Professional Documents

Culture Documents

TDS TH 7302

TDS TH 7302

Uploaded by

Polem IskandarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS TH 7302

TDS TH 7302

Uploaded by

Polem IskandarCopyright:

Available Formats

TECHNICAL DATA SHEET

Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)

EPOTEC TH 7302

Description Epotec TH 7302 is a low viscosity modified cycloaliphatic polyamine curing agent

for use with liquid epoxy resins such as epotec YD 128 to produce solvent free

room temperature curable thermoset coatings, floor toppings. When formulated

appropriately with epoxy resin it gives clear, hard surface resistant to variety of

chemicals such as acids, alkalies, hydrocarbons, water etc. Epotec TH 7302,

being cycloaliphatic, also provides better weather resistance than aliphatic

polyamines.

Applications

• Solvent-free, high solids coatings

• Primers and screeds

• Chemical resistant mortars and linings

• Water proofing

• Other construction applications

Specification

Appearance Visual Clear, light yellow liquid

Colour ASTM D 1544-04 3 G max.

Viscosity* @25ºC ASTM D 2196-05 280 – 420 cP

#

Pot life @25°C TEC-AS-P-111 25 – 35 min

* Brookfield viscometer # with epotc YD 128

Typical properties *

Odour --- Amine

Density @25ºC ASTM D 1475-98 1.05 g/cc

Amine value DIN 16945 300 – 320 mg KOH/g

AHEW --- ~ 95

PHR with epotec YD

--- 50 wt. %

128 (EEW ~ 190 g/eq)

Flash point ASTM D 93 100ºC

Thin film set time 6 – 7 hr

Glass transition

DIN 11357 52°C

temperature

2

Tensile strength ASTM D 638-86 540 kg/cm

TDS epotec TH 7302 Page 1 of 2 Effective Date : Mar 2011

TECHNICAL DATA SHEET

2

Flexural strength ASTM D 638-86 850 kg/cm

2

Compressive strength ASTM D 695-85 750 kg/cm

* = Typical properties are indicated for information only

Additional information Chemical resistance with variety of epoxy resins

2 3 4

Epotec YD 128 Epotec YDF 170 Epotec YDPN 661

Chemical

7 days 28 days 7 day 28 days 7 day 28 days

DI Water R R R R R R

50% Sodium

R R R R R R

hydroxide

10% sulfuric

R R R R R R

acid

30%

Hydrochloric R R R R R R

acid

10% acetic

A D R A R A

acid

Linseed oil

R R R R R R

fatty acid

Coconut oil

R R R R R R

fatty acid

Xylene R R R R R R

Ethanol R A R R R R

Gasoline R R R R R R

1 o

= Test method ASTM-D-543. Curing schedule 25 C / 7 days R = Resistant

2

= Standard Bisphenol A epoxy resin, EEW ~ 186 g/eq A = Attacked

3

= Standard Bisphenol F epoxy resin, EEW ~ 170 g/eq D = Damaged

4

= Multifunctional epoxy resin

Packing Epotec TH 7302 is packed and delivered in plastic drums, 200 kg per drum as a

standard pack.

Other pack sizes are available on request.

Storage Epotec TH 7302 should be stored in original tightly closed container, in dry and

cool conditions. When exposed to air the product epotec TH 7302 may absorb

moisture which may result in viscosity increase, frothing and white carbonation

product deposition. In such case it may affect the appearance of final coating/floor

topping. When stored in tightly closed container this product has a storage life of

at least one year from the date of manufacturing.

Handling Do not mix with epoxy resin until just prior to use since reacts chemically at room

temperature. Avoid contact with skin, eyes etc. Please refer to the MSDS of the

product for more instructions on safe storage and handling of epotec TH 7302.

TDS epotec TH 7302 Page 2 of 2 Effective Date : Mar 2011

TECHNICAL DATA SHEET

-- no data on this page --

Disclaimer

All recommendations for use of our products whether given by us in writing, verbally or to be implied from the results of tests carried

out by us are based on the current state of our knowledge. Although, the information contained in this sheet is accurate, no liability

can be accepted in respect of such information. We warrant only that our product will meet the designated specifications and make no

other warranty either express or implied, including any warranty of merchantability or fitness for a particular purpose as the conditions

of application are beyond our control.

For Additional Information, Please Contact:

Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)

th

Mahatun Plaza Bldg., 16 Floor 888/167 Ploenchit Road, Lumpini, Bangkok 10330 Thailand.

Tel: (662) 2535031-3, Fax: (662) 2535030

Web Site: www.adityabirlachemicals.com, E-Mail: epoxymktg@adityabirla.com

TDS epotec TH 7302 Page 3 of 2 Effective Date : Mar 2011

You might also like

- Microscale Inorganic Chemistry - A Comprehensive Laboratory Experience - Szafran, ZviDocument392 pagesMicroscale Inorganic Chemistry - A Comprehensive Laboratory Experience - Szafran, ZviJade Fromage79% (14)

- 2.2 GDP and Its DiscontentsDocument5 pages2.2 GDP and Its Discontentsnuoti guanNo ratings yet

- STAMFORD, HCM534F - Technical Data Sheet (Power Generators)Document11 pagesSTAMFORD, HCM534F - Technical Data Sheet (Power Generators)eduardo ayalaNo ratings yet

- Katalog Berlian InternationalDocument15 pagesKatalog Berlian InternationalHubbi NawaNo ratings yet

- (123doc) de Toeic Co Dap An Chi Tiet de 7Document62 pages(123doc) de Toeic Co Dap An Chi Tiet de 7Ngan LttNo ratings yet

- Unigaz Corporate Presentation (With References)Document36 pagesUnigaz Corporate Presentation (With References)MeraNo ratings yet

- 00 Saip 01Document14 pages00 Saip 01hammad2150% (2)

- Aof Sibichep 1Document19 pagesAof Sibichep 1Sibichen PhilipNo ratings yet

- Hon Role Sample With ListDocument4 pagesHon Role Sample With Listapi-449168853No ratings yet

- Gre Big Book Analogy Solution Test 1 & 2Document11 pagesGre Big Book Analogy Solution Test 1 & 2Kamal BU100% (5)

- SVV Bucket How To PDFDocument6 pagesSVV Bucket How To PDFBenjamin RomeroNo ratings yet

- 2.9.2 Lab - Basic Switch and End Device ConfigurationDocument3 pages2.9.2 Lab - Basic Switch and End Device ConfigurationjhonNo ratings yet

- Schedule Crew Bojonegoro-1Document15 pagesSchedule Crew Bojonegoro-1jamil taufikNo ratings yet

- The Rise of Leeds BicyclesypqlyDocument2 pagesThe Rise of Leeds Bicyclesypqlywhaledust81No ratings yet

- Ds7060 ProgDocument40 pagesDs7060 Progfabricio gaitaNo ratings yet

- Bharti GroupDocument41 pagesBharti GroupSaurabh G50% (2)

- 101+ Indian Brands & Businesses On TwitterDocument4 pages101+ Indian Brands & Businesses On TwitterBabu Raj KumarNo ratings yet

- "Mosquito Repellants" A Case StudyDocument10 pages"Mosquito Repellants" A Case StudyLewis SimonNo ratings yet

- MarketingDocument5 pagesMarketingHimanshu DhanukaNo ratings yet

- BUFFER STOCK AwalDocument106 pagesBUFFER STOCK Awalakadir jailaniNo ratings yet

- SDS NitomortarDocument26 pagesSDS NitomortarAbdus SamadNo ratings yet

- A1885 Partner Details Report 707351877Document124 pagesA1885 Partner Details Report 707351877Ahmed KhanNo ratings yet

- Cargo Packing Checklist - Provided DataDocument7 pagesCargo Packing Checklist - Provided Datanayenzaman6No ratings yet

- IB Security Assistant Exam Syllabus 2022Document6 pagesIB Security Assistant Exam Syllabus 2022Mundhe SameerNo ratings yet

- 0070 Afinotan Ojakorotu 2009 Niger DeltaDocument8 pages0070 Afinotan Ojakorotu 2009 Niger DeltaAdedayo MichaelNo ratings yet

- The Answer KEY of The CoursebookDocument19 pagesThe Answer KEY of The CoursebookMukhammedali YakyarNo ratings yet

- AccuraCap PMSDocument35 pagesAccuraCap PMSAnkur100% (1)

- Engineering and Applied Science Research Kinetics Study of Biodiesel Production at Room Temperature Based On Eggshell Derived Cao As Basic Heterogeneous CatalystDocument14 pagesEngineering and Applied Science Research Kinetics Study of Biodiesel Production at Room Temperature Based On Eggshell Derived Cao As Basic Heterogeneous CatalysthmneNo ratings yet

- Es01plan PDFDocument47 pagesEs01plan PDFnaval consulNo ratings yet

- Schematic DiagramDocument1 pageSchematic DiagramNoufal OthupurayilNo ratings yet

- Local Media2217661160242877100Document4 pagesLocal Media2217661160242877100Neil Ian Seth BacaniNo ratings yet

- Performance of Indian Defence Public Sector Undertakings: An OverviewDocument4 pagesPerformance of Indian Defence Public Sector Undertakings: An OverviewIJAR JOURNALNo ratings yet

- Mint HD Delhi 05 12 2022Document18 pagesMint HD Delhi 05 12 2022ZxcNo ratings yet

- 2 JolmaartiDocument13 pages2 JolmaartiXian JingNo ratings yet

- 3.1 Illustrating Limit of A FunctionDocument19 pages3.1 Illustrating Limit of A Functioncharlene quiambaoNo ratings yet

- Prueba Final Tipo Saber Pro Level Vi English TestDocument14 pagesPrueba Final Tipo Saber Pro Level Vi English TestMarcela MORALESNo ratings yet

- MAPEH Week 2 October 12 19Document35 pagesMAPEH Week 2 October 12 19Coren Jane M. TupanNo ratings yet

- Internship Report: Anand RathiDocument18 pagesInternship Report: Anand RathiRavi Kumar SPNo ratings yet

- Artepillin C As An Outstanding Phenolic Compound of Brazilian Green Propolis For Disease Treatment: A Review On Pharmacological AspectsDocument13 pagesArtepillin C As An Outstanding Phenolic Compound of Brazilian Green Propolis For Disease Treatment: A Review On Pharmacological AspectslyviaNo ratings yet

- Senco Gold RHPDocument499 pagesSenco Gold RHPRahul MehtaNo ratings yet

- Sikkim A Gift of NatureDocument15 pagesSikkim A Gift of NatureMohit Raj SinhaNo ratings yet

- MuskanDocument33 pagesMuskanRishabh TripathiNo ratings yet

- STE Annexure-1Document3 pagesSTE Annexure-104 Omkar BodkeNo ratings yet

- Epos Final 59 PDFDocument33 pagesEpos Final 59 PDFAkshay SrivastavaNo ratings yet

- Hong2020 Article PressurelessSilverSinteringOfSDocument9 pagesHong2020 Article PressurelessSilverSinteringOfSwalker fanNo ratings yet

- (A56-A79 & A43-A44) Vladimir Kramnik Playing The Benoni and Benko Defenses As WhiteDocument11 pages(A56-A79 & A43-A44) Vladimir Kramnik Playing The Benoni and Benko Defenses As WhiteOdysseas 57No ratings yet

- Booklet-6 To 8 - 2022 - April To JuneDocument16 pagesBooklet-6 To 8 - 2022 - April To June7A04Aditya MayankNo ratings yet

- Complete Health Insurance (Health Elite) 3Document1 pageComplete Health Insurance (Health Elite) 3arajendermcomNo ratings yet

- Raspberry Pi Based Security System PDFDocument56 pagesRaspberry Pi Based Security System PDFMohd KhanNo ratings yet

- Switchgear PDFDocument4 pagesSwitchgear PDFgsirinNo ratings yet

- Sasta SundarDocument13 pagesSasta Sundarkorak786100% (1)

- BT5121 Lab Manual - 2023 - v2Document41 pagesBT5121 Lab Manual - 2023 - v2Hrithik BaradiaNo ratings yet

- Pokmas 14 Senggigi PDFDocument1 pagePokmas 14 Senggigi PDFYT MomentNo ratings yet

- Worldwide Network: Electro-Cleen SystemDocument6 pagesWorldwide Network: Electro-Cleen SystemYuriy LysyukNo ratings yet

- A SHH Ar Paper PublishedDocument5 pagesA SHH Ar Paper PublishedLionel Antoine ELOUNA NGANo ratings yet

- DOP Finacle - Module Wise Menu List - SA POSTDocument8 pagesDOP Finacle - Module Wise Menu List - SA POSTJavedNo ratings yet

- Havells LED Price List Mar 2016Document24 pagesHavells LED Price List Mar 2016Dhanashekar CNo ratings yet

- Indian OilDocument41 pagesIndian Oilj_sachin09No ratings yet

- Camporee 2022 ProgramDocument5 pagesCamporee 2022 Programapi-294625351No ratings yet

- Palm Tower Brochure A4 - Last UpdatedDocument19 pagesPalm Tower Brochure A4 - Last UpdatedNis ANo ratings yet

- Description: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Document3 pagesDescription: Aditya Birla Chemicals (Thailand) Ltd. (Epoxy Division)Amr RagabNo ratings yet

- Latapoxy SP 100 TDSDocument3 pagesLatapoxy SP 100 TDSBithika DattaNo ratings yet

- Cepsa Fundicol Synt Ehc: Lubricants For Industrial UseDocument2 pagesCepsa Fundicol Synt Ehc: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Coating Thickness Uni-T 343D English User ManualDocument14 pagesCoating Thickness Uni-T 343D English User ManualPolem IskandarNo ratings yet

- Application Guide - Jotun Solvalitt AluDocument9 pagesApplication Guide - Jotun Solvalitt AluPolem IskandarNo ratings yet

- Technical Data Sheet - Jotun Jotatemp 540 ZincDocument5 pagesTechnical Data Sheet - Jotun Jotatemp 540 ZincPolem IskandarNo ratings yet

- List Material Pressure Indicator Dan Drain PDFDocument2 pagesList Material Pressure Indicator Dan Drain PDFPolem IskandarNo ratings yet

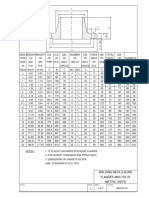

- Tabel FlangeDocument7 pagesTabel FlangePolem IskandarNo ratings yet

- Cat Menie Besi PropanDocument2 pagesCat Menie Besi PropanPolem IskandarNo ratings yet

- TDS Ydpn 661Document1 pageTDS Ydpn 661Polem IskandarNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- 12-11-2022 - Jee SR ELITE (CIPL, IPL IC & ISB) - Jee - 221112 - 181622Document12 pages12-11-2022 - Jee SR ELITE (CIPL, IPL IC & ISB) - Jee - 221112 - 181622kaveendra ChilukamarriNo ratings yet

- Mcqs Solved Lec-16 Enzymes-Properties, Classification and NomenclatureDocument4 pagesMcqs Solved Lec-16 Enzymes-Properties, Classification and NomenclatureELAKKIYA .U BA Eng LitNo ratings yet

- Diamond Grading Chart 2Document1 pageDiamond Grading Chart 2pedroNo ratings yet

- How To Make Your Own Liquid: Soap at HomeDocument51 pagesHow To Make Your Own Liquid: Soap at Homemesfin100% (2)

- Calcium Silicate False Ceiling TilesDocument6 pagesCalcium Silicate False Ceiling TilesDeepak ChandolaNo ratings yet

- CHEMISTRY Edexcel (9-1) Student Book Answers: Download NowDocument1 pageCHEMISTRY Edexcel (9-1) Student Book Answers: Download NowTiannaNo ratings yet

- 24 Silicon Controlled Rectifier ProjectsDocument164 pages24 Silicon Controlled Rectifier ProjectsghebarnaNo ratings yet

- Specification Sheet - Vmax® P550® Turf Reinforcement Mat: Index Property Test Method TypicalDocument2 pagesSpecification Sheet - Vmax® P550® Turf Reinforcement Mat: Index Property Test Method TypicalLuis MogrovejoNo ratings yet

- 1.5 LipidsDocument19 pages1.5 Lipidsasifh76543No ratings yet

- Chemistry 30 16.4 Interpreting PH CurvesDocument45 pagesChemistry 30 16.4 Interpreting PH CurvesSarah KhaderNo ratings yet

- CRP InggrisDocument2 pagesCRP InggrisLAB. GATOT SUBROTONo ratings yet

- Journal Polyphenols SugarcaneDocument11 pagesJournal Polyphenols SugarcaneMarkNo ratings yet

- Crystal Structure and Crystal System: Source: Dave - Ucsc.edu/myrtreia/crystal - HTMLDocument10 pagesCrystal Structure and Crystal System: Source: Dave - Ucsc.edu/myrtreia/crystal - HTMLJawehNo ratings yet

- Lascaray1952 - INDUSTRIAL FAT SPLITTINGDocument5 pagesLascaray1952 - INDUSTRIAL FAT SPLITTINGPrabandari 632No ratings yet

- ProblemsDocument20 pagesProblemsRenjith S AnandNo ratings yet

- B1e 004Document40 pagesB1e 004Ganesh BabuNo ratings yet

- HPLC Analysis Reversed Phase PDFDocument4 pagesHPLC Analysis Reversed Phase PDFEdgar ChoqueNo ratings yet

- Chemical KineticsDocument60 pagesChemical KineticsThe Rock75% (4)

- Chemistry Lab Report 4Document11 pagesChemistry Lab Report 4THASVIN OFFICIAL NETWORKNo ratings yet

- Form No: 066-00009-601QRP UC-2179Document37 pagesForm No: 066-00009-601QRP UC-2179Aloyce kampeleNo ratings yet

- Himedia BGLB Broth 2% M121Document2 pagesHimedia BGLB Broth 2% M121grjhb100% (1)

- Second Quarter Exam in General Biology IDocument5 pagesSecond Quarter Exam in General Biology IAubrey SalidoNo ratings yet

- Harvard Reduction NotesDocument18 pagesHarvard Reduction NotesSuhail FurqanNo ratings yet

- Honeywell PT ChartDocument2 pagesHoneywell PT Chartmarjan 01No ratings yet

- 5 BiosensorDocument20 pages5 Biosensortehreem iftikharNo ratings yet

- Reference Material Certificate I S O 1 7 0 3 4Document2 pagesReference Material Certificate I S O 1 7 0 3 4alexisNo ratings yet