Professional Documents

Culture Documents

Saep 1151

Saep 1151

Uploaded by

SamiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saep 1151

Saep 1151

Uploaded by

SamiCopyright:

Available Formats

Engineering Procedure 12 January 2021

SAEP-1151

Inspection Requirements for Contractor Procured Materials and Equipment

Document Responsibility: Project Quality Standards Committee

Previous Revision: 23 October 2017 Next Revision: 12 January 2026

Contact:(megraa0a) Page 1 of 21

© Saudi Arabian Oil Company, 2020

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Contents

Summary of Changes.................................................................................................... 3

Scope ...................................................................................................................... 5

Conflicts and Deviations .......................................................................................... 5

References .............................................................................................................. 5

Terminology ............................................................................................................ 6

Procurement Risk Management .............................................................................. 8

6. Contractor Purchase Requisition ........................................................................... 10

7 Inspection and Test Plan ....................................................................................... 10

8. Special SA-175 Forms .......................................................................................... 11

9. Minimum Inspection Levels ................................................................................... 12

10. Roles and Responsibilities .................................................................................... 13

Document History ........................................................................................................ 14

Appendix I - Procurement Risk Evaluation Guidelines ................................................ 15

Appendix II - Project Management Evaluation Guidelines........................................... 16

Appendix III - Proponent Evaluation Guidelines .......................................................... 17

Appendix IV - Procurement Risk Mitigation Guidelines ............................................... 18

Appendix V - 30% PO Focused Assessment Checklist ............................................... 19

Appendix VI - 60% PO Focused Assessment Checklist…………………………………20

Appendix VII - 90% PO Focused Assessment Checklist ............................................. 21

© Saudi Arabian Oil Company, 2020 Page 2 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Summary of Changes

Paragraph Number Change Type

(Addition, Modification, Technical Change(s)

Previous Revision Current Revision Deletion)

(03 November 2017) (13 January 2021)

Deletion of Saudi Aramco Inspection

3.1 NA Deletion Req. 175-32440 form reference

Modified to include RBI:

This section is applicable to all Type-A

and Type-B projects with the intent of

providing a systematic approach to

5 5 Modification

manage and implement risk-based

inspection coverage, in line with ISO

9001:2015 requirements.

New paragraph to start with risk level

- 5.1 Addition definition

Changed to add further explanation on

5.2 5.2 Modification

used RBI method

Re-arrangement of paragraph only and

5.1 5.3 Modification no change

This to identify Contractor risk register

- 5.4 Addition minimum requirement

New paragraph added to illustrate SAIR

- 5.5 Addition communication with related Stakeholder

Redistribution of weight % as per revised

Table 1 Table 1 Modification RBI WI

PQM concurrence on final RBI list and

- 5.6, 5.7 Addition authorization to change risk level

Final Risk levels relayed to Responsible

- 5.8 Addition Inspection Office (RIO)

Removal of frequency of technical and

quality focused assessments for bulk

Table 2 Table 2 Modification

material

Deleted as changes will require to follow

6.2.2 - Deletion para 6.2.1

© Saudi Arabian Oil Company, 2020 Page 3 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Modification to clarify Sub-vendor list

6.3 6.3 Modification

review and approval by company

Identification of ITP minimum

- 7.2.4 Addition requirement

For contractor to insure final approved

- 7.6 Addition ITP is shared with all relevant parties

8.3 8.3 Modification Special 175 form approval by SCC

Editorial change as this paragraph is

8.4 - Deletion cleared in other section

Changes made to identify requirement of

separate 175-forms as applicable for

8.5 8.4 Modification engineered equipment such as Skids,

Vessel and insure compliance to SAMSS

Proposed Inspection level for non-listed

materials/ equipment shall be approved

9.7 9.7 Modification

by SCC

Identify SAIR escalation process during

- 9.9 Addition release of equipment with punch items

Proposed Inspction level for non-listed

materials/ equipment shall be approved

10.1 10.1 Modification

by SCC

Modification:

• Procurement Risk Evaluation

Guidelines changed as per RBI

WI

• Procurement Risk Mitigation

Guidelines

Addition & Addition:

Appendix Appendix

Modification • Project Management Evaluation

Guidelines

• Proponent Evaluation Guidelines

• 30%, 60% and 90% PO Focused

Assessment Checklist

© Saudi Arabian Oil Company, 2020 Page 4 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Scope

This document, together with the purchase order and appropriate project

specifications define the minimum mandatory inspection requirements for

Contractor procured materials and equipment on projects.

Commentary Note:

As per the Procurement Manual 3.1.2, Short-form and Mid-form Contracts are also within the

scope of this procedure.

Conflicts and Deviations

Any conflicts between this document and other applicable Mandatory Saudi

Aramco Engineering Requirements (MSAERs) shall be addressed to the

EK&RD Coordinator.

Any deviation from the requirements herein shall follow internal company

procedure SAEP-302.

References

All referenced specifications, standards, codes, drawings, and similar material

are considered part of this (Engineering Procedure, Engineering Standard,

Material System Specification) to the extent specified, applying the latest

version, unless otherwise stated.

Saudi Aramco References

Saudi Aramco Engineering Procedures

SAEP-71 Portfolio Execution Planning (PXP)

SAEP-302 Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirements

SAEP-1150 Inspection Coverage on Projects

Industry Codes and Standards

International Organization for Standardization

ISO 9001 Quality Management Systems – Requirements

Other References

Schedule Q Quality Requirements

© Saudi Arabian Oil Company, 2020 Page 5 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Terminology

Acronyms

Quality Assurance (QA): All the planned and systematic activities

implemented within the quality system, and demonstrated as needed, to provide

adequate confidence that an entity will fulfill requirements for quality.

Quality Control (QC): The operational techniques and activities that are used

to fulfill requirements for quality.

Quality Control Procedure (QCP): A QCP is a documented procedure

detailing the processes necessary to complete a specific work activity.

PIM: Pre-inspection Meeting

Type-A & Type-B Projects: As defined in SAEP-71.

Inspection and Test Plan (ITP): An ITP is a document based on the detailed

manufacturing, fabrication and, construction program and identifies each

process description. The ITP will set out related sequence of activities to be

inspected, examined, and tested.

RIO: Responsible Inspection Office

Project Quality Manager (PQM): The senior Inspection Representative

responsible for coordinating all inspection requirements on behalf of the

Inspection Department with PM throughout all project phases.

SAIR: Saudi Aramco Inspection Representative

VID: Saudi Aramco Vendor Inspection Division

PMT: Project Management Team

SME: Special Matter Expert (usually from CSD and P&CSD)

NDT: Non-destructive Testing

EPM: Enterprise Project Management

MSAER: Mandatory Saudi Aramco Engineering Requirement

VQI: Vendor Quality Index in SAP

IAP: Inspection Assignment Package

© Saudi Arabian Oil Company, 2020 Page 6 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

EDR: Equipment Deficiency Report

NCR: Non-Conformity Report

PO: Purchase order

SCC: Standard Committee Chairman

Procurement Risk Register: A list of contractors planned and actual POs with

assigned level of risk (i.e., critical, high, moderate, or low).

Risk Based inspection (RBI): An analysis methodology and process that

requires qualitative or quantitative assessment of probability and impact of

failures associated with project Procurement and Construction works.

Commentary note:

Additional related terminologies are in SAEP-1150.

Definitions

Quality System: Organizational structure, procedures, and processes are

resources needed to implement quality management.

Hold Point: An inspection point, defined in an appropriate document, beyond

which an activity must not proceed without the approval of a designated

organization or authority.

Witness Point: An inspection point, defined in an appropriate document,

beyond which an activity can proceed after notifying the designated

organization or authority.

Review Point: Is the point at which a work activity cannot proceed without first

ensuring the review and approval of applicable documents or personnel

qualifications by a designated organization or authority.

© Saudi Arabian Oil Company, 2020 Page 7 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Procurement Risk Management

This section is applicable to all Type-A and Type-B projects with the intent of

providing a systematic approach to manage and implement risk-based

inspection coverage in line with ISO 9001:2015.

5.1 The risk level for each PO is a product of the probability of failure, and the

associated impact of failure.

5.2 Contractor POs are evaluated by the Project Team according to weighed

factors, as tabulated in Table.1. The measure of probability and impact of

failures are estimated for each PO as shown in Appendix I, Appendix II, and

Appendix III.

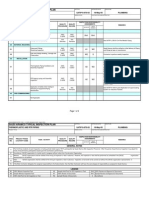

Table 1 - Contractor POs Risk Assessment Criteria

Criteria Evaluation Source Weight

(%)

Failure Frequency SAP, EPM, SME, EDR, NCR 30

Manufacturing Complexity MSAER, SME 20

Vendor/Manufacturer Vendor VQI 25

Probability* Performance

MSAER’s Availability SAP Material Description 15

Preservation and Handling MSAER, Manufacturer 10

Cost** Project Management Team 25

SME

Impact Schedule** Project Management Team 25

SME

Operation Quality, Safety and Proponent’s SME 50

Reliability***

Notes :

*Appendix I , ** Appendix II, *** Appendix III

5.3 Contractor, within one month from developing the Material Takeoff (MTO) list,

shall develop the risk register and submit it to Company for review.

5.4 Contractor risk register shall include as a minimum the following: material

requisition/PO, 9COM, inspection level and awarded vendor/manufacturer.

© Saudi Arabian Oil Company, 2020 Page 8 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

5.5 SAIR shall coordinate with Project Management Team and Proponent to evaluate

and score the probability and impact of failures for each PO, noting that scoring

mechanisms outlined under Appendix II and Appendix III are general guidelines

for Project Management and Proponent and can be modified accordingly to

determine the risk levels.

5.6 The final list shall be reviewed and concurred upon in writing by the Project

Quality Manager (PQM), with a copy sent to Quality Monitoring Unit Supervisor.

5.7 SAIR and/or PQM shall have the authority to change risk levels or mitigation

guidelines based on project stakeholder’s (PMT & Proponent) agreement, with

proper documented justification.

5.8 Critical and High-Risk POs shall be officially relayed to the Responsible

Inspection Office (RIO) upon the approval of a PO’s Inspection Assignment

Package (IAP). The risk level shall be indicated in the IAP, and noted in the

corresponding Inspection Lot by SAIR.

5.9 Contractor shall submit updated risk registries on monthly basis highlighting new

POs and/or purchase requisitions, POs progresses, and conducted PO Focused

Assessments. Monthly updates shall also consider risk assignments based on

technical alerts, major lessons learned, and deteriorating manufacturer

performances.

Commentary note:

In case of risk level change, PQM approval is required as per para. 5.7 above.

5.10 Contractor shall closely monitor and assess critical-and high-risk POs, to ensure

quality and minimize rework.

5.11 Contractor shall conduct PO Focused Assessments at the specified PO progress

in accordance with Table 2, in line with 5.13 requirement. Contractor shall also

submit PO Focused Assessments reports to Company highlighting technical

and/or quality findings, and required corrective actions plan and agreed

completion dates.

5.12 Contractor should notify Company of PO progress milestones at 30%, 60% and

90%, for Critical and High-Risk POs.

© Saudi Arabian Oil Company, 2020 Page 9 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Table 2 - Frequency of Contractor PO’s Focused Assessments

PO Progress

Risk

30% 60% 90%

Critical X X X

High X X

Medium X

5.13 Risk mitigation guidelines shall be as outlined in Appendix IV, noting that PO

Focused Assessments by PMT, Proponent, and Technical SMEs are optional

and subject to availability and resources.

5.14 PO Focused Assessments shall follow, as a minimum, the formats outlined under

Appendix V, Appendix VI and Appendix VII.

6. Contractor Purchase Requisition

6.1 Purchase requisition originators shall identify the applicable fabrication and

1inspection requirements stated in approved requisition shall be reflected in

purchase orders.

6.2 Purchase requisition originators may also modify the content of a coded SA-175

form for certain purchase orders provided the following procedure is followed:

6.2.1 If the modification is to delete or modify an inspection activity specified in

Mandatory Saudi Aramco Engineering Requirements, a waiver shall be

duly obtained as per SAEP-302 against applicable standards before

altering the coded SA-175 form.

Modified SA-175 forms will automatically become “175-SPECIAL” forms.

Refer to Section 8 for further instructions on 175-SPECIAL forms.

6.3 After PO award, contractor shall submit sub-vendor list for Company review

and approval. It shall include as a minimum the following: material description,

specification, 9COM, approved sub-vendor (Name and ID) and inspection level.

7 Inspection and Test Plan

7.1 The vendor and/or sub-vendors shall prepare detailed ITP’s for all assigned

equipment and materials in accordance with all relevant Saudi Aramco

inspection forms (SA-175 forms), Schedule Q, and purchase orders.

© Saudi Arabian Oil Company, 2020 Page 10 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

7.2 ITP shall provide:

7.2.1 Detailed inspection activities and the required tests which include, as

minimum, inspection hold, witness, review points, inspection frequency

as per applicable 175 form and assigned inspection level.

7.2.2 Sampling plan criteria shall be determined based on MSAER and

international standards.

7.2.3 Clearly defined roles and responsibilities for each inspection activity.

7.2.4 Identification of requirements for documents and acceptance criteria as

applicable (ASME Code, or SAMSS…etc.).

7.3 Sampling plan availability does not relieve the vendor of the responsibility to

ensure compliance with Company requirements.

7.4 SAIR reserves the right to increase inspection activities and sampling plan criteria

in coordination with Company Subject Matter Expert (SME) based on the

criticality of the purchase orders and past performance of selected

manufacturers.

7.5 As part of IAP submittal, Contractor shall provide review and approval status of

vendor and/or sub-vendor Non Material Requirements (NMR-601 documents),

quality control procedures such as welding, NDT, heat treatment, and the

required related procedures for that specific purchase order, as required by

Company standards and/or project specifications.

7.6 Contractor shall ensure the comments raised and agreed during the PIM on ITP

are properly incorporated through new form revision. Contractor shall ensure

distribution of revised ITP to all the relevant parties.

8. Special SA-175 Forms

8.1 Some inspectable materials do not have coded SA-175 forms linked to them.

When these materials are procured, the purchase requisition originators shall

specify source inspection requirements for materials, by filling in the blank special

SA-175 form.

8.2 The contractor is responsible to develop and maintain full document control of

issued special SA-175 forms during a project in term of numbering and

identification, approval, revisions and records preservation.

8.3 The PQM and/or SAIR are responsible to review contractor generated special

SA-175 forms, as applicable. special SA-175 forms shall be subject to SCC

approval.

© Saudi Arabian Oil Company, 2020 Page 11 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

8.4 For packaged, skid mounted equipment or any main equipment, separate SA-

175 form shall be applied on each inspectable sub-component in accordance

with main SAMSS and SA-175 form, in addition to the SA-175 form for the overall

equipment.

9. Minimum Inspection Levels

9.1 Inspection levels shall be assigned on project contractor’s materials and

equipment to specify the minimum amount of inspection coverage deemed

necessary by Saudi Aramco to ensure that a product or service conforms to

specifications at a specific supplier's and/or sub-supplier's factory or fabrication

site.

9.2 The following system of coding the level of planned inspections shall be used to

define the inspection requirements:

Level 0: Documentation requirements only as specified in applicable

SA-175 form; no vendor inspection required.

Level 1: Only final inspection including release for shipment is required

prior to shipping.

Level 2: Includes pre-inspection meetings, one or more unspecified “in

progress” surveillance visit/s, all witness and hold points, final

inspection, and release for shipment.

Level 3: Includes pre-inspection meetings, one or more unspecified “in

progress” surveillance visits, all witness and hold points, final

inspection, and release for shipment. Inspections shall be on

a regular basis (daily, weekly or bi-weekly).

Level 4: Resident inspector continually monitoring the work.

All inspectable material covered under the inspection levels as defined above,

shall be procured from Saudi Aramco approved manufacturers.

9.3 Minimum inspection levels by project contractor for procured materials and

equipment shall be as per the Company provided list of inspection levels

extracted from SAP per 9COM at the project cut-off date.

9.4 VID provides quality monitoring and inspection support for projects in

accordance with approved ITP. SAIR will determine which purchase orders and

vendor activities to be monitored based on guidelines in Appendix IV.

© Saudi Arabian Oil Company, 2020 Page 12 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

9.5 Inspection levels might be elevated or lowered by SAIR on case by case basis,

based on criticality of procured materials, performance of selected manufacturer

and qualification of contractor’s inspector, etc.

9.6 When vendor does not meet the specified performance requirements in the

purchase order, or Company has placed the vendor on-hold after the Company

has issued a “No Objection” letter to contractor, contractor shall increase the

inspection level to the next highest level for the purchase order without additional

cost to Company, subject to Company approval.

9.7 In case of materials/equipment not listed in the list as described in paragraph 9.3,

the SAIR and/or PQM will determine the appropriate inspection level. Inspction

level for non-listed materials/ equipment shall be approved by SCC.

9.8 Contractor shall not release material with punch list items unless approval is

obtained from Company representative.

9.9 SAIR is responsible to determine the criticality of material and severity of punch

list items during the release, and escalate to appropriate Quality Notification as

applicable.

10. Roles and Responsibilities

10.1 SAIR and/or PQM is responsible to verify the assignment of appropriate level of

inspection. They are also responsible to determine the level of inspection for non-

listed materials/ equipment. Inspction level for non-listed materials/ equipment

shall be approved by SCC.

10.2 Contractor is responsible to provide enough inspection coverage for Procured

Materials, perform the required inspection, track material inspection status and

inspection notifications and highlight any deficiencies to Company in timely

manner.

10.3 Contractor is responsible to propose the proper level of inspection in

accordance with this procedure and/or other contractual documents.

10.4 RIOs are responsible to provide monitoring inspection services when

requested by the SAIR.

10.5 SAIR is responsible to escalate to SAIR’s management any repetitive major

observations from the same vendor for any further actions.

10.6 SAPMT is responsible to provide contractor a list of all inspectable materials

with their respective inspection levels, extracted from SAP, as a part of IFB

(Issued for Bid) package.

© Saudi Arabian Oil Company, 2020 Page 13 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021 Inspection Requirements for Contractor

Next Revision: 12 January 2026 Procured Materials and Equipment

Document History

18 November 2012 New Saudi Aramco Engineering Procedure.

30 January 2017 Editorial revision to transfer document responsibility from Inspection Engineering

to Project Quality Standards Committee and other changes.

1 November 2017 Major revision for two main reasons; (1) to update the listed IR Codes and

associated equipment descriptions to reflect the current selection of inspectable

materials, and

(2) to make inspection levels more dynamic by obtaining inspection levels per the

project cut-off date from SAP. This revision will therefore no longer reflect

inspection levels.

12 January 2020 Major revision to reflect risk-based inspection requirements and other changes.

© Saudi Arabian Oil Company, 2020 Page 14 of 21

Saudi Aramco: Company General Use

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

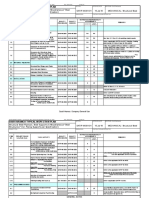

Appendix I

Procurement Risk Evaluation Guidelines

Criteria

Score Failure Preservation and

Manufacturing Complexity Vendor Performance MSAERs Availability

Frequency Handling

No Previous

0 N/A N/A N/A N/A

EDR or NCR

Normal preservation

1 2 EDR/NCR Final inspection RVL with VQI ≥ 85% and handling (e.g. only

or less MSAER and SA-175 box packing)

Forms available

Normal preservation

In-Process inspection – No RVL with VQI 85-

2 3 EDR/NCR and handling with

special processes review 75%

shade requirements

(Score 2 without PIM and

RVL with VQI 75- Controlled

3 4 EDR/NCR 3 with PIM) MSAER available and

70% environment

Special-175 Form

RVL with VQI 70-65% required Special preservation

4 5 EDR/NCR First time purchased –Non-RVL (e.g. N2, Oil, VCA)

engineered equipment – RVL with VQI ≤ 65%

Licensed equipment – – RVL on Hold –

MSAER not available

6 EDR/NCR Special preservation

5 Special design conditions and Special-175 Form

or more Newly Approved and handling

and metallurgy required

Vendor

© Saudi Arabian Oil Company, 2020 Page 15 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

Appendix II

Project Management Evaluation Guidelines

Criteria

Score

Cost Schedule (Option A) Schedule (Option B) Schedule (Option C)

0 N/A N/A N/A N/A

Acceptable delay ≥6

1 PO value ≤$10MM Float ≥6 months Bulk material

months

Acceptable delay 4-6 Cladded Pipes and

2 PO value $10-20MM Float 4-6 months

months Fittings

Acceptable delay 2-4

3 PO value $20-25MM Float 2-4 months Engineered Equipment

months

Acceptable delay ≤ 1 Rotating and Skid-

4 PO value $25-50MM Float ≤ 1 month

month Mounted Equipment

5 PO value ≥$50MM Project critical path Project critical path Project critical path

© Saudi Arabian Oil Company, 2020 Page 16 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

Appendix III

Proponent Evaluation Guidelines

Criteria

Score

Operation Quality (Option A) Operation Quality (Option B)

0 N/A N/A

No operation disruption with < 3 mhrs. internal

1 maintenance One-Leg operation

No production impact

No operation disruption with > 3 mhrs internal maintenance

2 Product spec. loss

No production impact

Operation disruption with internal maintenance

3 Unit shutdown – Plant shutdown

No production impact

Operation disruption with external maintenance

4 Immediate total plant shutdown

No production impact

5 Operation disruption with production impact Fatal hazard – loss of life or assets

© Saudi Arabian Oil Company, 2020 Page 17 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

Appendix IV

Procurement Risk Mitigation Guidelines

Purchase Order Focused Assessment

Senior

Company

Risk Level Monitoring Monitori Inspection (RIO) PMT** Proponent** Technical SME**

ng

Inspector

30% 60% 90% 30% 60% 90% 30% 60% 90% 30% 60% 90%

Critical ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓

High ✓ ✓ ✓ ✓ ✓

Medium ✓*

Low

*Applicable to Inspection Level 2 material and above, unless otherwise directed by SAIR.

**PO Focused Assessments by PMT, Proponent, and Technical SMEs are optional and subject to availability and resources.

© Saudi Arabian Oil Company, 2020 Page 18 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

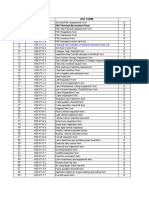

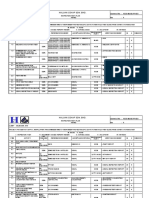

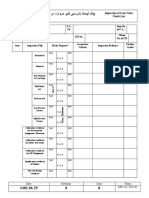

Appendix V - 30% PO Focused Assessment Checklist

© Saudi Arabian Oil Company, 2020 Page 19 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

Appendix VI - 60% PO Focused Assessment Checklist

© Saudi Arabian Oil Company, 2020 Page 20 of 21

Document Responsibility: Project Quality Standards Committee SAEP-1151

Issue Date: 12 January 2021

Next Revision: 12 January 2026 Inspection Requirements for Contractor Procured Materials and Equipment

Appendix VII - 90% PO Focused Assessment Checklist

© Saudi Arabian Oil Company, 2020 Page 21 of 21

You might also like

- Saudi Aramco Procurement Quality RequirementsDocument22 pagesSaudi Aramco Procurement Quality RequirementsMohamed S. Elrapat83% (6)

- Pqi InputDocument23 pagesPqi InputMohammad Sulaiman100% (11)

- AGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesDocument239 pagesAGBT07-18 Guide To Bridge Technology Part 7 Maintenance and Management of Existing BridgesRandy BenemeritoNo ratings yet

- SATIP SAIC SATR IndexDocument87 pagesSATIP SAIC SATR Indexlhanx2100% (9)

- GI 2.710 Latast PDFDocument35 pagesGI 2.710 Latast PDFfawad ali100% (1)

- Saep 347Document27 pagesSaep 347Qaiser Mahmood100% (2)

- Saep 383Document15 pagesSaep 383Ian Turgo Cabang Bang100% (3)

- Saep 85Document24 pagesSaep 85fawad ali25% (4)

- Asset Integrity and Corrosion ManagementDocument8 pagesAsset Integrity and Corrosion ManagementAppandai SureshNo ratings yet

- 11.schedule GDocument18 pages11.schedule Gjubail13100% (2)

- Saep 385Document77 pagesSaep 385Faisal Haque75% (8)

- Quality Management User Guide PDFDocument33 pagesQuality Management User Guide PDFDilip Ujagare100% (3)

- Saep 302Document12 pagesSaep 302Sami100% (2)

- Saep 1145Document22 pagesSaep 1145SamiNo ratings yet

- Saep 302Document12 pagesSaep 302Sami100% (2)

- Saep 1154Document5 pagesSaep 1154IRFAN NAZIR50% (2)

- Saudi Aramco Typical Inspection Plan: RH/ H RH/ HDocument2 pagesSaudi Aramco Typical Inspection Plan: RH/ H RH/ HZuhaib KhanNo ratings yet

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument6 pagesTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongNo ratings yet

- Typical Inspection Plan (TIP) Title: ElectricalDocument2 pagesTypical Inspection Plan (TIP) Title: ElectricalBhaskar Pitchika100% (1)

- Engineering Procedure: SAEP-12 29 June 2020 Project Execution PlanDocument35 pagesEngineering Procedure: SAEP-12 29 June 2020 Project Execution Planabcd100% (3)

- SOP 03 SP Painting Procedure PDFDocument5 pagesSOP 03 SP Painting Procedure PDFBalaji Guru100% (2)

- ABB LOAD Cell AUX Techno-Commercial Offer18!11!2014Document10 pagesABB LOAD Cell AUX Techno-Commercial Offer18!11!2014Prakash KumarNo ratings yet

- Saep 1151Document13 pagesSaep 1151fero67% (3)

- Saep 381 PDFDocument17 pagesSaep 381 PDFRami Elloumi100% (2)

- Schedule Q and Its AttachmentsDocument32 pagesSchedule Q and Its Attachmentssajeevismail67% (3)

- Satip Q-012-01Document10 pagesSatip Q-012-01Tayyab Achakzai100% (1)

- Saep 1152Document12 pagesSaep 1152Shazab Nawaz0% (1)

- Saep 44Document17 pagesSaep 44AbdullahNo ratings yet

- Saep 381Document27 pagesSaep 381Ramesh John100% (5)

- 09 Samss 088Document4 pages09 Samss 088Moustafa BayoumiNo ratings yet

- Satip Q 001 02Document1 pageSatip Q 001 02Abdul HannanNo ratings yet

- 175 000003Document1 page175 000003zhangNo ratings yet

- SAEP-379 Quality Issues Notification 2-MAR-2016Document4 pagesSAEP-379 Quality Issues Notification 2-MAR-2016asiqna100% (1)

- Saes Q 001 Saes-Q-006Document5 pagesSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- 1 SATIP-L-350-01 On-Plot Piping - Rev 01Document4 pages1 SATIP-L-350-01 On-Plot Piping - Rev 01zooplado75% (4)

- Saep 316 2016 PDFDocument25 pagesSaep 316 2016 PDFAllan LindoNo ratings yet

- SAEP-1150 Inspection Coverage On ProjectsDocument55 pagesSAEP-1150 Inspection Coverage On ProjectsAbdul Rahim Shaikh100% (5)

- Saic Q 1012Document2 pagesSaic Q 1012Hussain Nasser Al- Nowiesser100% (2)

- 175 320300Document1 page175 320300sridhar100% (1)

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289No ratings yet

- Saep-324 2018 PDFDocument23 pagesSaep-324 2018 PDFAdnan Rafiq100% (1)

- Saic L 1002Document2 pagesSaic L 1002Hussain Nasser Al- NowiesserNo ratings yet

- Saep 381 PDFDocument17 pagesSaep 381 PDFAbdul Aziz100% (1)

- SAEP-1152 - Approval Procedure For Ready-Mixed Concrete Mix DesignDocument10 pagesSAEP-1152 - Approval Procedure For Ready-Mixed Concrete Mix DesignADNAN REHMAT100% (2)

- SATIP S 070 03 ThermoplasticDocument2 pagesSATIP S 070 03 ThermoplasticMuhammad Farukh Manzoor100% (1)

- 2019 - Saep-1160Document24 pages2019 - Saep-1160smdriyazbashaNo ratings yet

- Saic Q 1004Document2 pagesSaic Q 1004Hussain Nasser Al- Nowiesser100% (1)

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalDocument12 pagesSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadNo ratings yet

- SAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionDocument7 pagesSAIC-Q-1061 Conventional Asphalt & Sulfur Extended Asphalt Concrete Receiving, Placement and Testing InspectionAbdul HannanNo ratings yet

- SATIP-Q-006-02 Rev 8 Conventional - Sulfur Extended Asphalt Paving FinalDocument3 pagesSATIP-Q-006-02 Rev 8 Conventional - Sulfur Extended Asphalt Paving FinalLeopoldo TalandatoNo ratings yet

- SATIP Q 006 02 (Recovered)Document10 pagesSATIP Q 006 02 (Recovered)Abdul HannanNo ratings yet

- 01 SATIP-H-003 Coating Application On ConcreteDocument2 pages01 SATIP-H-003 Coating Application On Concreteaamirsaddiq100% (1)

- Saudi Aramco Typical Inspection PlanDocument11 pagesSaudi Aramco Typical Inspection PlanAhdal NoushadNo ratings yet

- Saic A 1003Document2 pagesSaic A 1003Hussain Nasser Al- NowiesserNo ratings yet

- Saic Q 1007Document2 pagesSaic Q 1007Hussain Nasser Al- NowiesserNo ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- S.No. Questions AnswerDocument248 pagesS.No. Questions AnswerSyed Munawar Ali100% (2)

- Second List of Non Inspectable Materials For Sa Approval - Vid RemarksDocument6 pagesSecond List of Non Inspectable Materials For Sa Approval - Vid RemarksMohamed Reda100% (1)

- Saes-A-206 DT 09 April 2020Document18 pagesSaes-A-206 DT 09 April 2020Kiran NikateNo ratings yet

- SAES-A-206 - 2020 - Positive Material IdentificationDocument18 pagesSAES-A-206 - 2020 - Positive Material IdentificationMEHBOOB19786No ratings yet

- ES 403 - Portable Electrical Equipment Version 5Document24 pagesES 403 - Portable Electrical Equipment Version 5muhammad nomanNo ratings yet

- Saep 12Document39 pagesSaep 1269badbutchNo ratings yet

- FDA ISO Gap Analysis Checksheet - UpgradeDocument33 pagesFDA ISO Gap Analysis Checksheet - UpgradednrjbdNo ratings yet

- Saep 303Document86 pagesSaep 303AhmedNo ratings yet

- 「 (英文) Quality Control Standard for Cooperative Companies」Document38 pages「 (英文) Quality Control Standard for Cooperative Companies」LokNo ratings yet

- Saep 12Document35 pagesSaep 12OMER ELFADILNo ratings yet

- RFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)Document40 pagesRFP Clause Q010 - LOCAL DELIVERY PO (NON-CONCURRENT)SamiNo ratings yet

- MS8314004SHTS050120055019956640000101Document4 pagesMS8314004SHTS050120055019956640000101SamiNo ratings yet

- 04 Samss 035Document28 pages04 Samss 035SamiNo ratings yet

- Saep 1144Document24 pagesSaep 1144SamiNo ratings yet

- 04 Samss 048Document11 pages04 Samss 048Sami100% (1)

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument3 pagesInspection & Testing Requirements Scope:: Test and Inspection PerSamiNo ratings yet

- Inspection & Testing Requirements: ScopeDocument1 pageInspection & Testing Requirements: ScopeSamiNo ratings yet

- Tjc-Itp-Cwp-040506-L-2090Document6 pagesTjc-Itp-Cwp-040506-L-2090resky marantinanNo ratings yet

- Risk Assessment For Scaffolds and Ladders: ArticleDocument7 pagesRisk Assessment For Scaffolds and Ladders: Articles tpNo ratings yet

- Termite Risk Management Handbook PDFDocument24 pagesTermite Risk Management Handbook PDFst0372724162No ratings yet

- Building BYE-LAWS Chakwal MunicipalityDocument32 pagesBuilding BYE-LAWS Chakwal MunicipalityAkhtar RashidNo ratings yet

- HSE MASTER LIST Rev 20Document5 pagesHSE MASTER LIST Rev 20Agung Tri SugihartoNo ratings yet

- SOP For IQADocument25 pagesSOP For IQAMuhammad As'adNo ratings yet

- SP-1167-Specification For Welding On Pressurised PipesDocument11 pagesSP-1167-Specification For Welding On Pressurised Pipesarjunprasannan7No ratings yet

- Form Inspection and Test Plan (ITP) For Batery ChargerDocument2 pagesForm Inspection and Test Plan (ITP) For Batery ChargerSaipul AnwarNo ratings yet

- ITP For Installation of Automatic Sliding DoorDocument1 pageITP For Installation of Automatic Sliding DoorKalid JmalNo ratings yet

- GM 1927-16 - PcpaDocument12 pagesGM 1927-16 - PcpaNeumar NeumannNo ratings yet

- Body of Requisition - ROW Work Package PDFDocument60 pagesBody of Requisition - ROW Work Package PDFmahandhieNo ratings yet

- Specification For Contiguous Bored Piling: 1.0 General 1.1 Works in Accordance With SpecificationsDocument15 pagesSpecification For Contiguous Bored Piling: 1.0 General 1.1 Works in Accordance With SpecificationsThaung Myint OoNo ratings yet

- Inspection and SQC - NotesDocument10 pagesInspection and SQC - NotesJigar MevadaNo ratings yet

- Inspection Record and Report Master List As On 8.3.18Document32 pagesInspection Record and Report Master List As On 8.3.18Gomathyselvi100% (1)

- 175 171500Document3 pages175 171500balajiNo ratings yet

- Drilling Rigs Inspection ChecklistDocument14 pagesDrilling Rigs Inspection ChecklistRizwan Farid100% (3)

- Inspection & Test Plan For PipingDocument8 pagesInspection & Test Plan For PipingRanus unarNo ratings yet

- Development and Implementation of A High Energy Piping ProgramDocument25 pagesDevelopment and Implementation of A High Energy Piping ProgramKurt CobainNo ratings yet

- Monitoring and MeasurementDocument5 pagesMonitoring and MeasurementImtiyaz Akhtar100% (1)

- Machine and Coil Chain: Standard Specification ForDocument4 pagesMachine and Coil Chain: Standard Specification ForRafael CossolinoNo ratings yet

- Hydrotest Procedure - Rev 1Document7 pagesHydrotest Procedure - Rev 1Natarajan MurugesanNo ratings yet

- In-Line Eddy Current Testing of Wire Rod: Technical InformationDocument7 pagesIn-Line Eddy Current Testing of Wire Rod: Technical InformationBK ICTNo ratings yet

- Way & Works ManualDocument8 pagesWay & Works ManualSalikNo ratings yet

- Inspection of Gate Valve-Check ListDocument4 pagesInspection of Gate Valve-Check ListnavidNo ratings yet

- Awareness On en 15085Document5 pagesAwareness On en 15085SamsuNo ratings yet

- AQA Tech Standing Order For D and DDocument243 pagesAQA Tech Standing Order For D and DLakshman SinghNo ratings yet