Professional Documents

Culture Documents

Limited Slip Differential - Assemble: Desarmado y Armado

Limited Slip Differential - Assemble: Desarmado y Armado

Uploaded by

Khriztian BardalesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Limited Slip Differential - Assemble: Desarmado y Armado

Limited Slip Differential - Assemble: Desarmado y Armado

Uploaded by

Khriztian BardalesCopyright:

Available Formats

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng...

Pgina 1 de 10

Cerrar SIS Pantalla anterior

Producto: WHEEL LOADER Modelo: 924G WHEEL LOADER 3DZ Configuracin: 924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Engine

Desarmado y Armado

924G and 924GZ Wheel Loaders Power Train

Nmero de medio -RENR3506-04 Fecha de publicacin -01/05/2004 Fecha de actualizacin -19/05/2004

i03985498

Limited Slip Differential - Assemble

SMCS - 3263-016

Assembly Procedure

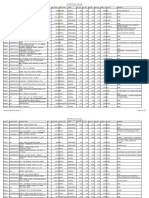

Table 1 Required Tools Tool Part Number 126-7183 6V-4011 1P-0519 7X-2556 A 9X-8257 8T-4132 8T-5092 8T-4223 B 8T-5096 Washer (M16) Nut (M16 X 2.0) Bolt (M12 X 1.75 X 150) Washer (M12) Dial Indicator Group 1 1 2 2 1 Part Description Crossblock Ring Plate Bolt (M16 X 2.0 X 100) Qty 1 1 1 1

Note: Cleanliness is an important factor. Before assembly, all parts should be thoroughly cleaned in cleaning fluid. Allow the parts to air dry. Wiping cloths or rags should not be used to dry parts. Lint may be deposited on the parts which may cause later trouble. Inspect all parts. If any parts are worn or damaged, use new parts for replacement. 1. Clean all parts of the differential. Inspect all parts of the differential. If any of the parts are worn or damaged, use new parts for replacement.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 2 de 10

Illustration 1

g00651696

2. Install thrust washer (17) . Lubricate the face of the thrust washer with clean axle oil. 3. Replace the disc packs if the friction material is worn. The disc packs must be symmetrical within 0.10 mm (0.004 inch).

Illustration 2

g00651708

4. The case is marked. Replace the old disc packs with the same disc packs. The disc packs cannot be mixed. Note: Lubricate the plates with clean axle oil. Lubricate the friction discs with clean axle oil prior to assembly.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 3 de 10

Illustration 3

g00891841

Illustration 4

g00651715

5. Install friction discs (15) and plates (16) . Start with a plate and end with a friction disc, as shown.

Illustration 5

g00651716

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 4 de 10

Illustration 6

g00651718

6. Align the keys of actuator housing (14) with the case housing. Install actuator housing (14) .

Illustration 7

g00651721

7. Install gear (13) . Note: Turn the gear until the spline engages with the friction discs that were installed in Step 5. Seat the gear fully.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 5 de 10

Illustration 8

g00651722

8. Install pinion gears (9) on pinion shaft (10) . Repeat for pinion gears (11) and pinion shaft (12) . Lubricate the assembly with clean axle oil.

Illustration 9

g00651730

9. Install pinion shaft (12) and pinion gears (11) , as shown. 10. Rotate pinion gears (11) until the pinion shaft rests in the slots of the actuator housing.

Illustration 10

g00651733

11. Install pinion shaft (10) and two pinion gears (9) , as shown.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 6 de 10

Illustration 11

g00470451

Illustration 12

g00651744

12. Assemble gear (8) and actuator housing (7) . Align the keys of the actuator housing with the slots in the case, as shown. Note: Lubricate the plates with clean axle oil. Lubricate the friction discs with clean axle oil prior to assembly.

Illustration 13

g00891840

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 7 de 10

Illustration 14

g00651747

13. Install friction discs (6) and plates (5) . Start with a friction disc and end with a plate. Note: The following steps show the procedure to measure the end play gap.

Illustration 15

g00651748

14. Install Tooling (A) on the differential assembly, as shown. Note: The center pusher bolt of Tooling (A) must have M16 X 2.0 thread in order to apply the proper preload.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 8 de 10

Illustration 16

g00651750

15. Tighten the center bolt of Tooling (A) to a torque of 27 Nm (20 lb ft) in order to apply 900 kg (2000 lb) of preload on the disc packs.

Illustration 17

g00651753

16. Mount the magnetic base of Tooling (B) on Face (A) , as shown. 17. Zero the dial indicator on Face (A) , as shown.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 Eng... Pgina 9 de 10

Illustration 18

g00651754

18. Rotate the magnetic base of Tooling (B) until the dial indicator is touching (Face B) . 19. Record the reading in three different areas of face (B) . 20. Average the three readings. This average is the end play gap. Note: If the existing disc packs were installed in Step 4, continue with Step 21. If new disc packs were installed in Step 4, continue with Step 22. 21. If the end play gap in Step 20 was greater than 0.81 mm (0.032 inch), replacement of the existing disc packs is necessary. Note: Use Steps 22 through 26 if new disc packs are used. 22. The case is marked. Replace the old disc packs with the same disc packs. The disc packs cannot be mixed. 23. Install the new disc packs. Measure the end play that was described in Steps 14 through 20. The measured end play must be between 0.203 mm (0.0080 inch) and 0.508 mm (0.0200 inch). 24. If the measured end play gap does not yet meet specifications, replace the pinion shafts and/or both actuator housings.

Illustration 19

g00651755

25. Change the mark on the housing for future reference If the disc packs were changed.

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

924G 924Gz Wheel Loader 3DZ00001-UP (MACHINE) POWERED BY 3056 E... Pgina 10 de 10

Illustration 20

g00651759

26. Install thrust washer (4) in bevel gear (2) . Note: Apply a small amount of grease to the back side of the thrust washer prior to installing. The grease will retain thrust washer (4) during the installation of bevel gear (2) .

Illustration 21

g00651760

27. Invert bevel gear (2) and install the bevel gear on case housing (3) . 28. Install bolts (1) and tighten bolts to a torque of 95 10 Nm (70 7 lb ft). Then turn each bolt for one half turn. End By: Install the differential.

Copyright 1993 - 2011 Caterpillar Inc. Todos los derechos reservados. Red privada para licenciados del SIS. Wed Jul 20 00:56:45 EST 2011

https://sis.cat.com/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/s... 20/07/2011

You might also like

- Caterpillar Cat 279D COMPACT TRACK LOADER (Prefix GTL) Service Repair Manual (GTL00001 and Up) PDFDocument7 pagesCaterpillar Cat 279D COMPACT TRACK LOADER (Prefix GTL) Service Repair Manual (GTL00001 and Up) PDFfksjdnkem0% (2)

- Lathe Machine Project Semester 2Document11 pagesLathe Machine Project Semester 2Ye Chonn80% (35)

- F4A4x at ManualDocument135 pagesF4A4x at Manualcavp271% (7)

- Armado de Deslizamiento Limitado de DiferencialDocument11 pagesArmado de Deslizamiento Limitado de DiferencialAlicia DiazNo ratings yet

- 320C Assemble Final DriveDocument15 pages320C Assemble Final DriveLuis ValenzuelaNo ratings yet

- C32 Cylinder Head - InstallDocument10 pagesC32 Cylinder Head - Installmanu luvungaNo ratings yet

- Caterpillar Cat 160h Motor Grader Prefix 9jm Service Repair Manual 9jm00001 and UpDocument23 pagesCaterpillar Cat 160h Motor Grader Prefix 9jm Service Repair Manual 9jm00001 and UpWalter RodriguezNo ratings yet

- Transmission Planetary - Assemble 966gDocument31 pagesTransmission Planetary - Assemble 966gcristian chuquicondor torres100% (2)

- Rotor Stub Shaft - 084637Document4 pagesRotor Stub Shaft - 084637Juan LopezNo ratings yet

- 9NZ Especificacions CabezaDocument6 pages9NZ Especificacions CabezaLuis OcampoNo ratings yet

- 140M Motor Grader B9D00001-UP (MACHINE) (SEBP4976 - 111) - DocumentaciónDocument11 pages140M Motor Grader B9D00001-UP (MACHINE) (SEBP4976 - 111) - Documentaciónpierre zuñiga100% (1)

- Caterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)Document23 pagesCaterpillar Cat 235D EXCAVATOR (Prefix 8TJ) Service Repair Manual (8TJ00001 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 336E L Excavator (Prefix KED) Service Repair Manual (KED00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix KED) Service Repair Manual (KED00001 and Up)kfsmmeNo ratings yet

- Rear Axle, Differential and Final Drive - Install: Cerrar SIS Pantalla AnteriorDocument11 pagesRear Axle, Differential and Final Drive - Install: Cerrar SIS Pantalla AnteriorFredy QuispeNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)Document24 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 62X) Service Repair Manual (62X00289 and Up)rpoy9396615No ratings yet

- Caterpillar Cat 329DL Excavator (Prefix TZL) Service Repair Manual (TZL00001 and Up) PDFDocument21 pagesCaterpillar Cat 329DL Excavator (Prefix TZL) Service Repair Manual (TZL00001 and Up) PDFfkdmma100% (1)

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeNo ratings yet

- Circle Drive - Assemble-I08509292Document13 pagesCircle Drive - Assemble-I08509292Taller HeavytechNo ratings yet

- 3408E and 3412E Crankshaft Main Bearings - InstallDocument6 pages3408E and 3412E Crankshaft Main Bearings - Installalonso100% (1)

- Preload Bearing Final DriveDocument6 pagesPreload Bearing Final DrivemahmudiNo ratings yet

- Gear Group (Front) - Install: Disassembly and AssemblyDocument5 pagesGear Group (Front) - Install: Disassembly and AssemblygustavoNo ratings yet

- 924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 81) - Systems & Components C2 PDFDocument4 pages924G 924Gz Wheel Loader RBB00001-UP (MACHINE) POWERED BY 3056E Engine (SEBP3526 - 81) - Systems & Components C2 PDFUbaldo Enrique Caraballo EstradaNo ratings yet

- Caterpillar Cat 228 SKID STEER LOADER (Prefix 6BZ) Service Repair Manual (6BZ00001-00699)Document26 pagesCaterpillar Cat 228 SKID STEER LOADER (Prefix 6BZ) Service Repair Manual (6BZ00001-00699)rpoy9396615No ratings yet

- Differential and Bevel Gear 966 InstallDocument14 pagesDifferential and Bevel Gear 966 InstallAlan GonzalezNo ratings yet

- Swing Rack - InstallDocument7 pagesSwing Rack - InstallGilney FreitasNo ratings yet

- Armado de OrbitrolDocument10 pagesArmado de OrbitrolANTONIO CRUZNo ratings yet

- Assembly Procedure VTC 254 TurbochargerDocument16 pagesAssembly Procedure VTC 254 TurbochargerMauricio MUÑOZ100% (1)

- Cylinder Head - Install: Cerrar SISDocument4 pagesCylinder Head - Install: Cerrar SISEdgarNo ratings yet

- Crankshaft - Install PDFDocument7 pagesCrankshaft - Install PDFsonjisahuriNo ratings yet

- Crankshaft - Install: Desmontagem e MontagemDocument11 pagesCrankshaft - Install: Desmontagem e MontagemTatiano BrolloNo ratings yet

- Armado de Rueda DelanteraDocument10 pagesArmado de Rueda DelanteraWilson Castillo AlvarezNo ratings yet

- Radiator - Assemble: Previous ScreenDocument8 pagesRadiator - Assemble: Previous ScreenKusuma JayaNo ratings yet

- Instalação - Motor 3054Document5 pagesInstalação - Motor 3054carlos nogueiraNo ratings yet

- 140h Dakyfa Final Drive - Final Drive - AssembleDocument11 pages140h Dakyfa Final Drive - Final Drive - AssembleDaniel TekleNo ratings yet

- Counterbalance Valve TravelDocument4 pagesCounterbalance Valve TravelSteven Y.MNo ratings yet

- Crankshaft - InstallDocument7 pagesCrankshaft - InstallLeonardo PerezNo ratings yet

- Armado Transmision D6GDocument23 pagesArmado Transmision D6GServimaquinaria Millan Sac0% (1)

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiNo ratings yet

- Engine Oil Pan - Remove and Install - Aluminum and Pressed Steel Oil PansDocument12 pagesEngine Oil Pan - Remove and Install - Aluminum and Pressed Steel Oil PansMbahdiro KolenxNo ratings yet

- Caterpillar Cat 257D MULTI TERRAIN LOADER (Prefix EML) Service Repair Manual (EML00001 and Up)Document21 pagesCaterpillar Cat 257D MULTI TERRAIN LOADER (Prefix EML) Service Repair Manual (EML00001 and Up)rpoy9396615No ratings yet

- Cylinder Head - Install: Disassembly and AssemblyDocument8 pagesCylinder Head - Install: Disassembly and AssemblySaeed KazemiNo ratings yet

- Caterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Document18 pagesCaterpillar Cat 120G MOTOR GRADER (Prefix 11W) Service Repair Manual (11W01019-01250)Arsel FirgiawanNo ratings yet

- Cambio Eje Trasero 793DDocument14 pagesCambio Eje Trasero 793Dtommy lanyonNo ratings yet

- CAT 242B Armado Motor de Traslación PDFDocument20 pagesCAT 242B Armado Motor de Traslación PDFjrincon26No ratings yet

- Adjust Pre Load Wheel Bearing 777 AGCDocument4 pagesAdjust Pre Load Wheel Bearing 777 AGCFaidh Allanz FairhiaNo ratings yet

- CulataDocument8 pagesCulataRobinson Manuel Acuña MalcaNo ratings yet

- Final Drive and Wheel - Install - RearDocument6 pagesFinal Drive and Wheel - Install - Rearhernan dueñasNo ratings yet

- Cylinder Head - InstallDocument7 pagesCylinder Head - Installmahamed.essam797No ratings yet

- 320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsDocument8 pages320D2 Excavator XBA00001-UP (MACHINE) POWERED BY C7.1 Engine (M0065912 - 13) - Systems & ComponentsYudi setiawanNo ratings yet

- Remover e Instalar Camisas de CilindrosDocument4 pagesRemover e Instalar Camisas de CilindrosAlejandro ValenzuelaNo ratings yet

- Travel Motor AssembleDocument10 pagesTravel Motor AssembleMaimun maimunNo ratings yet

- Cat 3176c Montagem Da Cabeça.Document7 pagesCat 3176c Montagem Da Cabeça.César PérezNo ratings yet

- Remove and Install Crankshaft Main BearingsDocument3 pagesRemove and Install Crankshaft Main Bearingsramom candido de macedoNo ratings yet

- Adjustment For The Final Drive BearingsDocument8 pagesAdjustment For The Final Drive BearingscridavarNo ratings yet

- Caterpillar Cat 245 EXCAVATOR (Prefix 94L) Service Repair Manual (94L00255 and Up)Document23 pagesCaterpillar Cat 245 EXCAVATOR (Prefix 94L) Service Repair Manual (94L00255 and Up)rpoy9396615No ratings yet

- Cylinder Block 3126 EspecificacionesDocument3 pagesCylinder Block 3126 EspecificacionesGerardoNo ratings yet

- Cabeçote Motor c7-2Document8 pagesCabeçote Motor c7-2Alaina SousaNo ratings yet

- Gear Group (Rear) - Install: Shutdown SIS Previous ScreenDocument10 pagesGear Group (Rear) - Install: Shutdown SIS Previous ScreenmohamedNo ratings yet

- Exhaust Manifold Remove InstallDocument5 pagesExhaust Manifold Remove InstallSteven Y.MNo ratings yet

- Alternator - Disassemble: Shutdown SIS Previous ScreenDocument15 pagesAlternator - Disassemble: Shutdown SIS Previous ScreennobodymagdesignNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorFrom EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNo ratings yet

- High-Quality Accessories For The Ambitious Model Maker: WWW - Fema-Modelltechnik - de E-Mail: Femamodelltechnik@Gmx - deDocument20 pagesHigh-Quality Accessories For The Ambitious Model Maker: WWW - Fema-Modelltechnik - de E-Mail: Femamodelltechnik@Gmx - deMLenting100% (1)

- Philips 14pv135-14pv235-14pv385Document87 pagesPhilips 14pv135-14pv235-14pv385doraemon007No ratings yet

- ITEM 2-5 - TBV-150LB-2in To 4in-WCB-SS316-RF-LeverDocument1 pageITEM 2-5 - TBV-150LB-2in To 4in-WCB-SS316-RF-LeversatphoenixNo ratings yet

- Bobcat Online Parts Catalog - Engine & Attaching Parts (Engine Mounts) - S130 - 22-08-2023 16-52-19Document3 pagesBobcat Online Parts Catalog - Engine & Attaching Parts (Engine Mounts) - S130 - 22-08-2023 16-52-19Gabriel Pereira SilvaNo ratings yet

- Zeme India Earthing BroucherDocument8 pagesZeme India Earthing BrouchervipinNo ratings yet

- 5 Parts List: CoverDocument59 pages5 Parts List: CoverРома СоловьевNo ratings yet

- Tugas B. InggrisDocument10 pagesTugas B. InggrisAskariz100% (1)

- Push Type Internal Tube Cutter ATP Series & PR68 SeriesDocument1 pagePush Type Internal Tube Cutter ATP Series & PR68 SeriesMilad MNo ratings yet

- Check List For: Installation of Fahu: Project Name & LogosDocument2 pagesCheck List For: Installation of Fahu: Project Name & LogosSamer AliNo ratings yet

- Sony Sa-Ve505Document28 pagesSony Sa-Ve505Sameer SippyNo ratings yet

- Report E&t MMM Tegal Supply BBBDocument46 pagesReport E&t MMM Tegal Supply BBBmmm.parttglNo ratings yet

- Bearing Number Code ReferenceDocument6 pagesBearing Number Code ReferenceIbraheem KhressNo ratings yet

- Brunswick Sweep Wagon AsmDocument11 pagesBrunswick Sweep Wagon AsmTaner İneviNo ratings yet

- Drill: Instruction ManualDocument12 pagesDrill: Instruction Manualcahaya subuhNo ratings yet

- On The Telephone - BusuuDocument5 pagesOn The Telephone - BusuuAida TeskeredžićNo ratings yet

- Microwave & OTG List 2022: VM One Recommended List 2022Document4 pagesMicrowave & OTG List 2022: VM One Recommended List 2022Naveen PandeyNo ratings yet

- Stabilizer GT ModelsDocument92 pagesStabilizer GT ModelsArun SinghNo ratings yet

- ToolsDocument21 pagesToolsKirubakaran AnnaduraiNo ratings yet

- Air Condition Manual Arp 3014Document32 pagesAir Condition Manual Arp 3014Al JacksonNo ratings yet

- Broaches ExporterDocument22 pagesBroaches ExporterDIC TOOLS INDIANo ratings yet

- Kxy5 - SC01 - 220KV Feeder Control Panel - Z.3 PDFDocument129 pagesKxy5 - SC01 - 220KV Feeder Control Panel - Z.3 PDFADE MRTNo ratings yet

- 8th Grade Safety TestDocument5 pages8th Grade Safety TestcankuhnNo ratings yet

- Kit PN 36939 PDFDocument12 pagesKit PN 36939 PDFCarlos Castillo UrrunagaNo ratings yet

- Manual BookDocument21 pagesManual BookAriantoNo ratings yet

- S04 BoomDocument82 pagesS04 BoomJoseNo ratings yet

- 2012 Polaris Service Manual Chapter 08 6x6Document18 pages2012 Polaris Service Manual Chapter 08 6x6Russell ReedNo ratings yet

- Pms449 1 Cache ItemsDocument307 pagesPms449 1 Cache ItemsOQC PetroleumNo ratings yet

- AgustusDocument10 pagesAgustusM zaenal mustofaNo ratings yet