Professional Documents

Culture Documents

Blasting SSPC-10

Blasting SSPC-10

Uploaded by

ISGEC NTPC, BarauniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blasting SSPC-10

Blasting SSPC-10

Uploaded by

ISGEC NTPC, BarauniCopyright:

Available Formats

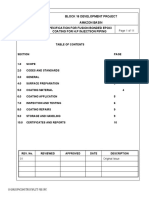

This page is integral part of Contract ref no. CS-8004-132C-9-FC/SC-COA-6949/50 dated 09.07.

2020, digitally signed between NTPC & ISGEC.

CLAUSE NO.

TECHNICAL REQUIREMENTS

5.01.00 (a) General (Applicable for Coating system as per 4.02.00 (a))

a) The coating and wrapping operation shall include surface preparations,

application of pre-wrapping solution (primer) and application of layer of anti-

corrosion protection tape. The above operation shall be performed under the

supervision of and performed by personnel skilled in the application of same type

of pre-fabricated tapes.

b) Inspection of the coating and wrapping of the pipes shall be performed by

qualified inspectors.

5.01.00 (b) General (Applicable for Coating system as per 4.02.00 (b))

a) The coating and wrapping operation shall include surface preparations,

application of primer, heating and applying the coaltar coating and wrapping of

glass fibre mat and white wash over external surface of finished coating. The

above operation shall be performed under the supervision of and performed by

personnel skilled in the application of coaltar enamel coating and wrapping.

b) Inspection of the coating and wrapping of the pipes shall be performed by

qualified inspectors.

5.02.00 Surface Preparation

a) Before the pipe is blasted, all oil, grease or other contaminants shall be removed

by flushing with a suitable solvent (in accordance with SSPC-SP-I) and wiping

with clean rags. The use of dirty or oily rags or dirty solvent will not be permitted.

b) Prior to cleaning operation, the pipes shall be visually examined to ensure that all

defects, flats and other parts damaged have been repaired or removed.

c) The abrasive blast material shall be free of impurities such as clay, dirt, debris,

oil, grease, salts or other contamination.

d) All metal surfaces shall be cleaned by blasting. Blasting operations shall remove

all rust scale and other impurities from the steel surface. The surface shall be

blast cleaned to near white metal finish as per SSPC SP10. Shot blast operation,

if adopted shall be done using automatic abrasive blasting equipment.

e) Pipes shall be visually inspected immediately after every blast cleaning operation

for surface defects such as slivers, laminations, leafing, scores, indentation,

slugs or any other defects considered injurious to the coating. Such defects shall

be reported to EMPLOYER and on permission from EMPLOYER; such defects

shall be removed by filling or grinding in such a way as not to “blue" the steel.

BARAUNI TPS

PHASE-I (2 X110 MW) SUB-SECTION-IIA-09

AND PHASE –II (2X250MW) BID DOC. NO.: TECHNICAL SPECIFICATIONS PAGE

COATING AND

GANGA WATER SUPPLY SECTION VI, PART-B 2 OF 9

CS-8004-132C-9 WRAPPING FOR PIPES

PACKAGE

Page 1010 of 2556

You might also like

- CP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01Document6 pagesCP 300 (A) - QCP-002 Laying of Vitrified Clay Pipes Rev. 01tarekNo ratings yet

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 pagesMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (7)

- Revised BOQ 24.02.2020 Unique RehabDocument25 pagesRevised BOQ 24.02.2020 Unique RehabSandeep MauryaNo ratings yet

- Application Guide Phenoline Tank ShieldDocument10 pagesApplication Guide Phenoline Tank ShieldNaveed AhmedNo ratings yet

- W M Ss 010Document43 pagesW M Ss 010naser712No ratings yet

- Rockit Pro DJ Manual v4Document52 pagesRockit Pro DJ Manual v4Almi ZarindiNo ratings yet

- Painting Process and Rules 涂装工艺: Cssc Xijiang Shipbuilding Co.,LtdDocument18 pagesPainting Process and Rules 涂装工艺: Cssc Xijiang Shipbuilding Co.,LtdHasib Ul Haque AmitNo ratings yet

- Enclosure To DYT/DDHP/15-16/106 (A) /PL-INCOD/IN SHIPS-ST3 STD/165 Dated 19 May 2016Document11 pagesEnclosure To DYT/DDHP/15-16/106 (A) /PL-INCOD/IN SHIPS-ST3 STD/165 Dated 19 May 2016Rajesh BNo ratings yet

- Phase - Crude Tankage, Pumps and Meters (127) : Appraised & Released For UseDocument12 pagesPhase - Crude Tankage, Pumps and Meters (127) : Appraised & Released For UseALI abd-alamamNo ratings yet

- Pl-Coat-7.0.0 (Specification For Fusion Bonded Epoxy CoatinDocument11 pagesPl-Coat-7.0.0 (Specification For Fusion Bonded Epoxy CoatinHector MejiaNo ratings yet

- DOC. NO:3392-00-69-00-0011 Field Application of Fusion Bonded Epoxy (FBE) Coating On The External Girth Weld Areas of Line PipesDocument8 pagesDOC. NO:3392-00-69-00-0011 Field Application of Fusion Bonded Epoxy (FBE) Coating On The External Girth Weld Areas of Line PipesMarianne SmithNo ratings yet

- Painting ProcedureDocument20 pagesPainting ProcedureCRUSTEK ENGINEERSNo ratings yet

- Method Statement For Laying of ACWC 20Document3 pagesMethod Statement For Laying of ACWC 20Fa DylaNo ratings yet

- Method Statement of WorksDocument24 pagesMethod Statement of WorksTuan Le100% (1)

- Gusau Tank Rehabilitation Cl0se-Out Report - 1203505-Adel-Rpt-E-0003Document31 pagesGusau Tank Rehabilitation Cl0se-Out Report - 1203505-Adel-Rpt-E-00039c8r962xpjNo ratings yet

- Quality Plan 1325-27 Rev 02 - Blasting PaintingDocument10 pagesQuality Plan 1325-27 Rev 02 - Blasting Paintingsuriya100% (1)

- Sor Wef 01-02-2013Document104 pagesSor Wef 01-02-2013Anonymous g1LSaANo ratings yet

- Section P2003 Microtunneling and Pipe JackingDocument17 pagesSection P2003 Microtunneling and Pipe JackingClark HonradoNo ratings yet

- Abstract & ARDocument18 pagesAbstract & ARAman SrivastavaNo ratings yet

- HSB - Hydro-Slurry BlastingDocument7 pagesHSB - Hydro-Slurry BlastingbalangceNo ratings yet

- 4-Part-B Civil PDFDocument65 pages4-Part-B Civil PDFPratik GuptaNo ratings yet

- Retrofitting For The Slab of An Existing Warehouse On PLOT L.R NO.11880/11 - NAIROBIDocument9 pagesRetrofitting For The Slab of An Existing Warehouse On PLOT L.R NO.11880/11 - NAIROBImusiomi2005No ratings yet

- Master Specification - Part Rd-Ew-C2 - Trench Excavation and BackfillDocument7 pagesMaster Specification - Part Rd-Ew-C2 - Trench Excavation and Backfillolgierd.karczmarzykNo ratings yet

- WP 11 Corrosion Protection Tape Coating123Document3 pagesWP 11 Corrosion Protection Tape Coating123KarthikNo ratings yet

- WP 11 Corrosion Protection Tape CoatingDocument3 pagesWP 11 Corrosion Protection Tape CoatingKarthikNo ratings yet

- Surface Preparation and Painting Procedure Rev 01 PDFDocument23 pagesSurface Preparation and Painting Procedure Rev 01 PDFNaceur Turki100% (3)

- Grade Beam Procedures Rev 3Document2 pagesGrade Beam Procedures Rev 3Rose ManipolNo ratings yet

- Mos Galvanizing ProceduresDocument23 pagesMos Galvanizing ProceduresRajeswaran Rajachockalingam100% (1)

- 6.2.2.section - 2 - Standard - Spe: Tender SpecificationDocument8 pages6.2.2.section - 2 - Standard - Spe: Tender SpecificationMangesh KoliNo ratings yet

- Specs Pre-Cast Segment LiningsDocument8 pagesSpecs Pre-Cast Segment Liningssatan007No ratings yet

- Technical Specifications - Painting of SteelDocument1 pageTechnical Specifications - Painting of SteeldineshNo ratings yet

- FAA 2022 1295 0005 - Attachment - 1Document19 pagesFAA 2022 1295 0005 - Attachment - 1Ahmad Ghazi EliasNo ratings yet

- As Clearing & GrubbingDocument5 pagesAs Clearing & GrubbingAllan WangNo ratings yet

- Method Statement - Tie Hole Filling Work - R0 - 01.11.2023Document2 pagesMethod Statement - Tie Hole Filling Work - R0 - 01.11.2023abir senguptaNo ratings yet

- Ebs1 Aaaa00 Saqa Prqa 0004Document12 pagesEbs1 Aaaa00 Saqa Prqa 0004SERT-QA/QC- BUZNo ratings yet

- Name of Work:-Replacement of Old Sewer Line at Sector 10 Bharat, Shiv Sagar, Shrdha, Shanti Kunj Apartment in Condominium at VashiDocument6 pagesName of Work:-Replacement of Old Sewer Line at Sector 10 Bharat, Shiv Sagar, Shrdha, Shanti Kunj Apartment in Condominium at VashiSheezan KhanNo ratings yet

- 250mm Dia Di Pipe LineDocument9 pages250mm Dia Di Pipe LineKantharajuNo ratings yet

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Document17 pagesIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNo ratings yet

- GTL-81-02 Rev 01 Coating and Wrapping of Buried PipingDocument17 pagesGTL-81-02 Rev 01 Coating and Wrapping of Buried Pipingjasminnee100% (2)

- Appendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Document20 pagesAppendix 1 Part 8 Eddy Current Inspector 4th Edition February 2016Cedric MercadoNo ratings yet

- MST For Ductbank ConstructionDocument7 pagesMST For Ductbank ConstructionDelta akathehusky100% (1)

- Manhole - MPW SPECIFICATIONDocument28 pagesManhole - MPW SPECIFICATIONttshareefNo ratings yet

- Application Guide Plasite 9570Document10 pagesApplication Guide Plasite 9570Yustiawan NESNo ratings yet

- Specs-Pavement MarkingsDocument4 pagesSpecs-Pavement MarkingsAnsar Bedharudeen100% (1)

- Construction Procedure For Building Fininshing Work - Rev.01Document17 pagesConstruction Procedure For Building Fininshing Work - Rev.01hadefNo ratings yet

- MS 8 Diaphragm Wall Barrettes Using Hydraulic GrabDocument12 pagesMS 8 Diaphragm Wall Barrettes Using Hydraulic GrabMarwa FaroukNo ratings yet

- Tech Specs Tensile CanopyDocument535 pagesTech Specs Tensile CanopyZafar BakhshNo ratings yet

- 255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Document216 pages255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Bruno Richard PhocusNo ratings yet

- Part CDocument23 pagesPart Ckonainglincho001No ratings yet

- MST For Concrete RepairDocument6 pagesMST For Concrete RepairDelta akathehusky100% (1)

- Residential Building at CoimbatoreDocument12 pagesResidential Building at CoimbatoreKarthi Keyan RNo ratings yet

- Corrosion Control - Jack-Up - SP-CO-ENG-CON-06-01Document37 pagesCorrosion Control - Jack-Up - SP-CO-ENG-CON-06-01evenNo ratings yet

- CCS 4 10 2 - 0 - 8001e1d4Document10 pagesCCS 4 10 2 - 0 - 8001e1d4Florin Daniel AnghelNo ratings yet

- Coating To Seawater Cooling Tower Rev 0 27-04-03Document33 pagesCoating To Seawater Cooling Tower Rev 0 27-04-03gururaj100% (1)

- Water Supplies Department: M-09-02 February 2014Document8 pagesWater Supplies Department: M-09-02 February 2014kryptos cNo ratings yet

- 09 30 00 Cement and Gypsum PlasteringDocument13 pages09 30 00 Cement and Gypsum PlasteringKiran D AnvekarNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Specification 2 PDFDocument1 pageSpecification 2 PDFHsaam HsaamNo ratings yet

- BOQ - Kaveri IDEMI PDFDocument13 pagesBOQ - Kaveri IDEMI PDFAnjum AttarNo ratings yet

- 2007 Section ViiiDocument3 pages2007 Section ViiiMiriam LopezNo ratings yet

- Storage TankDocument35 pagesStorage TankMostafaNo ratings yet

- Ceramic Materials for Energy Applications VIFrom EverandCeramic Materials for Energy Applications VIHua-Tay LinNo ratings yet

- Epcc03-Ihel-C00-Str-Std-000-0009 Sh. 3 of 8 (R4)Document1 pageEpcc03-Ihel-C00-Str-Std-000-0009 Sh. 3 of 8 (R4)ISGEC NTPC, BarauniNo ratings yet

- Muw LHSDocument22 pagesMuw LHSISGEC NTPC, BarauniNo ratings yet

- PT Area Civil StructureDocument2 pagesPT Area Civil StructureISGEC NTPC, BarauniNo ratings yet

- MessDocument3 pagesMessISGEC NTPC, BarauniNo ratings yet

- Co Relation RequiredDocument3 pagesCo Relation RequiredISGEC NTPC, BarauniNo ratings yet

- L-1-NDT Vs Mechanical TestingDocument10 pagesL-1-NDT Vs Mechanical TestingvigneshNo ratings yet

- INtro To SteelDocument29 pagesINtro To SteelAnima PNo ratings yet

- Almacenamiento Vida Anaquel-Placas PetrifilmsDocument1 pageAlmacenamiento Vida Anaquel-Placas PetrifilmsFiorella Silvana R R DiamontNo ratings yet

- Letters IIDocument8 pagesLetters IIksriniwasNo ratings yet

- Ind Inp-SahithDocument16 pagesInd Inp-SahithSàñdèép SûññyNo ratings yet

- M Aking An Impact at Kohat CementDocument4 pagesM Aking An Impact at Kohat CementDubistWhiteNo ratings yet

- 1.1.1.A HistoryCivilEngineeringArchitecureDocument3 pages1.1.1.A HistoryCivilEngineeringArchitecureAnonymous XQeqSWNo ratings yet

- IRFZ44 Data SheetDocument9 pagesIRFZ44 Data SheetColossus RhodesNo ratings yet

- October 2016Document13 pagesOctober 2016Pumper TraderNo ratings yet

- How To Connect Profibus Cable To Socket?Document3 pagesHow To Connect Profibus Cable To Socket?duniaengineering8666100% (4)

- Mil Chapter 13Document21 pagesMil Chapter 13Ver Dnad JacobeNo ratings yet

- Welcome ParentsDocument13 pagesWelcome Parentsapi-282638992No ratings yet

- 1.2.6.a.a MotorPowerSpreadsheetDocument7 pages1.2.6.a.a MotorPowerSpreadsheetcaleb zimmermanNo ratings yet

- Opinion in Massachusetts Defense of Marriage ActDocument43 pagesOpinion in Massachusetts Defense of Marriage Actmfinkelstein9438No ratings yet

- Data Communication Network 3Document60 pagesData Communication Network 3cooljseanNo ratings yet

- Sangoma TDM Gateway User GuideDocument257 pagesSangoma TDM Gateway User GuideFrank OchereNo ratings yet

- Energy Planning in MyanmarDocument26 pagesEnergy Planning in MyanmarHero MindNo ratings yet

- Toolkit Reference For The Microsoft Deployment Toolkit PDFDocument1,191 pagesToolkit Reference For The Microsoft Deployment Toolkit PDFAaron SemoNo ratings yet

- Public WiFiDocument12 pagesPublic WiFiBillMetcalfeNo ratings yet

- Arduino Pin Mapping On FBV 2560Document3 pagesArduino Pin Mapping On FBV 2560Ashish YadavNo ratings yet

- ECC Run Data Load 240922Document2 pagesECC Run Data Load 240922Obulareddy BiyyamNo ratings yet

- LR of Travel AppDocument12 pagesLR of Travel AppJackNo ratings yet

- ValvesDocument258 pagesValvesLorenaNo ratings yet

- Kit MG5000 F059 868Document9 pagesKit MG5000 F059 868rodrigoaranhaNo ratings yet

- Curiculum Vitae Theodor IstateDocument2 pagesCuriculum Vitae Theodor IstateTheo IstrateNo ratings yet

- Eos System Data Sheet Eos M 400-4 enDocument3 pagesEos System Data Sheet Eos M 400-4 enMagdalena TylichováNo ratings yet

- Selecting Efficient Support Methods For Tunnels: January 2006Document9 pagesSelecting Efficient Support Methods For Tunnels: January 2006gayathryNo ratings yet

- 2012 WERF ProductsDocument11 pages2012 WERF ProductsnghiasipraNo ratings yet