Professional Documents

Culture Documents

2pce7101 Process Equipment Design

2pce7101 Process Equipment Design

Uploaded by

Akshay UdayCopyright:

Available Formats

You might also like

- Cat d7 3t Operatons MtceDocument98 pagesCat d7 3t Operatons MtceMilagros Pullchs AriasNo ratings yet

- Mechanical Workshop Practice 20-21 (201 Copies)Document92 pagesMechanical Workshop Practice 20-21 (201 Copies)MOHAMMED MANSOORNo ratings yet

- Rock Characterization at El Teniente Mine PDFDocument15 pagesRock Characterization at El Teniente Mine PDFEmanuel NicolásNo ratings yet

- DR JPS FM 6feb - New - FormatDocument3 pagesDR JPS FM 6feb - New - Formatdiksha singhNo ratings yet

- File 5f2a7cecb9b64Document32 pagesFile 5f2a7cecb9b64GovindharajNo ratings yet

- FM LabDocument4 pagesFM Labdiksha singhNo ratings yet

- 2es1101 Engineering Grahpics Syllabus Semester IDocument2 pages2es1101 Engineering Grahpics Syllabus Semester IHaresh PatelNo ratings yet

- 22BES510Document2 pages22BES510Thirunavukkarasu ANo ratings yet

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDocument9 pagesSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetgopichandallakaNo ratings yet

- Concrete LabDocument1 pageConcrete Labmaruns004No ratings yet

- 2.6.1 Programme and Course Outcomes CIVIL Dept.Document76 pages2.6.1 Programme and Course Outcomes CIVIL Dept.PrashanthNo ratings yet

- Kallam Haranadhareddy Institute of Technology Ece DepartmentDocument3 pagesKallam Haranadhareddy Institute of Technology Ece DepartmentmuraliNo ratings yet

- MECHANICALDocument69 pagesMECHANICALSelvakumar SubbaiahNo ratings yet

- Estimation and Costing: 1 10 CO3 CO1 CO2Document8 pagesEstimation and Costing: 1 10 CO3 CO1 CO2Rekha RajshekarNo ratings yet

- TOM & MAC COsDocument7 pagesTOM & MAC COsTejas KadamNo ratings yet

- 19BT50107 Epc Svec2019 Iii I Oe 1Document9 pages19BT50107 Epc Svec2019 Iii I Oe 1Chithambar Ganesh ANo ratings yet

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDocument9 pagesSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetMurali VangalapatiNo ratings yet

- Design and Drawing COURSE PLAN 2017 FinalDocument5 pagesDesign and Drawing COURSE PLAN 2017 FinalqeftfgNo ratings yet

- Course Structure and Syllabus OF 2 Year M.Tech Petroleum EngineeringDocument23 pagesCourse Structure and Syllabus OF 2 Year M.Tech Petroleum EngineeringRajesh KumarNo ratings yet

- Natural Gas Eng Course PlanDocument6 pagesNatural Gas Eng Course PlanArsh AttriNo ratings yet

- Chemistry Course File CseDocument9 pagesChemistry Course File CseraniNo ratings yet

- Department of Mechanical Engineering: Bangalore Institute of TechnologyDocument76 pagesDepartment of Mechanical Engineering: Bangalore Institute of TechnologyVenkteshwarlu KNo ratings yet

- 4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementDocument6 pages4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementEric CookNo ratings yet

- Syllabus of Structural Analysis PCC-CVE204-TDocument2 pagesSyllabus of Structural Analysis PCC-CVE204-TManik GoyalNo ratings yet

- Production and Industrial Engineering ReviewedDocument36 pagesProduction and Industrial Engineering ReviewedabhijitsainiNo ratings yet

- MFT I SyllabusDocument3 pagesMFT I SyllabusVamsi RockzzNo ratings yet

- DMM Ii-CdsDocument5 pagesDMM Ii-CdsKrishna MurthyNo ratings yet

- THERMAL Assignment FrontpageDocument1 pageTHERMAL Assignment FrontpagedineshvaricomNo ratings yet

- Lecture - 1 - CO, PO, Evaluation Scheme, List of ExperimentsDocument12 pagesLecture - 1 - CO, PO, Evaluation Scheme, List of ExperimentsSavan PatelNo ratings yet

- Securities MRT Foun.Document2 pagesSecurities MRT Foun.DoremonNo ratings yet

- Thermo MEX SyllabusDocument3 pagesThermo MEX SyllabusPra GoNo ratings yet

- 2nd Year CO-PO Mapping FinalDocument14 pages2nd Year CO-PO Mapping FinalsantoshNo ratings yet

- Cet402 Quantity Surveying and ValuationDocument13 pagesCet402 Quantity Surveying and ValuationdipinnediyaparambathNo ratings yet

- P23. Mapping of Course Outcome With Program OutcomesDocument31 pagesP23. Mapping of Course Outcome With Program OutcomesBhaskar MondalNo ratings yet

- Sheet Metal Workshop - Lab ManualDocument40 pagesSheet Metal Workshop - Lab ManualHARSHAVARDHAN MADISHETTINo ratings yet

- JCT College of Engineering and Technology: Course Information SheetDocument6 pagesJCT College of Engineering and Technology: Course Information SheetDhamu DharanNo ratings yet

- Cs3271 Programming in C LaboratoryDocument4 pagesCs3271 Programming in C Laboratoryabinayasundaramoorthi2000No ratings yet

- Production Technology Lab ManualDocument59 pagesProduction Technology Lab Manualuma deviNo ratings yet

- CET309Document12 pagesCET309dipinnediyaparambathNo ratings yet

- Ec8452 Ec-Ii Unit-2Document103 pagesEc8452 Ec-Ii Unit-2Ananda Sailesh KNo ratings yet

- IDS SyllabusDocument3 pagesIDS SyllabusKhaushik KumaarNo ratings yet

- 2160503Document3 pages2160503Yash MadlaniNo ratings yet

- Workshop Practice One Side Print 28janDocument9 pagesWorkshop Practice One Side Print 28janDr. A. Praveen KumarNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument2 pagesTesting and Commissioning of Electrical EquipmentGuna PriyaNo ratings yet

- Chemical Engineering s7 & s8Document337 pagesChemical Engineering s7 & s8MaryamNo ratings yet

- Basics - of - Civil & Mechanical Eng.Document7 pagesBasics - of - Civil & Mechanical Eng.Rahul J.RNo ratings yet

- Course Objective(s) :: Major ElectiveDocument2 pagesCourse Objective(s) :: Major ElectiveKKNo ratings yet

- Irrigation Engineering and Environment DrawingDocument95 pagesIrrigation Engineering and Environment DrawingSE3094- Soundarya.SNo ratings yet

- COURSE FILE Nce 702 WREDocument19 pagesCOURSE FILE Nce 702 WREMohd AmirNo ratings yet

- MTech SMFE Rev12032019Document78 pagesMTech SMFE Rev12032019Mr.Bhaskar WabhitkarNo ratings yet

- SE SyllabusDocument2 pagesSE SyllabusAnil ChauvanNo ratings yet

- BCE Lab ManualDocument69 pagesBCE Lab ManualSuraj VyasNo ratings yet

- Excel File CO-PO Attainment For UG - RACDocument13 pagesExcel File CO-PO Attainment For UG - RACanshul9051No ratings yet

- 20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDocument55 pages20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDark ranger YtNo ratings yet

- Dce Sylllabus of 4th Semester - Collection by Engg Dedication Yt ChannelDocument36 pagesDce Sylllabus of 4th Semester - Collection by Engg Dedication Yt Channelusemobile7044No ratings yet

- Consumer Behavior - SyllabusDocument1 pageConsumer Behavior - SyllabusAshish raturiNo ratings yet

- 6 Semester MU-302: CAD/CAM Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementDocument7 pages6 Semester MU-302: CAD/CAM Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementNilesh AvhadNo ratings yet

- Aditya College of Engineering: Course Outcome Mapping With PO's and PSO'sDocument3 pagesAditya College of Engineering: Course Outcome Mapping With PO's and PSO'ssundarmeenakshiNo ratings yet

- Aditya College of Engineering: Course Outcome Mapping With PO's and PSO'sDocument3 pagesAditya College of Engineering: Course Outcome Mapping With PO's and PSO'ssundarmeenakshiNo ratings yet

- Updated - Analog & Digital Circuit Manual - BECL305Document98 pagesUpdated - Analog & Digital Circuit Manual - BECL305rvit22bec032.rvitmNo ratings yet

- PHP - LAB - Course PlanDocument13 pagesPHP - LAB - Course PlankhatNo ratings yet

- Isogeometric Analysis: Toward Integration of CAD and FEAFrom EverandIsogeometric Analysis: Toward Integration of CAD and FEANo ratings yet

- Activated Sludge ProcessDocument6 pagesActivated Sludge ProcessAkshay UdayNo ratings yet

- 7 - AnalysisDocument5 pages7 - AnalysisAkshay UdayNo ratings yet

- STUCOR - UG Higher Semester Except Sem IIIDocument1 pageSTUCOR - UG Higher Semester Except Sem IIIAkshay UdayNo ratings yet

- Unit I Introduction To Spectroscopical Methods of AnalysisDocument28 pagesUnit I Introduction To Spectroscopical Methods of AnalysisAkshay UdayNo ratings yet

- Annexure 1Document1 pageAnnexure 1Akshay UdayNo ratings yet

- Prob and Stats unit-IIIDocument5 pagesProb and Stats unit-IIIAkshay UdayNo ratings yet

- Modes of Mass TransferDocument20 pagesModes of Mass TransferAkshay UdayNo ratings yet

- Unit 2: CH8491 - Instrumental Methods of Analysis 2019-2020Document24 pagesUnit 2: CH8491 - Instrumental Methods of Analysis 2019-2020Akshay UdayNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit OperationAkshay UdayNo ratings yet

- Pleurobrachia & Cydippid LarvaDocument18 pagesPleurobrachia & Cydippid LarvaAkshay UdayNo ratings yet

- GE6351 Environmental Science and EngineeringDocument261 pagesGE6351 Environmental Science and EngineeringAkshay UdayNo ratings yet

- Asphyxia by SuffocationDocument15 pagesAsphyxia by SuffocationBryan Christopher Co Lao100% (1)

- HiaDocument9 pagesHiaSuryasumanthNo ratings yet

- Franck-Hertz Experiment P6241 eDocument4 pagesFranck-Hertz Experiment P6241 emsiarovNo ratings yet

- ISO Optical StandardsDocument16 pagesISO Optical Standardsflord21No ratings yet

- All G485 QuestionsDocument190 pagesAll G485 Questionsdasha962No ratings yet

- Got Milk? Background: Food Processing and PreservationDocument7 pagesGot Milk? Background: Food Processing and PreservationRaja VeluNo ratings yet

- What Is The Best Way To Truly Live?: (Your Free Download)Document11 pagesWhat Is The Best Way To Truly Live?: (Your Free Download)joanellNo ratings yet

- Kevlar by Abhishek JaguessarDocument5 pagesKevlar by Abhishek Jaguessarreedoye21No ratings yet

- Principle 3Document113 pagesPrinciple 3Mark Antony LevineNo ratings yet

- Medidor Caudal Kobold DpuDocument4 pagesMedidor Caudal Kobold DpuBase SistemasNo ratings yet

- Glibenclamide (Glibenclamidum) : The International Pharmacopoeia - Sixth Edition, 2016Document1 pageGlibenclamide (Glibenclamidum) : The International Pharmacopoeia - Sixth Edition, 2016Yuda Anzas MaraNo ratings yet

- (MVS) Deposit Type and Associated CommoditiesDocument12 pages(MVS) Deposit Type and Associated CommoditiesSalvadora1No ratings yet

- CITGO Classroom GlossaryDocument4 pagesCITGO Classroom GlossarycutefrenzyNo ratings yet

- Qmax Solids Control EquipmentDocument18 pagesQmax Solids Control Equipment2591995No ratings yet

- 455 - FST 504 Lecture Note-Dr BabajideDocument41 pages455 - FST 504 Lecture Note-Dr BabajideMahnoorIshtiaqNo ratings yet

- Pericles Exported CitationsDocument2 pagesPericles Exported CitationsManoj PrakashNo ratings yet

- NullDocument3 pagesNullapi-26374520No ratings yet

- Cpa Review School of The Philippines Auditing TheoryDocument16 pagesCpa Review School of The Philippines Auditing Theoryprincess_camarilloNo ratings yet

- Tips and Tricks For The Lab - Column Choices - Education - ChemistryViewsDocument8 pagesTips and Tricks For The Lab - Column Choices - Education - ChemistryViewsJoséFernandoNo ratings yet

- Sab 2112 - L4 AggregatesDocument51 pagesSab 2112 - L4 Aggregatesapi-19705508No ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS Systemsujay AvatiNo ratings yet

- CHP - G3512 - 555 KW 1200 RPM 12 G NOx - DM5209-02-EDocument3 pagesCHP - G3512 - 555 KW 1200 RPM 12 G NOx - DM5209-02-ENimNo ratings yet

- General Chemistry 2 (STEM) : Quarter 4 - Module 1 & 2Document27 pagesGeneral Chemistry 2 (STEM) : Quarter 4 - Module 1 & 2Alexa ValdezNo ratings yet

- Bohr Models For Atoms WsDocument2 pagesBohr Models For Atoms WsMehakpreet GillNo ratings yet

- Turbine Oil Monitoring PDFDocument23 pagesTurbine Oil Monitoring PDFAzhar1109100% (2)

- GeographyDocument6 pagesGeographyRonnith NandyNo ratings yet

- Ideal Color51 Tec EngDocument3 pagesIdeal Color51 Tec EngPedroNo ratings yet

- 6973-51 Welding PlantDocument1 page6973-51 Welding Plantabdulhanan86457No ratings yet

2pce7101 Process Equipment Design

2pce7101 Process Equipment Design

Uploaded by

Akshay UdayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2pce7101 Process Equipment Design

2pce7101 Process Equipment Design

Uploaded by

Akshay UdayCopyright:

Available Formats

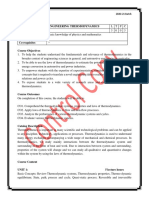

GANPAT UNIVERSITY

FACULTY OF ENGINEERING & TECHNOLOGY

Programme Bachelor of Technology Branch/Spec Petrochemical Engineering

Semester VII Version 1.0.0.0

Effective from Academic Year 2022-23 Effective for the Batch admitted in July 2019

Course Code 2PCE7101 Course Name Process Equipment Design

Teaching Scheme Examination Scheme (Marks)

(Per Lecture (DT) Practical (Lab.) Total CE SEE Total

week)

L TU P TW

Credit 3 1 1 0 5 Theory 40 60 100

Hours 3 1 2 0 6 Practical 30 20 50

Pre-requisites

Basic understanding of Unit Operations of Chemical Engineering and mechanical properties associated with

the material, Material and Energy balance.

Course Outcomes

On successful completion of the course, the students will be able to:

CO1 Identify the design aspects of vessel under internal and external pressure, tall vessel and supports.

CO2 Relate the basic concepts of process design development and general design considerations.

CO3 Demonstrate design aspects of shell & tube heat exchanger, distillation column, absorber and

extractor.

CO4 Explain the specification sheet of process equipment.

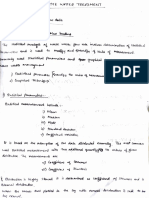

Theory Syllabus

Unit Content Hrs.

Introduction to vessel design: Selection Criteria for vessel design, Design Preliminaries

like excessive allowable stress, design stress, factor of safety, Poisson’s ratio, elastic

1

deformation, plastic instability, brittle rupture, creep, thickness of vessel wall, Introduction 7

to vessel codes and standards.

Design of pressure vessels under internal pressure: Design of wall thickness based on

Lame theorem and membrane stress theory, Types of closers for pressure vessel, design

thickness of closer, Selection and Design of nozzles and reinforcement pads, Introduction

2 to flanges and gasket, types and selection, design of flanges for pressure vessels. 10

Industrial pressure vessels under external pressure: Design of vessel wall in presence

and absence of stiffeners using analytical & graphical methods, Design of circumferential

stiffeners, Design of closers subjected to external pressure

Design of Tall Column: Industrial requirement of tall vessels, Construction & features in

column stress & determination of shell thickness.

3 10

Support for Vessels: Selection and design of different types – bracket or lug support, skirt

support & saddle support, design calculations

Process design of Shell and Tube Heat exchangers: General design method of shell &

tube heat exchanger, Criteria of selection among Fixed Tube sheet, U Tube & Floating

4 8

Head heat exchanger, Process design of without phase change heat exchanger, Process

design of condenser, Criteria of selection for Horizontal and vertical condenser

Process design of Distillation Column: Introduction, Criteria of selection, Selection of

equipment for distillation, Distillation column design, Selection of key components for

multi-component distillation, Determination of operating pressure for distillation column,

5 15

Determination of nos. of theoretical stages for multi-component distillation by Fenskey-

Underwood-Gilliland’s method, Selection of trays, Calculations for tower diameter &

pressure drop of sieve tray tower.

Process design of Absorbers & Extractor: Introduction, Criteria for selection among

different types of absorption equipment, Process Design of packed tower type absorber:

Determination of actual amount of solvent, Selection of packing, Determination of tower

6 10

diameter & pressure drop, Process design & selection criteria of liquid distributors,

redistributors & packing support. Process design of counter current multistage extractor,

mixer-settler type extractor & packed tower type extractor.

Practical Content

Practical, assignments and tutorials are based on above syllabus.

Text Books

1 Umarji, S. B.; Mahajani, V.V. Joshi’s Process Equipment Design; 5th ed.; Trinity Press: New Delhi,

2016.

2 Introduction to Process Engineering and Design by S B Thakore and B I Bhatt, Tata McGraw Hill,

1st Edition, 2007

Reference Books

1 Ray Sinnott, Gavin Towler, Chemical Engineering Design - Principles, Practice and Economics of

Plant and Process Design, Butterworth - Heinemann, 2008.

2 Srikant D Dawande, “Process Equipment Design” Volume -I & II, Denett publication.

3 Bhattacharya, B.C. Process Equipment Design: Mechanical Aspect; 1st ed.; CBS Publisher and

Distributors Pvt. Ltd.: New Delhi, 2014.

4 Don W. Green, Robert H. Perry, Perry's Chemical Engineers' Handbook, 8th Edn., McGraw -Hill,

New York, 2008

5 James R. Couper, James R. Fair & W. Roy Penney, Chemical Process Equipment - Selection and

Design, 2nd Edn., Butterworth - Heinemann, 2010.

ICT/MOOCs Reference

1 https://nptel.ac.in/courses/103/107/103107207/

Mapping of CO with PO and PSO:

PSO1

PSO2

PSO3

PO10

PO11

PO12

PO1

PO2

PO3

PO4

PO5

PO6

PO7

PO8

PO9

CO1 3 2 2 2 2 1 1 1 2 2 1 2 2 2 1

CO2 2 3 2 3 3 1 2 1 2 2 2 2 3 2 3

CO3 3 3 3 3 3 2 2 1 3 2 2 3 3 2 3

CO4 1 1 0 2 1 0 0 2 1 1 1 2 3 1 2

You might also like

- Cat d7 3t Operatons MtceDocument98 pagesCat d7 3t Operatons MtceMilagros Pullchs AriasNo ratings yet

- Mechanical Workshop Practice 20-21 (201 Copies)Document92 pagesMechanical Workshop Practice 20-21 (201 Copies)MOHAMMED MANSOORNo ratings yet

- Rock Characterization at El Teniente Mine PDFDocument15 pagesRock Characterization at El Teniente Mine PDFEmanuel NicolásNo ratings yet

- DR JPS FM 6feb - New - FormatDocument3 pagesDR JPS FM 6feb - New - Formatdiksha singhNo ratings yet

- File 5f2a7cecb9b64Document32 pagesFile 5f2a7cecb9b64GovindharajNo ratings yet

- FM LabDocument4 pagesFM Labdiksha singhNo ratings yet

- 2es1101 Engineering Grahpics Syllabus Semester IDocument2 pages2es1101 Engineering Grahpics Syllabus Semester IHaresh PatelNo ratings yet

- 22BES510Document2 pages22BES510Thirunavukkarasu ANo ratings yet

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDocument9 pagesSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetgopichandallakaNo ratings yet

- Concrete LabDocument1 pageConcrete Labmaruns004No ratings yet

- 2.6.1 Programme and Course Outcomes CIVIL Dept.Document76 pages2.6.1 Programme and Course Outcomes CIVIL Dept.PrashanthNo ratings yet

- Kallam Haranadhareddy Institute of Technology Ece DepartmentDocument3 pagesKallam Haranadhareddy Institute of Technology Ece DepartmentmuraliNo ratings yet

- MECHANICALDocument69 pagesMECHANICALSelvakumar SubbaiahNo ratings yet

- Estimation and Costing: 1 10 CO3 CO1 CO2Document8 pagesEstimation and Costing: 1 10 CO3 CO1 CO2Rekha RajshekarNo ratings yet

- TOM & MAC COsDocument7 pagesTOM & MAC COsTejas KadamNo ratings yet

- 19BT50107 Epc Svec2019 Iii I Oe 1Document9 pages19BT50107 Epc Svec2019 Iii I Oe 1Chithambar Ganesh ANo ratings yet

- Swarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetDocument9 pagesSwarnandhra College of Engineering & Technology Department of Mechanical Engineering Course Information SheetMurali VangalapatiNo ratings yet

- Design and Drawing COURSE PLAN 2017 FinalDocument5 pagesDesign and Drawing COURSE PLAN 2017 FinalqeftfgNo ratings yet

- Course Structure and Syllabus OF 2 Year M.Tech Petroleum EngineeringDocument23 pagesCourse Structure and Syllabus OF 2 Year M.Tech Petroleum EngineeringRajesh KumarNo ratings yet

- Natural Gas Eng Course PlanDocument6 pagesNatural Gas Eng Course PlanArsh AttriNo ratings yet

- Chemistry Course File CseDocument9 pagesChemistry Course File CseraniNo ratings yet

- Department of Mechanical Engineering: Bangalore Institute of TechnologyDocument76 pagesDepartment of Mechanical Engineering: Bangalore Institute of TechnologyVenkteshwarlu KNo ratings yet

- 4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementDocument6 pages4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementEric CookNo ratings yet

- Syllabus of Structural Analysis PCC-CVE204-TDocument2 pagesSyllabus of Structural Analysis PCC-CVE204-TManik GoyalNo ratings yet

- Production and Industrial Engineering ReviewedDocument36 pagesProduction and Industrial Engineering ReviewedabhijitsainiNo ratings yet

- MFT I SyllabusDocument3 pagesMFT I SyllabusVamsi RockzzNo ratings yet

- DMM Ii-CdsDocument5 pagesDMM Ii-CdsKrishna MurthyNo ratings yet

- THERMAL Assignment FrontpageDocument1 pageTHERMAL Assignment FrontpagedineshvaricomNo ratings yet

- Lecture - 1 - CO, PO, Evaluation Scheme, List of ExperimentsDocument12 pagesLecture - 1 - CO, PO, Evaluation Scheme, List of ExperimentsSavan PatelNo ratings yet

- Securities MRT Foun.Document2 pagesSecurities MRT Foun.DoremonNo ratings yet

- Thermo MEX SyllabusDocument3 pagesThermo MEX SyllabusPra GoNo ratings yet

- 2nd Year CO-PO Mapping FinalDocument14 pages2nd Year CO-PO Mapping FinalsantoshNo ratings yet

- Cet402 Quantity Surveying and ValuationDocument13 pagesCet402 Quantity Surveying and ValuationdipinnediyaparambathNo ratings yet

- P23. Mapping of Course Outcome With Program OutcomesDocument31 pagesP23. Mapping of Course Outcome With Program OutcomesBhaskar MondalNo ratings yet

- Sheet Metal Workshop - Lab ManualDocument40 pagesSheet Metal Workshop - Lab ManualHARSHAVARDHAN MADISHETTINo ratings yet

- JCT College of Engineering and Technology: Course Information SheetDocument6 pagesJCT College of Engineering and Technology: Course Information SheetDhamu DharanNo ratings yet

- Cs3271 Programming in C LaboratoryDocument4 pagesCs3271 Programming in C Laboratoryabinayasundaramoorthi2000No ratings yet

- Production Technology Lab ManualDocument59 pagesProduction Technology Lab Manualuma deviNo ratings yet

- CET309Document12 pagesCET309dipinnediyaparambathNo ratings yet

- Ec8452 Ec-Ii Unit-2Document103 pagesEc8452 Ec-Ii Unit-2Ananda Sailesh KNo ratings yet

- IDS SyllabusDocument3 pagesIDS SyllabusKhaushik KumaarNo ratings yet

- 2160503Document3 pages2160503Yash MadlaniNo ratings yet

- Workshop Practice One Side Print 28janDocument9 pagesWorkshop Practice One Side Print 28janDr. A. Praveen KumarNo ratings yet

- Testing and Commissioning of Electrical EquipmentDocument2 pagesTesting and Commissioning of Electrical EquipmentGuna PriyaNo ratings yet

- Chemical Engineering s7 & s8Document337 pagesChemical Engineering s7 & s8MaryamNo ratings yet

- Basics - of - Civil & Mechanical Eng.Document7 pagesBasics - of - Civil & Mechanical Eng.Rahul J.RNo ratings yet

- Course Objective(s) :: Major ElectiveDocument2 pagesCourse Objective(s) :: Major ElectiveKKNo ratings yet

- Irrigation Engineering and Environment DrawingDocument95 pagesIrrigation Engineering and Environment DrawingSE3094- Soundarya.SNo ratings yet

- COURSE FILE Nce 702 WREDocument19 pagesCOURSE FILE Nce 702 WREMohd AmirNo ratings yet

- MTech SMFE Rev12032019Document78 pagesMTech SMFE Rev12032019Mr.Bhaskar WabhitkarNo ratings yet

- SE SyllabusDocument2 pagesSE SyllabusAnil ChauvanNo ratings yet

- BCE Lab ManualDocument69 pagesBCE Lab ManualSuraj VyasNo ratings yet

- Excel File CO-PO Attainment For UG - RACDocument13 pagesExcel File CO-PO Attainment For UG - RACanshul9051No ratings yet

- 20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDocument55 pages20ME403 Engineering Materials and Metallurgy Unit - IV Digital MaterialDark ranger YtNo ratings yet

- Dce Sylllabus of 4th Semester - Collection by Engg Dedication Yt ChannelDocument36 pagesDce Sylllabus of 4th Semester - Collection by Engg Dedication Yt Channelusemobile7044No ratings yet

- Consumer Behavior - SyllabusDocument1 pageConsumer Behavior - SyllabusAshish raturiNo ratings yet

- 6 Semester MU-302: CAD/CAM Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementDocument7 pages6 Semester MU-302: CAD/CAM Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementNilesh AvhadNo ratings yet

- Aditya College of Engineering: Course Outcome Mapping With PO's and PSO'sDocument3 pagesAditya College of Engineering: Course Outcome Mapping With PO's and PSO'ssundarmeenakshiNo ratings yet

- Aditya College of Engineering: Course Outcome Mapping With PO's and PSO'sDocument3 pagesAditya College of Engineering: Course Outcome Mapping With PO's and PSO'ssundarmeenakshiNo ratings yet

- Updated - Analog & Digital Circuit Manual - BECL305Document98 pagesUpdated - Analog & Digital Circuit Manual - BECL305rvit22bec032.rvitmNo ratings yet

- PHP - LAB - Course PlanDocument13 pagesPHP - LAB - Course PlankhatNo ratings yet

- Isogeometric Analysis: Toward Integration of CAD and FEAFrom EverandIsogeometric Analysis: Toward Integration of CAD and FEANo ratings yet

- Activated Sludge ProcessDocument6 pagesActivated Sludge ProcessAkshay UdayNo ratings yet

- 7 - AnalysisDocument5 pages7 - AnalysisAkshay UdayNo ratings yet

- STUCOR - UG Higher Semester Except Sem IIIDocument1 pageSTUCOR - UG Higher Semester Except Sem IIIAkshay UdayNo ratings yet

- Unit I Introduction To Spectroscopical Methods of AnalysisDocument28 pagesUnit I Introduction To Spectroscopical Methods of AnalysisAkshay UdayNo ratings yet

- Annexure 1Document1 pageAnnexure 1Akshay UdayNo ratings yet

- Prob and Stats unit-IIIDocument5 pagesProb and Stats unit-IIIAkshay UdayNo ratings yet

- Modes of Mass TransferDocument20 pagesModes of Mass TransferAkshay UdayNo ratings yet

- Unit 2: CH8491 - Instrumental Methods of Analysis 2019-2020Document24 pagesUnit 2: CH8491 - Instrumental Methods of Analysis 2019-2020Akshay UdayNo ratings yet

- Mechanical Separations: Unit OperationDocument5 pagesMechanical Separations: Unit OperationAkshay UdayNo ratings yet

- Pleurobrachia & Cydippid LarvaDocument18 pagesPleurobrachia & Cydippid LarvaAkshay UdayNo ratings yet

- GE6351 Environmental Science and EngineeringDocument261 pagesGE6351 Environmental Science and EngineeringAkshay UdayNo ratings yet

- Asphyxia by SuffocationDocument15 pagesAsphyxia by SuffocationBryan Christopher Co Lao100% (1)

- HiaDocument9 pagesHiaSuryasumanthNo ratings yet

- Franck-Hertz Experiment P6241 eDocument4 pagesFranck-Hertz Experiment P6241 emsiarovNo ratings yet

- ISO Optical StandardsDocument16 pagesISO Optical Standardsflord21No ratings yet

- All G485 QuestionsDocument190 pagesAll G485 Questionsdasha962No ratings yet

- Got Milk? Background: Food Processing and PreservationDocument7 pagesGot Milk? Background: Food Processing and PreservationRaja VeluNo ratings yet

- What Is The Best Way To Truly Live?: (Your Free Download)Document11 pagesWhat Is The Best Way To Truly Live?: (Your Free Download)joanellNo ratings yet

- Kevlar by Abhishek JaguessarDocument5 pagesKevlar by Abhishek Jaguessarreedoye21No ratings yet

- Principle 3Document113 pagesPrinciple 3Mark Antony LevineNo ratings yet

- Medidor Caudal Kobold DpuDocument4 pagesMedidor Caudal Kobold DpuBase SistemasNo ratings yet

- Glibenclamide (Glibenclamidum) : The International Pharmacopoeia - Sixth Edition, 2016Document1 pageGlibenclamide (Glibenclamidum) : The International Pharmacopoeia - Sixth Edition, 2016Yuda Anzas MaraNo ratings yet

- (MVS) Deposit Type and Associated CommoditiesDocument12 pages(MVS) Deposit Type and Associated CommoditiesSalvadora1No ratings yet

- CITGO Classroom GlossaryDocument4 pagesCITGO Classroom GlossarycutefrenzyNo ratings yet

- Qmax Solids Control EquipmentDocument18 pagesQmax Solids Control Equipment2591995No ratings yet

- 455 - FST 504 Lecture Note-Dr BabajideDocument41 pages455 - FST 504 Lecture Note-Dr BabajideMahnoorIshtiaqNo ratings yet

- Pericles Exported CitationsDocument2 pagesPericles Exported CitationsManoj PrakashNo ratings yet

- NullDocument3 pagesNullapi-26374520No ratings yet

- Cpa Review School of The Philippines Auditing TheoryDocument16 pagesCpa Review School of The Philippines Auditing Theoryprincess_camarilloNo ratings yet

- Tips and Tricks For The Lab - Column Choices - Education - ChemistryViewsDocument8 pagesTips and Tricks For The Lab - Column Choices - Education - ChemistryViewsJoséFernandoNo ratings yet

- Sab 2112 - L4 AggregatesDocument51 pagesSab 2112 - L4 Aggregatesapi-19705508No ratings yet

- Annexure D - For Cable Cellar MVWS SystemDocument1 pageAnnexure D - For Cable Cellar MVWS Systemsujay AvatiNo ratings yet

- CHP - G3512 - 555 KW 1200 RPM 12 G NOx - DM5209-02-EDocument3 pagesCHP - G3512 - 555 KW 1200 RPM 12 G NOx - DM5209-02-ENimNo ratings yet

- General Chemistry 2 (STEM) : Quarter 4 - Module 1 & 2Document27 pagesGeneral Chemistry 2 (STEM) : Quarter 4 - Module 1 & 2Alexa ValdezNo ratings yet

- Bohr Models For Atoms WsDocument2 pagesBohr Models For Atoms WsMehakpreet GillNo ratings yet

- Turbine Oil Monitoring PDFDocument23 pagesTurbine Oil Monitoring PDFAzhar1109100% (2)

- GeographyDocument6 pagesGeographyRonnith NandyNo ratings yet

- Ideal Color51 Tec EngDocument3 pagesIdeal Color51 Tec EngPedroNo ratings yet

- 6973-51 Welding PlantDocument1 page6973-51 Welding Plantabdulhanan86457No ratings yet