Professional Documents

Culture Documents

VPC Wiring

VPC Wiring

Uploaded by

panca nanginOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VPC Wiring

VPC Wiring

Uploaded by

panca nanginCopyright:

Available Formats

DeLaval vacuum pump controller VPC (LVP)

101 Installation

Installation

DeLaval vacuum pump controller

VPC (LVP)

1 General

Danger!

The electrical installation or any

other work on the electrical

equipment must be done by an

authorised electrician. It must

comply to any applicable rules

and regulations and supplied

wiring diagrams.

Warning!

Be sure to install, wire and

ground in compliance with rele-

vant electrical standards and

codes and in accordance with the

utility company regulations appli-

cable at the installation site.

Warning!

Make sure there is no power to

any component while wiring.

Warning!

Never operate a vacuum system

without a functioning and cor-

rectly adjusted mechanical

vacuum regulator. Failure to

comply with this may ultimately

result in poor udder health and/or

damage to vacuum system and

© DeLaval 2018.All rights reserved. 1 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

milking system.

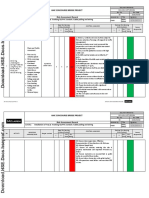

2 VPC connection guide

Note! Use cable glands P 9, for position 1-11

and cable glands PG 13.5 for position 12-14.

201382

Fig. 1: Position - Connection

1: Analog out 1 + enable cable for vacuum

pump A

2: Analog out 2 + enable cable for vacuum

pump B

3: Analog out 3 + enable cable for vacuum

pump C

4: Optional - External warning light cable

5: Temperature sensor cable for pump B

6: Clean valve cable

7: Spray valve cable

8: Temperature sensor cable for pump A

9: Temperature sensor cable for pump C

10: Vacuum sensor cable

11: Alcom-bus cable

12: Wash relay cable

13: Milk relay cable

14: Main supply cable

© DeLaval 2018.All rights reserved. 2 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

3 VPC with stand-alone variable

speed drive

3.1 Tools and supplies

The following tools and supplies are necessary:

Tools

§ 3 Allen key

§ 16 mm open-end wrench

§ 21 mm open-end wrench

§ 24 mm open-end wrench

§ 0.6 x 3.5 mm flat screwdriver

§ Wire cutter

§ Wire stripper

Check for all contents and supplies

§ Drive unit of the correct voltage and power.

The rating information is on the drive.

Manual is included.

§ SVF-VSD filter with correct phase, voltage

and power ratings.

§ VPC.

§ Pressure sensor with 30.5 m (100 feet) of

electrical cord.

§ 1.8 m (6 feet) yellow cord with end connec-

tors.

§ Three 3 m (10 feet) sections VSD to motor

power connection wire or cable.

§ 3 m (10 feet) VSD to motor ground connec-

tion wire.

Supplies not included:

§ 12 screws to mount the SVF-VSD, the drive

unit and the VPC.

§ Plastic nonmetallic conduit or plastic cov-

ered cable for all wiring to filter, drive and

motor.

Reset Current Vacuum Regulators

§ Reset the mechanical vacuum regulator

sensor to maintain vacuum, 2-3.4 kPa (0.6

to 1 Hg), greater than VSD set point.

This allows the vacuum regulators to act as

a system failsafe if the pressure sensor

signal is lost and the VSD defaults to full

© DeLaval 2018.All rights reserved. 3 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

speed.

It also sets the maximum vacuum level that will

be maintained when the VSD goes to full speed

during wash.

Install vacuum sensor

§ The vacuum sensor must be mounted at

least 10 times the diameter of the pipe

above a single sanitary trap system or any

other source of disturbance in the air flow. If

mounted in a two trap system, place the

sensor in the middle of the horizontal cros-

sover pipe.

§ Be sure to route the wire back to where the

VPC will be installed.

201392

§ Always mount the sensor vertically - use an

Fig. 2: elbow to mount the sensor into a vertical

vacuum pipe.

A: 1/4", 18 NPT

§ Always mount the sensor on plastic pipe or

B: 11 mm (7/16") with a plastic connector between sensor and

a metal pipe.

201390

Fig. 3: Use the following measures:

1: L < 10 x pipe diameter

2: 1/2 Horizontal pipe length

3.2 Install and wire drive system

© DeLaval 2018.All rights reserved. 4 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

Warning!

Make sure there is no power to

any component while wiring.

§ The distance from the drive unit to the

vacuum pump to be controlled must be less

than 3 m (10 feet).

§ Mount the drive unit at eye level on a

smooth vertical surface capable of sup-

porting it without vibration. Each fastener

must be able to hold at least 67 N

(15 pounds).

Ÿ A minimum clearance of 150 mm

(6 inches) should be maintained around

all sides of the drive unit.

§ Select overcurrent protection rated at 150%

of input current rating of the VSD at appro-

priate voltage.

3.3 Install and wire SVF-VSD filter

Mount the filter next to the drive, allowing room

for air circulation. The wires will go from the

drive, to the filter, to the motor.

Use separate rigid nonmetallic conduits or plas-

tic covered cable to bring wires to the drive and

from drive to filter.

Note! No lightning, line reactor or power factor

correction technology can be installed together

with the SVF-VSD Filter.

Minimum distance between power and control

wiring is 3” and in separate conduit or cable.

For wiring of input and output of the SVF-VSD

filter use copper conductors, 600 V, 105 ºC

(221 ºF) with stranded wire. The gauge of the

bonding/earth wire conductor is determined by

electrical codes. It must be insulated.

Refer to manual supplied with SVF-VSD filter

for more details about installation.

© DeLaval 2018.All rights reserved. 5 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

3.4 Install and wire drive system

201394

Fig. 4: Complete power wiring

1: Free space around 150 mm (6 inches).

2: Ground (PE).

3: 3-phase connection only.

4: Plastic rigid or flexible conduit.

5: 3-phase motor.

6: SVF-VSD filter PE.

7: Disconnect (required).

8: Fuse power supply.

© DeLaval 2018.All rights reserved. 6 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

9: Ground (PE). These MUST be followed to ensure NO

Drive damage occurs:

§ Do NOT connect incoming AC power to T1,

T2 , or T3.

§ Wire voltage ratings: 600 V stranded copper.

§ Wire gauge must be based on minimum of

150% of the rated output current of the drive

and 105 ºC (221 ºF) insulation rating, UL

THHN; CSA or CE listed and approved wire,

copper wire only, less than 20 strands.

§ Do not mount above a heat source such as

another drive.

§ Do not use power correction capacitors be-

tween drive and motor.

Do not install any contactors between the drive

and motor.

§ Complete the included SVF-VSD Filter

installation instructions.

§ Complete the drive system wiring according

to the VSD complete power wiring diagram.

Be sure to install, wire and ground in

accordance with applicable codes.

Ÿ Use only the provided THHN type wire

between the motor and drive.

Ÿ Do not extend the length of the motor

wire provided.

VSD Control Terminal Connection

VSD function description VSD/VPC cord wire colour

Stop/run signal Red/black

Circuit common Green

Slave speed return Red/yellow

Connected to 12 A NA

Connected to 2 NA

Connected to chassis ground and 2 NA

Connected to chassis ground and 13 A NA

VSD output relay Water valve function VSD/VPC cord wire colour

16 Normally open Water valve

17 Common Red

NA Water valve Red/white

© DeLaval 2018.All rights reserved. 7 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

§ Connections to water valve for LVP are

made in the drive (VSD) unit box. The NO

output relay for the drive is closed when that

drive is running LVP. This enables cleaning

output from VPC to be connected to the

water valve when that LVP is running. Install

water valve directly on vacuum pump inlet

replacing manual cleaning tube. Connect

water valve cable to valve using two flat

connectors.

§ Connect the vacuum sensor to the VPC.

Use connection guide to locate entrance

position (10) for the cable to VPC. See

chapter Diagram for installing the cable wire

to VPC.

§ Mount temperature sensor clamp to metal

pipe between vacuum pump head and si-

lencer, as close as possible to vacuum

pump head. Screw temperature sensor into

pipe bushing. Snap temperature sensor

cable connector into temperature sensor

body. Use connection guide to locate en-

trance position (5, 8, and 9) for cable to

VPC. See chapter Diagram for installing

temperature sensor A, B and C to VPC.

§ Connect VSD control cable (5 pin) between

each VSD and the analog out connection for

vacuum pump A, B and C in VPC. The cable

receptacle must be installed in the VPC at

the correct position (1, 2, and 3) shown in

the connection guide. See chapter Diagram

for connecting to VPC.

§ VPC accepts a signal (115 V or 230 V) from

wash or system controller. Run signal cable

through position 13 in VPC, see chapter for

connection to VPC.

VPC can be programmed for a different vacuum

level during wash/CIP function. Connect a wash

relay signal cable (115 V or 230 V) from wash

controller to VPC at correct position (12) shown

in connection guide. See chapter Diagram for

connections to VPC.

§ Connect 220 V single phase power supply

for VPC through correct position (14) shown

in connection guide. See chapter Diagram

© DeLaval 2018.All rights reserved. 8 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

for connections to VPC.

201378

Fig. 5:

3.5 Wire the VPC for LVP

B B1(A) VSD (A)

B2(B) VSD (B)

B3(C) VSD (C)

D D1 Water valve (A)

D2 Water valve (B)

D3 Water valve (C)

© DeLaval 2018.All rights reserved. 9 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

201397

Fig. 6:

E Warning light

F F1 Temperature sensor (A)

F2 Temperature sensor (B)

F3 Temperature sensor (C)

© DeLaval 2018.All rights reserved. 10 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

From To

VPC (A): X17 - 2 Vacuum sensor (C): signal output, black

VPC (A): X17 - 3 Vacuum sensor (C): power, red

VPC (A): X16 - 11 VSD B1= 2 (green wire - crimp with X18-11)

VPC (A): X16 - 12 VSD B1= 5 A (red/yellow wire) - speed reference

VPC (A): X18 - 11 VSD B1 = 2 (green wire – crimp with X16-11)

VPC (A): X18 - 12 VSD B1 = (red/black wire) - run/stop signal

VPC (A): X16 - 9 VSD B2= 2 (green wire - crimp with X18-9)

VPC (A): X16 - 10 VSD B2= 5 A (red/yellow wire) - speed reference

VPC (A): X18 - 9 VSD B2= 2 (green wire - crimp with X16-9)

VPC (A): X18 - 10 VSD B2= 1 (red/black wire) - run/stop signal

VPC (A): X16 - 7 VSD B3= 2 (green wire - crimp with X18-7)

VPC (A): X16 - 8 VSD B3= 5 A (red/yellow wire) - speed reference

VPC (A): X18 - 7 VSD B3= 2 (green wire - crimp with X16-7)

VPC (A): X18 - 8 VSD B3= 1 (red/black wire) - run/stop signal

VPC (A): X17 - 11 Temperature sensor F1

VPC (A): X17 - 10 Temperature sensor F1

VPC (A): X17 - 8 Temperature sensor F2

VPC (A): X17 - 7 Temperature sensor F2

VPC (A): X17 - 5 Temperature sensor F3

VPC (A): X17 - 4 Temperature sensor F3

VPC (A): X16 - 4 Jumper to X18-6

VPC (A): X18 - 5 VSD B1,B2,B3: red/white to water valve (D1,D2,D3)

VPC (A): X16 - 3 VSD B1,B2,B3: 17 (red wire)

VPC (A): X16 - 6 Jumper to X18-2

VPC (A): X18 - 1 Warning light (+) E

VPC (A): X16 - 5 Warning light (-) E

VPC (A): X21 - 1 190-250 VAC N/L2

VPC (A): X21 - 2 190-250 VAC L/L1

VPC (A): X33 - 1 Optional If no Alcom bus; apply 230 VAC washing signal neutral N from

cleaning unit. For 120 VAC signal connect jumper at X14

VPC (A): X33 - 2 Optional If no Alcom bus; apply 230 VAC washing signal from cleaning unit.

For 120 VAC signal connect jumper at X14

© DeLaval 2018.All rights reserved. 11 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

VPC (A): X35 - 1 If no Alcom bus; apply 230 VAC milking signal neutral N from

cleaning unit. For 120 VAC signal connect jumper at X12

VPC (A): X35 - 2 If no Alcom bus; apply 230VAC milking signal from cleaning unit.

For 120VAC signal connect jumper at X12

VPC (A): X16 - 1 Alcom bus (if applicable)

VPC (A): X16 - 2 Alcom bus (if applicable)

VPC chassie ground: PE PE (ground)

4 Input / output connections

201399

Fig. 7:

Socket group Terminal Description

© DeLaval 2018.All rights reserved. 12 (13)

Printout from Memoviewer 3/8/2018.

DeLaval vacuum pump controller VPC (LVP)

101 Installation

A Chassi ground PE

X16 1, 2 Alcom bus

X16 3, 5, 7, 9, 11 Common ground

X16 4, 6 DC power supply +12 VDC, 0.5 A

X16 8 Analog output 0 to +10 VDC, pump C to VSD

X16 10 Analog output 0 to +10 VDC, pump B to VSD

X16 12 Analog output 0 to +10 VDC, pump A to VSD

X17 1, 4, 7, 10 Common ground

X17 2 Analog input signal 0-12 VDC / 4-20 mA, vacuum sensor

X17 3 Input device supply +12 VDC, 0.5 A, vacuum sensor

X17 5 Analog input signal from temperature sensor for pump C,

0-10 VDC / 4-20 mA / 0-35 kOhm

X17 8 Analog input signal from temperature sensor for pump B,

0-10 VDC / 4-20 mA / 0-35 kOhm

X17 11 Analog input signal from temperature sensor for pump A,

0-10 VDC / 4-20 mA / 0-35 kOhm

X17 6, 9, 12 Input device supply +12 VDC, 0.5 A

X18 1, 3, 5, 7, 9, 11 Output relay, 0-24 V, position 1

X18 2, 4, 6, 8, 10, 12 Output relay, 0-24 V, position 2

X21 1 Power in 190-250 VAC N/L2

X21 2 Power in 190-250 VAC L/L1

X33 and X14 1-2 Input wash relay 100-130 VAC (with jumper X14) /

190-250 VAC (no jumper)

X34 and X13 1-2 Input idle relay 100-130 VAC (with jumper X13) / 190-250 VAC

(no jumper)

X35 and X12 1-2 Input milk relay 100-130 VAC (with jumper X12) / 190-250 VAC

(no jumper)

© DeLaval 2018.All rights reserved. 13 (13)

Printout from Memoviewer 3/8/2018.

You might also like

- VDR G4 Manual Steinsohn PDFDocument185 pagesVDR G4 Manual Steinsohn PDFVariya Dharmesh100% (1)

- VPC & VSD SetupDocument15 pagesVPC & VSD Setuppanca nanginNo ratings yet

- Manual Te 805 EnuDocument11 pagesManual Te 805 EnuMutu Daniel100% (2)

- Operating Instructions DVD Recorder Model No. DMR-EZ17Document72 pagesOperating Instructions DVD Recorder Model No. DMR-EZ17fmick576847No ratings yet

- 1027 Electrical QualityManualSampleDocument21 pages1027 Electrical QualityManualSampleT suresh100% (1)

- Network CablesDocument42 pagesNetwork CablesEL Rodolfo Idio IINo ratings yet

- BTC User Manual PDFDocument78 pagesBTC User Manual PDFLuis AlvarezNo ratings yet

- ssp3117b-1 1-3k SORODocument32 pagesssp3117b-1 1-3k SOROPaul Abi Najem100% (2)

- Installation and Operation Manual: 701 Digital Speed Control For Reciprocating EnginesDocument70 pagesInstallation and Operation Manual: 701 Digital Speed Control For Reciprocating EnginesS M NaveedNo ratings yet

- Epg - Sota - Renr7902 - 00 - Proof - Emcp3 - March 04Document100 pagesEpg - Sota - Renr7902 - 00 - Proof - Emcp3 - March 04Waleed AzzawiNo ratings yet

- Instruction Manual: MSA 230 Polivalent Electrofusion UnitDocument36 pagesInstruction Manual: MSA 230 Polivalent Electrofusion UnitOmar GuillenNo ratings yet

- Ac70 Manual v1 3 PDFDocument147 pagesAc70 Manual v1 3 PDFkasim leeNo ratings yet

- Jumo Itron 16Document41 pagesJumo Itron 16ngone LuangamathNo ratings yet

- NXZ (H) B、NXZ (H) M Series ATS-Catalog-2019 PDFDocument17 pagesNXZ (H) B、NXZ (H) M Series ATS-Catalog-2019 PDFMarpicoloCaesarNo ratings yet

- Auto Start & Auto Mains Failure Control Modules: GensetDocument2 pagesAuto Start & Auto Mains Failure Control Modules: GensetJan Ahmed67% (3)

- Installation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDocument32 pagesInstallation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDjebali MouradNo ratings yet

- Sprite TL ManualDocument8 pagesSprite TL ManualJuan GamboaNo ratings yet

- Vacuum Circuit-Breaker 12 - 17,5 KV ( 2500 A, 31,5 Ka) : Installation Operation Maintenance No. DRC NTV 142Document24 pagesVacuum Circuit-Breaker 12 - 17,5 KV ( 2500 A, 31,5 Ka) : Installation Operation Maintenance No. DRC NTV 142Prasad ShahNo ratings yet

- Variable Speed Pump and Drive Technical Guide: © 2011 Hayward Pool ProductsDocument50 pagesVariable Speed Pump and Drive Technical Guide: © 2011 Hayward Pool Productsrandal mcfaddenNo ratings yet

- AGS531301 en PDFDocument32 pagesAGS531301 en PDFKamillAL-akhrasNo ratings yet

- Model 8540: Instruction ManualDocument22 pagesModel 8540: Instruction ManualLaboratorio GTO Perú S.A.C.No ratings yet

- FRAKO Commicssioning and Maintenance of PFC SystemsDocument8 pagesFRAKO Commicssioning and Maintenance of PFC SystemsJose EspinozaNo ratings yet

- Installation and Operational Manual For RMUDocument44 pagesInstallation and Operational Manual For RMUJessica MathisNo ratings yet

- 9590 4002 Wired Control - Installation - Owners Ver. 6 PDFDocument32 pages9590 4002 Wired Control - Installation - Owners Ver. 6 PDFMartin StevensonNo ratings yet

- Netcontroller II For Ul864 Installation Instructions - enDocument10 pagesNetcontroller II For Ul864 Installation Instructions - enesantos151No ratings yet

- 72R-1000 - CTX O&m MX60Document18 pages72R-1000 - CTX O&m MX60Rosario ComprayventaNo ratings yet

- Installation & Maintenance Instructions: Im-Ind-536985-Revaa-Sec1Document9 pagesInstallation & Maintenance Instructions: Im-Ind-536985-Revaa-Sec1Santiago JuradoNo ratings yet

- Samsung ManualDocument144 pagesSamsung ManualZiverNo ratings yet

- TCS3000 Electronic Register Installation ManualDocument44 pagesTCS3000 Electronic Register Installation ManualDiego Meza ObregonNo ratings yet

- Installation Instructions Operator: Save These Instructions For Future Use!Document8 pagesInstallation Instructions Operator: Save These Instructions For Future Use!jabarnesNo ratings yet

- Comfort Control TAC Installation InstructionsDocument28 pagesComfort Control TAC Installation InstructionsANo ratings yet

- Switch Installation Guide: Warnings and ConsiderationsDocument4 pagesSwitch Installation Guide: Warnings and ConsiderationsAndres PARDO ARAQUENo ratings yet

- Mounting Instruction-Installation V6.2 EngDocument20 pagesMounting Instruction-Installation V6.2 EngMarkoNo ratings yet

- Pro-E English Manl PDFDocument13 pagesPro-E English Manl PDFYeferson Mauricio Rodriguez RodriguezNo ratings yet

- TTR Raan NS Sffeer R Ee Q QU Uiip PM Meen NTT Ffo OR R P PO OR Rttaab Bllee G Geen Neer Raatto OR RS SDocument14 pagesTTR Raan NS Sffeer R Ee Q QU Uiip PM Meen NTT Ffo OR R P PO OR Rttaab Bllee G Geen Neer Raatto OR RS SPj SolomonNo ratings yet

- Pro-E Series: User's ManualDocument13 pagesPro-E Series: User's Manualjeferson mauricio rodriguez rodriguezNo ratings yet

- FC 300 DanfossDocument100 pagesFC 300 Danfossiman sulaemanNo ratings yet

- Pro-E English Manl PDFDocument13 pagesPro-E English Manl PDFSimón HincapiéNo ratings yet

- RX-V765 Owner's ManualDocument160 pagesRX-V765 Owner's ManualDillan TimpanyNo ratings yet

- Manual Trava Dog (Unificado)Document2 pagesManual Trava Dog (Unificado)Jorge Daniel OrtaNo ratings yet

- KRF-V8030D VR-409: Instruction ManualDocument42 pagesKRF-V8030D VR-409: Instruction ManualsportistaNo ratings yet

- MWTU 11 ServiceDocument32 pagesMWTU 11 ServiceIain JubbNo ratings yet

- SMART-STAT-II Remote Control Kits: FCC RequirementsDocument10 pagesSMART-STAT-II Remote Control Kits: FCC RequirementsMike McCoy RPTNo ratings yet

- 3tr006576hda WJ-NV200K Ig 1421221641Document102 pages3tr006576hda WJ-NV200K Ig 1421221641บัณฑิตย์ จันทร์ทาNo ratings yet

- 90-879172243 - 4c - Sistema ElectricoDocument14 pages90-879172243 - 4c - Sistema ElectricoJorge SoberanoNo ratings yet

- FC300 OperatingInstructions MG33AJ02 PDFDocument89 pagesFC300 OperatingInstructions MG33AJ02 PDFyudiar djamaldilliahNo ratings yet

- TLX ReferenceManual GBDocument116 pagesTLX ReferenceManual GBcarl clarkNo ratings yet

- Techrite Siemens Siemens Lme Series Burner Controls 013060320901Document28 pagesTechrite Siemens Siemens Lme Series Burner Controls 013060320901Kang KamalNo ratings yet

- Installation Manual 1VDD005976 GB - Rev December 2015Document41 pagesInstallation Manual 1VDD005976 GB - Rev December 2015maruf048100% (1)

- Constant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENDocument28 pagesConstant Running Hydraulic Pump (E12171, E12172) Installation Instructions 87039-3-ENPanificados MarielaNo ratings yet

- ESC Hobby King PDFDocument2 pagesESC Hobby King PDFWahyuUlyaNo ratings yet

- 2412B 2412THB 2424 2424TH Manual I56-0286Document4 pages2412B 2412THB 2424 2424TH Manual I56-0286HanganovNo ratings yet

- Operating Instructions: VLT Automationdrive FC 300Document95 pagesOperating Instructions: VLT Automationdrive FC 300Đỗ TrìnhNo ratings yet

- Note To Spec. Writer: This System Must Be Only Installed On Bushings That HaveDocument6 pagesNote To Spec. Writer: This System Must Be Only Installed On Bushings That HaveRisdian Tetap OutsiderNo ratings yet

- TDR1000/3 TDR1000/3P CFL510G TDR500/3 Time Domain ReflectometersDocument28 pagesTDR1000/3 TDR1000/3P CFL510G TDR500/3 Time Domain Reflectometershernandez.josedomingo6804No ratings yet

- 34 Series Quick ManualDocument8 pages34 Series Quick ManualFrancisco GalindoNo ratings yet

- Sharp Lc-32le244e SMDocument38 pagesSharp Lc-32le244e SMIonel SimaNo ratings yet

- Sharp LC-32L400M Service ManualDocument70 pagesSharp LC-32L400M Service ManualNugroho100% (1)

- Im Avl Smy11enDocument1 pageIm Avl Smy11enNassar Al-shabiNo ratings yet

- Amcx24-Mft: Modulating, Non-Spring Return, 24 V, Multi-Function Technology®Document3 pagesAmcx24-Mft: Modulating, Non-Spring Return, 24 V, Multi-Function Technology®cafmp3No ratings yet

- Pages From IrrigationDesignManualDocument7 pagesPages From IrrigationDesignManualalaa sadikNo ratings yet

- Precautions FCC Information: InstructionsDocument2 pagesPrecautions FCC Information: InstructionsjwrbensonNo ratings yet

- ESD User ManualDocument58 pagesESD User ManualRamesh darwin100% (1)

- 3124141Document64 pages3124141subasratnaNo ratings yet

- Man pr6207 Inst en 949905317400Document44 pagesMan pr6207 Inst en 949905317400EngWadahSalihNo ratings yet

- Rig Inspection ChecklistDocument19 pagesRig Inspection ChecklistMuhammad UzairNo ratings yet

- RA For Cable Pulling and WiringDocument11 pagesRA For Cable Pulling and Wiringnikhilsingh1087No ratings yet

- Operating Manual TR1200IPDocument21 pagesOperating Manual TR1200IPFelipe Gallardo CatrilNo ratings yet

- Wilo-Star RS, RSD: Pioneering For YouDocument136 pagesWilo-Star RS, RSD: Pioneering For YouKirill KNo ratings yet

- LSZHDocument8 pagesLSZHMOSBAHISOUHAIEBNo ratings yet

- CS7-IR Test Report For Electrical DrumsDocument1 pageCS7-IR Test Report For Electrical DrumsAbdullah Al-ObaidyNo ratings yet

- Multiorganics 50 KLDDocument24 pagesMultiorganics 50 KLDArjun KrishnakumarNo ratings yet

- Gensys Compact Mains en Technical Documentation E2019 PDFDocument249 pagesGensys Compact Mains en Technical Documentation E2019 PDFRic RioNo ratings yet

- GVK General PDFDocument76 pagesGVK General PDFRahmat BudiNo ratings yet

- 25 SQDocument2 pages25 SQelectric locoNo ratings yet

- Iec 61238Document46 pagesIec 61238RamNo ratings yet

- Microcut HSTD ManualDocument25 pagesMicrocut HSTD ManualPedro IsmaelNo ratings yet

- Item Description Unit Qty 1 Turbine & AuxiliariesDocument4 pagesItem Description Unit Qty 1 Turbine & AuxiliariesPritam SinghNo ratings yet

- Advantages of HVDC Over AC TransmissionDocument3 pagesAdvantages of HVDC Over AC TransmissionHrishi MauryaNo ratings yet

- CMMB-SY 2017-05 8068715g1Document92 pagesCMMB-SY 2017-05 8068715g1jampukNo ratings yet

- Power Cable Technology ReviewDocument11 pagesPower Cable Technology Reviewtees220510No ratings yet

- Catalogo Burndy Telecommunications ProductsDocument66 pagesCatalogo Burndy Telecommunications ProductsGregor RojasNo ratings yet

- Module: Anglais Technique Text 01Document2 pagesModule: Anglais Technique Text 01Mustapha BerbariNo ratings yet

- Can-Am-WARN Winch Installation instructions-RT25-RT30Document16 pagesCan-Am-WARN Winch Installation instructions-RT25-RT30rick.mccort2766No ratings yet

- ZORS95TF55Document2 pagesZORS95TF55Nicu PuscasNo ratings yet

- Lesson 1 Eim 10Document17 pagesLesson 1 Eim 10stfup zeliaNo ratings yet

- DT436 500 Sq. MM PDFDocument3 pagesDT436 500 Sq. MM PDFHamedObaidNo ratings yet

- 132kV Cable Schedule - Rev.2Document28 pages132kV Cable Schedule - Rev.2Bilal JavaidNo ratings yet

- Documentacion Tecnica Del Modulo de ProteccionDocument110 pagesDocumentacion Tecnica Del Modulo de ProteccionmasanmartinfNo ratings yet

- 1363-2 Manual Ph-Ec TransmitterDocument4 pages1363-2 Manual Ph-Ec TransmitterGustavo Gonzalez ToledoNo ratings yet