Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

34 viewsErection of Sag Rods

Erection of Sag Rods

Uploaded by

Karan PrabhakarThis document provides a standard operating procedure for fixing sag rods during construction. It outlines responsibilities for the work and safety protocols to follow, including inspecting lifting equipment, having trained operators, and ensuring a clear work area. The procedure specifies preparing a level, compacted work space and barricades. It describes accessing the work location safely and studying drawings before starting to fix sag rods by securing one end at the eave and the other at the corresponding purlin, and painting fully upon completion.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Checklist Piling Work .Pile ConstructionDocument2 pagesChecklist Piling Work .Pile Constructionyash shah89% (35)

- MS Installation Ductile Iron Water Supply (Scribd)Document17 pagesMS Installation Ductile Iron Water Supply (Scribd)Mohd Asyhar91% (33)

- Method Statement For Precast Boundary Wall WorksDocument5 pagesMethod Statement For Precast Boundary Wall WorksRsjBugtong100% (1)

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- Method Ststement For Sulphuric Acid PlantDocument9 pagesMethod Ststement For Sulphuric Acid PlantMurali Muvvala100% (1)

- METHOD STATEMENT Transmission Line PDFDocument8 pagesMETHOD STATEMENT Transmission Line PDFSyed Mohiuddin Pasha100% (1)

- Procedure - For Pile Load TestDocument14 pagesProcedure - For Pile Load TestimranNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya50% (4)

- Acceptance of Works Inspection ChecklistDocument6 pagesAcceptance of Works Inspection ChecklistJulius Mak'Oderoh100% (1)

- CI Checklist Pile InstallationDocument6 pagesCI Checklist Pile InstallationDilhara WickramaarachchiNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Method Statement AbutmentDocument9 pagesMethod Statement AbutmentRamesh Joshi100% (2)

- Method Statement For Scaffolding Erection - Docx R3Document14 pagesMethod Statement For Scaffolding Erection - Docx R3magramya100% (1)

- Installation Procedure of Heat ExchangerDocument6 pagesInstallation Procedure of Heat Exchangeryayan hNo ratings yet

- Method Statement For ELSDocument13 pagesMethod Statement For ELSymkawai224No ratings yet

- Slide Presentation of Cfa Installation (Benisede) Final 04-04-16-1Document33 pagesSlide Presentation of Cfa Installation (Benisede) Final 04-04-16-1oaklamNo ratings yet

- Methodology of Bridge Load TestDocument3 pagesMethodology of Bridge Load TestRavikant TyagiNo ratings yet

- Installation of Spot PillarDocument5 pagesInstallation of Spot PillarTerryNo ratings yet

- PierDocument15 pagesPierGANGARAJU N BNo ratings yet

- Pile Driving ProcessDocument14 pagesPile Driving ProcessPedro CedeñoNo ratings yet

- Method Statement For ExcavationDocument13 pagesMethod Statement For Excavationymkawai224No ratings yet

- Tank Method Statement - r0Document11 pagesTank Method Statement - r0AravindanNo ratings yet

- QMP RDocument5 pagesQMP RahmedNo ratings yet

- MOS Pipe Jacking Slurry MethodDocument9 pagesMOS Pipe Jacking Slurry Methodasr.engineering2023No ratings yet

- 33 05 23.13 - Horizontal Directional DrillingDocument17 pages33 05 23.13 - Horizontal Directional DrillingThomas Bennett100% (1)

- Construction Methodology For Slope Stability.Document19 pagesConstruction Methodology For Slope Stability.mehra.yogesh160No ratings yet

- Prosedur ScaffoldingDocument38 pagesProsedur ScaffoldingFafa seyza100% (4)

- QAQC Meeting - 2020 - TemplateDocument9 pagesQAQC Meeting - 2020 - TemplatedavethiyaguNo ratings yet

- Guide Lines For Erection of Verticallift GatesDocument46 pagesGuide Lines For Erection of Verticallift GatesMahipal Reddy100% (1)

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- Aux Boiler - Karan REV.03Document14 pagesAux Boiler - Karan REV.03sharif339No ratings yet

- Petrol & Gas Construction Co.: Elevator Shaft ErectionDocument9 pagesPetrol & Gas Construction Co.: Elevator Shaft ErectionBoj MingiNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Requirement of ISO 9000. Item 4.18 (6.2.2) "Training" Prepared By: Maria L. Quitian Date: August 2001Document33 pagesRequirement of ISO 9000. Item 4.18 (6.2.2) "Training" Prepared By: Maria L. Quitian Date: August 2001sameh100% (2)

- STANDART PROCEDUR1 TankDocument6 pagesSTANDART PROCEDUR1 TankvayakunNo ratings yet

- Method Statement For Storage Tanks PDFDocument27 pagesMethod Statement For Storage Tanks PDFMohd AshrafNo ratings yet

- Procedure For Instalattion of VesselDocument6 pagesProcedure For Instalattion of Vesselyayan hNo ratings yet

- Method Statement FOR Piling Works at The Site of Bunhill 2 Energy Centre, Islington. Ec1V 8enDocument4 pagesMethod Statement FOR Piling Works at The Site of Bunhill 2 Energy Centre, Islington. Ec1V 8enMohsen KeramatiNo ratings yet

- Metro Project LATESTDocument39 pagesMetro Project LATESTRahul ChauhanNo ratings yet

- Piling ProcedureDocument7 pagesPiling ProcedureimranNo ratings yet

- SOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONDocument24 pagesSOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONAvidip DeyNo ratings yet

- Excavation Earthwork and FillingDocument4 pagesExcavation Earthwork and FillingTAHER AMMARNo ratings yet

- Guidelines For Fabrication of Steel Girder Procedure in WordDocument17 pagesGuidelines For Fabrication of Steel Girder Procedure in WordManas Rawat100% (1)

- Report of The Inspection Carried Out On Construction of byDocument4 pagesReport of The Inspection Carried Out On Construction of byaloysius akpanNo ratings yet

- Ity of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresDocument4 pagesIty of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresLazar AndonovNo ratings yet

- BLD Permit Insp Checklist AsphaltPavementInspectionDocument4 pagesBLD Permit Insp Checklist AsphaltPavementInspectionSyed WasifNo ratings yet

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNo ratings yet

- Dokumen - Tips - Lighting High Mast Installation ProcedureDocument41 pagesDokumen - Tips - Lighting High Mast Installation Procedurekatiki216No ratings yet

- Site Test Procedure: DOC. NO.: Issued By: SA Approved By: GD Title: Site Test Procedure For Overhead CraneDocument17 pagesSite Test Procedure: DOC. NO.: Issued By: SA Approved By: GD Title: Site Test Procedure For Overhead CraneIsmuliono I100% (1)

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Piling Good Practice Guide (LABC Warranty, 2014)Document3 pagesPiling Good Practice Guide (LABC Warranty, 2014)sandycastleNo ratings yet

- Method Statement For Sheet PilingDocument8 pagesMethod Statement For Sheet PilingAbdul Muneer PalapraNo ratings yet

- 01 - Method Statement For Excavation Work222Document9 pages01 - Method Statement For Excavation Work222Ahmed Samir SalimNo ratings yet

- Methodology For Rebars InstallationDocument4 pagesMethodology For Rebars InstallationVector DesignsNo ratings yet

- WMS Roof Sheet Replacement-BMS-334-1Document7 pagesWMS Roof Sheet Replacement-BMS-334-1rashid khattakNo ratings yet

- Purpose 2Document5 pagesPurpose 2Er Rizwan AhmedNo ratings yet

- 1.method of Statement - Cable Tray - R0Document2 pages1.method of Statement - Cable Tray - R0JaveedMdJaveedNo ratings yet

- MS For Excavation, Sand Filling & Back Filling Activities.Document7 pagesMS For Excavation, Sand Filling & Back Filling Activities.Just Do LoveNo ratings yet

- MJ Idarro 2Document47 pagesMJ Idarro 2AbudaFrancisNo ratings yet

- Guidelines For Fabrication of Steel GirderDocument17 pagesGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- CGC Shelter - 1drainage CalculationDocument1 pageCGC Shelter - 1drainage CalculationKaran PrabhakarNo ratings yet

- 121B37 B224-EPCC07-LT-MEP-SES-AD-1002-SH-244 - Rev 00Document1 page121B37 B224-EPCC07-LT-MEP-SES-AD-1002-SH-244 - Rev 00Karan PrabhakarNo ratings yet

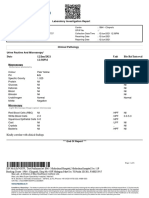

- Date 12/jun/2021 12:38PM Unit Bio Ref Interval: Laboratory Investigation ReportDocument7 pagesDate 12/jun/2021 12:38PM Unit Bio Ref Interval: Laboratory Investigation ReportKaran PrabhakarNo ratings yet

- ( F J PG: 9™ Level, C-Wing, Delhi Sachivalaya I.P.ESTATE, NEW DELHI-110002Document4 pages( F J PG: 9™ Level, C-Wing, Delhi Sachivalaya I.P.ESTATE, NEW DELHI-110002Karan PrabhakarNo ratings yet

- Electric Forklift Truck: Higher Reliability Higher Performance Higher ProductivityDocument6 pagesElectric Forklift Truck: Higher Reliability Higher Performance Higher ProductivityKaran PrabhakarNo ratings yet

- Auto Secure Private Car Package PolicyDocument9 pagesAuto Secure Private Car Package PolicyKaran PrabhakarNo ratings yet

- LPL - Amit Sharma FPSC Loni Road-Gzb Shop No-4, Saharanpur Road, Loni Road, Main Tiraha, Loni, Ghaziabad, Loni S.ODocument3 pagesLPL - Amit Sharma FPSC Loni Road-Gzb Shop No-4, Saharanpur Road, Loni Road, Main Tiraha, Loni, Ghaziabad, Loni S.OKaran PrabhakarNo ratings yet

- Design Aid To Is 800-2007: Safe Load For Angle StrutsDocument5 pagesDesign Aid To Is 800-2007: Safe Load For Angle StrutsKaran PrabhakarNo ratings yet

Erection of Sag Rods

Erection of Sag Rods

Uploaded by

Karan Prabhakar0 ratings0% found this document useful (0 votes)

34 views2 pagesThis document provides a standard operating procedure for fixing sag rods during construction. It outlines responsibilities for the work and safety protocols to follow, including inspecting lifting equipment, having trained operators, and ensuring a clear work area. The procedure specifies preparing a level, compacted work space and barricades. It describes accessing the work location safely and studying drawings before starting to fix sag rods by securing one end at the eave and the other at the corresponding purlin, and painting fully upon completion.

Original Description:

Original Title

Erection of sag rods

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a standard operating procedure for fixing sag rods during construction. It outlines responsibilities for the work and safety protocols to follow, including inspecting lifting equipment, having trained operators, and ensuring a clear work area. The procedure specifies preparing a level, compacted work space and barricades. It describes accessing the work location safely and studying drawings before starting to fix sag rods by securing one end at the eave and the other at the corresponding purlin, and painting fully upon completion.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

34 views2 pagesErection of Sag Rods

Erection of Sag Rods

Uploaded by

Karan PrabhakarThis document provides a standard operating procedure for fixing sag rods during construction. It outlines responsibilities for the work and safety protocols to follow, including inspecting lifting equipment, having trained operators, and ensuring a clear work area. The procedure specifies preparing a level, compacted work space and barricades. It describes accessing the work location safely and studying drawings before starting to fix sag rods by securing one end at the eave and the other at the corresponding purlin, and painting fully upon completion.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

DOCUMENT NO :

REVISION NO. :

SOP- Fixing of Sag Rod EFFECTIVE DATE :

PAGE NO. :

1.0 Purpose

Fixing of Sag Rods.

2.0 Scope

a) Safe lifting of Sag Rods.

b) Ensure the Working area and access is leveled and compacted properly.

c) Check & Ensure that the working area is Barricaded.

3.0 Responsibility

a) Erector supervisor / lifting supervisor / SIPL site engineers / SIPL site in-charge.

4.0 Procedures

4.1 Control measures:

a) Inspection of all lifting tools, tackles, cranes and boom lift to be used.

b) Trained / competent Crane operator to be available and load chart to be followed.

c) Trained work force, trained & validated fitter & signal man.

4.2 Work Location/Access Requirements:

a) The suitability of the ground for the vehicle and load stability (for example whether the

ground is flat and firm).

b) No obstructions at the erection area for underground and above ground utilities (including

parked cars, overhead cables and pipes)

c) The boom lift should be checked to make sure that it can access the lifting area safely, If

Boom lift not Available then we should arrange Scaffolding or Aluminum Ladder for Safe

Access to the Columns and Rafters.

4.3 Method of work

a) Study the Erection drawings and start fixing of sag rods.

b) Ensure the all the purlins are fixed as per latest revised erection drawings.

c) Ensure the overlapping and tightening of nut bolt is done.

d) Ensure the ground is well compacted and leveled for the safe movement of boom lift.

e) Start fixing of sag rods from the eave top that is one end of sag rod at eave top and other at

the rigid point of another corresponding purlin.

f) By this way fix all other Sag rods accordingly opposite to the Direction of Slope of the

Building.

g) Ensure full tightness of sag rods which imparts strength to the structure.

h) Ensure the fixing of sag rods are fully painted otherwise repainting should be conducted.

You might also like

- Checklist Piling Work .Pile ConstructionDocument2 pagesChecklist Piling Work .Pile Constructionyash shah89% (35)

- MS Installation Ductile Iron Water Supply (Scribd)Document17 pagesMS Installation Ductile Iron Water Supply (Scribd)Mohd Asyhar91% (33)

- Method Statement For Precast Boundary Wall WorksDocument5 pagesMethod Statement For Precast Boundary Wall WorksRsjBugtong100% (1)

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- Method Ststement For Sulphuric Acid PlantDocument9 pagesMethod Ststement For Sulphuric Acid PlantMurali Muvvala100% (1)

- METHOD STATEMENT Transmission Line PDFDocument8 pagesMETHOD STATEMENT Transmission Line PDFSyed Mohiuddin Pasha100% (1)

- Procedure - For Pile Load TestDocument14 pagesProcedure - For Pile Load TestimranNo ratings yet

- Method Statement - Cable Tray ErectionDocument2 pagesMethod Statement - Cable Tray Erectionsoubhagya50% (4)

- Acceptance of Works Inspection ChecklistDocument6 pagesAcceptance of Works Inspection ChecklistJulius Mak'Oderoh100% (1)

- CI Checklist Pile InstallationDocument6 pagesCI Checklist Pile InstallationDilhara WickramaarachchiNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Method Statement AbutmentDocument9 pagesMethod Statement AbutmentRamesh Joshi100% (2)

- Method Statement For Scaffolding Erection - Docx R3Document14 pagesMethod Statement For Scaffolding Erection - Docx R3magramya100% (1)

- Installation Procedure of Heat ExchangerDocument6 pagesInstallation Procedure of Heat Exchangeryayan hNo ratings yet

- Method Statement For ELSDocument13 pagesMethod Statement For ELSymkawai224No ratings yet

- Slide Presentation of Cfa Installation (Benisede) Final 04-04-16-1Document33 pagesSlide Presentation of Cfa Installation (Benisede) Final 04-04-16-1oaklamNo ratings yet

- Methodology of Bridge Load TestDocument3 pagesMethodology of Bridge Load TestRavikant TyagiNo ratings yet

- Installation of Spot PillarDocument5 pagesInstallation of Spot PillarTerryNo ratings yet

- PierDocument15 pagesPierGANGARAJU N BNo ratings yet

- Pile Driving ProcessDocument14 pagesPile Driving ProcessPedro CedeñoNo ratings yet

- Method Statement For ExcavationDocument13 pagesMethod Statement For Excavationymkawai224No ratings yet

- Tank Method Statement - r0Document11 pagesTank Method Statement - r0AravindanNo ratings yet

- QMP RDocument5 pagesQMP RahmedNo ratings yet

- MOS Pipe Jacking Slurry MethodDocument9 pagesMOS Pipe Jacking Slurry Methodasr.engineering2023No ratings yet

- 33 05 23.13 - Horizontal Directional DrillingDocument17 pages33 05 23.13 - Horizontal Directional DrillingThomas Bennett100% (1)

- Construction Methodology For Slope Stability.Document19 pagesConstruction Methodology For Slope Stability.mehra.yogesh160No ratings yet

- Prosedur ScaffoldingDocument38 pagesProsedur ScaffoldingFafa seyza100% (4)

- QAQC Meeting - 2020 - TemplateDocument9 pagesQAQC Meeting - 2020 - TemplatedavethiyaguNo ratings yet

- Guide Lines For Erection of Verticallift GatesDocument46 pagesGuide Lines For Erection of Verticallift GatesMahipal Reddy100% (1)

- JPPL Ehs 19 03 SWP 02Document12 pagesJPPL Ehs 19 03 SWP 02MohamedSaidNo ratings yet

- Aux Boiler - Karan REV.03Document14 pagesAux Boiler - Karan REV.03sharif339No ratings yet

- Petrol & Gas Construction Co.: Elevator Shaft ErectionDocument9 pagesPetrol & Gas Construction Co.: Elevator Shaft ErectionBoj MingiNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Requirement of ISO 9000. Item 4.18 (6.2.2) "Training" Prepared By: Maria L. Quitian Date: August 2001Document33 pagesRequirement of ISO 9000. Item 4.18 (6.2.2) "Training" Prepared By: Maria L. Quitian Date: August 2001sameh100% (2)

- STANDART PROCEDUR1 TankDocument6 pagesSTANDART PROCEDUR1 TankvayakunNo ratings yet

- Method Statement For Storage Tanks PDFDocument27 pagesMethod Statement For Storage Tanks PDFMohd AshrafNo ratings yet

- Procedure For Instalattion of VesselDocument6 pagesProcedure For Instalattion of Vesselyayan hNo ratings yet

- Method Statement FOR Piling Works at The Site of Bunhill 2 Energy Centre, Islington. Ec1V 8enDocument4 pagesMethod Statement FOR Piling Works at The Site of Bunhill 2 Energy Centre, Islington. Ec1V 8enMohsen KeramatiNo ratings yet

- Metro Project LATESTDocument39 pagesMetro Project LATESTRahul ChauhanNo ratings yet

- Piling ProcedureDocument7 pagesPiling ProcedureimranNo ratings yet

- SOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONDocument24 pagesSOP-0016 - Standard Operating (Work) Procedure - ToWER ERECTIONAvidip DeyNo ratings yet

- Excavation Earthwork and FillingDocument4 pagesExcavation Earthwork and FillingTAHER AMMARNo ratings yet

- Guidelines For Fabrication of Steel Girder Procedure in WordDocument17 pagesGuidelines For Fabrication of Steel Girder Procedure in WordManas Rawat100% (1)

- Report of The Inspection Carried Out On Construction of byDocument4 pagesReport of The Inspection Carried Out On Construction of byaloysius akpanNo ratings yet

- Ity of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresDocument4 pagesIty of Ilpitas Inspection Checklist: Asphalt Pavement Inspection ProceduresLazar AndonovNo ratings yet

- BLD Permit Insp Checklist AsphaltPavementInspectionDocument4 pagesBLD Permit Insp Checklist AsphaltPavementInspectionSyed WasifNo ratings yet

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezNo ratings yet

- Dokumen - Tips - Lighting High Mast Installation ProcedureDocument41 pagesDokumen - Tips - Lighting High Mast Installation Procedurekatiki216No ratings yet

- Site Test Procedure: DOC. NO.: Issued By: SA Approved By: GD Title: Site Test Procedure For Overhead CraneDocument17 pagesSite Test Procedure: DOC. NO.: Issued By: SA Approved By: GD Title: Site Test Procedure For Overhead CraneIsmuliono I100% (1)

- TH THDocument9 pagesTH THP.MannaNo ratings yet

- Piling Good Practice Guide (LABC Warranty, 2014)Document3 pagesPiling Good Practice Guide (LABC Warranty, 2014)sandycastleNo ratings yet

- Method Statement For Sheet PilingDocument8 pagesMethod Statement For Sheet PilingAbdul Muneer PalapraNo ratings yet

- 01 - Method Statement For Excavation Work222Document9 pages01 - Method Statement For Excavation Work222Ahmed Samir SalimNo ratings yet

- Methodology For Rebars InstallationDocument4 pagesMethodology For Rebars InstallationVector DesignsNo ratings yet

- WMS Roof Sheet Replacement-BMS-334-1Document7 pagesWMS Roof Sheet Replacement-BMS-334-1rashid khattakNo ratings yet

- Purpose 2Document5 pagesPurpose 2Er Rizwan AhmedNo ratings yet

- 1.method of Statement - Cable Tray - R0Document2 pages1.method of Statement - Cable Tray - R0JaveedMdJaveedNo ratings yet

- MS For Excavation, Sand Filling & Back Filling Activities.Document7 pagesMS For Excavation, Sand Filling & Back Filling Activities.Just Do LoveNo ratings yet

- MJ Idarro 2Document47 pagesMJ Idarro 2AbudaFrancisNo ratings yet

- Guidelines For Fabrication of Steel GirderDocument17 pagesGuidelines For Fabrication of Steel Girderradhakrishnang100% (3)

- CGC Shelter - 1drainage CalculationDocument1 pageCGC Shelter - 1drainage CalculationKaran PrabhakarNo ratings yet

- 121B37 B224-EPCC07-LT-MEP-SES-AD-1002-SH-244 - Rev 00Document1 page121B37 B224-EPCC07-LT-MEP-SES-AD-1002-SH-244 - Rev 00Karan PrabhakarNo ratings yet

- Date 12/jun/2021 12:38PM Unit Bio Ref Interval: Laboratory Investigation ReportDocument7 pagesDate 12/jun/2021 12:38PM Unit Bio Ref Interval: Laboratory Investigation ReportKaran PrabhakarNo ratings yet

- ( F J PG: 9™ Level, C-Wing, Delhi Sachivalaya I.P.ESTATE, NEW DELHI-110002Document4 pages( F J PG: 9™ Level, C-Wing, Delhi Sachivalaya I.P.ESTATE, NEW DELHI-110002Karan PrabhakarNo ratings yet

- Electric Forklift Truck: Higher Reliability Higher Performance Higher ProductivityDocument6 pagesElectric Forklift Truck: Higher Reliability Higher Performance Higher ProductivityKaran PrabhakarNo ratings yet

- Auto Secure Private Car Package PolicyDocument9 pagesAuto Secure Private Car Package PolicyKaran PrabhakarNo ratings yet

- LPL - Amit Sharma FPSC Loni Road-Gzb Shop No-4, Saharanpur Road, Loni Road, Main Tiraha, Loni, Ghaziabad, Loni S.ODocument3 pagesLPL - Amit Sharma FPSC Loni Road-Gzb Shop No-4, Saharanpur Road, Loni Road, Main Tiraha, Loni, Ghaziabad, Loni S.OKaran PrabhakarNo ratings yet

- Design Aid To Is 800-2007: Safe Load For Angle StrutsDocument5 pagesDesign Aid To Is 800-2007: Safe Load For Angle StrutsKaran PrabhakarNo ratings yet