Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

40 viewsPreventive Maintenance Sim

Preventive Maintenance Sim

Uploaded by

BBKFP Training CenterThis document outlines maintenance procedures and intervals for various systems on an aircraft simulator. It includes procedures for inspecting and cleaning components like actuators, filters, fans, and batteries on a regular basis. Some key tasks include lubricating moving parts, checking for unusual noises, replacing filters, testing electrical systems, and calibrating actuators. Maintenance intervals range from daily to every 5 years, with most components requiring monthly, quarterly, semi-annual or annual maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Medical Imaging Equipment Maintenance Checklist CompressDocument6 pagesMedical Imaging Equipment Maintenance Checklist CompressHamed64No ratings yet

- Quarterly Extruder Performance Checklist: Control Panel Barrel HeatersDocument1 pageQuarterly Extruder Performance Checklist: Control Panel Barrel HeatersAntonius Prakosa100% (2)

- Operations and Maintenance Preventive Maintenance Checklists PDFDocument35 pagesOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra0% (1)

- Chapter 13 SERVICE DATA: 13.1 Maintenance ScheduleDocument62 pagesChapter 13 SERVICE DATA: 13.1 Maintenance ScheduleAuxiliar Mantenimiento EcaNo ratings yet

- Active Stabilization System OverviewDocument10 pagesActive Stabilization System OverviewOktay YusufovNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Kinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Document11 pagesKinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Mohammad Kh100% (1)

- Attachment 3 Medical Imaging Equipment Maintenance ChecklistDocument5 pagesAttachment 3 Medical Imaging Equipment Maintenance ChecklistAri Randa Sebayang100% (2)

- Maintenanace Proposal NAF Officers Mess & Suites AC PDFDocument9 pagesMaintenanace Proposal NAF Officers Mess & Suites AC PDFM.Y AbdulrahimNo ratings yet

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- PM Checklist BNMDocument3 pagesPM Checklist BNMmuhammad afendyNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- Service 38559Document2 pagesService 38559Sumeet SawlaniNo ratings yet

- RCG Electrical Equip Maint Guides 913 Bre PDFDocument4 pagesRCG Electrical Equip Maint Guides 913 Bre PDFBarney ParadoxNo ratings yet

- MHC Checklist04Document13 pagesMHC Checklist04Tawfiq ZidanNo ratings yet

- 7.internal Combustion Engines For Class ApprovalDocument18 pages7.internal Combustion Engines For Class ApprovalRokhmatu SivaNo ratings yet

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurNo ratings yet

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument6 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- Method of Statement For Testing Commissioning of Ventilation General Exhaust FansDocument2 pagesMethod of Statement For Testing Commissioning of Ventilation General Exhaust Fanslesystemsb systemNo ratings yet

- Maintenance Procedure DetectorDocument1 pageMaintenance Procedure DetectorloayNo ratings yet

- Chapter 1 Pneumatic SystemDocument19 pagesChapter 1 Pneumatic Systemdivien rajNo ratings yet

- Unit 1 Control SystemDocument86 pagesUnit 1 Control SystemVijay Ct67% (3)

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- MHC Checklist05Document4 pagesMHC Checklist05Tawfiq ZidanNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPGovinda RaiNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Service Guide: Section TwoDocument78 pagesService Guide: Section TworemguNo ratings yet

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadNo ratings yet

- Irrigator Preseason Check ListsDocument10 pagesIrrigator Preseason Check ListsriyazNo ratings yet

- Ontrol Ngineering: NtroductionDocument31 pagesOntrol Ngineering: NtroductionShz AwanNo ratings yet

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- Hvac Air Balance Report FormDocument8 pagesHvac Air Balance Report FormAbdullah.N FAAliNo ratings yet

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiNo ratings yet

- E&M Health CheckupDocument3 pagesE&M Health CheckupAlliedNo ratings yet

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- Managing Your Building Automation SystemDocument85 pagesManaging Your Building Automation SystemNadeem HassoonNo ratings yet

- Startup & Shutdown Procedure and Maintenance GuidelinesDocument2 pagesStartup & Shutdown Procedure and Maintenance GuidelinesKrystianNo ratings yet

- Report Group OneDocument70 pagesReport Group OneeroksNo ratings yet

- Test Procedures: For Products Manufactured by ITT Flygt, SwedenDocument6 pagesTest Procedures: For Products Manufactured by ITT Flygt, SwedenyutNo ratings yet

- Dry Test 1907Document10 pagesDry Test 1907talhaNo ratings yet

- P&id PDFDocument66 pagesP&id PDFFarook Mohideen100% (1)

- Process & Instrumentation Diagram (P&ID) : Dr. RameshDocument66 pagesProcess & Instrumentation Diagram (P&ID) : Dr. Rameshalejandro inostrozaNo ratings yet

- Process & Instrumentation Diagram (P&ID)Document66 pagesProcess & Instrumentation Diagram (P&ID)Syed HameedNo ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- Technical Health DCCMDocument25 pagesTechnical Health DCCMibsamengistu29No ratings yet

- Mirrlees Diesels BlackstoneDocument12 pagesMirrlees Diesels Blackstoneophar100% (1)

- System Dynamics AND Control: Chapter 1 IntroductionDocument54 pagesSystem Dynamics AND Control: Chapter 1 Introductionali kartalNo ratings yet

- Control Systems - UNIT 1Document104 pagesControl Systems - UNIT 1charu singhNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong VanraNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra100% (1)

- Classic E.O.S. From SN #BE7Document4 pagesClassic E.O.S. From SN #BE7Foued MbarkiNo ratings yet

- B.Tech VI Semester Regular Examinations 17EI10-Process Control Instrumentation Scheme of ValuationDocument13 pagesB.Tech VI Semester Regular Examinations 17EI10-Process Control Instrumentation Scheme of ValuationSunny BNo ratings yet

- For RFQ - Scope of Works PM of AHU, FCU and PumpsDocument8 pagesFor RFQ - Scope of Works PM of AHU, FCU and PumpsJay MarkNo ratings yet

- Installation and Commissioning: Centrifugal PumpsDocument3 pagesInstallation and Commissioning: Centrifugal PumpsKu KemaNo ratings yet

- Pengantar DSPDocument27 pagesPengantar DSPYeni PutryNo ratings yet

- GTMedia V8Nova Rease NoteDocument3 pagesGTMedia V8Nova Rease NoteSamul IranzoNo ratings yet

- 2822 HDocument3 pages2822 HKrank101No ratings yet

- Electron Detector For SemDocument25 pagesElectron Detector For Semmm11_nedNo ratings yet

- Analytical Design Procedure For ResonantInductively Coupled Wireless Power Transfer SystemWith Class-DE Inverter and Class-E RectifierDocument4 pagesAnalytical Design Procedure For ResonantInductively Coupled Wireless Power Transfer SystemWith Class-DE Inverter and Class-E Rectifierjuan8aNo ratings yet

- MP Rggvy Status 07.13Document6 pagesMP Rggvy Status 07.13harshagarwal5No ratings yet

- AFL Fiber Cable Accessories PDFDocument160 pagesAFL Fiber Cable Accessories PDFMilagros Mercedes Olmos CervantesNo ratings yet

- Switching Strategies of Three Phase Matrix Converter Fed Induction Motor DriveDocument6 pagesSwitching Strategies of Three Phase Matrix Converter Fed Induction Motor DriveDr Mohammad Asif IqbalNo ratings yet

- Electrical ElectronicsDocument112 pagesElectrical ElectronicsArun JerardNo ratings yet

- 32HL95 Toshiba Manual de ServicioDocument39 pages32HL95 Toshiba Manual de ServiciojonnycoolNo ratings yet

- Brain Signal Amplifier For 6-Channel Eeg-Based Biofeedback HeadpieceDocument60 pagesBrain Signal Amplifier For 6-Channel Eeg-Based Biofeedback HeadpieceAnne Margaret AlmedaNo ratings yet

- Strain Gauge Presentation PPTXDocument32 pagesStrain Gauge Presentation PPTXArun Raja K KNo ratings yet

- 33Document12 pages33Pardeep SainiNo ratings yet

- Tutorial Sheet2Document1 pageTutorial Sheet2Samarth Mohan100% (2)

- Applied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodDocument5 pagesApplied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodHasham AliNo ratings yet

- T BJT - TIP41 - TIP42 (Met Pinout) PDFDocument4 pagesT BJT - TIP41 - TIP42 (Met Pinout) PDFLodewyk KleynhansNo ratings yet

- Micro-Power Supply-Voltage Supervisors: General Description FeaturesDocument12 pagesMicro-Power Supply-Voltage Supervisors: General Description FeaturesShaswat DubeyNo ratings yet

- LECROY-WAVESURFER 454-DatasheetDocument4 pagesLECROY-WAVESURFER 454-DatasheetVIETNo ratings yet

- MD3060 Trouble ShootingDocument396 pagesMD3060 Trouble ShootingOmar Robles G83% (23)

- 10334158Document30 pages10334158Fandi HerlandiNo ratings yet

- Imageformula dr9050cDocument19 pagesImageformula dr9050ckusdoganNo ratings yet

- EEP1 Topic 3Document27 pagesEEP1 Topic 3Saiful IslamNo ratings yet

- Bug ReportDocument4,473 pagesBug ReportVijaypalu BoldheadNo ratings yet

- Lab Manual FOR Electronic Devices and Circuits Lab With SimulationDocument43 pagesLab Manual FOR Electronic Devices and Circuits Lab With Simulationrama krishnaNo ratings yet

- SGTL5000 QFN32Document73 pagesSGTL5000 QFN32yamaha640No ratings yet

- Timing AnalysisDocument3 pagesTiming Analysisgenx142No ratings yet

- Sharp 25ub1 - 25uf1Document11 pagesSharp 25ub1 - 25uf1winda rinaNo ratings yet

- Ohm's Law Formulas: Voltage Calculation FormulaDocument3 pagesOhm's Law Formulas: Voltage Calculation FormulaNuaman PatelNo ratings yet

- Chapter 3 - Alternating Current MetersDocument35 pagesChapter 3 - Alternating Current MetersANDREW LEONG CHUN TATT STUDENTNo ratings yet

- s71200 Motion Control Function Manual en-US en-US-2 PDFDocument442 pagess71200 Motion Control Function Manual en-US en-US-2 PDFricardo2022No ratings yet

Preventive Maintenance Sim

Preventive Maintenance Sim

Uploaded by

BBKFP Training Center0 ratings0% found this document useful (0 votes)

40 views4 pagesThis document outlines maintenance procedures and intervals for various systems on an aircraft simulator. It includes procedures for inspecting and cleaning components like actuators, filters, fans, and batteries on a regular basis. Some key tasks include lubricating moving parts, checking for unusual noises, replacing filters, testing electrical systems, and calibrating actuators. Maintenance intervals range from daily to every 5 years, with most components requiring monthly, quarterly, semi-annual or annual maintenance.

Original Description:

Original Title

Preventive maintenance sim

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines maintenance procedures and intervals for various systems on an aircraft simulator. It includes procedures for inspecting and cleaning components like actuators, filters, fans, and batteries on a regular basis. Some key tasks include lubricating moving parts, checking for unusual noises, replacing filters, testing electrical systems, and calibrating actuators. Maintenance intervals range from daily to every 5 years, with most components requiring monthly, quarterly, semi-annual or annual maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

40 views4 pagesPreventive Maintenance Sim

Preventive Maintenance Sim

Uploaded by

BBKFP Training CenterThis document outlines maintenance procedures and intervals for various systems on an aircraft simulator. It includes procedures for inspecting and cleaning components like actuators, filters, fans, and batteries on a regular basis. Some key tasks include lubricating moving parts, checking for unusual noises, replacing filters, testing electrical systems, and calibrating actuators. Maintenance intervals range from daily to every 5 years, with most components requiring monthly, quarterly, semi-annual or annual maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 4

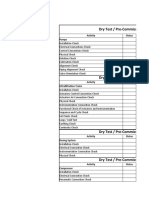

System Procedure

Accesway System General visual inspection

Operate and check for unusual noises or behavior

Clean, Inspect, and Lubricate accesway actuator and mechanism

Lubricate pivot bearing

Disassemble, clean, inspect & re-lubricate accesway actuator

Cab Ventilation System Clean or replace all Air Filters

Lubricate Fan Bearings

Drain and Inspect Condensate Drain

Clean Evaporator Coil

Test Compressor Current Draw

Test Temperature Gradient Across Heat Exchanger

Computers & Networks Clean and verify operation of Fans (CPU, Power Suplly and other)

Replace Real-Time Clock Batteries

Control Loading - ECol Inspect Primary Control Loading

Computer Blower Replace fan if ECoL8000QC-IOM necessary (ball bearing type).

Clean Primary Control Loading Clean Computer Blower Inlet. Remove dust carefully if ne

40-Nm Actuators - fixed-mode force check and recalibrate if necessary

40-Nm Actuators - position check and recalibrate if necessary

150-Nm Actuators - fixed-mode force check and recalibrate if necessary

150-Nm Actuators - position check and recalibrate if necessary

Emergency Lighting System Test Emergency Lighting System

Replace Emergency Lighting UPS Battery

Full Cab Motion System E-Cue General visual inspection of joints and pads

Visually inspect cables and connections at Motion base

General visual inspection of motion system control cabinet

Drain condensate from buffer reservoir

General visual inspection of actuators

Operate and check for unusual noises and behavior of motion base.

Clean motion base and check for damage

Check torque marks on motion base fasteners, including those to the floor

Check motion computer air filter and fan

Emergency and interlock checks (per IOM 4.1)

Lubricate electric actuators (per IOM 4.1)

Pneumatic system maintenance (per IOM 4.3)

Lubricate upper and lower joints (per IOM 4.2)

Electronics cabinet maintenance (per IOM 4.4)

Visually inspect motion base structure and welds at upper joint unit, lower joint, pads.

Clean and service smoke detector in the motion system control cabinet.

Check Motion base fasteners to floor

Re-torque and apply torque marking paint on all motion base fasteners

I/O System Inspect Under-Seat Connections

I/O System Calibration

Miscellaneous Hardware Oil Landing gear lever mechanism

Oil thrust reserver hinge points

Clean or replace all Air Filters

Lubricate IOS Tower Tracks

Lubricate Seat Tracks

Check and clean all Cooling Fans

Power Distribution and control Tighten all connections on DC power supply units, onboard and off

Smoke detection system Replace dust separator filter(s), one per fire detection unit.

Sound and audio system Check calibration of sound and audio system

Uniterruptible power supply Test

Replace battery

Visual System Check system allignment

Check that all cables are free of chaffing, kinks and damage

Visual display system-Monthly maintenance routine

Check that all cables are securely connected and correctly positioned.

check projector lenses are clean, dust-free. If needed, clean per manufacturer's instructi

Check operation of projector cooling fans

check that all fasteners are secure

Clean projector cabinets and vacuum all projector air vents

Interval

Daily

Weekly

Monthly

Annual

3-Year

Quarterly

Quarterly

Semi-Annual

Annual

Annual

2-Year

Semi-Annual

5-Year

(ball bearing type).

Remove dust carefully if necessary

e to the floor

nt unit, lower joint, pads.

er manufacturer's instructions

You might also like

- Medical Imaging Equipment Maintenance Checklist CompressDocument6 pagesMedical Imaging Equipment Maintenance Checklist CompressHamed64No ratings yet

- Quarterly Extruder Performance Checklist: Control Panel Barrel HeatersDocument1 pageQuarterly Extruder Performance Checklist: Control Panel Barrel HeatersAntonius Prakosa100% (2)

- Operations and Maintenance Preventive Maintenance Checklists PDFDocument35 pagesOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra0% (1)

- Chapter 13 SERVICE DATA: 13.1 Maintenance ScheduleDocument62 pagesChapter 13 SERVICE DATA: 13.1 Maintenance ScheduleAuxiliar Mantenimiento EcaNo ratings yet

- Active Stabilization System OverviewDocument10 pagesActive Stabilization System OverviewOktay YusufovNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Kinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Document11 pagesKinetics of Alkaline Hydrolysis of Ethyl Acetate by Conductometric Measurement Approach Over Temperature Ranges (298.15-343.15K)Mohammad Kh100% (1)

- Attachment 3 Medical Imaging Equipment Maintenance ChecklistDocument5 pagesAttachment 3 Medical Imaging Equipment Maintenance ChecklistAri Randa Sebayang100% (2)

- Maintenanace Proposal NAF Officers Mess & Suites AC PDFDocument9 pagesMaintenanace Proposal NAF Officers Mess & Suites AC PDFM.Y AbdulrahimNo ratings yet

- Fcu OjtDocument3 pagesFcu OjtHuzairi SulaimanNo ratings yet

- PM Checklist BNMDocument3 pagesPM Checklist BNMmuhammad afendyNo ratings yet

- Cashman EM Solutions Brochure 3 16Document2 pagesCashman EM Solutions Brochure 3 16jov100% (1)

- Service 38559Document2 pagesService 38559Sumeet SawlaniNo ratings yet

- RCG Electrical Equip Maint Guides 913 Bre PDFDocument4 pagesRCG Electrical Equip Maint Guides 913 Bre PDFBarney ParadoxNo ratings yet

- MHC Checklist04Document13 pagesMHC Checklist04Tawfiq ZidanNo ratings yet

- 7.internal Combustion Engines For Class ApprovalDocument18 pages7.internal Combustion Engines For Class ApprovalRokhmatu SivaNo ratings yet

- Air Handling Units GuidelineDocument5 pagesAir Handling Units GuidelineImam MansyurNo ratings yet

- Generator Set Start-Up Checklist: Open Enclosed Generator SetsDocument6 pagesGenerator Set Start-Up Checklist: Open Enclosed Generator SetsEng Mamon StiNo ratings yet

- Method of Statement For Testing Commissioning of Ventilation General Exhaust FansDocument2 pagesMethod of Statement For Testing Commissioning of Ventilation General Exhaust Fanslesystemsb systemNo ratings yet

- Maintenance Procedure DetectorDocument1 pageMaintenance Procedure DetectorloayNo ratings yet

- Chapter 1 Pneumatic SystemDocument19 pagesChapter 1 Pneumatic Systemdivien rajNo ratings yet

- Unit 1 Control SystemDocument86 pagesUnit 1 Control SystemVijay Ct67% (3)

- Wave Let TutorialDocument26 pagesWave Let TutorialBhavik PrajapatiNo ratings yet

- MHC Checklist05Document4 pagesMHC Checklist05Tawfiq ZidanNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPGovinda RaiNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekNo ratings yet

- 50 200 Cylinder Diesel EngineDocument30 pages50 200 Cylinder Diesel EngineFranklin FernandezNo ratings yet

- Service Guide: Section TwoDocument78 pagesService Guide: Section TworemguNo ratings yet

- HVAC Preventive Maintenance Checklists-12Document61 pagesHVAC Preventive Maintenance Checklists-12JawadNo ratings yet

- Irrigator Preseason Check ListsDocument10 pagesIrrigator Preseason Check ListsriyazNo ratings yet

- Ontrol Ngineering: NtroductionDocument31 pagesOntrol Ngineering: NtroductionShz AwanNo ratings yet

- 2.2L Basic TestingDocument12 pages2.2L Basic TestingAndres Florentin Pizarro LazarteNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- Hvac Air Balance Report FormDocument8 pagesHvac Air Balance Report FormAbdullah.N FAAliNo ratings yet

- Engstrom CarestationDocument24 pagesEngstrom CarestationmaruthaiNo ratings yet

- E&M Health CheckupDocument3 pagesE&M Health CheckupAlliedNo ratings yet

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- Managing Your Building Automation SystemDocument85 pagesManaging Your Building Automation SystemNadeem HassoonNo ratings yet

- Startup & Shutdown Procedure and Maintenance GuidelinesDocument2 pagesStartup & Shutdown Procedure and Maintenance GuidelinesKrystianNo ratings yet

- Report Group OneDocument70 pagesReport Group OneeroksNo ratings yet

- Test Procedures: For Products Manufactured by ITT Flygt, SwedenDocument6 pagesTest Procedures: For Products Manufactured by ITT Flygt, SwedenyutNo ratings yet

- Dry Test 1907Document10 pagesDry Test 1907talhaNo ratings yet

- P&id PDFDocument66 pagesP&id PDFFarook Mohideen100% (1)

- Process & Instrumentation Diagram (P&ID) : Dr. RameshDocument66 pagesProcess & Instrumentation Diagram (P&ID) : Dr. Rameshalejandro inostrozaNo ratings yet

- Process & Instrumentation Diagram (P&ID)Document66 pagesProcess & Instrumentation Diagram (P&ID)Syed HameedNo ratings yet

- PM Text As Per Bcel-002Document4 pagesPM Text As Per Bcel-002Jay Rameshbhai ParikhNo ratings yet

- Technical Health DCCMDocument25 pagesTechnical Health DCCMibsamengistu29No ratings yet

- Mirrlees Diesels BlackstoneDocument12 pagesMirrlees Diesels Blackstoneophar100% (1)

- System Dynamics AND Control: Chapter 1 IntroductionDocument54 pagesSystem Dynamics AND Control: Chapter 1 Introductionali kartalNo ratings yet

- Control Systems - UNIT 1Document104 pagesControl Systems - UNIT 1charu singhNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong VanraNo ratings yet

- Testing and Commissioning Procedure For Ventilation and General Exhaust FansDocument3 pagesTesting and Commissioning Procedure For Ventilation and General Exhaust FansDong Vanra100% (1)

- Classic E.O.S. From SN #BE7Document4 pagesClassic E.O.S. From SN #BE7Foued MbarkiNo ratings yet

- B.Tech VI Semester Regular Examinations 17EI10-Process Control Instrumentation Scheme of ValuationDocument13 pagesB.Tech VI Semester Regular Examinations 17EI10-Process Control Instrumentation Scheme of ValuationSunny BNo ratings yet

- For RFQ - Scope of Works PM of AHU, FCU and PumpsDocument8 pagesFor RFQ - Scope of Works PM of AHU, FCU and PumpsJay MarkNo ratings yet

- Installation and Commissioning: Centrifugal PumpsDocument3 pagesInstallation and Commissioning: Centrifugal PumpsKu KemaNo ratings yet

- Pengantar DSPDocument27 pagesPengantar DSPYeni PutryNo ratings yet

- GTMedia V8Nova Rease NoteDocument3 pagesGTMedia V8Nova Rease NoteSamul IranzoNo ratings yet

- 2822 HDocument3 pages2822 HKrank101No ratings yet

- Electron Detector For SemDocument25 pagesElectron Detector For Semmm11_nedNo ratings yet

- Analytical Design Procedure For ResonantInductively Coupled Wireless Power Transfer SystemWith Class-DE Inverter and Class-E RectifierDocument4 pagesAnalytical Design Procedure For ResonantInductively Coupled Wireless Power Transfer SystemWith Class-DE Inverter and Class-E Rectifierjuan8aNo ratings yet

- MP Rggvy Status 07.13Document6 pagesMP Rggvy Status 07.13harshagarwal5No ratings yet

- AFL Fiber Cable Accessories PDFDocument160 pagesAFL Fiber Cable Accessories PDFMilagros Mercedes Olmos CervantesNo ratings yet

- Switching Strategies of Three Phase Matrix Converter Fed Induction Motor DriveDocument6 pagesSwitching Strategies of Three Phase Matrix Converter Fed Induction Motor DriveDr Mohammad Asif IqbalNo ratings yet

- Electrical ElectronicsDocument112 pagesElectrical ElectronicsArun JerardNo ratings yet

- 32HL95 Toshiba Manual de ServicioDocument39 pages32HL95 Toshiba Manual de ServiciojonnycoolNo ratings yet

- Brain Signal Amplifier For 6-Channel Eeg-Based Biofeedback HeadpieceDocument60 pagesBrain Signal Amplifier For 6-Channel Eeg-Based Biofeedback HeadpieceAnne Margaret AlmedaNo ratings yet

- Strain Gauge Presentation PPTXDocument32 pagesStrain Gauge Presentation PPTXArun Raja K KNo ratings yet

- 33Document12 pages33Pardeep SainiNo ratings yet

- Tutorial Sheet2Document1 pageTutorial Sheet2Samarth Mohan100% (2)

- Applied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodDocument5 pagesApplied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodHasham AliNo ratings yet

- T BJT - TIP41 - TIP42 (Met Pinout) PDFDocument4 pagesT BJT - TIP41 - TIP42 (Met Pinout) PDFLodewyk KleynhansNo ratings yet

- Micro-Power Supply-Voltage Supervisors: General Description FeaturesDocument12 pagesMicro-Power Supply-Voltage Supervisors: General Description FeaturesShaswat DubeyNo ratings yet

- LECROY-WAVESURFER 454-DatasheetDocument4 pagesLECROY-WAVESURFER 454-DatasheetVIETNo ratings yet

- MD3060 Trouble ShootingDocument396 pagesMD3060 Trouble ShootingOmar Robles G83% (23)

- 10334158Document30 pages10334158Fandi HerlandiNo ratings yet

- Imageformula dr9050cDocument19 pagesImageformula dr9050ckusdoganNo ratings yet

- EEP1 Topic 3Document27 pagesEEP1 Topic 3Saiful IslamNo ratings yet

- Bug ReportDocument4,473 pagesBug ReportVijaypalu BoldheadNo ratings yet

- Lab Manual FOR Electronic Devices and Circuits Lab With SimulationDocument43 pagesLab Manual FOR Electronic Devices and Circuits Lab With Simulationrama krishnaNo ratings yet

- SGTL5000 QFN32Document73 pagesSGTL5000 QFN32yamaha640No ratings yet

- Timing AnalysisDocument3 pagesTiming Analysisgenx142No ratings yet

- Sharp 25ub1 - 25uf1Document11 pagesSharp 25ub1 - 25uf1winda rinaNo ratings yet

- Ohm's Law Formulas: Voltage Calculation FormulaDocument3 pagesOhm's Law Formulas: Voltage Calculation FormulaNuaman PatelNo ratings yet

- Chapter 3 - Alternating Current MetersDocument35 pagesChapter 3 - Alternating Current MetersANDREW LEONG CHUN TATT STUDENTNo ratings yet

- s71200 Motion Control Function Manual en-US en-US-2 PDFDocument442 pagess71200 Motion Control Function Manual en-US en-US-2 PDFricardo2022No ratings yet