Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

19 viewsPentens: Description Technical & Physical Data

Pentens: Description Technical & Physical Data

Uploaded by

chengkkPENTENS E-603 is a two-component epoxy resin floor coating designed for industrial use. It forms a hard, flexible, semi-gloss coating that is resistant to chemicals and easy to clean. The coating has a pot life of 40 minutes at 20°C and cures fully in 7 days. It is applied in two coats at 0.3kg/m2 to achieve a dry film thickness of 0.3mm. PENTENS E-603 provides protection for areas that require resistance to chemical attack such as production facilities and plating plants.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- CyBro-2 User Manual v5Document32 pagesCyBro-2 User Manual v5Dubravko BituhNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- SpECtite HP600Document3 pagesSpECtite HP600ahmed hamedNo ratings yet

- Emaco Nanocrete AP PDS ASEAN 060409Document2 pagesEmaco Nanocrete AP PDS ASEAN 060409EkoAndriAntoNo ratings yet

- PDS Monolevel 844SPDocument3 pagesPDS Monolevel 844SPerawrestlingNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Datarobi setiawanNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- 2 Ardacolor Xtrem Easy - EN - TMDocument2 pages2 Ardacolor Xtrem Easy - EN - TMAngelo Carlo MalabananNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- Sikagard 63n PdsDocument4 pagesSikagard 63n PdsHendro YuniantoNo ratings yet

- RZ 5141 6Document3 pagesRZ 5141 6behrooz rajabshehniNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- Epoxy Mastic Primer Epiplus 556Document2 pagesEpoxy Mastic Primer Epiplus 556rh decoratorsNo ratings yet

- Pentens E-501LN Data SheetDocument2 pagesPentens E-501LN Data Sheetamelinda jocelinNo ratings yet

- Weberfloor 514 SL TDS SelflevelDocument3 pagesWeberfloor 514 SL TDS SelflevelMusab yassinNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Tikidan Tds - Tiki Aquaseal Pu-She, r9Document3 pagesTikidan Tds - Tiki Aquaseal Pu-She, r9sandeepNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Ex Pan Proof 600Document4 pagesEx Pan Proof 600Amar WadoodNo ratings yet

- TDS-Conbextra-HR-India5 6Document3 pagesTDS-Conbextra-HR-India5 6onshore purchaseNo ratings yet

- Nano Ceramic Thermal Insulation CoatingDocument2 pagesNano Ceramic Thermal Insulation CoatingAli AlghanimNo ratings yet

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Document3 pagesEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaNo ratings yet

- Epoxy Modified Cementitious Self Smoothing Floor ScreedDocument2 pagesEpoxy Modified Cementitious Self Smoothing Floor ScreedSameehu TVNo ratings yet

- ColourDur J701 SC3Document4 pagesColourDur J701 SC3anunand.sNo ratings yet

- Abe. Proof PU ECO: PolyurethaneDocument2 pagesAbe. Proof PU ECO: Polyurethanecremildo maetinhoNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor CoatingAshvin ParmessurNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- 11 EPB FLOOR Coating G 78 & M 86Document2 pages11 EPB FLOOR Coating G 78 & M 86shrikrishna rathodNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Roff Hyguard Ex TDS DownloadDocument5 pagesRoff Hyguard Ex TDS DownloadKajal SarkarNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- Concrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoDocument2 pagesConcrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoVincent JavateNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Pds Pentens HKP T 100Document2 pagesPds Pentens HKP T 100As-Syaff ResourcesNo ratings yet

- Pentens® T-200H: Product Data SheetDocument2 pagesPentens® T-200H: Product Data SheetProyek ATCNo ratings yet

- E 008Document2 pagesE 008ウィリアムズ アンディNo ratings yet

- Appendix 4 TDS & MSDSDocument8 pagesAppendix 4 TDS & MSDSmohsin.meizaNo ratings yet

- Masteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerDocument2 pagesMasteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerMuhammad Fadhil ImansyahNo ratings yet

- Dry 110 FX Grey/White: Flexible High Performance Cement-Based Waterproof CoatingDocument2 pagesDry 110 FX Grey/White: Flexible High Performance Cement-Based Waterproof CoatingDharryl Dharryl DharrylNo ratings yet

- 2K Epoxy Mastic Coating 80Document2 pages2K Epoxy Mastic Coating 80Sachin SinghalNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor Coatingengramir07No ratings yet

- Capcoat E: N F B EDocument2 pagesCapcoat E: N F B EEng-Medrar AlkateryNo ratings yet

- Epoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Document3 pagesEpoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Rajesh GiriNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Hvpak 17-66 IecDocument39 pagesHvpak 17-66 IecchengkkNo ratings yet

- Hvpak 18-02Document1 pageHvpak 18-02chengkkNo ratings yet

- LAK 7992 Rev1Document1 pageLAK 7992 Rev1chengkkNo ratings yet

- LAK 8017 Rev 1Document1 pageLAK 8017 Rev 1abdulNo ratings yet

- Enp GW55Document28 pagesEnp GW55chengkkNo ratings yet

- Manufacturer Statement - PEXLIM P-Z SADocument1 pageManufacturer Statement - PEXLIM P-Z SAchengkkNo ratings yet

- Enp JW11-72.5-300Document14 pagesEnp JW11-72.5-300chengkkNo ratings yet

- Hvpak 18-01Document1 pageHvpak 18-01chengkkNo ratings yet

- Pexlim P-Z LeafletDocument2 pagesPexlim P-Z LeafletchengkkNo ratings yet

- ISO Certificate ABB ABDocument1 pageISO Certificate ABB ABchengkkNo ratings yet

- ISO 9001-2015 Certificate 2021 - Daikin MalaysiaDocument2 pagesISO 9001-2015 Certificate 2021 - Daikin Malaysiachengkk100% (1)

- Pentens Industrial Flooring Catalogue Final FA (LR)Document24 pagesPentens Industrial Flooring Catalogue Final FA (LR)chengkkNo ratings yet

- 9001-Ottobrunn-Eng - March 2020Document1 page9001-Ottobrunn-Eng - March 2020chengkkNo ratings yet

- Iec60076 10 2016Document128 pagesIec60076 10 2016chengkkNo ratings yet

- Epp 0850 6 - 13Document4 pagesEpp 0850 6 - 13chengkkNo ratings yet

- Acson Company Profile 2019 - LowresDocument20 pagesAcson Company Profile 2019 - LowreschengkkNo ratings yet

- PPR-2833 OHVT-72H 800sqmm CpriDocument38 pagesPPR-2833 OHVT-72H 800sqmm CprichengkkNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical DatachengkkNo ratings yet

- Ca Ohvt Bro 0217 Epp0413 - EngDocument4 pagesCa Ohvt Bro 0217 Epp0413 - EngchengkkNo ratings yet

- PENTENS T-888+E-603 MTHDocument1 pagePENTENS T-888+E-603 MTHchengkkNo ratings yet

- 2.a. Technical Specs - Bare LugDocument11 pages2.a. Technical Specs - Bare LugchengkkNo ratings yet

- 2.a. Technical Specs - Insulated LugDocument17 pages2.a. Technical Specs - Insulated LugchengkkNo ratings yet

- SAP Transacciones Lista y Analisis Completo SAP-TCodes - Module - CRM-EnDocument1,122 pagesSAP Transacciones Lista y Analisis Completo SAP-TCodes - Module - CRM-EnJohan GarciaNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Ckla g1 U4 TG EngageDocument248 pagesCkla g1 U4 TG EngageRivka ShareNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Fundamentals Activities PrintDocument514 pagesFundamentals Activities PrintTOP NOTCHNo ratings yet

- 16 How To LamentDocument3 pages16 How To Lamentjudy.i.galidoNo ratings yet

- TMC Equipment Master 16sep2021Document97 pagesTMC Equipment Master 16sep2021Francis DedumoNo ratings yet

- Vo Dai Quang Semantics - Lectures in Broad OutlineDocument89 pagesVo Dai Quang Semantics - Lectures in Broad OutlineThu PhạmNo ratings yet

- Masters2 52558Document91 pagesMasters2 52558nermeen ahmedNo ratings yet

- Difference Between Discrete & Repetitive ManufacturingDocument2 pagesDifference Between Discrete & Repetitive ManufacturingSyed Amir HussainNo ratings yet

- InheritanceDocument59 pagesInheritanceTiju ThomasNo ratings yet

- Maltego CEDocument4 pagesMaltego CEArief PrihantoroNo ratings yet

- Bipolar NCP With Drug StudiesDocument10 pagesBipolar NCP With Drug StudiesJulius Matthew LuzanaNo ratings yet

- Inditex Green To Wear StandardDocument8 pagesInditex Green To Wear StandardRokok IndonesiaNo ratings yet

- Jupeb 2019 Biology SyllabusDocument20 pagesJupeb 2019 Biology SyllabusAlexis RockelleNo ratings yet

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- Activity1 - nickiejaneGE1Document3 pagesActivity1 - nickiejaneGE1nickie jane gardoseNo ratings yet

- Accutron Service Manual Series 218 PDFDocument52 pagesAccutron Service Manual Series 218 PDFtunimao100% (1)

- Gea Varivent Hygienic Special Application Valves 262509Document162 pagesGea Varivent Hygienic Special Application Valves 262509DianaNo ratings yet

- (2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewDocument5 pages(2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewNam Huu TranNo ratings yet

- Key Answer Org DevDocument15 pagesKey Answer Org DevSheennah Lee LimNo ratings yet

- Higher Modern Languages: What Is New?Document28 pagesHigher Modern Languages: What Is New?bleinNo ratings yet

- Respuestas Ingles Modul 6Document16 pagesRespuestas Ingles Modul 6Ximena Silva CelyNo ratings yet

- Ford Half ShaftDocument10 pagesFord Half Shaftsuysuy00No ratings yet

- Numerical MethodsDocument25 pagesNumerical MethodsSamip RegmiNo ratings yet

- Seeing Into The Soul: N Fourteenth Century IenaDocument4 pagesSeeing Into The Soul: N Fourteenth Century Ienasalveregina1917No ratings yet

- HRC - Forms - Employee Application - Rev2019 NewDocument3 pagesHRC - Forms - Employee Application - Rev2019 NewGanang CucuNo ratings yet

- Grades of NdFeB MagnetsDocument127 pagesGrades of NdFeB MagnetsjgreenguitarsNo ratings yet

- Material: ASTM A395 Ductile Iron or ASTM A105 Forged Steel: ID H TDocument1 pageMaterial: ASTM A395 Ductile Iron or ASTM A105 Forged Steel: ID H T1mmahoneyNo ratings yet

Pentens: Description Technical & Physical Data

Pentens: Description Technical & Physical Data

Uploaded by

chengkk0 ratings0% found this document useful (0 votes)

19 views2 pagesPENTENS E-603 is a two-component epoxy resin floor coating designed for industrial use. It forms a hard, flexible, semi-gloss coating that is resistant to chemicals and easy to clean. The coating has a pot life of 40 minutes at 20°C and cures fully in 7 days. It is applied in two coats at 0.3kg/m2 to achieve a dry film thickness of 0.3mm. PENTENS E-603 provides protection for areas that require resistance to chemical attack such as production facilities and plating plants.

Original Description:

Original Title

E-603 V1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPENTENS E-603 is a two-component epoxy resin floor coating designed for industrial use. It forms a hard, flexible, semi-gloss coating that is resistant to chemicals and easy to clean. The coating has a pot life of 40 minutes at 20°C and cures fully in 7 days. It is applied in two coats at 0.3kg/m2 to achieve a dry film thickness of 0.3mm. PENTENS E-603 provides protection for areas that require resistance to chemical attack such as production facilities and plating plants.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views2 pagesPentens: Description Technical & Physical Data

Pentens: Description Technical & Physical Data

Uploaded by

chengkkPENTENS E-603 is a two-component epoxy resin floor coating designed for industrial use. It forms a hard, flexible, semi-gloss coating that is resistant to chemicals and easy to clean. The coating has a pot life of 40 minutes at 20°C and cures fully in 7 days. It is applied in two coats at 0.3kg/m2 to achieve a dry film thickness of 0.3mm. PENTENS E-603 provides protection for areas that require resistance to chemical attack such as production facilities and plating plants.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

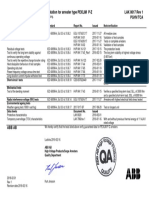

PDS E-603 10/17_V1

PENTENS E-603

High Performance Epoxy Floor Coating

Description Technical & Physical Data

PENTENS E-603 is a two-component solvent-based The values given below are average figures achieved

epoxy resin coating system that is designed in laboratory tests at 20°C and 35°C. Actual values

specifically for industrial use. obtained on site may show minor variations from those

quoted.

The cured film forms a hard but flexible coating with

excellent adhesion to clean concrete, sand/cement and @20°C @34°C

granolithic screeds as well as certain metal surfaces. It Pot Life 40 mins 30 mins

cures to form a semi-gloss, impervious finish which is Tack Free Time 3-4 hrs 2-3 hrs

easily cleaned. Time Between Coats 12-16 hrs 8-12 hrs

Initial Hardness 24 hrs 18 hrs

Uses Full Cure 7 days 5 days

To provide a hardwearing, easy-to-maintain, attractive Dry Film Thickness 0.3mm (approx)

floor coating in areas where high resistance against (include primer)

chemical attack is required. It is suitable for use in:

Abrasive Test (g) – 0.042

● Production assembly areas

Taber CS-17, 1000g ,

● M & E room

1000 Cycles

● Staircase

ASTM C501

● TNB room

Storage Store in a dry, cool place

● Workshops

● Dairies Shelf Life 1 year when unopened

● Soft drink production and undamaged.

● Bottling plants Packaging

● Breweries ■ E-603A 4kg /pail & 20kg /pail

● Kitchens ■ E-603B 1kg /pail & 5kg /pail

● Showrooms etc. Consumption 0.3kg/m²/2 coats

Chemical Resistance No objectionable alteration

It is particularly suitable for use in wet working areas (ASTM D1308-02(2007) in the surface

and areas where chemical spillage is likely, e.g. plating Sea Water

processing plants, dye works etc. Distilled Water

Advantages Chemical Resistant Properties

■ Easy application.

PENTENS E-603 is resistant to a wide range of

■ Super adhesive strength.

chemicals. Specific data is available upon request.

■ Low maintenance cost.

■ High mechanical strength.

Good housekeeping is essential in areas where

■ Easily-cleaned surface.

chemical spillage is likely to occur. It is especially

■ High resistance against a wide range of

important that such spillage should not be allowed to

industrial chemicals.

dry ro avoid excess concentration of chemicals.

■ Hygienic - impervious finishing provides easily-

cleaned surface. (Such as acid, alkali, solvent etc.)

Limitations

■ Attractive – available in a range of standard

PENTENS E-603 should not be applied onto surfaces

colors as well as clear grade to improve the

known likely to suffer from:

working environment.

● Temperatures below 5°C

■ Low viscosity.

● Rising dampness.

■ Short waiting time.

● Relative humidity greater than 75% RH

● Very heavy traffic such as sound work benches,

drink machines etc.

● Asphalt floor & PVC tiles or sheet

Application Instructions PENTENS E-603 is designed for application in two

coats at 0.3kg/m² to achieve a totally dry film

Surface Preparation thickness of approximately 0.3mm. The mixed

It is essential that PENTENS E-603 is applied to PENTENS E-603 should be applied to the prepared

sound, clean and dry substrates in order to achieve surface using a brush or lamb wool roller.

maximum adhesion between the floor coating and

substrate. The second coat may be applied as soon as the first

coat shows initial drying (typically 6 to 8 hours). The

PENTENS E-603 is a relatively thin coating, therefore time interval will depend on the type of surface and

substrate must be in fine texture. Any surface the ambient conditions.

irregularities may show through and cause excessive

wear on high spots which might also change the Cleaning

perceived color of the coating. PENTENS E-603 should be removed from tools and

equipment with thinner immediately after use.

New Concrete Floors Hardened material can only be removed mechanically.

Unless water content is specially reduced, the floor

should be at least 28 days old or a maximum of 4% in Maintenance

moisture content and primed with a layer of The service life of a floor can be considerably

PENTENS E-008 Solvent Free Epoxy Primer. extended by good housekeeping practices. Regular

cleaning of PENTENS E-603 may be carried out using

Old Concrete Floors a rotary scrubbing machine with a water miscible

A sound and clean substrate is essential to achieve cleaning agent or by hot water washing at

maximum adhesion. Light grit blasting or acid etching temperatures up to 50°C.

should be carried out. Oil and grease penetration

should be removed by hot compressed air treatment Safety

and primed with PENTENS E-008 Solvent Free PENTENS E-603 should not come in contact with

Epoxy Primer. skin and eyes or swallowed. Ensure adequate

ventilation and avoid inhalation of its vapors when

Steel Substrates using the products. The smell may cause irritation to

Steel substrates should be grit-blasted according to people who are sensitive to resins, hardeners and

surface quality and primed with an epoxy primer. solvents. Wear suitable protective clothing, gloves and

eye protection. If working in confined areas, suitable

Epoxy Screed respiratory protective equipment must be used. The

PENTENS E-603 can be applied to PENTENS E-502 use of barrier creams provides additional skin

epoxy resin screeds. High spots or trowel marks protection. In case of contact with skin, rinse with

should be rubbed away and dust and other debris plenty of clean water, followed by soap and water. Do

removed by vacuum cleaning. not use solvent. In case of contact with eyes, rinse

immediately with plenty of clean water and seek

Mixing medical advice. If swallowed, seek medical treatment

Before application, both components of PENTENS immediately – do not induce vomiting. PENTENS

E-603 are carefully re-stirred by using a slow-rotating E-603 is flammable. Keep away from sources of

electrical drill. PENTENS E-603 A/B are then mixed ignition. In the event of fire, extinguish with CO2 or

homogeneously using an electrical or pneumatic foam. Do not use a water jet.

power stirrer at approximately 300-400 rpm. Mixing

time is minimum 3-4 minutes but depending on the

circumstances it may take longer until a homogeneous

mix is achieved.

Application

Mix PENTENS E-008 A/B homogeneously prior to

application using an electrical or pneumatic power

stirrer. Brush-applied the mixed primer at 0.2kg/m²

onto the substrate to ensure good wetting of the

substrate and sealing of the pores.

UFON NANO-CHEMICAL LTD. DONG JI (M) SDN. BHD.

8F, No.2, Lane 348, Sec 2, Chung-Shang Road, No.8, Jalan TPP 5/7, Taman Perindustrian Puchong,

Chung Ho City, Taipei Hsien, Taiwan, R.O.C. 47100 Puchong Selangor, Malaysia.

Tel: +886 2 2240 0220 Fax: +886 2 2242 6536 Tel: +603 8060 4396 Fax: +603 8060 4394

URL: www.pentens.com URL: www.pentens.com.my

E-mail: pentens@ms35.hinet.net E-mail: dji@pentens.com.my

You might also like

- MasterProtect 1891Document2 pagesMasterProtect 1891SHAIK ASIMUDDINNo ratings yet

- Masterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 1822: A Non-Toxic High Build, Phenol Novolac Protective Epoxy Resin CoatingSHAIK ASIMUDDINNo ratings yet

- CyBro-2 User Manual v5Document32 pagesCyBro-2 User Manual v5Dubravko BituhNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- SpECtite HP600Document3 pagesSpECtite HP600ahmed hamedNo ratings yet

- Emaco Nanocrete AP PDS ASEAN 060409Document2 pagesEmaco Nanocrete AP PDS ASEAN 060409EkoAndriAntoNo ratings yet

- PDS Monolevel 844SPDocument3 pagesPDS Monolevel 844SPerawrestlingNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Datarobi setiawanNo ratings yet

- Abe Construction Chemicals Duraflex DatasheetDocument2 pagesAbe Construction Chemicals Duraflex DatasheetEthanNo ratings yet

- 2 Ardacolor Xtrem Easy - EN - TMDocument2 pages2 Ardacolor Xtrem Easy - EN - TMAngelo Carlo MalabananNo ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- Sikagard 63n PdsDocument4 pagesSikagard 63n PdsHendro YuniantoNo ratings yet

- RZ 5141 6Document3 pagesRZ 5141 6behrooz rajabshehniNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- Bipigard Coaltar FinishDocument2 pagesBipigard Coaltar FinishKhirod Krout100% (1)

- Basf MasterEmaco S 488Document3 pagesBasf MasterEmaco S 488abdul majeedNo ratings yet

- Epoxy Mastic Primer Epiplus 556Document2 pagesEpoxy Mastic Primer Epiplus 556rh decoratorsNo ratings yet

- Pentens E-501LN Data SheetDocument2 pagesPentens E-501LN Data Sheetamelinda jocelinNo ratings yet

- Weberfloor 514 SL TDS SelflevelDocument3 pagesWeberfloor 514 SL TDS SelflevelMusab yassinNo ratings yet

- Bipigard Coaltar Finish PDFDocument2 pagesBipigard Coaltar Finish PDFKhirod KroutNo ratings yet

- Duraflex DSDocument2 pagesDuraflex DSFeyiNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Tikidan Tds - Tiki Aquaseal Pu-She, r9Document3 pagesTikidan Tds - Tiki Aquaseal Pu-She, r9sandeepNo ratings yet

- Tds-Unichem AlumcoatDocument3 pagesTds-Unichem AlumcoatAnvesh BondugulaNo ratings yet

- Ex Pan Proof 600Document4 pagesEx Pan Proof 600Amar WadoodNo ratings yet

- TDS-Conbextra-HR-India5 6Document3 pagesTDS-Conbextra-HR-India5 6onshore purchaseNo ratings yet

- Nano Ceramic Thermal Insulation CoatingDocument2 pagesNano Ceramic Thermal Insulation CoatingAli AlghanimNo ratings yet

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Document3 pagesEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaNo ratings yet

- Epoxy Modified Cementitious Self Smoothing Floor ScreedDocument2 pagesEpoxy Modified Cementitious Self Smoothing Floor ScreedSameehu TVNo ratings yet

- ColourDur J701 SC3Document4 pagesColourDur J701 SC3anunand.sNo ratings yet

- Abe. Proof PU ECO: PolyurethaneDocument2 pagesAbe. Proof PU ECO: Polyurethanecremildo maetinhoNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor CoatingAshvin ParmessurNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical Dataウィリアムズ アンディNo ratings yet

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocument2 pagesPDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNo ratings yet

- Basf Masteremaco S 488 TdsDocument3 pagesBasf Masteremaco S 488 TdsArindamBhattacharjee100% (2)

- Cemcoat PuttyDocument2 pagesCemcoat Puttyosama mohNo ratings yet

- 11 EPB FLOOR Coating G 78 & M 86Document2 pages11 EPB FLOOR Coating G 78 & M 86shrikrishna rathodNo ratings yet

- Hempadur Fast Dry 17410 En-GbDocument2 pagesHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaNo ratings yet

- Roff Hyguard Ex TDS DownloadDocument5 pagesRoff Hyguard Ex TDS DownloadKajal SarkarNo ratings yet

- Florgard SL: Self Levelling Epoxy Based FlooringDocument3 pagesFlorgard SL: Self Levelling Epoxy Based FlooringRavi KantNo ratings yet

- Concrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoDocument2 pagesConcrete Repair - Pinhole and Reprofile 1-5mm 20mpa SodamcoVincent JavateNo ratings yet

- 15 - TDS - Concresive ERLDocument3 pages15 - TDS - Concresive ERLAlexi ALfred H. TagoNo ratings yet

- Epilux 9 Phenolic CoatingDocument2 pagesEpilux 9 Phenolic CoatingdineshNo ratings yet

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationDocument2 pagesCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Pds Pentens HKP T 100Document2 pagesPds Pentens HKP T 100As-Syaff ResourcesNo ratings yet

- Pentens® T-200H: Product Data SheetDocument2 pagesPentens® T-200H: Product Data SheetProyek ATCNo ratings yet

- E 008Document2 pagesE 008ウィリアムズ アンディNo ratings yet

- Appendix 4 TDS & MSDSDocument8 pagesAppendix 4 TDS & MSDSmohsin.meizaNo ratings yet

- Masteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerDocument2 pagesMasteremaco P 5000: Single Component, Cement Based, Multi-Use, Bonding and Active Protective PrimerMuhammad Fadhil ImansyahNo ratings yet

- Dry 110 FX Grey/White: Flexible High Performance Cement-Based Waterproof CoatingDocument2 pagesDry 110 FX Grey/White: Flexible High Performance Cement-Based Waterproof CoatingDharryl Dharryl DharrylNo ratings yet

- 2K Epoxy Mastic Coating 80Document2 pages2K Epoxy Mastic Coating 80Sachin SinghalNo ratings yet

- Abecote 340: Epoxy Resin Floor CoatingDocument2 pagesAbecote 340: Epoxy Resin Floor Coatingengramir07No ratings yet

- Capcoat E: N F B EDocument2 pagesCapcoat E: N F B EEng-Medrar AlkateryNo ratings yet

- Epoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Document3 pagesEpoxy Repair Mortar TDS FloArm-ERM-Ver-6 24-01-2023Rajesh GiriNo ratings yet

- TDS Weberdry RoofDocument2 pagesTDS Weberdry RoofMahendra Singh BudhathokiNo ratings yet

- Hyperdesmo 815Document5 pagesHyperdesmo 815Roger DaoudNo ratings yet

- 302 Epoxy Ester Floor Paint TDSDocument2 pages302 Epoxy Ester Floor Paint TDSraja qammar100% (1)

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds enadriansyahNo ratings yet

- Expangrout AGDocument2 pagesExpangrout AGPMG04 EKLNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Hvpak 17-66 IecDocument39 pagesHvpak 17-66 IecchengkkNo ratings yet

- Hvpak 18-02Document1 pageHvpak 18-02chengkkNo ratings yet

- LAK 7992 Rev1Document1 pageLAK 7992 Rev1chengkkNo ratings yet

- LAK 8017 Rev 1Document1 pageLAK 8017 Rev 1abdulNo ratings yet

- Enp GW55Document28 pagesEnp GW55chengkkNo ratings yet

- Manufacturer Statement - PEXLIM P-Z SADocument1 pageManufacturer Statement - PEXLIM P-Z SAchengkkNo ratings yet

- Enp JW11-72.5-300Document14 pagesEnp JW11-72.5-300chengkkNo ratings yet

- Hvpak 18-01Document1 pageHvpak 18-01chengkkNo ratings yet

- Pexlim P-Z LeafletDocument2 pagesPexlim P-Z LeafletchengkkNo ratings yet

- ISO Certificate ABB ABDocument1 pageISO Certificate ABB ABchengkkNo ratings yet

- ISO 9001-2015 Certificate 2021 - Daikin MalaysiaDocument2 pagesISO 9001-2015 Certificate 2021 - Daikin Malaysiachengkk100% (1)

- Pentens Industrial Flooring Catalogue Final FA (LR)Document24 pagesPentens Industrial Flooring Catalogue Final FA (LR)chengkkNo ratings yet

- 9001-Ottobrunn-Eng - March 2020Document1 page9001-Ottobrunn-Eng - March 2020chengkkNo ratings yet

- Iec60076 10 2016Document128 pagesIec60076 10 2016chengkkNo ratings yet

- Epp 0850 6 - 13Document4 pagesEpp 0850 6 - 13chengkkNo ratings yet

- Acson Company Profile 2019 - LowresDocument20 pagesAcson Company Profile 2019 - LowreschengkkNo ratings yet

- PPR-2833 OHVT-72H 800sqmm CpriDocument38 pagesPPR-2833 OHVT-72H 800sqmm CprichengkkNo ratings yet

- Pentens: Description Technical & Physical DataDocument2 pagesPentens: Description Technical & Physical DatachengkkNo ratings yet

- Ca Ohvt Bro 0217 Epp0413 - EngDocument4 pagesCa Ohvt Bro 0217 Epp0413 - EngchengkkNo ratings yet

- PENTENS T-888+E-603 MTHDocument1 pagePENTENS T-888+E-603 MTHchengkkNo ratings yet

- 2.a. Technical Specs - Bare LugDocument11 pages2.a. Technical Specs - Bare LugchengkkNo ratings yet

- 2.a. Technical Specs - Insulated LugDocument17 pages2.a. Technical Specs - Insulated LugchengkkNo ratings yet

- SAP Transacciones Lista y Analisis Completo SAP-TCodes - Module - CRM-EnDocument1,122 pagesSAP Transacciones Lista y Analisis Completo SAP-TCodes - Module - CRM-EnJohan GarciaNo ratings yet

- The Literary Formofthe QuranDocument10 pagesThe Literary Formofthe QuranTrina CanizoNo ratings yet

- Ckla g1 U4 TG EngageDocument248 pagesCkla g1 U4 TG EngageRivka ShareNo ratings yet

- Gertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Document5 pagesGertrud Rosshalde Ultima Vara A Lui Klingsor Romanian Edition by Hermann Hesse 6066096141Zaiu DaiuNo ratings yet

- Fundamentals Activities PrintDocument514 pagesFundamentals Activities PrintTOP NOTCHNo ratings yet

- 16 How To LamentDocument3 pages16 How To Lamentjudy.i.galidoNo ratings yet

- TMC Equipment Master 16sep2021Document97 pagesTMC Equipment Master 16sep2021Francis DedumoNo ratings yet

- Vo Dai Quang Semantics - Lectures in Broad OutlineDocument89 pagesVo Dai Quang Semantics - Lectures in Broad OutlineThu PhạmNo ratings yet

- Masters2 52558Document91 pagesMasters2 52558nermeen ahmedNo ratings yet

- Difference Between Discrete & Repetitive ManufacturingDocument2 pagesDifference Between Discrete & Repetitive ManufacturingSyed Amir HussainNo ratings yet

- InheritanceDocument59 pagesInheritanceTiju ThomasNo ratings yet

- Maltego CEDocument4 pagesMaltego CEArief PrihantoroNo ratings yet

- Bipolar NCP With Drug StudiesDocument10 pagesBipolar NCP With Drug StudiesJulius Matthew LuzanaNo ratings yet

- Inditex Green To Wear StandardDocument8 pagesInditex Green To Wear StandardRokok IndonesiaNo ratings yet

- Jupeb 2019 Biology SyllabusDocument20 pagesJupeb 2019 Biology SyllabusAlexis RockelleNo ratings yet

- Islamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafDocument90 pagesIslamic States in Java 1500-1700 Eight Dutch Books and Articles by Dr. H.J. de GraafEwinNo ratings yet

- Activity1 - nickiejaneGE1Document3 pagesActivity1 - nickiejaneGE1nickie jane gardoseNo ratings yet

- Accutron Service Manual Series 218 PDFDocument52 pagesAccutron Service Manual Series 218 PDFtunimao100% (1)

- Gea Varivent Hygienic Special Application Valves 262509Document162 pagesGea Varivent Hygienic Special Application Valves 262509DianaNo ratings yet

- (2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewDocument5 pages(2022, Review, Saran) 3D Printing of Composite Materials - A Short ReviewNam Huu TranNo ratings yet

- Key Answer Org DevDocument15 pagesKey Answer Org DevSheennah Lee LimNo ratings yet

- Higher Modern Languages: What Is New?Document28 pagesHigher Modern Languages: What Is New?bleinNo ratings yet

- Respuestas Ingles Modul 6Document16 pagesRespuestas Ingles Modul 6Ximena Silva CelyNo ratings yet

- Ford Half ShaftDocument10 pagesFord Half Shaftsuysuy00No ratings yet

- Numerical MethodsDocument25 pagesNumerical MethodsSamip RegmiNo ratings yet

- Seeing Into The Soul: N Fourteenth Century IenaDocument4 pagesSeeing Into The Soul: N Fourteenth Century Ienasalveregina1917No ratings yet

- HRC - Forms - Employee Application - Rev2019 NewDocument3 pagesHRC - Forms - Employee Application - Rev2019 NewGanang CucuNo ratings yet

- Grades of NdFeB MagnetsDocument127 pagesGrades of NdFeB MagnetsjgreenguitarsNo ratings yet

- Material: ASTM A395 Ductile Iron or ASTM A105 Forged Steel: ID H TDocument1 pageMaterial: ASTM A395 Ductile Iron or ASTM A105 Forged Steel: ID H T1mmahoneyNo ratings yet