Professional Documents

Culture Documents

02 Vetonit Masonry Mortar - Group 180821

02 Vetonit Masonry Mortar - Group 180821

Uploaded by

Maha MuflehOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

02 Vetonit Masonry Mortar - Group 180821

02 Vetonit Masonry Mortar - Group 180821

Uploaded by

Maha MuflehCopyright:

Available Formats

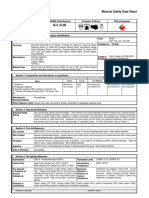

Construction Materials Product Data Sheet

Vetonit Masonry

Mortar

Premixed cementitious masonry

mortar

Uses

u Use Masonry Mortar internally or externally, in

wet & dry conditions, onto block walls & rough

surfaces.

u Use Masonry Mortar for cement & concrete

blocks and panels.

u Use Masonry Mortar for filling walls and joints.

Product Description

Masonry Mortar is a cement-based coat composed of hydraulic binders, selected aggregates, and high-performance

additives. It is supplied as a dry powder in pre-weighed bags ready to use on-site, which requires only the addition

of clean water to produce cohesive mortar. Masonry Mortar is a premium quality product that contains a special

adhesion additive. Masonry Mortar can be applied in thickness from 5mm to 50mm.

Mortar

Advantages Technical Data

u Factory controlled pre-blend ensures Vetonit Masonry Mortar Typical Values @ 25ºC

consistently high quality. Appearance Grey colour Powder

Technical Data Sheet -Vetonit Masonry

u Requires only the addition of water on-site at Aggregate size 2.4 mm max

the time of usage. Wet density (Kg/Liter) 1.90 approx.

u Suitable for ME harsh weather conditions. Pot time @ 25°C 1.5 hrs approx.

Setting Time @ 25°C 3 - 4 hrs

u When using the Silo system Easy application Compressive Strength

with uniform work flow enables high 12.4 N/mm2

@ 28 day (ASTM C109)

productivity & superior finishing.

Flexural Strength

3.0 N/mm2

u Strong adhesion on a variety of concrete blocks. @ 28 day (ASTM C348)

u Strong bond in blocks & wall joints. Flexural Bond Strength

0.15 N/mm2

@ 28 day (ASTM C1072)

u Internal & external applications. Air Content ≤ 14%

u Suitable for wet to dry conditions. Reaction to Fire

Class A1

(BSEN 998-2)

Standards Compliance Usage Instructions

h ASTM C348 & C109 Block Surface Preparation

h ASTM C270 & C780 The block wall surface should be sound, clean, free from

h BSEN 998-2, Type G loose material, grease, laitance, dirt curing compound,

etc.

h ASTM C1072

Before Masonry Mortar’s application, wet the entire

surface with clean potable water, and the surface

should look damp at the time of Masonry Mortar’s

application.

Product Data Sheet Construction Materials

Mixing Shelf Life & Storage

Add to the mixing container 8 - 10 liters of water for

The original sealed bag of Masonry Mortar has a shelf

each 50Kg bag of Masonry Mortar. Add the powder to

life of 12 months, provided it is stored clear of ground

the water and mix with a mechanical plaster mixer or

in a dry, shaded place, at temperatures between 5ºC -

low-speed electric drill fitted with a suitable paddle

35ºC.

for 3-4 minutes until achieving a uniform, lump-free

consistency.

Health & Safety

Leave the mixed material to stand for 10 min and briefly

Masonry Mortar is highly alkaline; therefore, avoid

remix without the addition of water.

direct contact with eyes or skin. It is recommended to

Blend Masonry Mortar manually for small quantities use protective gloves and goggles during application.

and maintain the correct amount of powder to water. Any skin contact should be wash with soap & water. In

Mix for approximately 1-2 minutes, until achieving a case of eye irritation, immediately wash with a copious

homogeneous mix. amount of clean cold water. Seek medical advice.

Application Masonry Mortar is non-flammable.

Neutralize the suction of the block surface with water For further information, please refer to the material

before applying mortar. Remove any excess water. safety data sheet.

Spread Masonry mortar with a trowel on the surface Additional Information

and joints where the blocks are mounted.

Saveto manufactures a wide range of construction

Fill joint in a similar way as conventional sand/cement chemicals and specialty products for various

mortar. applications divided into the following product groups:

After stiffening, give the masonry mortar a final u Waterproofing Systems.

smoothing to remove protrusions and eliminates

undulations. u Concrete Repairs & Grouts.

Mortar

u Flooring Systems.

Cleaning

u Wall & Facade Systems.

Clean all tools immediately after finishing by water.

Clean hardened material mechanically. u Sealants and Joints.

u Renders & Finishes.

Packaging & Coverage

Technical Data Sheet -Vetonit Masonry

u Plasters & Masonry.

Product Pack Size u Tiling Systems

Masonry Mortar 50 Kg Bag

u Primers & Ancillary Products.

Product Coverage u Thermal Insulation Systems.

15 L.M/ 10mm (Solid block

400x200x200 mm u Pretective Coatings.

22 L.M/ 10mm (Solid block u Accessories.

Masonry Mortar

400x200x150 mm

Saveto also provides various technical information

31 L.M/ 10mm (Solid block

such as CAD details, detailed method statements,

400x200x100 mm

specification clauses, application manuals, product

Stated consumption data are for general guidance. selectors and technical support both in contractors

Actual consumption depends on the nature of the and consultants offices as well as construction sites.

substrate, method of application, and wastage.

For further information on these products and systems

kindly check our website or contact your local Saveto

representative.

LEGAL DISCLAIMER

Saveto endeavors to ensure that any advice, recommendations, information it may give is accurate and correct. It cannot accept any

liability either directly or indirectly arising from the use of its products because it has no direct or continuous control over where or how

its products are applied, whether or not following any advice, specification, recommendation, or information given by us. Saveto has the

right to change any of the technical datasheets’ specifications upon its discretion without prior notification.

Hard copies of TDSs are printed once or twice a year. Our technical data sheets are continuously updated as per R&D improvements and

new 3rd party testing; kindly refer to our website for the latest updated TDSs.

Ref No.: G7-PP0012-9-21 www.saveto.com

You might also like

- UCO Reporter 2022, March Edition, February 27, 2022Document44 pagesUCO Reporter 2022, March Edition, February 27, 2022ucopresidentNo ratings yet

- ACLS Study Guide NewDocument35 pagesACLS Study Guide NewNIRANJANA SHALINI100% (1)

- Typologies GSAS Design Assessment v2.1Document180 pagesTypologies GSAS Design Assessment v2.1Dinesh GuptaNo ratings yet

- Northern Research GroupDocument2 pagesNorthern Research GroupTeam GuidoNo ratings yet

- PC Marine Epoxy PuttyDocument8 pagesPC Marine Epoxy PuttymarkmarkNo ratings yet

- Green Building Leed Rating LEED NC GeneralDocument6 pagesGreen Building Leed Rating LEED NC GeneralAmit Kumar GuptaNo ratings yet

- LEED V4 Green Associate SimplifiedDocument42 pagesLEED V4 Green Associate SimplifiedBABUNo ratings yet

- ISI Envision Manual v3 en BookmarkedDocument192 pagesISI Envision Manual v3 en Bookmarkedsaurabh singhNo ratings yet

- Talib Tareq Mohan Program 30CDocument1 pageTalib Tareq Mohan Program 30CTalib AltememyNo ratings yet

- Gsas Check ListDocument10 pagesGsas Check ListΒΑΓΓΕΛΗΣ ΑΝΤΩΝΙΟΥNo ratings yet

- Saudi Environmental Standard 1Document13 pagesSaudi Environmental Standard 1Babu Veeraraghavan100% (1)

- Chapter 1-Introduction To Green BuildingsDocument40 pagesChapter 1-Introduction To Green Buildingsniti860No ratings yet

- Mudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byDocument2 pagesMudon Ahlia Real Estate Co.W.L.L. Annual Training Plan 2014: Prepared byHebatallah FahmyNo ratings yet

- Environmental Aspects, Impacts and Its Evaluation: AuthorizationDocument7 pagesEnvironmental Aspects, Impacts and Its Evaluation: AuthorizationMukilan ThiruNo ratings yet

- NEBOSH IGC3 - Tanveer Sayyad at Green World GroupDocument24 pagesNEBOSH IGC3 - Tanveer Sayyad at Green World GroupTapas DasNo ratings yet

- GSAS Technical Guide V2.2-06Document88 pagesGSAS Technical Guide V2.2-06pallabdgNo ratings yet

- Implementing LEED: How You Can Do It, TooDocument50 pagesImplementing LEED: How You Can Do It, TooktbaluNo ratings yet

- L E E D: T C P: Eadership IN Nergy AND Nvironmental Esign HE Ertification RocessDocument4 pagesL E E D: T C P: Eadership IN Nergy AND Nvironmental Esign HE Ertification RocessMichael BrownNo ratings yet

- Nadeem Environmental Engineer CV For Job in UAEDocument3 pagesNadeem Environmental Engineer CV For Job in UAEmerajNo ratings yet

- Training Methods: H. LouisDocument31 pagesTraining Methods: H. LouisHazelLouisNo ratings yet

- (Sop13) Lus Hse Sp2 446 005.01 Fire PreventionDocument28 pages(Sop13) Lus Hse Sp2 446 005.01 Fire PreventionRichu PaliNo ratings yet

- Enhanced Indoor Air Quality Strategies LEEDv4Document3 pagesEnhanced Indoor Air Quality Strategies LEEDv4Clifford Allen CooperNo ratings yet

- LEED For New Construction and Major Renovations (v4) : Location & TransportationDocument1 pageLEED For New Construction and Major Renovations (v4) : Location & TransportationAnupama ChettyNo ratings yet

- Exam MMUP TotalDocument11 pagesExam MMUP TotalTariq AtiyahNo ratings yet

- Reactive Chemicals Training PresentationDocument25 pagesReactive Chemicals Training Presentationtatarey79100% (1)

- PCRS Submittal User Guide - PQPDocument22 pagesPCRS Submittal User Guide - PQPneshat.sakeenaNo ratings yet

- Bitustick - XL-Material Safety Data SheetDocument2 pagesBitustick - XL-Material Safety Data Sheetaldred_chezka100% (1)

- Eco Friendly FestivalsDocument41 pagesEco Friendly FestivalsAnantha Chandra100% (1)

- Basf Masterkure 181 TdsDocument2 pagesBasf Masterkure 181 Tdssirui xuNo ratings yet

- WWW - Mgli.gujarat - Gov.in: (An Autonomous Institute of The Govt. of Gujarat)Document1 pageWWW - Mgli.gujarat - Gov.in: (An Autonomous Institute of The Govt. of Gujarat)feafvaevsNo ratings yet

- Technical Writtig and Presentation Skills: To Study The Green ConceptDocument22 pagesTechnical Writtig and Presentation Skills: To Study The Green ConceptMehwishNo ratings yet

- LEEDDocument11 pagesLEEDShafiur RahmanNo ratings yet

- Forklift Operator Training CourseDocument57 pagesForklift Operator Training Courseshahbaz akramNo ratings yet

- EIA Consultant OrganizationDocument41 pagesEIA Consultant Organizationshobhit2310100% (1)

- 3340-Sds-Petromin Atf Dexron Ii e V#2Document6 pages3340-Sds-Petromin Atf Dexron Ii e V#2SICIM SAUDI ARABIANo ratings yet

- Environmental ChecklistDocument5 pagesEnvironmental ChecklistKaycee ChirendaNo ratings yet

- LEED GA Handbook 2020 PDFDocument19 pagesLEED GA Handbook 2020 PDFsumana raniNo ratings yet

- Emergency PlanDocument1 pageEmergency Planapi-285003764No ratings yet

- Leed AP Exam PostDocument1 pageLeed AP Exam PostJadedTNo ratings yet

- Professional Accreditation Exam: Study GuideDocument4 pagesProfessional Accreditation Exam: Study GuideSk Abdul RavoofNo ratings yet

- Diesel Fuel MsdsDocument5 pagesDiesel Fuel MsdsAngelNo ratings yet

- Environmental Management Monitoring PlanDocument4 pagesEnvironmental Management Monitoring PlanMekonen YeteshaNo ratings yet

- 6-National Environmental Standards-Best Practicable Environmental Option For Waste Disposal PDFDocument19 pages6-National Environmental Standards-Best Practicable Environmental Option For Waste Disposal PDFfedericoNo ratings yet

- EM001 Environment ManualDocument19 pagesEM001 Environment ManualAvinash KumarNo ratings yet

- Fire Prevention Checklist For Storage WarehouseDocument2 pagesFire Prevention Checklist For Storage WarehouseNikita KadamNo ratings yet

- HSSE Manual Table of ContentDocument40 pagesHSSE Manual Table of ContentTao Qu100% (1)

- LL86 Reporting Worksheet-LEEDDocument2 pagesLL86 Reporting Worksheet-LEEDChris GonzalesNo ratings yet

- Construction Waste Management and DisposalDocument6 pagesConstruction Waste Management and DisposalLOCKEY SQUADNo ratings yet

- Safety Assessment in HM SymphonyDocument26 pagesSafety Assessment in HM Symphonyvilge rogesonNo ratings yet

- EHS Manager or Safety Director or Safety Engineer or Manager IHDocument2 pagesEHS Manager or Safety Director or Safety Engineer or Manager IHapi-77833504No ratings yet

- Hazardous WasteDocument16 pagesHazardous WasteJasonNo ratings yet

- Prequalification Manual FOR Scaffolding ServicesDocument63 pagesPrequalification Manual FOR Scaffolding ServicesmariaNo ratings yet

- Eia Project 3 Alaojipowerstationrep1Document171 pagesEia Project 3 Alaojipowerstationrep1Bakare Horlaniyi HaryodeleNo ratings yet

- Guide GreenOps c2009Document108 pagesGuide GreenOps c2009Andreea GavriloaeaNo ratings yet

- IDC Candidate Handbook 2018Document18 pagesIDC Candidate Handbook 2018Sushil SirsatNo ratings yet

- 5-Monthly Environment ReportDocument2 pages5-Monthly Environment ReportMohamed RizwanNo ratings yet

- Incident/Accident Report: NO: INC/FCSB/HSE/001/2022 Dindings Poultry Processing Project PlantDocument5 pagesIncident/Accident Report: NO: INC/FCSB/HSE/001/2022 Dindings Poultry Processing Project PlantKhaty JahNo ratings yet

- LEED Certification WorkflowDocument1 pageLEED Certification WorkflowCarissa WatanabeNo ratings yet

- CEM - Question Bank (Answers)Document25 pagesCEM - Question Bank (Answers)Ar Venu NatarajNo ratings yet

- Sound Level Survey Form I: Person/EquipmentDocument1 pageSound Level Survey Form I: Person/EquipmentRetselisitsoeNo ratings yet

- LEEDGreenAssociate v4 CandidateHandbook 0Document15 pagesLEEDGreenAssociate v4 CandidateHandbook 0aNo ratings yet

- 01 Masonry Grout Filler - Group 180821Document2 pages01 Masonry Grout Filler - Group 180821Maha MuflehNo ratings yet

- 06 Premium Project Fix - Group 180821Document2 pages06 Premium Project Fix - Group 180821m.aliNo ratings yet

- BE-186, BE-188 Series MSDSDocument8 pagesBE-186, BE-188 Series MSDSMaha MuflehNo ratings yet

- Product Doc 3076Document14 pagesProduct Doc 3076Maha MuflehNo ratings yet

- Epikure 3200 3223 3234 3245 TDSDocument2 pagesEpikure 3200 3223 3234 3245 TDSMaha MuflehNo ratings yet

- SeminarDocument88 pagesSeminarMaha MuflehNo ratings yet

- Vetoproof EC720 - MSDSDocument15 pagesVetoproof EC720 - MSDSMaha MuflehNo ratings yet

- VINNAPAS®Document20 pagesVINNAPAS®Maha MuflehNo ratings yet

- Isomat Resin Floorings - enDocument36 pagesIsomat Resin Floorings - enMaha MuflehNo ratings yet

- Guide To BS EN 998 - 1Document6 pagesGuide To BS EN 998 - 1Maha MuflehNo ratings yet

- Monneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Document3 pagesMonneli Epofloor E250 - DOC - TECHNICAL - MAP - en - 963Maha MuflehNo ratings yet

- ProLast - Hardener - MSDS - 0Document6 pagesProLast - Hardener - MSDS - 0Maha MuflehNo ratings yet

- The Classic Balance With Robust Tuning Fork Measuring SystemDocument2 pagesThe Classic Balance With Robust Tuning Fork Measuring SystemMaha MuflehNo ratings yet

- Sikafloor - 290 PrimerDocument4 pagesSikafloor - 290 PrimerMaha MuflehNo ratings yet

- SDS Weberfloor VB HardenerDocument22 pagesSDS Weberfloor VB HardenerMaha MuflehNo ratings yet

- Polyplast - TDS - PC Type R - Powder - v2021Document2 pagesPolyplast - TDS - PC Type R - Powder - v2021Maha MuflehNo ratings yet

- 1120 - Epoxy Grundierharz GH 50 Komp B - (GB)Document8 pages1120 - Epoxy Grundierharz GH 50 Komp B - (GB)Maha MuflehNo ratings yet

- Epocure - Product GuideDocument12 pagesEpocure - Product GuideMaha MuflehNo ratings yet

- Sika Sikafloor 151 Sds B Promain 22 07 2019Document14 pagesSika Sikafloor 151 Sds B Promain 22 07 2019Maha MuflehNo ratings yet

- Flexprime PS100 - BaseDocument6 pagesFlexprime PS100 - BaseMaha MuflehNo ratings yet

- MasterTop P 617 PTADocument15 pagesMasterTop P 617 PTAMaha MuflehNo ratings yet

- Nitoprime 25 Base SDS26566 44Document9 pagesNitoprime 25 Base SDS26566 44Maha MuflehNo ratings yet

- 1119 - Epoxy Grundierharz GH 50 Komp A - (GB)Document9 pages1119 - Epoxy Grundierharz GH 50 Komp A - (GB)Maha MuflehNo ratings yet

- 2566 - 30305 - Epoxy Grundierharz GH 50 - 20200513 - 110701Document4 pages2566 - 30305 - Epoxy Grundierharz GH 50 - 20200513 - 110701Maha MuflehNo ratings yet

- Mastertop - 1620 v1Document2 pagesMastertop - 1620 v1Maha MuflehNo ratings yet

- NITOFLOR SL2000 Jordan 1 5 19Document3 pagesNITOFLOR SL2000 Jordan 1 5 19Maha MuflehNo ratings yet

- SDS Weberfloor VB ResinDocument25 pagesSDS Weberfloor VB ResinMaha MuflehNo ratings yet

- Nitoflor BrochureDocument13 pagesNitoflor BrochureMaha MuflehNo ratings yet

- TDS Weberfloor EposilDocument2 pagesTDS Weberfloor EposilMaha MuflehNo ratings yet

- 18 Vetogrout EG340 - 180321Document2 pages18 Vetogrout EG340 - 180321Maha MuflehNo ratings yet

- SDS NITOFLOR SL1000 IndiaDocument29 pagesSDS NITOFLOR SL1000 IndiaMaha MuflehNo ratings yet

- TDS Weberfloor Epo PrimeDocument2 pagesTDS Weberfloor Epo PrimeMaha MuflehNo ratings yet

- Display CAT PDFDocument2 pagesDisplay CAT PDFAndres130No ratings yet

- Südmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesDocument2 pagesSüdmo: Leakage Butterfly Valves Hygienic Shut-Off ValvesBob DylanNo ratings yet

- Performance Task 1. Piecewise FunctionDocument3 pagesPerformance Task 1. Piecewise FunctionKatherine Jane GeronaNo ratings yet

- GSB Samaj Foundation - List of Goud Saraswat Brahmin SurnamesDocument2 pagesGSB Samaj Foundation - List of Goud Saraswat Brahmin SurnamesShree Vishnu ShastriNo ratings yet

- Soliven vs. FastformsDocument2 pagesSoliven vs. FastformsClaudine Allyson DungoNo ratings yet

- Cases Study of Kellogg's Failure in Indian Market FullDocument17 pagesCases Study of Kellogg's Failure in Indian Market FullAjay PillaiNo ratings yet

- CV (2) - 2Document3 pagesCV (2) - 2abhishek.berkmanNo ratings yet

- BOMDocument1 pageBOMHytech Pvt. Ltd.No ratings yet

- 3admin - 7Document13 pages3admin - 7JMXNo ratings yet

- Example of Research Paper About Science and TechnologyDocument6 pagesExample of Research Paper About Science and Technologygz8aqe8wNo ratings yet

- Adaptable Multi Nut Fastner With Manual Height Adjustment SystemDocument48 pagesAdaptable Multi Nut Fastner With Manual Height Adjustment SystemANAND KRISHNANNo ratings yet

- Kirch GroupDocument13 pagesKirch GroupStacy ChackoNo ratings yet

- Minerals Potential - Minerals Law of Lao PDRDocument44 pagesMinerals Potential - Minerals Law of Lao PDRkhamsone pengmanivongNo ratings yet

- 5 Basement Cu Belt Zambia PDFDocument51 pages5 Basement Cu Belt Zambia PDFAlberto Lobo-Guerrero SanzNo ratings yet

- PointersDocument147 pagesPointersSoumya VijoyNo ratings yet

- Compatibilidades Equipos HaierDocument5 pagesCompatibilidades Equipos HaierAndrei AtofaneiNo ratings yet

- Notice of Meeting-1st MDC Ldip Alignment Meeting & WsDocument5 pagesNotice of Meeting-1st MDC Ldip Alignment Meeting & WsByaheng CawayanNo ratings yet

- Dynamic Simulation of A Crude Oil DistillationDocument14 pagesDynamic Simulation of A Crude Oil DistillationAL-JABERI SADEQ AMEEN ABDO / UPMNo ratings yet

- Athul AjiDocument5 pagesAthul AjiAsif SNo ratings yet

- M Cecconi 2023 Intensive Care FundamentalsDocument278 pagesM Cecconi 2023 Intensive Care FundamentalsGustavo ParedesNo ratings yet

- DHL Strategy ModelDocument59 pagesDHL Strategy Modelfssankar100% (12)

- Study On Vehicle Loan Disbursement ProceDocument11 pagesStudy On Vehicle Loan Disbursement ProceRuby PrajapatiNo ratings yet

- CA ProjectDocument21 pagesCA Projectkalaswami100% (1)

- NJM072B/082B/072/082: Dual J-Fet Input Operational AmplifierDocument5 pagesNJM072B/082B/072/082: Dual J-Fet Input Operational Amplifieryuni supriatinNo ratings yet

- Gyrator - Wikipedia PDFDocument44 pagesGyrator - Wikipedia PDFRishabh MishraNo ratings yet

- Corona RT 46 160Document120 pagesCorona RT 46 160Rimbert100% (2)

- Solar Charge Controller User Manual: I Functional CharacteristicsDocument5 pagesSolar Charge Controller User Manual: I Functional CharacteristicsAmer WarrakNo ratings yet