Professional Documents

Culture Documents

SM1 Process

SM1 Process

Uploaded by

True StoryCopyright:

Available Formats

You might also like

- O&M Scope of Work-1Document6 pagesO&M Scope of Work-1Krishna Swamy100% (1)

- Contract To Lease 8 SignedDocument3 pagesContract To Lease 8 SignedBill Turco0% (1)

- Detroit Diesel: Series DD13Document46 pagesDetroit Diesel: Series DD13Jose Santos80% (5)

- Xerox WC 7655-7665-7675 SMDocument1,127 pagesXerox WC 7655-7665-7675 SMPeter xu50% (2)

- National Youth Service Corps: Nysc State Secretariat UyoDocument1 pageNational Youth Service Corps: Nysc State Secretariat UyoAkpoke ShedrackNo ratings yet

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- SM3 ProcessDocument1 pageSM3 ProcessTrue StoryNo ratings yet

- SM2 ProcessDocument1 pageSM2 ProcessTrue StoryNo ratings yet

- BEMS-MP-06 OHS Monitoring and Measurement PlanDocument13 pagesBEMS-MP-06 OHS Monitoring and Measurement PlanrememberNo ratings yet

- EMR Installing PV-380-R3 - AHDocument3 pagesEMR Installing PV-380-R3 - AHahmed nourNo ratings yet

- Manual MCW Trane PDFDocument22 pagesManual MCW Trane PDFNildo MatiasNo ratings yet

- Engine SectionDocument21 pagesEngine SectionKarthii AjuNo ratings yet

- VND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Document5 pagesVND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Asif NNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- BTU Inpections and ReplacementDocument3 pagesBTU Inpections and Replacementshadrack.xuluNo ratings yet

- Earthmoving ChecklistDocument8 pagesEarthmoving ChecklistramodNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Component Replacement Labor: For Crushing EquipmentDocument2 pagesComponent Replacement Labor: For Crushing EquipmentKarin AndersonNo ratings yet

- Checklist - Planning The Safe Set-Up and Operation of Earthmoving EquipmentDocument8 pagesChecklist - Planning The Safe Set-Up and Operation of Earthmoving EquipmentsumayyaNo ratings yet

- Technical Information Letter: Dangers of Bearing RefurbishmentDocument7 pagesTechnical Information Letter: Dangers of Bearing RefurbishmentJJNo ratings yet

- Special Batch Recruitment PT GHPJBDocument1 pageSpecial Batch Recruitment PT GHPJBAshfa UlyaNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- CG SVX19C E4 0911Document100 pagesCG SVX19C E4 0911Omar PiñaNo ratings yet

- ELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentDocument46 pagesELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentRavinder SharmaNo ratings yet

- Handling Not Auto-Assigned Cases Handling Not Auto-Assigned CasesDocument2 pagesHandling Not Auto-Assigned Cases Handling Not Auto-Assigned CasesGinna CuadraNo ratings yet

- Defect Report Sat C AntennaDocument2 pagesDefect Report Sat C AntennaRose AriantiNo ratings yet

- CE Guidance For Construction Machines AttachmentsDocument15 pagesCE Guidance For Construction Machines AttachmentsNikolic DejanNo ratings yet

- Installation Manual: Tall Floor Split Systems 36,000 - 90,000 Btu Cooling Only MCV Series 50/60 HZDocument12 pagesInstallation Manual: Tall Floor Split Systems 36,000 - 90,000 Btu Cooling Only MCV Series 50/60 HZViệt Đặng XuânNo ratings yet

- Cxam IomDocument100 pagesCxam IomThành CôngNo ratings yet

- Common JSA-Job Safety Analysis - 2024Document7 pagesCommon JSA-Job Safety Analysis - 2024Shovon khanNo ratings yet

- en 32 - HCPPDocument9 pagesen 32 - HCPPsoniya RNo ratings yet

- LOGISTIC MAINTENANCE PRESENTATION New-1Document4 pagesLOGISTIC MAINTENANCE PRESENTATION New-1Arief ArbiNo ratings yet

- MC PartsDocument14 pagesMC PartsManoj MariappanNo ratings yet

- SS JSP - 017 Backfilling and CompactionDocument6 pagesSS JSP - 017 Backfilling and CompactionSn Ahsan100% (1)

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Tracer ch532Document32 pagesTracer ch532Валерій МиколайовичNo ratings yet

- 02 - Maintenance MethodDocument32 pages02 - Maintenance MethodLaouali DJARIRI100% (1)

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L Lombardero100% (1)

- Hvac R TechnologiesDocument24 pagesHvac R TechnologiesHifi High-EndNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Garantía Fca de MEGADocument2 pagesGarantía Fca de MEGACristobal Gutierrez CarrascoNo ratings yet

- Ergonomic & Safety Assessment Guide For Machines and EquipmentDocument8 pagesErgonomic & Safety Assessment Guide For Machines and EquipmentqwertyNo ratings yet

- Dungs Mpa22Document112 pagesDungs Mpa22Piotr MNo ratings yet

- 10-Risk AssessmentFor Scaffolding WorkDocument1 page10-Risk AssessmentFor Scaffolding WorkNouman AliNo ratings yet

- Damage Assessment and Reporting: 1. GeneralDocument40 pagesDamage Assessment and Reporting: 1. GeneralhugorgonzalezNo ratings yet

- Form - Inventory of EquipmentDocument2 pagesForm - Inventory of EquipmentBrittaney BatoNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Manufacturing and Service Operations: Learning Block 7 Maintenance and QualityDocument26 pagesManufacturing and Service Operations: Learning Block 7 Maintenance and Qualitymohammad baniissaNo ratings yet

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- MCW Iom Wall Mounted - pdf292 PDFDocument16 pagesMCW Iom Wall Mounted - pdf292 PDFRami Allouh Abu OmarNo ratings yet

- WSD Field Safety Survey Check List - Rev. Jan. 01-23-20Document4 pagesWSD Field Safety Survey Check List - Rev. Jan. 01-23-20Myla AguadoNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Incident Report Template Sample PDF ReportDocument5 pagesIncident Report Template Sample PDF ReportBelbaraka AbdoNo ratings yet

- Lecture 7B Five Countermeasures To Zero BreakdownsDocument1 pageLecture 7B Five Countermeasures To Zero BreakdownsMuhammadNo ratings yet

- SEG Site Survey Agenda For Salak - 02 June 2021Document50 pagesSEG Site Survey Agenda For Salak - 02 June 2021IlkuNo ratings yet

- Detroit Diesel: Series I900Document53 pagesDetroit Diesel: Series I900Jose SantosNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- 09 - Hole CleaningDocument3 pages09 - Hole CleaningTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument19 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument9 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 7.1 - Data AqDocument1 page7.1 - Data AqTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument11 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument24 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 5 - HP Lines Safety ClampDocument1 page5 - HP Lines Safety ClampTrue StoryNo ratings yet

- 6 - Low Pressure Hoses and AccessoriesDocument1 page6 - Low Pressure Hoses and AccessoriesTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument20 pages03 - Rig ComponentsTrue StoryNo ratings yet

- Retrievable Bridge Plug 3Document1 pageRetrievable Bridge Plug 3True StoryNo ratings yet

- Rheological Profile 4Document1 pageRheological Profile 4True StoryNo ratings yet

- Sludge Test 1Document1 pageSludge Test 1True StoryNo ratings yet

- 2 in T.IRONDocument1 page2 in T.IRONTrue StoryNo ratings yet

- Rheological Profile 3Document1 pageRheological Profile 3True StoryNo ratings yet

- Retrievable Bridge Plug 4Document1 pageRetrievable Bridge Plug 4True StoryNo ratings yet

- Retrievable Bridge Plug 5Document1 pageRetrievable Bridge Plug 5True StoryNo ratings yet

- Hydrostatic Setting Tool 8Document1 pageHydrostatic Setting Tool 8True StoryNo ratings yet

- Hydrostatic Setting Tool 5Document1 pageHydrostatic Setting Tool 5True StoryNo ratings yet

- Link Bank Account Application FormDocument4 pagesLink Bank Account Application FormDesire MaharjanNo ratings yet

- Course DescriptionDocument6 pagesCourse DescriptionRyanne BrownNo ratings yet

- Hooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsDocument34 pagesHooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsRafaelMallquiAntialonNo ratings yet

- Paragraph Unity and CoherenceDocument4 pagesParagraph Unity and CoherenceBurhan MuhammadNo ratings yet

- JSD Supply Files Temporary Restraining Order Against ATF May 2022Document129 pagesJSD Supply Files Temporary Restraining Order Against ATF May 2022AmmoLand Shooting Sports News100% (1)

- Republic of The Philippines Securities and Exchange CommissionDocument13 pagesRepublic of The Philippines Securities and Exchange CommissionArmando TerceroNo ratings yet

- Deed of Absolute SaleDocument2 pagesDeed of Absolute SaleDaffodil Queen Poliquit DanosaNo ratings yet

- JMC 2013 01Document97 pagesJMC 2013 01Stephen C AmistadNo ratings yet

- In Re - Cloyd GarraDocument2 pagesIn Re - Cloyd Garrafmrcsc2023No ratings yet

- Quality Improvement 9th Edition Besterfield Solutions ManualDocument35 pagesQuality Improvement 9th Edition Besterfield Solutions Manualmatte.caudalebvf100% (29)

- History - CivicsDocument7 pagesHistory - CivicsSwasthikNo ratings yet

- Condonation of DelayDocument5 pagesCondonation of DelayKabirs CollectionNo ratings yet

- Special Proceedings and Special WritsDocument63 pagesSpecial Proceedings and Special WritsjoliwanagNo ratings yet

- Cruz V People (Exeception of A Warrantless Search - Search Is Valid When It Preceded by A Lawful Arrest)Document2 pagesCruz V People (Exeception of A Warrantless Search - Search Is Valid When It Preceded by A Lawful Arrest)JM BanaNo ratings yet

- AMSA547 - Adhoc Exemption ApplicationDocument2 pagesAMSA547 - Adhoc Exemption Applicationinmran.gNo ratings yet

- Udicial Cademy Harkhand: S S C JDocument46 pagesUdicial Cademy Harkhand: S S C JRicha KesarwaniNo ratings yet

- Agreement Contract Australia - Ahsan, AliDocument4 pagesAgreement Contract Australia - Ahsan, AliDanish KhanNo ratings yet

- CRPC R.P PDFDocument11 pagesCRPC R.P PDFChintakayala SaikrishnaNo ratings yet

- Inter Se BiddingDocument7 pagesInter Se BiddingyamikaNo ratings yet

- Bonafide Certificate Application NewDocument2 pagesBonafide Certificate Application NewRaushan karnNo ratings yet

- Oposa vs. FactoranDocument2 pagesOposa vs. FactoranKARL NERI PLURADNo ratings yet

- Supreme Court Respondents Brief in OppositionDocument16 pagesSupreme Court Respondents Brief in OppositionOKCFOXNo ratings yet

- Tan v. Cinco, Et Al, G.R. No. 213054, June 15, 2016Document2 pagesTan v. Cinco, Et Al, G.R. No. 213054, June 15, 2016Emmanuel Silang100% (1)

- EO No. 002, s-2019 oRGANIZING nEIGHBORHOOD wATCHDocument2 pagesEO No. 002, s-2019 oRGANIZING nEIGHBORHOOD wATCHronamae canoyNo ratings yet

- PWDCertificateDocument1 pagePWDCertificateBipin PatilNo ratings yet

- Jadual Pvif & PvifaDocument2 pagesJadual Pvif & PvifaIsmail FaizelNo ratings yet

- Revised Debate Guidelines AP Week 2022 1Document3 pagesRevised Debate Guidelines AP Week 2022 1JUSTICE100% (1)

- Bandoy v. Jacinto, JR., A.M. No. RTJ-14-2399. November 19, 2014.Document13 pagesBandoy v. Jacinto, JR., A.M. No. RTJ-14-2399. November 19, 2014.Johzzyluck R. MaghuyopNo ratings yet

SM1 Process

SM1 Process

Uploaded by

True StoryOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SM1 Process

SM1 Process

Uploaded by

True StoryCopyright:

Available Formats

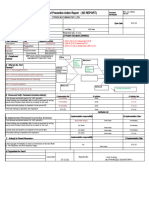

Prepared by:

M. Aly ,MSV Location:

Approved by: Created on: Apr 21

SM1 Process Version:1.0

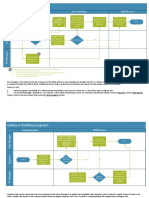

Scope

Each facility shall have a documented process that covers all maintenance requirements arising from preventative maintenance. This Process must include

repair order close out and communication of unit status.

Objective

To maintain all CSC equipment efficiently and uniformly in accordance with WI-OSD-WSD-01, enabling the equipment to perform the task for which it is

designed, in the safest and most cost efficient manner.

Employee Responsibility:

Performing pre-job & post job SM1 is the responsibility of the JS who is in charge of the job execution or any related activity. JS is also responsible for timely

return of SM1 forms to Maintenance Manager. Employees must report the equipment Meter Reading & Fixed Asset Number on SM1 form. Updating unit’s

reports will be done by technicians.

Management Responsibility:

Once notified, Maintenance Manager, Cell Leader/Operation Manager will be responsible for supporting & repairing the reported defects. In the event the

unit will be used with those defects, e.g. awaiting spares or manpower, the need for exemption will be discussed by Maintenance Manager, Cell

Leader/Operation Manager. If necessary, an exemption will be submitted by Maintenance Manager. The Unit will not be released for operation until the

exemption is approved or the unit has been brought to full serviceability status.

GMS/CL receive and review SM1

from field crew GMS review and checks SM1

Technician to update Meter No Are any Yes

Reading on system defects noted?

Technician to file the hardcopy of GMS to assign MT/ET to repair the

SM1 in the proper folder defects. Technician to start work order

Order Spares or Materials.

No Are all spares

available?

GMS discuss the need of the unit and its Yes

current limitation with Cell Leader

Repair defects and test the unit

Technician to record work carried

GMS/CL determine the out, parts used, man hours.

defect/s will have acceptable

No

or no operational impact on

unit performance and can it

carry out the job GMS to review and close the work

order

Exemption not approved

If required GMS

submit exemption

Exemption approved or not required

Unit is out of service unit spares

available and defects rectified

GMS follow up with Repair order,

unit used till spares received

Unit status must be confirmed red

tagged with operation

GMS/CL removes unit from services,

Technician open Repair order

CL: Cell leader

GMS: General Maintenance Manager

"Note: For any question on this SM-1 Process, please refer to WI-OSD-WSD-01Maintenance 'or contact GMS or Location SQ for any help or more guideline.

You might also like

- O&M Scope of Work-1Document6 pagesO&M Scope of Work-1Krishna Swamy100% (1)

- Contract To Lease 8 SignedDocument3 pagesContract To Lease 8 SignedBill Turco0% (1)

- Detroit Diesel: Series DD13Document46 pagesDetroit Diesel: Series DD13Jose Santos80% (5)

- Xerox WC 7655-7665-7675 SMDocument1,127 pagesXerox WC 7655-7665-7675 SMPeter xu50% (2)

- National Youth Service Corps: Nysc State Secretariat UyoDocument1 pageNational Youth Service Corps: Nysc State Secretariat UyoAkpoke ShedrackNo ratings yet

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- SM3 ProcessDocument1 pageSM3 ProcessTrue StoryNo ratings yet

- SM2 ProcessDocument1 pageSM2 ProcessTrue StoryNo ratings yet

- BEMS-MP-06 OHS Monitoring and Measurement PlanDocument13 pagesBEMS-MP-06 OHS Monitoring and Measurement PlanrememberNo ratings yet

- EMR Installing PV-380-R3 - AHDocument3 pagesEMR Installing PV-380-R3 - AHahmed nourNo ratings yet

- Manual MCW Trane PDFDocument22 pagesManual MCW Trane PDFNildo MatiasNo ratings yet

- Engine SectionDocument21 pagesEngine SectionKarthii AjuNo ratings yet

- VND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Document5 pagesVND Openxmlformats-Officedocument Wordprocessingml Document&rendition 1Asif NNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- BTU Inpections and ReplacementDocument3 pagesBTU Inpections and Replacementshadrack.xuluNo ratings yet

- Earthmoving ChecklistDocument8 pagesEarthmoving ChecklistramodNo ratings yet

- New JuneDocument6 pagesNew JuneShovon khanNo ratings yet

- Component Replacement Labor: For Crushing EquipmentDocument2 pagesComponent Replacement Labor: For Crushing EquipmentKarin AndersonNo ratings yet

- Checklist - Planning The Safe Set-Up and Operation of Earthmoving EquipmentDocument8 pagesChecklist - Planning The Safe Set-Up and Operation of Earthmoving EquipmentsumayyaNo ratings yet

- Technical Information Letter: Dangers of Bearing RefurbishmentDocument7 pagesTechnical Information Letter: Dangers of Bearing RefurbishmentJJNo ratings yet

- Special Batch Recruitment PT GHPJBDocument1 pageSpecial Batch Recruitment PT GHPJBAshfa UlyaNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Opertaing Window LimitsDocument6 pagesOpertaing Window LimitshejaNo ratings yet

- CG SVX19C E4 0911Document100 pagesCG SVX19C E4 0911Omar PiñaNo ratings yet

- ELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentDocument46 pagesELEC-E8409 High Voltage Engineering Condition Monitoring of Electrical EquipmentRavinder SharmaNo ratings yet

- Handling Not Auto-Assigned Cases Handling Not Auto-Assigned CasesDocument2 pagesHandling Not Auto-Assigned Cases Handling Not Auto-Assigned CasesGinna CuadraNo ratings yet

- Defect Report Sat C AntennaDocument2 pagesDefect Report Sat C AntennaRose AriantiNo ratings yet

- CE Guidance For Construction Machines AttachmentsDocument15 pagesCE Guidance For Construction Machines AttachmentsNikolic DejanNo ratings yet

- Installation Manual: Tall Floor Split Systems 36,000 - 90,000 Btu Cooling Only MCV Series 50/60 HZDocument12 pagesInstallation Manual: Tall Floor Split Systems 36,000 - 90,000 Btu Cooling Only MCV Series 50/60 HZViệt Đặng XuânNo ratings yet

- Cxam IomDocument100 pagesCxam IomThành CôngNo ratings yet

- Common JSA-Job Safety Analysis - 2024Document7 pagesCommon JSA-Job Safety Analysis - 2024Shovon khanNo ratings yet

- en 32 - HCPPDocument9 pagesen 32 - HCPPsoniya RNo ratings yet

- LOGISTIC MAINTENANCE PRESENTATION New-1Document4 pagesLOGISTIC MAINTENANCE PRESENTATION New-1Arief ArbiNo ratings yet

- MC PartsDocument14 pagesMC PartsManoj MariappanNo ratings yet

- SS JSP - 017 Backfilling and CompactionDocument6 pagesSS JSP - 017 Backfilling and CompactionSn Ahsan100% (1)

- Jsa For Choke Valve InstallationDocument9 pagesJsa For Choke Valve InstallationjavithNo ratings yet

- Tracer ch532Document32 pagesTracer ch532Валерій МиколайовичNo ratings yet

- 02 - Maintenance MethodDocument32 pages02 - Maintenance MethodLaouali DJARIRI100% (1)

- 1420-2R1 Lube Oil Logic Enhancement PDFDocument4 pages1420-2R1 Lube Oil Logic Enhancement PDFManuel L Lombardero100% (1)

- Hvac R TechnologiesDocument24 pagesHvac R TechnologiesHifi High-EndNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Garantía Fca de MEGADocument2 pagesGarantía Fca de MEGACristobal Gutierrez CarrascoNo ratings yet

- Ergonomic & Safety Assessment Guide For Machines and EquipmentDocument8 pagesErgonomic & Safety Assessment Guide For Machines and EquipmentqwertyNo ratings yet

- Dungs Mpa22Document112 pagesDungs Mpa22Piotr MNo ratings yet

- 10-Risk AssessmentFor Scaffolding WorkDocument1 page10-Risk AssessmentFor Scaffolding WorkNouman AliNo ratings yet

- Damage Assessment and Reporting: 1. GeneralDocument40 pagesDamage Assessment and Reporting: 1. GeneralhugorgonzalezNo ratings yet

- Form - Inventory of EquipmentDocument2 pagesForm - Inventory of EquipmentBrittaney BatoNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- Manufacturing and Service Operations: Learning Block 7 Maintenance and QualityDocument26 pagesManufacturing and Service Operations: Learning Block 7 Maintenance and Qualitymohammad baniissaNo ratings yet

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- Job Safety AnalysisDocument6 pagesJob Safety AnalysisMuhammad TariqNo ratings yet

- MCW Iom Wall Mounted - pdf292 PDFDocument16 pagesMCW Iom Wall Mounted - pdf292 PDFRami Allouh Abu OmarNo ratings yet

- WSD Field Safety Survey Check List - Rev. Jan. 01-23-20Document4 pagesWSD Field Safety Survey Check List - Rev. Jan. 01-23-20Myla AguadoNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Incident Report Template Sample PDF ReportDocument5 pagesIncident Report Template Sample PDF ReportBelbaraka AbdoNo ratings yet

- Lecture 7B Five Countermeasures To Zero BreakdownsDocument1 pageLecture 7B Five Countermeasures To Zero BreakdownsMuhammadNo ratings yet

- SEG Site Survey Agenda For Salak - 02 June 2021Document50 pagesSEG Site Survey Agenda For Salak - 02 June 2021IlkuNo ratings yet

- Detroit Diesel: Series I900Document53 pagesDetroit Diesel: Series I900Jose SantosNo ratings yet

- Jsa-Rp-003 Rebar WorksDocument15 pagesJsa-Rp-003 Rebar Worksibaig1970100% (1)

- Jsa-Rp-004 Form WorksDocument13 pagesJsa-Rp-004 Form Worksibaig1970No ratings yet

- 09 - Hole CleaningDocument3 pages09 - Hole CleaningTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument19 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument9 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 7.1 - Data AqDocument1 page7.1 - Data AqTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument11 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument24 pages03 - Rig ComponentsTrue StoryNo ratings yet

- 5 - HP Lines Safety ClampDocument1 page5 - HP Lines Safety ClampTrue StoryNo ratings yet

- 6 - Low Pressure Hoses and AccessoriesDocument1 page6 - Low Pressure Hoses and AccessoriesTrue StoryNo ratings yet

- 03 - Rig ComponentsDocument20 pages03 - Rig ComponentsTrue StoryNo ratings yet

- Retrievable Bridge Plug 3Document1 pageRetrievable Bridge Plug 3True StoryNo ratings yet

- Rheological Profile 4Document1 pageRheological Profile 4True StoryNo ratings yet

- Sludge Test 1Document1 pageSludge Test 1True StoryNo ratings yet

- 2 in T.IRONDocument1 page2 in T.IRONTrue StoryNo ratings yet

- Rheological Profile 3Document1 pageRheological Profile 3True StoryNo ratings yet

- Retrievable Bridge Plug 4Document1 pageRetrievable Bridge Plug 4True StoryNo ratings yet

- Retrievable Bridge Plug 5Document1 pageRetrievable Bridge Plug 5True StoryNo ratings yet

- Hydrostatic Setting Tool 8Document1 pageHydrostatic Setting Tool 8True StoryNo ratings yet

- Hydrostatic Setting Tool 5Document1 pageHydrostatic Setting Tool 5True StoryNo ratings yet

- Link Bank Account Application FormDocument4 pagesLink Bank Account Application FormDesire MaharjanNo ratings yet

- Course DescriptionDocument6 pagesCourse DescriptionRyanne BrownNo ratings yet

- Hooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsDocument34 pagesHooks: Safety Standard For Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and SlingsRafaelMallquiAntialonNo ratings yet

- Paragraph Unity and CoherenceDocument4 pagesParagraph Unity and CoherenceBurhan MuhammadNo ratings yet

- JSD Supply Files Temporary Restraining Order Against ATF May 2022Document129 pagesJSD Supply Files Temporary Restraining Order Against ATF May 2022AmmoLand Shooting Sports News100% (1)

- Republic of The Philippines Securities and Exchange CommissionDocument13 pagesRepublic of The Philippines Securities and Exchange CommissionArmando TerceroNo ratings yet

- Deed of Absolute SaleDocument2 pagesDeed of Absolute SaleDaffodil Queen Poliquit DanosaNo ratings yet

- JMC 2013 01Document97 pagesJMC 2013 01Stephen C AmistadNo ratings yet

- In Re - Cloyd GarraDocument2 pagesIn Re - Cloyd Garrafmrcsc2023No ratings yet

- Quality Improvement 9th Edition Besterfield Solutions ManualDocument35 pagesQuality Improvement 9th Edition Besterfield Solutions Manualmatte.caudalebvf100% (29)

- History - CivicsDocument7 pagesHistory - CivicsSwasthikNo ratings yet

- Condonation of DelayDocument5 pagesCondonation of DelayKabirs CollectionNo ratings yet

- Special Proceedings and Special WritsDocument63 pagesSpecial Proceedings and Special WritsjoliwanagNo ratings yet

- Cruz V People (Exeception of A Warrantless Search - Search Is Valid When It Preceded by A Lawful Arrest)Document2 pagesCruz V People (Exeception of A Warrantless Search - Search Is Valid When It Preceded by A Lawful Arrest)JM BanaNo ratings yet

- AMSA547 - Adhoc Exemption ApplicationDocument2 pagesAMSA547 - Adhoc Exemption Applicationinmran.gNo ratings yet

- Udicial Cademy Harkhand: S S C JDocument46 pagesUdicial Cademy Harkhand: S S C JRicha KesarwaniNo ratings yet

- Agreement Contract Australia - Ahsan, AliDocument4 pagesAgreement Contract Australia - Ahsan, AliDanish KhanNo ratings yet

- CRPC R.P PDFDocument11 pagesCRPC R.P PDFChintakayala SaikrishnaNo ratings yet

- Inter Se BiddingDocument7 pagesInter Se BiddingyamikaNo ratings yet

- Bonafide Certificate Application NewDocument2 pagesBonafide Certificate Application NewRaushan karnNo ratings yet

- Oposa vs. FactoranDocument2 pagesOposa vs. FactoranKARL NERI PLURADNo ratings yet

- Supreme Court Respondents Brief in OppositionDocument16 pagesSupreme Court Respondents Brief in OppositionOKCFOXNo ratings yet

- Tan v. Cinco, Et Al, G.R. No. 213054, June 15, 2016Document2 pagesTan v. Cinco, Et Al, G.R. No. 213054, June 15, 2016Emmanuel Silang100% (1)

- EO No. 002, s-2019 oRGANIZING nEIGHBORHOOD wATCHDocument2 pagesEO No. 002, s-2019 oRGANIZING nEIGHBORHOOD wATCHronamae canoyNo ratings yet

- PWDCertificateDocument1 pagePWDCertificateBipin PatilNo ratings yet

- Jadual Pvif & PvifaDocument2 pagesJadual Pvif & PvifaIsmail FaizelNo ratings yet

- Revised Debate Guidelines AP Week 2022 1Document3 pagesRevised Debate Guidelines AP Week 2022 1JUSTICE100% (1)

- Bandoy v. Jacinto, JR., A.M. No. RTJ-14-2399. November 19, 2014.Document13 pagesBandoy v. Jacinto, JR., A.M. No. RTJ-14-2399. November 19, 2014.Johzzyluck R. MaghuyopNo ratings yet