Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

10 viewsShoot Crossbow

Shoot Crossbow

Uploaded by

Labriss LabrissCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LG HB2 MSDSDocument7 pagesLG HB2 MSDSLabriss LabrissNo ratings yet

- A3290081Document1 pageA3290081Labriss LabrissNo ratings yet

- A 3290045Document1 pageA 3290045Labriss LabrissNo ratings yet

- A3290053Document1 pageA3290053Labriss LabrissNo ratings yet

- A 3290077Document1 pageA 3290077Labriss LabrissNo ratings yet

- A3290079Document1 pageA3290079Labriss LabrissNo ratings yet

- A 3290074Document1 pageA 3290074Labriss LabrissNo ratings yet

- A3290064Document1 pageA3290064Labriss LabrissNo ratings yet

- A 3290071Document1 pageA 3290071Labriss LabrissNo ratings yet

- A3290070Document1 pageA3290070Labriss LabrissNo ratings yet

- A 3290052Document1 pageA 3290052Labriss LabrissNo ratings yet

- A 3290031Document1 pageA 3290031Labriss LabrissNo ratings yet

- A 3290041Document1 pageA 3290041Labriss LabrissNo ratings yet

- A3290034Document1 pageA3290034Labriss LabrissNo ratings yet

- A 3290043Document1 pageA 3290043Labriss LabrissNo ratings yet

- A 3290006Document1 pageA 3290006Labriss LabrissNo ratings yet

- A 3290003Document1 pageA 3290003Labriss LabrissNo ratings yet

- A 3290004Document1 pageA 3290004Labriss LabrissNo ratings yet

- Aa RRDocument1 pageAa RRLabriss LabrissNo ratings yet

- A 3290005Document1 pageA 3290005Labriss LabrissNo ratings yet

- FullDocument1 pageFullLabriss LabrissNo ratings yet

- A 3200046Document1 pageA 3200046Labriss LabrissNo ratings yet

- Shoot Harpoon GunDocument2 pagesShoot Harpoon GunLabriss LabrissNo ratings yet

- Misc PartsDocument1 pageMisc PartsLabriss LabrissNo ratings yet

- Xiaomi Dual Motor V1.1Document1 pageXiaomi Dual Motor V1.1Labriss LabrissNo ratings yet

- Shoot Two LongbowsDocument2 pagesShoot Two LongbowsLabriss LabrissNo ratings yet

Shoot Crossbow

Shoot Crossbow

Uploaded by

Labriss Labriss0 ratings0% found this document useful (0 votes)

10 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views4 pagesShoot Crossbow

Shoot Crossbow

Uploaded by

Labriss LabrissCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 4

Hunter's

Crossbow

This old-

power and accuracy of a modern rifle.

¢ weapon has the hitting

By E. Milton Grassell

HIS crossbow, with all the romance and

charm of a medieval weapon, is so power-

ful and accurate that it is used extensively for

hunting and precision target shooting. It’s

a deadly weapon, not a toy, exceptionally fine

for hunting rabbits, pheasants, squirrels, and

even capable of killing big game like deer,

elk, antelope, and cougar when used by one

skilled in its handling. Therefore it is most

imperative that the crossbow be handled care-

fully. Never hold it in a position where it

might endanger anyone if fired accidently,

and always reckon with the area beyond the

target or game in the event you should miss

hitting the object aimed at.

A similar crossbow would cost from $50 up

commercially, but the total cost, if you make

it, should not exceed $7.50, providing there

are a few scrap hardwood pieces, a dab of

lacquer, welding rod and some other common

materials around your workshop.

Sold on making one? Okay, here's how

Mr. Chester Stevenson of Eugene, Ore., makes

his most popularly demanded crossbow, and

Mechanix Illustrated

Photon by Frances H Sebults

‘The proper method of cocking the crossbow with a

bolt in firing position. As shown here, practice

cocking without a belt until you acquire skill.

eee

Se ourer

Pare

ep Loc remeotces

eed wen Clk

BUNT wer

ee ra

HUNTING BOLTS TO 19" TARGET BOUTS 14°10 15

how you, too, can become a jet-age Robin

Hood with this powerful weapon.

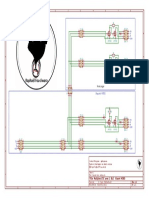

‘On crossbows, the “barrel” is included in

the stock piece.” If you don’t have a hard-

wood board about 114x8x36-in., glue scrap

pieces together. This works just as well.

In fact, the whole design can be modified,

providing the draw (14-in, from the back

of the bow to the trigger release latch) and

the trigger unit are not altered. Follow the

drawings and you'll have no trouble mak~

ing any parts of the crossbow.

Alter cutting the general contour, a re-

cess is chiseled in the stock for the trigger

assembly. Between this and the end of

the barrel, make a kerf (a bolt groove)

approximately ;yx'%-in, deep down the

center, Sandpaper is used to make the

¥%-in. chamfer on both edges of the bolt

groove,

‘The unique trigger, modified by Mr.

Stevenson, will fire the bolt with approxi-

mately the same finger pressure used to

shoot an ordi- [Continued on page 196]

Making bolts is largely a matier of

assembling stock items obicined

from archery supply houses,

Shown hore are: AA—blunt points

for small game, BB—target points,

CC—big game points. X—shaft,

Y—trimmed feathers, and DD—

« fully assembled hunting bolt.

Meciranix Illustrated

Wexwe xd NOx saextve'x 3 THe REST

BOT COVER” SCREWS (2) _/WHEN COCHRG BORGTRING

NO6- SCREW

a

a We

SM anmosa ecaneoms ALE Ns

50 YARDS, ETC.

bs

NOTCH FoR 30, 20,

i

tea AEE EEEEEEEEY

Gry Ese

STRING CATCH.

20M) AND TRIGGER

FROM METAL OR FER SHEET

December, 1953 123°

Hunter’s Crossbow

[Continued from page 122]

nary rifle, when the release latch is cocked

with a 75-pound pressute.

The trigger guard, made from No. 16 gauge

brass, 4x6-in., is bent and fastened with three

No. 6 half-inch roundhead brass screws.

When hunting, you will probably aim along

the bolt, but sights are preferable for target

shooting. The peep sight shown in the photos,

made from %xlxl-in. brass scrap, is ex-

tremely precise, yet it can be made with three

drills (1/64, %, and %-in.), a hacksaw and

afile. It has both vertical and horizontal ad-

justments which are held with lock screws

(see drawing).

bow attachment assembly is the

weakest part of the stock assembly. There-

fore, two %-in. thick strips are used to

reinforce this area. You can machine the

required combination screw-bolts, and the

fancy knurled lock nuts, but it's simpler to

buy two closet screws from the neighborhood

plum!

There are two other parts to this unit—a

wedge-shaped block, and the bow lock plate,

used to hold the bow securely in place.

‘The bow has two unusual features: (1) the

¥Y%x2x36-in. solid stave (either yew wood or

* osage orange), and the Fiberglas, when cut

according to plan, requires no tillering, and

(2) the reverse curve gives added speed.

That's the reason this crossbow has jet-like

power.

Don’t let the steaming and reverse curve

bending worry you. It’s really simple, as the

photos show. You can make a steam pot from

old brake drums and a piece of pipe, as shown

in drawing. The strap metal bending jig is

also easy to make.

Take the measurement of the finished bow

from nock to nock and order:a bow string

from an archery supply firm. Today, archery

supply houses also sell arrow shafts, piles

(points), ground feathers, and other acces-

sories that practically reduce bolt making to

an assembling and finishing job.

Order several ‘-in. straight 30-in. shafts.

Since bolts are shorter than long bow arrows,

these can be cut so as to make two bolts from

each shaft.

If you purchase slip-over type points, no

tenon is necessary on the shaft. This further

simplifies bolt making.

Before fletching the shaft, finish it with dip-

ping or brushing lacquer. Never use varnish

on target bolts. Friction causes the shaft to

heat when it penetrates straw targets and the

varnish blisters.

Either right or left wing turkey feathers

can be used, providing they are the same on

196

any one arrow. The feathers can be trimmed

with scissors. Place them in a fletching jig

(these sell from $1.50 up with directions in-

cluded) and glue them on the shaft with

household cement. When fletching shafts

with broadhead points, be sure the- cock

feather and the vertical surface of the broad-

head are in the same plane. (See drawing.)

‘The nock, customarily found on arrows, is

not used on bolts. Nothing is done to the

rear of the shaft. Before you load the cross-

bow with a bolt, try cocking it a few times, ©

as shown in photo, until you have developed

a real feel for the job. ©

BILL OF MATERIALS

1 Wrasse” hardwood stock (including

)

Vaal" x2fa”

ante

10 wire for trig-

cid

Yor20 N.C. lock nuts

iy.

SHAM"

wiry”

Mg ee

TANG RNA

plum

Ean knurl ‘your own lack

ge

ood “bow foc plate

wood w

seclvaets snd tar

ayers i welding att

es erent

lockicrew for peep sight

wind gauge

adjustment on sights

Hteam pot

bending jig

Fiberglan, 2 of 3-pl

Cecily Bloch to bil bow

te sia when it fits In slot

in Hock

few or otage orange wood

Ir tip from for clamps

innertubs

The

Port Orford Cedar belt

shalt

turkey feathers

fletching lig

December, 1953

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LG HB2 MSDSDocument7 pagesLG HB2 MSDSLabriss LabrissNo ratings yet

- A3290081Document1 pageA3290081Labriss LabrissNo ratings yet

- A 3290045Document1 pageA 3290045Labriss LabrissNo ratings yet

- A3290053Document1 pageA3290053Labriss LabrissNo ratings yet

- A 3290077Document1 pageA 3290077Labriss LabrissNo ratings yet

- A3290079Document1 pageA3290079Labriss LabrissNo ratings yet

- A 3290074Document1 pageA 3290074Labriss LabrissNo ratings yet

- A3290064Document1 pageA3290064Labriss LabrissNo ratings yet

- A 3290071Document1 pageA 3290071Labriss LabrissNo ratings yet

- A3290070Document1 pageA3290070Labriss LabrissNo ratings yet

- A 3290052Document1 pageA 3290052Labriss LabrissNo ratings yet

- A 3290031Document1 pageA 3290031Labriss LabrissNo ratings yet

- A 3290041Document1 pageA 3290041Labriss LabrissNo ratings yet

- A3290034Document1 pageA3290034Labriss LabrissNo ratings yet

- A 3290043Document1 pageA 3290043Labriss LabrissNo ratings yet

- A 3290006Document1 pageA 3290006Labriss LabrissNo ratings yet

- A 3290003Document1 pageA 3290003Labriss LabrissNo ratings yet

- A 3290004Document1 pageA 3290004Labriss LabrissNo ratings yet

- Aa RRDocument1 pageAa RRLabriss LabrissNo ratings yet

- A 3290005Document1 pageA 3290005Labriss LabrissNo ratings yet

- FullDocument1 pageFullLabriss LabrissNo ratings yet

- A 3200046Document1 pageA 3200046Labriss LabrissNo ratings yet

- Shoot Harpoon GunDocument2 pagesShoot Harpoon GunLabriss LabrissNo ratings yet

- Misc PartsDocument1 pageMisc PartsLabriss LabrissNo ratings yet

- Xiaomi Dual Motor V1.1Document1 pageXiaomi Dual Motor V1.1Labriss LabrissNo ratings yet

- Shoot Two LongbowsDocument2 pagesShoot Two LongbowsLabriss LabrissNo ratings yet