Professional Documents

Culture Documents

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Uploaded by

Yasmin RedaCopyright:

Available Formats

You might also like

- SAT PhysicsDocument25 pagesSAT PhysicsEric D'SouzaNo ratings yet

- 85-218-Lab 2-ManualDocument5 pages85-218-Lab 2-Manualjoseph0% (1)

- Mechanics of Metal Cutting: Tool EngineeringDocument26 pagesMechanics of Metal Cutting: Tool EngineeringChen WANYINGNo ratings yet

- Exp 4 Effect of Rake Angle in Orthogonal MachiningDocument1 pageExp 4 Effect of Rake Angle in Orthogonal MachiningYasmin RedaNo ratings yet

- Evaluating of Cutting Forces in Thread MachiningDocument12 pagesEvaluating of Cutting Forces in Thread MachiningFlorin MilasNo ratings yet

- Metal Cutting TheoryDocument8 pagesMetal Cutting TheorySheetal SoniNo ratings yet

- Orthogonal Machining PDFDocument6 pagesOrthogonal Machining PDFManideep AnanthulaNo ratings yet

- Chapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormDocument12 pagesChapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormkidusNo ratings yet

- 2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnDocument6 pages2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnJesus Ismael Jimenez GarciaNo ratings yet

- Design AspectsDocument8 pagesDesign Aspectsprateekverma07No ratings yet

- Production EnggDocument41 pagesProduction EnggRinne UchihaNo ratings yet

- Comprehensive Simulation of Surface Texture For An End-Milling ProcessDocument8 pagesComprehensive Simulation of Surface Texture For An End-Milling Processirinuca12No ratings yet

- Lecture-2.Conventional Machining - 2018 PDFDocument80 pagesLecture-2.Conventional Machining - 2018 PDFSaumya ShahNo ratings yet

- SHEETSDocument13 pagesSHEETSXHaMzAXNo ratings yet

- Modeling and Simulation of The Orthogonal Cut by Using The Law of DamageDocument4 pagesModeling and Simulation of The Orthogonal Cut by Using The Law of DamageHayderyNo ratings yet

- Yusuf Altintas-Cutting Mechanics and Mechanistic ModellingDocument15 pagesYusuf Altintas-Cutting Mechanics and Mechanistic ModellingsinabirecikNo ratings yet

- 05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsDocument7 pages05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsAli KhalfallahNo ratings yet

- CIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavaDocument4 pagesCIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavarajeshNo ratings yet

- Merchant's Circle NotsDocument5 pagesMerchant's Circle NotsSaravanan MathiNo ratings yet

- cobaCES53 56 2018 3Document8 pagescobaCES53 56 2018 3miltoncobaNo ratings yet

- Lect 9Document19 pagesLect 9SAMARTH TIWARINo ratings yet

- 2nd Btech MECH 2021-22 MCMT Ses-K4 PDFDocument14 pages2nd Btech MECH 2021-22 MCMT Ses-K4 PDFGopi TNo ratings yet

- 2014ijetae 0114 01Document6 pages2014ijetae 0114 01Sc PhamNo ratings yet

- Sheet Metal Bending-3Document15 pagesSheet Metal Bending-3Sai Sujan100% (1)

- Direct Shear and Punching TestDocument3 pagesDirect Shear and Punching TestAdil Javed Chaudhary100% (1)

- Cutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and WorkpieceDocument7 pagesCutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and Workpiecematic91No ratings yet

- CH 3Document10 pagesCH 3alsltanyhasanNo ratings yet

- Deep Drawing Analysis by Using Explicit Dynamics in Ansys WorkbenchDocument8 pagesDeep Drawing Analysis by Using Explicit Dynamics in Ansys Workbenchsunhell1611No ratings yet

- MCTD MannualDocument67 pagesMCTD MannualcoolarunsmartNo ratings yet

- MCT D ManualDocument25 pagesMCT D ManualAmit KumarNo ratings yet

- A Study On The Tool Edge Geometry Effect On Nano-Cutting: Original ArticleDocument11 pagesA Study On The Tool Edge Geometry Effect On Nano-Cutting: Original ArticleDavid MNo ratings yet

- Force: 'A' TwoDocument11 pagesForce: 'A' TwoApaar PandeyNo ratings yet

- Machining Forces and Merchant's Circle Diagram (MCD)Document40 pagesMachining Forces and Merchant's Circle Diagram (MCD)AswinNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Tribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoDocument13 pagesTribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoAnonymous gM6RZL5lYdNo ratings yet

- Articulo Corte OrtogonalDocument14 pagesArticulo Corte OrtogonalCinthia Morales RendonNo ratings yet

- M. Fontaine, A. Devillez, A. Moufki, D. DudzinskiDocument14 pagesM. Fontaine, A. Devillez, A. Moufki, D. DudzinskiOscar RamónNo ratings yet

- Analysis and Prediction of Cutting Force Through Lathe Tool Dynamometer in CNC Turning ProcessDocument6 pagesAnalysis and Prediction of Cutting Force Through Lathe Tool Dynamometer in CNC Turning ProcessfaizanNo ratings yet

- Unit 2 Theory of Metal CuttingDocument51 pagesUnit 2 Theory of Metal CuttingKranium ANo ratings yet

- Figure 1 Orthogonal Forces Cutting ModelDocument10 pagesFigure 1 Orthogonal Forces Cutting ModelAnonymous AqiKhuzSbNo ratings yet

- A Numeric Investigation of The Rake Face Stress Distribution in Orthogonal MachiningDocument6 pagesA Numeric Investigation of The Rake Face Stress Distribution in Orthogonal MachiningArul KirubakaranNo ratings yet

- Dsedfef OjojeoDocument7 pagesDsedfef OjojeoMZSHBNo ratings yet

- Effect of Cutting Condition Toward Chips Thickness Ratio On Steel Shaft TurningDocument4 pagesEffect of Cutting Condition Toward Chips Thickness Ratio On Steel Shaft TurningAgeng TaslimNo ratings yet

- J JSV 2012 10 035Document13 pagesJ JSV 2012 10 035sundaramaks saravana muruganNo ratings yet

- Lecture-04-Mechanics of Metal CuttingDocument33 pagesLecture-04-Mechanics of Metal CuttingAkoto BlessNo ratings yet

- Study On Elliptical Vibration CuttingDocument4 pagesStudy On Elliptical Vibration CuttingTran AnhNo ratings yet

- MillingDocument105 pagesMillingsai mohanNo ratings yet

- Metal Cutting Theory and MechanismDocument75 pagesMetal Cutting Theory and Mechanismnishantdubey1183No ratings yet

- Materials Lab. (0944374) Lab. Report: TotalDocument10 pagesMaterials Lab. (0944374) Lab. Report: TotalMohammed AL-MaaitahNo ratings yet

- A New Dynamic Model For Drilling and Reaming Processes Yang2002Document13 pagesA New Dynamic Model For Drilling and Reaming Processes Yang2002RihabChommakhNo ratings yet

- HW 1 DSVDocument3 pagesHW 1 DSVAnonymous 2xjDjAcZNo ratings yet

- 3 Dof With MathlabDocument9 pages3 Dof With MathlabFarhan mahmud RashikNo ratings yet

- Ch-2 Force & Power in Metal CuttingDocument43 pagesCh-2 Force & Power in Metal CuttingNimish JoshiNo ratings yet

- QSD 1976Document10 pagesQSD 1976Felipe ChagasNo ratings yet

- Experiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryDocument20 pagesExperiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryMuhammad ShahryabNo ratings yet

- Milling Wear of Carbide Tool For Processing Nickel-Based Alloy in Cryogenic Based On The Entropy ChangeDocument11 pagesMilling Wear of Carbide Tool For Processing Nickel-Based Alloy in Cryogenic Based On The Entropy ChangeRAMACHANDRAN MNITNo ratings yet

- Finite Element Simulation Using Abaqus: Internship OnDocument24 pagesFinite Element Simulation Using Abaqus: Internship OnranjithkrajNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Finite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaFrom EverandFinite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaNo ratings yet

- Exp 2 CALIBRATION OF A TWO COMPONENT CUTTING FORCE DYNAMOMETERDocument5 pagesExp 2 CALIBRATION OF A TWO COMPONENT CUTTING FORCE DYNAMOMETERYasmin RedaNo ratings yet

- Exp 1 Chip Formation ExpermentDocument2 pagesExp 1 Chip Formation ExpermentYasmin RedaNo ratings yet

- Sheet 2Document4 pagesSheet 2Yasmin RedaNo ratings yet

- Exp 5 Effect of The Application of AlubricationDocument4 pagesExp 5 Effect of The Application of AlubricationYasmin RedaNo ratings yet

- Exp 4 Effect of Rake Angle in Orthogonal MachiningDocument1 pageExp 4 Effect of Rake Angle in Orthogonal MachiningYasmin RedaNo ratings yet

- Sheet 1Document5 pagesSheet 1Yasmin RedaNo ratings yet

- Sheet 5Document2 pagesSheet 5Yasmin RedaNo ratings yet

- Sheet 4Document3 pagesSheet 4Yasmin RedaNo ratings yet

- Sheet 3Document5 pagesSheet 3Yasmin RedaNo ratings yet

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDocument7 pagesFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNo ratings yet

- MCQ - Slope and Deflection - ME Subjects - Concepts SimplifiedDocument6 pagesMCQ - Slope and Deflection - ME Subjects - Concepts SimplifiedrajkumarNo ratings yet

- Tutorial Problem Set - 3 PDFDocument3 pagesTutorial Problem Set - 3 PDFMazin AbdallaNo ratings yet

- Moment of Inertia Cone-To-Shell Junction ASME VIII, Div 1Document6 pagesMoment of Inertia Cone-To-Shell Junction ASME VIII, Div 1Julien aNo ratings yet

- HW4 SolutionsDocument7 pagesHW4 SolutionserfanghlmNo ratings yet

- Simple Modelling Using SACSDocument13 pagesSimple Modelling Using SACSLeonardo Alexandre De LucenaNo ratings yet

- CFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsDocument9 pagesCFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsNavaneeth Krishnan NairNo ratings yet

- 5e Engineering Manual Mechanics Si Solutions Statics VersionDocument2 pages5e Engineering Manual Mechanics Si Solutions Statics VersionTaetaeyaeNo ratings yet

- Class 3 - Hydraulic Models and Similitude PDFDocument11 pagesClass 3 - Hydraulic Models and Similitude PDFRana GNo ratings yet

- Exercise 1 ThermodynamicsDocument5 pagesExercise 1 ThermodynamicsJunNo ratings yet

- Design and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-MarathonDocument76 pagesDesign and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-Marathonanhelllo100% (1)

- Phys p2Document16 pagesPhys p2Kalana GamageNo ratings yet

- Tailing Lug Calculations 01Document2 pagesTailing Lug Calculations 01sammar_10No ratings yet

- Stepwise Simulation of Vacuum Transfer Line HydraulicsDocument6 pagesStepwise Simulation of Vacuum Transfer Line HydraulicsJose CantorNo ratings yet

- Aircraft Design Project-2 Eight Seater Short Range Business Jet AircraftDocument69 pagesAircraft Design Project-2 Eight Seater Short Range Business Jet AircraftVignesh Selvaraj79% (14)

- Clicker Chapter 30Document74 pagesClicker Chapter 30riffyjiffyNo ratings yet

- 5.1 FEA of Excavations and Embankment ConstructionDocument41 pages5.1 FEA of Excavations and Embankment ConstructionNaitik ShuklaNo ratings yet

- 1-3 Simple Stresses 1-3-1 Axial StressDocument32 pages1-3 Simple Stresses 1-3-1 Axial StressHazim KhalilNo ratings yet

- Vehicle Dynamics Simulation, Part 1: Mathematical Model: Iztok Ciglaric and Ivan PrebilDocument10 pagesVehicle Dynamics Simulation, Part 1: Mathematical Model: Iztok Ciglaric and Ivan PrebildeepNo ratings yet

- Aerodynamics of Road Vehicles HUCHO PDFDocument55 pagesAerodynamics of Road Vehicles HUCHO PDFigormagalhaes87100% (1)

- 1w5q Chapter 3 Dynamics of Linear MotionDocument2 pages1w5q Chapter 3 Dynamics of Linear MotionKHOO YI XIAN MoeNo ratings yet

- Design Study Seal NC NASADocument30 pagesDesign Study Seal NC NASAMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- Interaction Between Vertical and Lateral Loads On The Response of Piles in Soft ClaysDocument5 pagesInteraction Between Vertical and Lateral Loads On The Response of Piles in Soft ClaysVetriselvan ArumugamNo ratings yet

- 1.1 Energy BalanceDocument25 pages1.1 Energy BalancenandhakumarmeNo ratings yet

- 100 TOP MOST MAGNETISM and ELECTROMAGNETISM - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice Questions PDFDocument27 pages100 TOP MOST MAGNETISM and ELECTROMAGNETISM - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice Questions PDFSIVAKAMI92% (12)

- A Theoretical Rigid Body Model of Vibrating ScreenDocument16 pagesA Theoretical Rigid Body Model of Vibrating ScreenJuliana AguiarNo ratings yet

- Soil Loads On PipelinesDocument10 pagesSoil Loads On Pipelinesdicktracy11No ratings yet

- Additional MUS QuestionsDocument27 pagesAdditional MUS Questionsalma rejiNo ratings yet

- Multi-Component Acoustic Characterization of Porous Media - Karel N. Van DalenDocument182 pagesMulti-Component Acoustic Characterization of Porous Media - Karel N. Van DalenSasaNo ratings yet

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Uploaded by

Yasmin RedaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Exp 3 Effect of Speed and Feed in Orthogonal Machining

Uploaded by

Yasmin RedaCopyright:

Available Formats

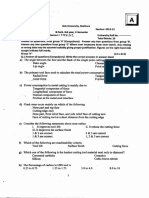

Faculty of Engineering

Mechanical Engineering Dept. 3rd Year production engineering.

Benha M1371 theory of metal cutting

University Instructor: Dr. Ashraf Hassan Laboratory

experiments.

Experiment No (3)

Effect of speed and feed in orthogonal machining

Introduction

In the machining of metals, changes in cutting speed and feed produce certain

important effects. These effects can be measured in terms of a number of parameters,

namely,

The specific cutting energy𝑷𝒔 , the work in cutting per unit volume of material

𝑭𝑪

removed, which is given by𝑷𝒔 =

𝑨𝒄

Where 𝐹𝑐 the cutting component of the resultant tool is force, and 𝑨𝒄 is the cross-

sectional area of the uncut chip.

The cutting ratio𝑟𝑐 , which is given by

𝒂𝒄

𝒓𝒄 =

𝒂𝟎

Where 𝑎𝑐 is the unreformed chip thickness, and 𝑎0 is the chip thickness

The mean angle of friction on the tool face β, which can be obtained from

𝑭𝒕

= 𝐭𝐚𝐧( 𝛃 − 𝜸𝒏𝒆 )

𝑭𝒄

Where 𝜸𝒏𝒆 is the working normal rake, and 𝑭𝒕 is the thrust component of the resultant

tool face,

The apparent sear strength of the work material 𝝉𝒔 , which is the shear stress on the

shear plane and is given by

(𝑭𝒄 𝐜𝐨𝐬 ɸ − 𝑭𝒕 𝐬𝐢𝐧 ɸ) 𝐬𝐢𝐧 ɸ

𝝉𝒔 =

𝑨𝒄

Where ɸ is the shear angle and is given by

1Page Dr. Ashraf Hassan theory of metal cutting Oct. 2021

𝒓𝒄 𝐜𝐨𝐬 𝜸𝒏𝒆

𝐭𝐚𝐧 ɸ =

𝟏 − 𝒓𝒄 𝐬𝐢𝐧 𝜸𝒏𝒆

Equipment

1. Lathe

2. tubular workpiece of 85/15 brass

3. Two-component cutting force dynamometer and necessary recording

equipment

4. High-speed steel cutting tool with a 25° normal rake

Procedure

The measurement of the thickness of the chip produced during each test can

be made with a ball micrometer if the chip is reasonably straight and has smooth

surfaces If the chip is not straight and does not have smooth surfaces, chip

thickness can be estimated by weighing a sample length of chip and using the

expression

𝒎

𝒂𝟎= 𝒄

𝝆𝒍𝒄 𝒂𝒘

𝒎𝒄 = mass of the chip sample

𝒍𝒄 = length 0f the chip sample

𝒂𝒘 =width of the chip

𝝆=density of the work material

Finally the specific cutting energy 𝒑𝒄 , the cutting ratio 𝒓𝒄 , the mean angle of

friction on the tool face β, and the apparent shear strength of the work material

𝝉𝒔 , are calculated from Eqs. Each of these factors ls

then plotted against the logarithm of the cutting speed (log V) for each value of

undeformed chip thickness𝒂𝒄 and against 𝒂𝒄 for each value of v.

2Page Dr. Ashraf Hassan theory of metal cutting Oct. 2021

You might also like

- SAT PhysicsDocument25 pagesSAT PhysicsEric D'SouzaNo ratings yet

- 85-218-Lab 2-ManualDocument5 pages85-218-Lab 2-Manualjoseph0% (1)

- Mechanics of Metal Cutting: Tool EngineeringDocument26 pagesMechanics of Metal Cutting: Tool EngineeringChen WANYINGNo ratings yet

- Exp 4 Effect of Rake Angle in Orthogonal MachiningDocument1 pageExp 4 Effect of Rake Angle in Orthogonal MachiningYasmin RedaNo ratings yet

- Evaluating of Cutting Forces in Thread MachiningDocument12 pagesEvaluating of Cutting Forces in Thread MachiningFlorin MilasNo ratings yet

- Metal Cutting TheoryDocument8 pagesMetal Cutting TheorySheetal SoniNo ratings yet

- Orthogonal Machining PDFDocument6 pagesOrthogonal Machining PDFManideep AnanthulaNo ratings yet

- Chapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormDocument12 pagesChapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormkidusNo ratings yet

- 2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnDocument6 pages2004-Deng-Finite Element Analysis of Effects of Ball Burnishing Parameters OnJesus Ismael Jimenez GarciaNo ratings yet

- Design AspectsDocument8 pagesDesign Aspectsprateekverma07No ratings yet

- Production EnggDocument41 pagesProduction EnggRinne UchihaNo ratings yet

- Comprehensive Simulation of Surface Texture For An End-Milling ProcessDocument8 pagesComprehensive Simulation of Surface Texture For An End-Milling Processirinuca12No ratings yet

- Lecture-2.Conventional Machining - 2018 PDFDocument80 pagesLecture-2.Conventional Machining - 2018 PDFSaumya ShahNo ratings yet

- SHEETSDocument13 pagesSHEETSXHaMzAXNo ratings yet

- Modeling and Simulation of The Orthogonal Cut by Using The Law of DamageDocument4 pagesModeling and Simulation of The Orthogonal Cut by Using The Law of DamageHayderyNo ratings yet

- Yusuf Altintas-Cutting Mechanics and Mechanistic ModellingDocument15 pagesYusuf Altintas-Cutting Mechanics and Mechanistic ModellingsinabirecikNo ratings yet

- 05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsDocument7 pages05 - Development of Ring Hoop Shear Test For The Mechanical Characterization of Tubular MaterialsAli KhalfallahNo ratings yet

- CIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavaDocument4 pagesCIRP Annals - Manufacturing Technology: T. O Zel, Y. Karpat, A. SrivastavarajeshNo ratings yet

- Merchant's Circle NotsDocument5 pagesMerchant's Circle NotsSaravanan MathiNo ratings yet

- cobaCES53 56 2018 3Document8 pagescobaCES53 56 2018 3miltoncobaNo ratings yet

- Lect 9Document19 pagesLect 9SAMARTH TIWARINo ratings yet

- 2nd Btech MECH 2021-22 MCMT Ses-K4 PDFDocument14 pages2nd Btech MECH 2021-22 MCMT Ses-K4 PDFGopi TNo ratings yet

- 2014ijetae 0114 01Document6 pages2014ijetae 0114 01Sc PhamNo ratings yet

- Sheet Metal Bending-3Document15 pagesSheet Metal Bending-3Sai Sujan100% (1)

- Direct Shear and Punching TestDocument3 pagesDirect Shear and Punching TestAdil Javed Chaudhary100% (1)

- Cutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and WorkpieceDocument7 pagesCutting Forces in Hard Turning Comprising Tool Flank Wear and Its Implication For The Friction Between Tool and Workpiecematic91No ratings yet

- CH 3Document10 pagesCH 3alsltanyhasanNo ratings yet

- Deep Drawing Analysis by Using Explicit Dynamics in Ansys WorkbenchDocument8 pagesDeep Drawing Analysis by Using Explicit Dynamics in Ansys Workbenchsunhell1611No ratings yet

- MCTD MannualDocument67 pagesMCTD MannualcoolarunsmartNo ratings yet

- MCT D ManualDocument25 pagesMCT D ManualAmit KumarNo ratings yet

- A Study On The Tool Edge Geometry Effect On Nano-Cutting: Original ArticleDocument11 pagesA Study On The Tool Edge Geometry Effect On Nano-Cutting: Original ArticleDavid MNo ratings yet

- Force: 'A' TwoDocument11 pagesForce: 'A' TwoApaar PandeyNo ratings yet

- Machining Forces and Merchant's Circle Diagram (MCD)Document40 pagesMachining Forces and Merchant's Circle Diagram (MCD)AswinNo ratings yet

- MC&TDDocument4 pagesMC&TDGopal Krishan0% (1)

- Tribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoDocument13 pagesTribology International: Bikash Chandra Behera, Sudarsan Ghosh, P. Venkateswara RaoAnonymous gM6RZL5lYdNo ratings yet

- Articulo Corte OrtogonalDocument14 pagesArticulo Corte OrtogonalCinthia Morales RendonNo ratings yet

- M. Fontaine, A. Devillez, A. Moufki, D. DudzinskiDocument14 pagesM. Fontaine, A. Devillez, A. Moufki, D. DudzinskiOscar RamónNo ratings yet

- Analysis and Prediction of Cutting Force Through Lathe Tool Dynamometer in CNC Turning ProcessDocument6 pagesAnalysis and Prediction of Cutting Force Through Lathe Tool Dynamometer in CNC Turning ProcessfaizanNo ratings yet

- Unit 2 Theory of Metal CuttingDocument51 pagesUnit 2 Theory of Metal CuttingKranium ANo ratings yet

- Figure 1 Orthogonal Forces Cutting ModelDocument10 pagesFigure 1 Orthogonal Forces Cutting ModelAnonymous AqiKhuzSbNo ratings yet

- A Numeric Investigation of The Rake Face Stress Distribution in Orthogonal MachiningDocument6 pagesA Numeric Investigation of The Rake Face Stress Distribution in Orthogonal MachiningArul KirubakaranNo ratings yet

- Dsedfef OjojeoDocument7 pagesDsedfef OjojeoMZSHBNo ratings yet

- Effect of Cutting Condition Toward Chips Thickness Ratio On Steel Shaft TurningDocument4 pagesEffect of Cutting Condition Toward Chips Thickness Ratio On Steel Shaft TurningAgeng TaslimNo ratings yet

- J JSV 2012 10 035Document13 pagesJ JSV 2012 10 035sundaramaks saravana muruganNo ratings yet

- Lecture-04-Mechanics of Metal CuttingDocument33 pagesLecture-04-Mechanics of Metal CuttingAkoto BlessNo ratings yet

- Study On Elliptical Vibration CuttingDocument4 pagesStudy On Elliptical Vibration CuttingTran AnhNo ratings yet

- MillingDocument105 pagesMillingsai mohanNo ratings yet

- Metal Cutting Theory and MechanismDocument75 pagesMetal Cutting Theory and Mechanismnishantdubey1183No ratings yet

- Materials Lab. (0944374) Lab. Report: TotalDocument10 pagesMaterials Lab. (0944374) Lab. Report: TotalMohammed AL-MaaitahNo ratings yet

- A New Dynamic Model For Drilling and Reaming Processes Yang2002Document13 pagesA New Dynamic Model For Drilling and Reaming Processes Yang2002RihabChommakhNo ratings yet

- HW 1 DSVDocument3 pagesHW 1 DSVAnonymous 2xjDjAcZNo ratings yet

- 3 Dof With MathlabDocument9 pages3 Dof With MathlabFarhan mahmud RashikNo ratings yet

- Ch-2 Force & Power in Metal CuttingDocument43 pagesCh-2 Force & Power in Metal CuttingNimish JoshiNo ratings yet

- QSD 1976Document10 pagesQSD 1976Felipe ChagasNo ratings yet

- Experiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryDocument20 pagesExperiment 1: Aim: Study and Practice of Orthogonal & Oblique Cutting On A Lathe. Apparatus: Lathe Machine TheoryMuhammad ShahryabNo ratings yet

- Milling Wear of Carbide Tool For Processing Nickel-Based Alloy in Cryogenic Based On The Entropy ChangeDocument11 pagesMilling Wear of Carbide Tool For Processing Nickel-Based Alloy in Cryogenic Based On The Entropy ChangeRAMACHANDRAN MNITNo ratings yet

- Finite Element Simulation Using Abaqus: Internship OnDocument24 pagesFinite Element Simulation Using Abaqus: Internship OnranjithkrajNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Finite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaFrom EverandFinite Elements for Truss and Frame Structures: An Introduction Based on the Computer Algebra System MaximaNo ratings yet

- Exp 2 CALIBRATION OF A TWO COMPONENT CUTTING FORCE DYNAMOMETERDocument5 pagesExp 2 CALIBRATION OF A TWO COMPONENT CUTTING FORCE DYNAMOMETERYasmin RedaNo ratings yet

- Exp 1 Chip Formation ExpermentDocument2 pagesExp 1 Chip Formation ExpermentYasmin RedaNo ratings yet

- Sheet 2Document4 pagesSheet 2Yasmin RedaNo ratings yet

- Exp 5 Effect of The Application of AlubricationDocument4 pagesExp 5 Effect of The Application of AlubricationYasmin RedaNo ratings yet

- Exp 4 Effect of Rake Angle in Orthogonal MachiningDocument1 pageExp 4 Effect of Rake Angle in Orthogonal MachiningYasmin RedaNo ratings yet

- Sheet 1Document5 pagesSheet 1Yasmin RedaNo ratings yet

- Sheet 5Document2 pagesSheet 5Yasmin RedaNo ratings yet

- Sheet 4Document3 pagesSheet 4Yasmin RedaNo ratings yet

- Sheet 3Document5 pagesSheet 3Yasmin RedaNo ratings yet

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDocument7 pagesFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNo ratings yet

- MCQ - Slope and Deflection - ME Subjects - Concepts SimplifiedDocument6 pagesMCQ - Slope and Deflection - ME Subjects - Concepts SimplifiedrajkumarNo ratings yet

- Tutorial Problem Set - 3 PDFDocument3 pagesTutorial Problem Set - 3 PDFMazin AbdallaNo ratings yet

- Moment of Inertia Cone-To-Shell Junction ASME VIII, Div 1Document6 pagesMoment of Inertia Cone-To-Shell Junction ASME VIII, Div 1Julien aNo ratings yet

- HW4 SolutionsDocument7 pagesHW4 SolutionserfanghlmNo ratings yet

- Simple Modelling Using SACSDocument13 pagesSimple Modelling Using SACSLeonardo Alexandre De LucenaNo ratings yet

- CFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsDocument9 pagesCFD Study For Assessment of Axial Thrust Balance in Centrifugal Multistage PumpsNavaneeth Krishnan NairNo ratings yet

- 5e Engineering Manual Mechanics Si Solutions Statics VersionDocument2 pages5e Engineering Manual Mechanics Si Solutions Statics VersionTaetaeyaeNo ratings yet

- Class 3 - Hydraulic Models and Similitude PDFDocument11 pagesClass 3 - Hydraulic Models and Similitude PDFRana GNo ratings yet

- Exercise 1 ThermodynamicsDocument5 pagesExercise 1 ThermodynamicsJunNo ratings yet

- Design and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-MarathonDocument76 pagesDesign and Simulate An Aerodynamic Urban Concept Car Body For The Shell Eco-Marathonanhelllo100% (1)

- Phys p2Document16 pagesPhys p2Kalana GamageNo ratings yet

- Tailing Lug Calculations 01Document2 pagesTailing Lug Calculations 01sammar_10No ratings yet

- Stepwise Simulation of Vacuum Transfer Line HydraulicsDocument6 pagesStepwise Simulation of Vacuum Transfer Line HydraulicsJose CantorNo ratings yet

- Aircraft Design Project-2 Eight Seater Short Range Business Jet AircraftDocument69 pagesAircraft Design Project-2 Eight Seater Short Range Business Jet AircraftVignesh Selvaraj79% (14)

- Clicker Chapter 30Document74 pagesClicker Chapter 30riffyjiffyNo ratings yet

- 5.1 FEA of Excavations and Embankment ConstructionDocument41 pages5.1 FEA of Excavations and Embankment ConstructionNaitik ShuklaNo ratings yet

- 1-3 Simple Stresses 1-3-1 Axial StressDocument32 pages1-3 Simple Stresses 1-3-1 Axial StressHazim KhalilNo ratings yet

- Vehicle Dynamics Simulation, Part 1: Mathematical Model: Iztok Ciglaric and Ivan PrebilDocument10 pagesVehicle Dynamics Simulation, Part 1: Mathematical Model: Iztok Ciglaric and Ivan PrebildeepNo ratings yet

- Aerodynamics of Road Vehicles HUCHO PDFDocument55 pagesAerodynamics of Road Vehicles HUCHO PDFigormagalhaes87100% (1)

- 1w5q Chapter 3 Dynamics of Linear MotionDocument2 pages1w5q Chapter 3 Dynamics of Linear MotionKHOO YI XIAN MoeNo ratings yet

- Design Study Seal NC NASADocument30 pagesDesign Study Seal NC NASAMUHAMMAD ASYRAAF BIN ANUARNo ratings yet

- Interaction Between Vertical and Lateral Loads On The Response of Piles in Soft ClaysDocument5 pagesInteraction Between Vertical and Lateral Loads On The Response of Piles in Soft ClaysVetriselvan ArumugamNo ratings yet

- 1.1 Energy BalanceDocument25 pages1.1 Energy BalancenandhakumarmeNo ratings yet

- 100 TOP MOST MAGNETISM and ELECTROMAGNETISM - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice Questions PDFDocument27 pages100 TOP MOST MAGNETISM and ELECTROMAGNETISM - Electrical Engineering Multiple Choice Questions and Answers Electrical Engineering Multiple Choice Questions PDFSIVAKAMI92% (12)

- A Theoretical Rigid Body Model of Vibrating ScreenDocument16 pagesA Theoretical Rigid Body Model of Vibrating ScreenJuliana AguiarNo ratings yet

- Soil Loads On PipelinesDocument10 pagesSoil Loads On Pipelinesdicktracy11No ratings yet

- Additional MUS QuestionsDocument27 pagesAdditional MUS Questionsalma rejiNo ratings yet

- Multi-Component Acoustic Characterization of Porous Media - Karel N. Van DalenDocument182 pagesMulti-Component Acoustic Characterization of Porous Media - Karel N. Van DalenSasaNo ratings yet