet

- Hps2007b EeDocument1 pageHps2007b Eeapi-3709639No ratings yet

- CCE TV HPS-2023 Diagrama EsquematicoDocument1 pageCCE TV HPS-2023 Diagrama EsquematicoFlorian LeordeanuNo ratings yet

- Gad LusDocument1 pageGad LusArun K RajNo ratings yet

- B RA-620356 002 B 963 C204: NotesDocument1 pageB RA-620356 002 B 963 C204: NotesmuthuvelaaNo ratings yet

- SP 2390 StressDocument60 pagesSP 2390 StressVenkat Rangan100% (1)

- 1671 8560 71 C160 0165 Commented 25.10.22Document1 page1671 8560 71 C160 0165 Commented 25.10.22Venkat RanganNo ratings yet

- PAPER 8 The Miskar Gas Field RevDocument27 pagesPAPER 8 The Miskar Gas Field RevVenkat RanganNo ratings yet

- SP 1125Document12 pagesSP 1125Venkat RanganNo ratings yet

- General Design Specification Piping Design Basis: CFU Feed Handling ProjectDocument7 pagesGeneral Design Specification Piping Design Basis: CFU Feed Handling ProjectVenkat RanganNo ratings yet

- Apps On Google PlayDocument5 pagesApps On Google PlayVenkat RanganNo ratings yet

- PMS (1CC1P01)Document263 pagesPMS (1CC1P01)Venkat RanganNo ratings yet

- Process Design Basis: LPG Train-4 Project at MAA RefineryDocument42 pagesProcess Design Basis: LPG Train-4 Project at MAA RefineryVenkat RanganNo ratings yet

- ISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpDocument8 pagesISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpVenkat RanganNo ratings yet

- Driving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneDocument2 pagesDriving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneVenkat RanganNo ratings yet

- Pipe Hangers and SupportsDocument179 pagesPipe Hangers and SupportsVenkat RanganNo ratings yet

- Metric PVC Piping SystemDocument20 pagesMetric PVC Piping SystemVenkat RanganNo ratings yet

- Caesar II App GuideDocument5 pagesCaesar II App GuideVenkat RanganNo ratings yet

- Method 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresDocument11 pagesMethod 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresVenkat RanganNo ratings yet

- Constant Spring HangerDocument25 pagesConstant Spring HangerVenkat Rangan100% (1)

- Sample Business Associate Acknowledgment LetterDocument1 pageSample Business Associate Acknowledgment LetterVenkat RanganNo ratings yet

- Open Pit Burning: General Facts and InformationDocument2 pagesOpen Pit Burning: General Facts and InformationVenkat RanganNo ratings yet

- Project Standards and Specifications Flare and Blowdown Systems Rev01Document12 pagesProject Standards and Specifications Flare and Blowdown Systems Rev01Venkat Rangan100% (1)

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- The Study On Outdoor Space Type of Kindergarten Based On The Architectural Typology With BUA Kindergarten As An Example, Sheng LuDocument7 pagesThe Study On Outdoor Space Type of Kindergarten Based On The Architectural Typology With BUA Kindergarten As An Example, Sheng LuexeNo ratings yet

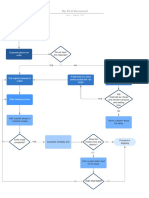

- User Flow DiagramDocument1 pageUser Flow DiagramjimNo ratings yet

- Hanad General Trading Financial Statements 2023Document8 pagesHanad General Trading Financial Statements 2023Nyakwar Leoh NyabayaNo ratings yet

- Textile Internship - Usha YarnsDocument49 pagesTextile Internship - Usha YarnsROHAN GIREESHNo ratings yet

- Bigmart Sales Solution MethodologyDocument5 pagesBigmart Sales Solution MethodologyArnab DeyNo ratings yet

- Selectivemarine.comDocument76 pagesSelectivemarine.comisraelieliteforceNo ratings yet

- Articulo-Watson Crick PDFDocument2 pagesArticulo-Watson Crick PDFAjedrez ItineranteNo ratings yet

- Electrical and Chemical Diagnostics of Transformer InsulationDocument33 pagesElectrical and Chemical Diagnostics of Transformer InsulationVikas Vooturi100% (1)

- Nutricosmetics Apr08Document59 pagesNutricosmetics Apr08mayataNo ratings yet

- STD 5 Unit 7 Simple Machines Study MaterialDocument6 pagesSTD 5 Unit 7 Simple Machines Study MaterialCool WritzNo ratings yet

- 1h 2019 Assessment1Document72 pages1h 2019 Assessment1api-406108641No ratings yet

- HE-210 P-2604A-B - DEBUTANIZER FEED PREHEATING - Rev 0CxDocument1 pageHE-210 P-2604A-B - DEBUTANIZER FEED PREHEATING - Rev 0CxMariaNo ratings yet

- Preterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateDocument26 pagesPreterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateCristinaCaprosNo ratings yet

- Japanese Suite: Gustav HolstDocument55 pagesJapanese Suite: Gustav HolstLaTonya Hutchison 101No ratings yet

- Sobha LTD Q2 FY 2020 21 Investor PresentationDocument47 pagesSobha LTD Q2 FY 2020 21 Investor PresentationAdarsh Reddy GuthaNo ratings yet

- General Characteristics of Fungi. Details AbcdefDocument9 pagesGeneral Characteristics of Fungi. Details Abcdefabdul hadiNo ratings yet

- Lab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareDocument8 pagesLab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareArif AzmiNo ratings yet

- Analytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesDocument9 pagesAnalytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesamitNo ratings yet

- Structural Developments: Inland Waterway Towboats and BargesDocument8 pagesStructural Developments: Inland Waterway Towboats and BargesEd UrquizaNo ratings yet

- Media Richness TheoryDocument10 pagesMedia Richness Theoryestefania sofea zahara100% (2)

- List of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016Document7 pagesList of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016mppatilmayur1679No ratings yet

- Child 210 Collaborative Quest Team Project GuidelinesDocument2 pagesChild 210 Collaborative Quest Team Project GuidelinesDominique ArguellesNo ratings yet

- Kilmarnock To ArdrossanDocument2 pagesKilmarnock To Ardrossanadamdon89100% (1)

- Catalogo Vidrio Mobicell DistribuidorDocument3 pagesCatalogo Vidrio Mobicell DistribuidorANTHONY SANCHEZNo ratings yet

- Sepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603Document114 pagesSepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603makarandmone100% (9)

- BK Ambari InstallationDocument72 pagesBK Ambari InstallationFernovy GesnerNo ratings yet

- DokDocument5 pagesDokNur IdahNo ratings yet

- Latihan UtsDocument8 pagesLatihan UtsFadhli Aulia SNo ratings yet

- Captcha SeminarDocument35 pagesCaptcha SeminarSachin ItgampalliNo ratings yet

Passive Fire Proofing Layout For Proposed Equipments

Passive Fire Proofing Layout For Proposed Equipments

Uploaded by

Venkat RanganOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Passive Fire Proofing Layout For Proposed Equipments

Passive Fire Proofing Layout For Proposed Equipments

Uploaded by

Venkat RanganCopyright:

Available Formats

115000

GENERAL NOTES : KEY PLAN:

TR

UE 7500 7300 92400 7800

ND

NO

RT WI

H NG E 11024.140

1. ALL DIMENSIONS ARE IN MM AND COORDINATES ARE IN METERS UNLESS OTHERWISE SPECIFIED.

LI

TR

UE

ND

AI GATE NO WI

RT

H NG

LI

EV PR

EV

AI

PR 2 N 8348.595 2. EQUIPMENTS LOCATIONS ARE TENTATIVE. WILL BE FINALIZED ONCE RECEIVED THE VENDOR GA. ROAD "J"

PLANT NORTH

TANK YARD- 3

PC2 BL

31° 14' 39"

36° 15' 21"

M

UP

UP

B- 21

TY AREA

PF EL+ 15025

PF EL+ 9075

ESEL GENERATOR

B AREA

040

PF EL+ 5825

3. PROJECT SCOPE COORDINATES MENTIONED TENTATIVELY. WILL BE FINALIZED AFTER SITE

B22

EG

PI

OF HVAC FOR PI

4195

EM ERGENCY DI

4600m 3 =

HVAC

CCR-1

M

LI

7m

UP

SS-

PI

ke= 2.

PLANT NORTH

UTI

Di

S/S & PIB PIPE RACK

SS- 041

L CATCHM ENT DRUM

UP

UP

SURVEY.

S/S &

EG

UP

B- 22

TRANSFROM ER

(72m x 12m )

OI

SS41

9

on &

SS- 042

5175 17500

ROAD "35"

ROAD "36"

31° 14' 39"

UP

PI

CAMERA

UP

36° 15' 21"

S/Stati

STEAM VALVE SETS

M

8000

UP

EL+ 16025

M

E 11024.140

UP

M

4. ALL EQUIPMENT TAG NUMBERS SHALL BE FINALIZED DURING DETAIL ENGINEERING STAGE.

UP

7

PE RACK

EL+ 14000

UP

EL+ 11000

EL+ 8000

EL+ 5000

PE RACK

EL+ 14000

EL+ 11000

EL+ 8000

EL+ 5000

C

A

T

UP

UP

PI

MI

(TYP.) POLE

PI

#200/300 AREA

8

BATTERY LI

ON CONCRETE SLAB

EG

M

UP

1

14

STRUCTURE

9

EL+6500

Y11

M

PIPE RACK

Y10

UP

10

N 8463.595

CATA. CONV. AREA

REACTOR

11

M

M

M

3

UP

5. ALL EQUIPMENT SHALL ASSUMED TO BE LOCATED IN OPEN OR ADEQUATELY VENTILATED AREA.

12

EC

M

PF EL+ 5525

PF EL+ 3025

R COM P. &

LIGHT

PROTECTI

STRUCTURE

B'

LIGHT

L

ST RAI

13

CAMERA

HOI

M

THIS DRAWING

UP

4

ON STRUCTURE

EG ANALYZER HOUSE

14

PF EL+ 4025

PF EL+ 8075

M

3F EL+ 18025

UP

ON

CATI

M

CATI

PE RACK

PC2 BL

M

M

FI

TO M EG PURFI

PF EL+ 5025

PURI

M

POLE

M

6

POLE

UP

M

M EG

POLE 6. ALL BELOW GRADE SUMPS SHALL BE CLASSIFIED AS ZONE-1.

M

22

M

M

AI

M

M

UP

M

M

M

E

F

D

PE RACK

PE RACK

PE RACK

EL+ 14000

EL+ 14000

EL+ 11000

EL+ 11000

EL+ 8000

EL+ 5000

EL+ 8000

EL+ 5000

PC2 BL

DE PI

CO2 EVAPORATOR STRUCTURE

PI

PI

LIGHT

D

C

T

M EG UNI

25

M

MIDDLE PIPE RACK

M

PO UNI

UP

SOUTH SI

UP

8

B

C

A

7. THE BATTERY ROOM SHALL BE CONSIDERED CLASS 1, ZONE 1, GROUP IIC, AND EXPLOSION PROOF

UP

1

M

M

UP

M

M

DE PI

M

M

M

M

UP

M

PF EL+ 4275

PF EL+ 7525

M

UP

POLE

H

G

M

M

2

M

LIGHT

M

PE RACK

EL+ 11000

M

EL+ 8000

EL+ 5000

M

M

M

M

M

M

M

PI

#400/500 AREA

M

M

M

#100 AREA

3

M

M

M

PPER STRUCTURE

NORTH SI

M

M

M

UP

M

M

M

M

um n

M

2FL EL+ 18025

PF EL+ 6525

M

ON CONCRETE SLAB

M

ght End Col

M

M

(future)

TO EO STRI

UP

10

4

M

M

PF EL+18025

STRUCTURE

M

Li

M

M

M

31

POLE

11

M

M

UP

ENCLOSURES SHALL BE INSTALLED FOR ALL APPLIANCES IN THESE ROOMS.

PF EL+ 18000

PE RACK

PE RACK

M

EL+ 14000

EL+ 14000

EL+ 11000

EL+ 11000

UP

EL+ 8000

EL+ 5000

EL+ 8000

EL+ 5000

UP

1

Area

L

K

M

PI

PI

UP

PF EL+ 4025

12

PPER

M

UP

UP

M

UP

Kerbed

FUTURE EXPANSION

M

ST RAI

M

E

F

D

STRI

M

2

M

HOI

T

M

L CONSOLE UNI

M

UP

PF EL+ 18025

M

UP

5

EO

M

3

M

M

L

ST RAI

PROTECTI

M

OI

M

M

M

HOI

13

M

6

UP

PF EL+ 5525

UP

M

M

DN

UP

4

M

M

M

UP

UP

M

B

A

M M

M

M

PF EL+25525

8. ALL PROCESS VENTS, RELIEF VALVES AND INSTRUMENT OR CONTROL VALVE VENTS SHALL BE

UP

7

M

14

M

M

UP

P

M

M

M

M

M

M

M

M

M

M

M

M

M

M

TO CO2 ABSORBER STRUCTURE

M

L

PF EL+ 25500

F

ST RAI

UP

M

UP

M

M

HOI

4FL EL+ 25025

PF EL+ 4625

PF EL+ 8025

PF EL+ 32275

STRUCTURE

STRUCTURE

L

ST RAI

CLASSIFIED FOLLOWING API 505 DURING DETAIL ENGINEERING CONSIDERING FREQUENCY OF

L

ST RAI

HOI

TO EO REACTOR STRUCTURE

HOI

TO CO2 ABSORBER STRUCTURE

3FL EL+ 18025

REACTOR

3FL EL+ 18025

ABSORBER

PF EL+ 18025

42

EAST PIPE TRACK

EO

PF EL+ 4025

CO2

PIT

VALVE

Area

VENTING.

PF EL+ 18025

M

PF EL+ 18025

M

PE RACK

M

EL+ 14000

EL+ 11000

EL+ 8000

EL+ 5000

M

Kerbed

M

M

M

M

PI

SL

TANK YARD- 1

T

PF EL+18525

) PI

TANK YARD- 2

Area

NST.

Kerbed

EO ANALYZER HOUSE

FI (I

)

x 3m

PE TRACK

CW

46

PE TRACK

( 11m

9. ALL THE REFERENCE VALUES ARE TAKEN FROM "PFD AND MSDS" PROVIDED BY CLIENT. EL+4000

1 PI

EL+6500

PIPE RACK

M

DDLE PI

M

M

T

VALVE PI

PE RACK

2 MI

EL+ 11000

EL+ 8000

EL+ 5000

PI

SL

10. THE STREAM COMPOSITION OF THE FLUIDS ARE CONSIDERED WITH RESPECT TO THE DOMINANT

CW

VALVE

T

PI

55

EL+6500

PIPE RACK

2 WEST SIDE PIPE TRACK

VENT STACK

THERMAL

OXIDIZER

11. ANALYZER SHELTER SHALL BE CLASSIFIED AS ZONE 1 AND AND GROUP CONSISTENT

33300

PI

/ 800 UNDER GROUND PI NG

A B

(FUTURE)

FUTURE EXPANSION

FUTURE SPACE

WITH LIQUIDS OR GASES BEING HANDLED. SCREEN FILTER

GATE

FLOOR EL+2790

MSL+3600

CAS

B MSL+2600

W AO

500

N 8326.

(NOTE-6) 12. FIRE ZONES ARE INDICATIVE ONLY.HOWEVER,THE HAZARDOUS AREA CLASSIFICATIONS (FUTURE) 237

UO1

(FUTURE)

LORRY

T

AREA

MI

CONTRACTOR LI

CT- 4

000

NERATOR

ARE CONSIDERED AS PER FLUID COMPOSITIONS RECEIVED FROM CLIENT

T N 8460.

C

"G"

MI

CONTRACTOR LI

SS- 044

NCI

OPERATOR

000

SHELTER

N 8451.

I

/ 800 UNDER GROUND PIPING

EXISTING CONCRETE

DUCT

ROAD "H"

C

EXISTING ELECTRICAL

SUB STATION 10.6

SL FIRE ZONE

DELETE 1

FACILITY DESCRIPTION

FIRE ZONE01 UTILITY BUILDING

THIS NOTE 2 FIRE ZONE02 AMMONIA/COOLING WATER AREA

LIGHT LEGENDS:

9000 POLE 22500 TABLE. 3 FIRE ZONE03 PROCESS SHED

3600

A

4 FIRE ZONE04 CONTROL ROOM ZONE 0 PFP ZONE ZONE 2

78600

BATH

URINALS

5 FIRE ZONE05 CO2 STORAGE

7000

W.C PHS

CANTEEN PRAYER MAINTENANCE WARE

ROOM ROOM ROOM HOUSE

UTILITY

WWC

W ASH

W.C

4200 FIRE ZONE-01 5000

3800 4500

6 FIRE ZONE06 TRUCK PARKING AREA

TOILET

X

6600

X

6600

X

6600

X

6600

BUILDING ZONE 1

3800X6600

LOCK 7 FIRE ZONE07 DISPATCH ROOM AND GUARD ROOM UNCLASSIFIED

ROOM

B LIGHT

)

TYP.

POLE

3000 (

1 2 3 4 5 6

1 2 3 4 5 6

FIRE RATING OF 2 HOURS.

FOR FURTHER DETAILS,

17800

)

TYP.

REFERENCE DOCUMENTS DRAWING NO.

REFER HSE & CIVIL

42000 (

PROCESS FLOW DIAGRAM 2411-8140-20-C030-0001

9 12

DESIGN BASIS. ELECTRICAL AREA CLASSIFICATION SAES-B-068

RAM P

FIREPROOFING PRACTICES

FIRE ZONE-02

RECOMMENDED PRACTICE FOR

ROLLING SHUTTER (RS)

FIRE WALL

A

OVERHEAD CRANE (8 TON CAPACITY)

SWITCH GEAR

TR-1

13.8/0.4 KV

FENCE

IN PETROLEUM

LOCATIONS AND

FOR ELECTRICAL

API RP 505 API RP 2218

5000 X 5000

PETROCHEMICAL

13.8 KV

6000 X 6000

(REMOVABLE) INSTALLATIONS AT PETROLEUM

B

TR-2

13.8/0.4 KV

DELETE IT. PROCESSING

FACILITIES PLANTS

PLC ROOM

5000 X 5000

3800 X 6000

FIRE ZONE-03 FIRE ZONE-04

8000 DESIGN BASIS

HAZARDOUS FOR

AREA HSE

CLASSIFICATION 1671-8140-RP-C160-0160 DOC. NUMBER

30000

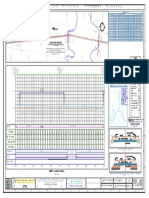

MCC ROOM

D 8000 X 11200 SCHEDULE WITH REPORT

180000

E

LIGHT

4600X5000

4600X2800

4600X3000

M EETING

QC ROOM

00B 20-10-2022 ISSUED FOR APPROVAL VT JJ VB

PANTRY

ROOM

POLE

)

TYP.

F 00A 09-08-2022 ISSUED FOR REVIEW VT JJ VB

CORRIDOR 1.2 M WIDTH

LIGHT

HCIS CLASS-III FENCE (

REV. DATE DESCRIPTION PREP CHKDAPP'D

POLE

NEED TO

5000 X 1800

TOILET

CONTROL

G

PROCESS INTERFACE PLANT

ROOM

MANGER

REVISIONS

H

BUILDING

ROLLING SHUTTER (RS)

CARBOSCAN

ANALYZER

5000X5000

5000X4000

STORM WATER DRAIN UPDATE. CONSULTANT :

RAM P

STORM WATER DRAIN

7 8 10 11 (TYP)(SEE NOTES:9)

12000

9000 24200 11600

35800

HPP. EL. +0.00M

1. Fireproofing shall be applied only within fire scenario

REFRIGERATOR UNIT

ASPHALT PAVING where indicated.

2. Fireproofing shall be applied to steel saddles that support

horizontal heat exchangers, coolers, condensers, drum re- CONTRACTOR : CONTRACTOR No.1671

ceivers and accumulators that have a diameter greater than

30 inches (0.76m) if the vertical distance between the con-

crete pier and the shell of the vessel exceeds 12 inches

TRANSFER PUM P

LIGHT

(0.300m).

300KL TANK

300KL TANK

300KL TANK

300KL TANK

POLE FIRE ZONE-06

35600

LIGHT

3. Fireproofing shall be applied to the power / signals lines

COMPANY :

POLE

that are connected to the valve, the actuating mechanism

93400

FIRE ZONE-05 and the valve body. The valve's actuator shall be fire pro-

tected long enough for the valve to fully open or close. Power

and signal lines supplied with the fire resistance material

need not to be fireproofed. THIS DRAWING IS THE PROPERTY OF

4. Refer to Design Basis for Fireproofing for futher details. RABIGH REFINING AND PETROCHEMICAL COMPANY

AND IS LENT WITHOUT CONSIDERATION OTHER THAN THE BORROWER'S AGREEMENT THAT IT SHALL NOT BE

5. Two hours of fire rating shall be provided between trans- REPRODUCED, COPIED, LENT, OR DISPOSED OF DIRECTLY OR INDIRECTLY NOR USED FOR ANY PURPOSE OTHER

THAT FOR WHICH IT IS SPECIFICALLY FURNISHED. THE APPARATUS SHOWN IN THE DRAWING IS COVERED BY PATENTS.

TANK FARM CAMERA former and control building.

11150 22400 POLE

LOCATION : RABIGH, SAUDI ARABIA

W EIGH BRIDGE

PROJECT : CO2 RECOVERY PROJECT (CAPTURE AND SALES PROJECT)

TRUCK PARKING

RABIGH REFINING AND PETROCHEMICAL COMPANY

)

CAR PARKING

TYP.

32700

PLANT: DRAWING TYPE:

COVERED

21000 (

PETRO RABIGH HAZ

LIGHT

POLE

TITLE :

PASSIVE FIRE

FIRE ZONE ANDPROOFING LAYOUT

HAZARDOUS AREA

W IDE

SIDEW ALK

FIRE ZONE-07

DESPATCH

3000

5M

TYP.

1.

ROOM

3000x3700 LIGHT

POLE

FOR CO2

CLASSIFICATION RECOVERY

LAYOUT PLANT

CO2 RECOVERY PLANT

10287

(

SEPTIC

CAMERA TANK

GAURD ROOM

POLE LIGHT 3000x3700

7.3M WIDE DRIVE

POLE

SLIDING GATE-1

MAIN GATE-1 SCALE : 1:250 REV. SIZE SHEET No.

1360

PERSONAL GATE COMPANY DRAWING NO.

E 10844.140 E 10844.140

N 8463.595 N 8348.595

00B A0 1OF1

1700 7600 -

0 5 10 15 20 25M

CONTRACTOR DRAWING NO.

17350 SCALE 1:250

00B A0 1OF1

STORM WATER DRAIN

1671-8560-71-C160-0162 NEW NUMBER

You might also like

- Eric Evans Domain Driven Design PDFDocument2 pagesEric Evans Domain Driven Design PDFMayra10% (10)

- Burn Pit CriteriaDocument28 pagesBurn Pit CriteriaVenkat Rangan100% (7)

- 1671 8560 71 C160 0165 Commented 25.10.22Document1 page1671 8560 71 C160 0165 Commented 25.10.22Venkat RanganNo ratings yet

- Major993502x12.2pscslab V5 Approve P12Document1 pageMajor993502x12.2pscslab V5 Approve P12rushi123No ratings yet

- 20100PE-DW02-0007 Rev1 11-SD-2123Document1 page20100PE-DW02-0007 Rev1 11-SD-2123Jovit BeaNo ratings yet

- 14july Inlet-Gad-1Document1 page14july Inlet-Gad-1varanasirk1No ratings yet

- 6starmhbasement-001 (Sheet 1 of 6)Document1 page6starmhbasement-001 (Sheet 1 of 6)Jacob FryeNo ratings yet

- Utility Mechanical Room Scada Room: - R KA 356289 01 - NA422Document1 pageUtility Mechanical Room Scada Room: - R KA 356289 01 - NA422John Philip BuntalesNo ratings yet

- B1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Document1 pageB1 COMMUNITY CENTER GROUND FLOOR PUBLIC ADDRESS SYSTEM LAYOUT-Layout1Dessouki SamakNo ratings yet

- D 11 Rural Base ModelDocument1 pageD 11 Rural Base ModelMiller Daniel PardoNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- UWP 25418 001 Elevated Water Tank 5000L CR02 PDFDocument1 pageUWP 25418 001 Elevated Water Tank 5000L CR02 PDFer.praveenraj30No ratings yet

- LAYOUTDocument3 pagesLAYOUTARUL SANKARANNo ratings yet

- GF GCOT B 14 4002 - 1 SignedDocument2 pagesGF GCOT B 14 4002 - 1 SignedYuan DiNo ratings yet

- B1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDocument1 pageB1 COMMUNITY CENTER FIRST FLOOR VOICE & DATA LAYOUT-Layout1 PDFDessouki SamakNo ratings yet

- T572750001PD 1Document1 pageT572750001PD 1waqas21 nawafNo ratings yet

- Wa-345225 0004 0000Document1 pageWa-345225 0004 0000Gavriel NgNo ratings yet

- 9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Document1 page9204-BP12A-MMJV-DWG-FA-P1-L05-02304-REV.D03 (Commented)Michael Camit EsoNo ratings yet

- t76-R-pp-476561-001 - Rev B Utility Ome Building PlanDocument1 paget76-R-pp-476561-001 - Rev B Utility Ome Building PlanTayyab AchakzaiNo ratings yet

- 18-Alignment Plan &profile KM 90-100Document1 page18-Alignment Plan &profile KM 90-100Tamrayehu KuremaNo ratings yet

- CCCW Pumping & Heat Exchanger 3814-XZ-DM-122021-Is06DDocument1 pageCCCW Pumping & Heat Exchanger 3814-XZ-DM-122021-Is06DJose Alberto Uribe MinierNo ratings yet

- SLD - CBSE Patna - PDF 2Document1 pageSLD - CBSE Patna - PDF 2nbcccbsepatnaNo ratings yet

- Major1107202x12.2pscslab V4 Approve P11Document1 pageMajor1107202x12.2pscslab V4 Approve P11rushi123No ratings yet

- Wa-345225 0002 0000Document1 pageWa-345225 0002 0000Gavriel NgNo ratings yet

- Sơ Đ Nguyên Lý Thoát Nư C: Ghi Chuù - NotesDocument1 pageSơ Đ Nguyên Lý Thoát Nư C: Ghi Chuù - NotesHuy NguyễnNo ratings yet

- 132 KV HANSI-ModelDocument1 page132 KV HANSI-ModelShariq KhanNo ratings yet

- Major1047005x18.3pscgirder V5 Approve P13Document1 pageMajor1047005x18.3pscgirder V5 Approve P13rushi123No ratings yet

- For Guidance: Australasian HFG Standard Components DTUR-14 Dirty Utility, 14MDocument1 pageFor Guidance: Australasian HFG Standard Components DTUR-14 Dirty Utility, 14MChristdel VivarNo ratings yet

- 00 RA-610978 001 R 964 U211: NotesDocument1 page00 RA-610978 001 R 964 U211: NotesMohammedAmmarSalamehNo ratings yet

- 100 PH 323 30004 - 001Document2 pages100 PH 323 30004 - 001Muhammad Khoirul KhabibiNo ratings yet

- 100 PH 323 30003 - 002Document1 page100 PH 323 30003 - 002Muhammad Khoirul KhabibiNo ratings yet

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- 6starmhplatform-004 (Sheet 1 of 6)Document1 page6starmhplatform-004 (Sheet 1 of 6)Jacob FryeNo ratings yet

- PlanoDocument1 pagePlanoHELEN GREYS MONTALVAN SOLISNo ratings yet

- 18 Ocs General Assemblies OverlapDocument36 pages18 Ocs General Assemblies OverlapMounika100% (1)

- Elm 03 JGC CV Gas 0010Document1 pageElm 03 JGC CV Gas 0010Amin GNo ratings yet

- House Shilongo ERF 385Document2 pagesHouse Shilongo ERF 385Rosalia Loide Hauwanga NdafyaalakoNo ratings yet

- Wa-345225 0003 0000Document1 pageWa-345225 0003 0000Gavriel NgNo ratings yet

- Tooth Detail: Camber DiagramDocument1 pageTooth Detail: Camber DiagramCarl Lou BaclayonNo ratings yet

- Ea-000001.0002.0000 (Proposal-01)Document1 pageEa-000001.0002.0000 (Proposal-01)Noufal AsifNo ratings yet

- Longitudinal Section A-A View 'B': NotesDocument1 pageLongitudinal Section A-A View 'B': NotesMAULIK RAVALNo ratings yet

- Master Plan': B E Y R O U T HDocument1 pageMaster Plan': B E Y R O U T HYADNYAYEE PAWARNo ratings yet

- Bhandara Proposed Parking LayoutDocument1 pageBhandara Proposed Parking LayoutAyush GuptaNo ratings yet

- Final Jury Layout-ModelDocument1 pageFinal Jury Layout-Modelraneen zaidmNo ratings yet

- Tech Pecific: Section Pier Bed PlateDocument1 pageTech Pecific: Section Pier Bed PlateEr Navneet JassiNo ratings yet

- Zeiss CeilingDocument1 pageZeiss CeilingShantanuNo ratings yet

- Trial PlotDocument1 pageTrial PlotArmand Mikhail TempladoNo ratings yet

- Cantilever Upvc Duct Support Detail: 422-C220-SH-M-23-GF0301 03Document1 pageCantilever Upvc Duct Support Detail: 422-C220-SH-M-23-GF0301 03shoebNo ratings yet

- Column LayoutDocument1 pageColumn LayoutAugustine yigaNo ratings yet

- G6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MapDocument1 pageG6 G5 G3 G2 G1 G5' G7 G4: 1 Elephant Holding Ground Floor Level Load MaphemanthsridharaNo ratings yet

- Yas MZ Acm ST C40 B1 DT 06003 (A)Document1 pageYas MZ Acm ST C40 B1 DT 06003 (A)hemanthsridharaNo ratings yet

- TGC NPC Eda GF Mep Ac SD 0001Document1 pageTGC NPC Eda GF Mep Ac SD 0001Shameel MoNo ratings yet

- Basemap - Kalitengah RW 12 Sampai RW 15Document1 pageBasemap - Kalitengah RW 12 Sampai RW 15ahmadanto170No ratings yet

- Plano en Planta: Gobierno Regional de PunoDocument1 pagePlano en Planta: Gobierno Regional de PunoHenry Ligue MonzonNo ratings yet

- 21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0Document1 page21057423-Cs-csd-5000-0040 Weighing Scale Control Room Structural and Foundation Detail Drawing Rev.0arjunNo ratings yet

- Block A TB Layout Rev 2Document1 pageBlock A TB Layout Rev 2gagan.saluja85No ratings yet

- Hps2007b EeDocument1 pageHps2007b Eeapi-3709639No ratings yet

- CCE TV HPS-2023 Diagrama EsquematicoDocument1 pageCCE TV HPS-2023 Diagrama EsquematicoFlorian LeordeanuNo ratings yet

- Gad LusDocument1 pageGad LusArun K RajNo ratings yet

- B RA-620356 002 B 963 C204: NotesDocument1 pageB RA-620356 002 B 963 C204: NotesmuthuvelaaNo ratings yet

- SP 2390 StressDocument60 pagesSP 2390 StressVenkat Rangan100% (1)

- 1671 8560 71 C160 0165 Commented 25.10.22Document1 page1671 8560 71 C160 0165 Commented 25.10.22Venkat RanganNo ratings yet

- PAPER 8 The Miskar Gas Field RevDocument27 pagesPAPER 8 The Miskar Gas Field RevVenkat RanganNo ratings yet

- SP 1125Document12 pagesSP 1125Venkat RanganNo ratings yet

- General Design Specification Piping Design Basis: CFU Feed Handling ProjectDocument7 pagesGeneral Design Specification Piping Design Basis: CFU Feed Handling ProjectVenkat RanganNo ratings yet

- Apps On Google PlayDocument5 pagesApps On Google PlayVenkat RanganNo ratings yet

- PMS (1CC1P01)Document263 pagesPMS (1CC1P01)Venkat RanganNo ratings yet

- Process Design Basis: LPG Train-4 Project at MAA RefineryDocument42 pagesProcess Design Basis: LPG Train-4 Project at MAA RefineryVenkat RanganNo ratings yet

- ISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpDocument8 pagesISO 13709/ API 610 (VS6) Vertical Multistage Double Case Process PumpVenkat RanganNo ratings yet

- Driving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneDocument2 pagesDriving On Biomass: John Ohlrogge, Doug Allen, Bill Berguson, Dean Dellapenna, Yair Shachar-Hill, Sten StymneVenkat RanganNo ratings yet

- Pipe Hangers and SupportsDocument179 pagesPipe Hangers and SupportsVenkat RanganNo ratings yet

- Metric PVC Piping SystemDocument20 pagesMetric PVC Piping SystemVenkat RanganNo ratings yet

- Caesar II App GuideDocument5 pagesCaesar II App GuideVenkat RanganNo ratings yet

- Method 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresDocument11 pagesMethod 22 - Visual Determination of Fugitive Emissions From Material Sources and Smoke Emissions From FlaresVenkat RanganNo ratings yet

- Constant Spring HangerDocument25 pagesConstant Spring HangerVenkat Rangan100% (1)

- Sample Business Associate Acknowledgment LetterDocument1 pageSample Business Associate Acknowledgment LetterVenkat RanganNo ratings yet

- Open Pit Burning: General Facts and InformationDocument2 pagesOpen Pit Burning: General Facts and InformationVenkat RanganNo ratings yet

- Project Standards and Specifications Flare and Blowdown Systems Rev01Document12 pagesProject Standards and Specifications Flare and Blowdown Systems Rev01Venkat Rangan100% (1)

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- The Study On Outdoor Space Type of Kindergarten Based On The Architectural Typology With BUA Kindergarten As An Example, Sheng LuDocument7 pagesThe Study On Outdoor Space Type of Kindergarten Based On The Architectural Typology With BUA Kindergarten As An Example, Sheng LuexeNo ratings yet

- User Flow DiagramDocument1 pageUser Flow DiagramjimNo ratings yet

- Hanad General Trading Financial Statements 2023Document8 pagesHanad General Trading Financial Statements 2023Nyakwar Leoh NyabayaNo ratings yet

- Textile Internship - Usha YarnsDocument49 pagesTextile Internship - Usha YarnsROHAN GIREESHNo ratings yet

- Bigmart Sales Solution MethodologyDocument5 pagesBigmart Sales Solution MethodologyArnab DeyNo ratings yet

- Selectivemarine.comDocument76 pagesSelectivemarine.comisraelieliteforceNo ratings yet

- Articulo-Watson Crick PDFDocument2 pagesArticulo-Watson Crick PDFAjedrez ItineranteNo ratings yet

- Electrical and Chemical Diagnostics of Transformer InsulationDocument33 pagesElectrical and Chemical Diagnostics of Transformer InsulationVikas Vooturi100% (1)

- Nutricosmetics Apr08Document59 pagesNutricosmetics Apr08mayataNo ratings yet

- STD 5 Unit 7 Simple Machines Study MaterialDocument6 pagesSTD 5 Unit 7 Simple Machines Study MaterialCool WritzNo ratings yet

- 1h 2019 Assessment1Document72 pages1h 2019 Assessment1api-406108641No ratings yet

- HE-210 P-2604A-B - DEBUTANIZER FEED PREHEATING - Rev 0CxDocument1 pageHE-210 P-2604A-B - DEBUTANIZER FEED PREHEATING - Rev 0CxMariaNo ratings yet

- Preterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateDocument26 pagesPreterm Prelabor Rupture of Membranes - Clinical Manifestations and Diagnosis - UpToDateCristinaCaprosNo ratings yet

- Japanese Suite: Gustav HolstDocument55 pagesJapanese Suite: Gustav HolstLaTonya Hutchison 101No ratings yet

- Sobha LTD Q2 FY 2020 21 Investor PresentationDocument47 pagesSobha LTD Q2 FY 2020 21 Investor PresentationAdarsh Reddy GuthaNo ratings yet

- General Characteristics of Fungi. Details AbcdefDocument9 pagesGeneral Characteristics of Fungi. Details Abcdefabdul hadiNo ratings yet

- Lab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareDocument8 pagesLab 4 - Introduction To Printed Circuit Board (PCB) Drawing SoftwareArif AzmiNo ratings yet

- Analytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesDocument9 pagesAnalytical Modeling of Gate-All-Around Junctionless Transistor Based Biosensors For Detection of Neutral Biomolecule SpeciesamitNo ratings yet

- Structural Developments: Inland Waterway Towboats and BargesDocument8 pagesStructural Developments: Inland Waterway Towboats and BargesEd UrquizaNo ratings yet

- Media Richness TheoryDocument10 pagesMedia Richness Theoryestefania sofea zahara100% (2)

- List of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016Document7 pagesList of Candidates For Entrance Test of PH D (Tech) in Pharma Through M Pharm & M Tech For Entrance Test 2015 - 2016mppatilmayur1679No ratings yet

- Child 210 Collaborative Quest Team Project GuidelinesDocument2 pagesChild 210 Collaborative Quest Team Project GuidelinesDominique ArguellesNo ratings yet

- Kilmarnock To ArdrossanDocument2 pagesKilmarnock To Ardrossanadamdon89100% (1)

- Catalogo Vidrio Mobicell DistribuidorDocument3 pagesCatalogo Vidrio Mobicell DistribuidorANTHONY SANCHEZNo ratings yet

- Sepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603Document114 pagesSepharial - The Science of Foreknowledge Cd13 Id 1928069166 Size603makarandmone100% (9)

- BK Ambari InstallationDocument72 pagesBK Ambari InstallationFernovy GesnerNo ratings yet

- DokDocument5 pagesDokNur IdahNo ratings yet

- Latihan UtsDocument8 pagesLatihan UtsFadhli Aulia SNo ratings yet

- Captcha SeminarDocument35 pagesCaptcha SeminarSachin ItgampalliNo ratings yet