Professional Documents

Culture Documents

VLSI Tech - End - Sem

VLSI Tech - End - Sem

Uploaded by

Rajendra Thamerci0 ratings0% found this document useful (0 votes)

14 views2 pagesOriginal Title

VLSI tech_end_sem

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

14 views2 pagesVLSI Tech - End - Sem

VLSI Tech - End - Sem

Uploaded by

Rajendra ThamerciCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 2

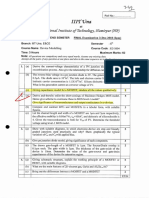

National institute of Technology, Hamirpur (HP)

[Name of Examinaton: B.Tech, (Dual Degree) End Semester Examination, 20" May, 2021

Branch: ECE (B.Tech, Dual Degree) Semester: 4"

Subject: VLSI Technology Subject Code: £¢-224

‘Time: 2 Hows (10 am— 12:00 noon) Maximum Marks: 50

Note: a. Attempt all questions ( There are 5 questions in the paper), b. Error Function Table is given at the

‘end ofthis question paper.

+t (@) The graph shown in the figure Q-fla) is avaiable for Wet

thermal oxidaton of <100> Si wafers. Suppose Si war with of <100>

has an inal oxide thickness of 05 jm. With Wet-Oxidaton at 1000 °C,

‘what isthe requied oxidation time to oblain a toll thickness of fm?

Note: Use graph to calculate the time. bm

+4 (b) One micton of siicon dioxide is grown on a wafer. You

subsequenty determine thatthe oxidation step has caused the doping

concentration near the surface of substrate ( at the inerface between

‘ode and Si substrate) to rise compared to the bulk in the substrate

Explain why this has happened, and what ths means about the

segregation coefficient and the difusion of his dopantin SiO [3M]

Ose Thickness om)

(Q-1(c) Explain Reactive fon Etching (RIE) bom

2 (a) Arsenic is implanted at 40 keV to a dose of 1.5*10 cnr” through a 20 nm polyerystaline Si fim having

same range salisties as Si substrate (range and straggle are same as in single crystal slicon and polycrystaine Si

fim). Take Rp= 30 nm and ARp = 13 nm, [Note: We have polysilicon flm of 20 nm deposited ove single crystal Si

substrate) tem

(i) Whats the value of peak doping concentration in singe crystal S substrate and its locaton from the top

surface ofthe polysicion film?

{i Whats value of peak doping concentration in polysitoen fim and is location from the top surface ofthe

polysicon fim?

(i) What dose will penetrate through the Poly-Sifim int the single crystal Si substrate?

2 (b) A resistor isto fabricated using ps cifusion on a ghily doped n-type <100> Si wafer. Describe your process

‘ow and draw the cross-sectional view ofthe device afer each process steps. tm

Q-3 (a) Suppose you have to meet a faitly tight resistivity specification during CZ crystal growth under rapid stirring

condition. (a) Would you prefer to grow N type or P type crystals and Why? (b) What dopant would you use in

growing N-type crystals? Why? rom

3 (b) Design a constant-dose itision of Antimony into p-type silicon wafer that gives a surface concentration of

5x10 cm and a junction depth of 1 um. The background p-type doping in the slicon is 5x10" cm, Fo this case,

fnd sutable values of Dt and @, where D= dusty of he dopant lom in sien wafer, dfusion te and Q=

dose. fem)

(2-4 (a) You are using KOH to define a hole in a 400 tm thick silicon water (100) aa] “

as shown in he figure Q-(a), What miimum bichness of Siz is needed to

Brovide a mask for KOH etching. The eleh rte for SiO, and Siis SO mfr, 267

rv respectively What sie of he opening (W) would you need onthe lop ofthe

water?

ee Figure Q-4 (a) : Wet oxidation graph

(2-4 (b) Write the major difference between the unimited source diffusion and the ited source difusion. [9M]

5 (a) Explain Local oxidation of Silicon (LOCOS) an Shallow Trench (ST) device isolation techniques used in

VLS' technology tam

(25 (b) Explain briefly al the steps (substrate preparation fo resist sipping) volved in photlthography. [4M]

(55 (c) Write @ short note on PVD (physical vapor deposition) techniques om

25 (d) Write @ short note on MBE (molecular beam esitaxy) [ou

“End of Question Paper“

Error Function Table

eae tere

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5825)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2018-May ECD-221 25Document1 page2018-May ECD-221 25Rajendra ThamerciNo ratings yet

- 2018-Dec EC-727 219Document1 page2018-Dec EC-727 219Rajendra ThamerciNo ratings yet

- 2019-Dec ECD-314 30Document2 pages2019-Dec ECD-314 30Rajendra ThamerciNo ratings yet

- N Elemant ArrayDocument14 pagesN Elemant ArrayRajendra ThamerciNo ratings yet

- 2020-Dec ECD-314 1Document1 page2020-Dec ECD-314 1Rajendra ThamerciNo ratings yet

- For Image Ec-677Document2 pagesFor Image Ec-677Rajendra ThamerciNo ratings yet

- 2018-Dec EC-3504 249Document2 pages2018-Dec EC-3504 249Rajendra ThamerciNo ratings yet

- The Nyquist Plot A Frequency Response Analysis TechniqueDocument33 pagesThe Nyquist Plot A Frequency Response Analysis TechniqueRajendra ThamerciNo ratings yet

- Jagadguru Adi Sankara - enDocument47 pagesJagadguru Adi Sankara - enRajendra ThamerciNo ratings yet

- 194520digital ..Lab - RajendraDocument75 pages194520digital ..Lab - RajendraRajendra ThamerciNo ratings yet

- Naming Reaction FinalDocument9 pagesNaming Reaction FinalRajendra ThamerciNo ratings yet

- B.tech (C) - I (Ece - 101 Paper - Mathematics - I)Document3 pagesB.tech (C) - I (Ece - 101 Paper - Mathematics - I)Rajendra ThamerciNo ratings yet

- Magnetic Materials For MEMSDocument4 pagesMagnetic Materials For MEMSRajendra ThamerciNo ratings yet

- Rajendra: Analog (Onmu (Document15 pagesRajendra: Analog (Onmu (Rajendra ThamerciNo ratings yet